Fancoil got its name from two English words: fan - fan and coil - heat exchanger. That is, the literal translation is "heat exchanger-fan", and its purpose is appropriate. It either conditions the surrounding air or heats it up. That is, it is one of the simplest air conditioning systems. The fan coil unit consists of a radiator, which plays the role of a heat exchanger and a fan. One has only to drive hot or cold water (or any suitable technical liquid) through the insides of the device, as it takes the temperature of the radiator with the help of a fan supplying air to it.

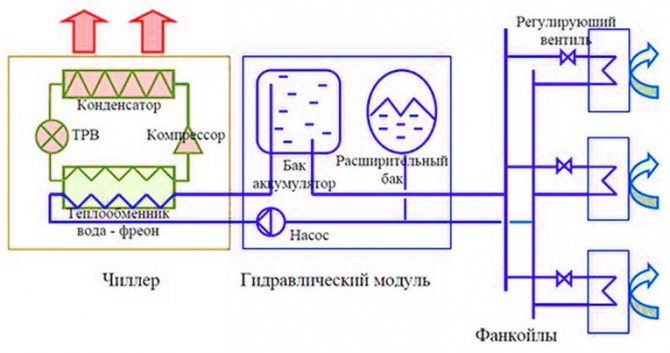

But where can you get chilled water to supply to your fan coil unit? By itself, this simple device cannot pre-cool the liquid. For this, a chiller is needed - a refrigeration unit that forms air conditioning systems with a chiller and fan coil units.

Fan coil units are:

- cassette;

- channel;

- wall-mounted;

- floor and ceiling;

- case floor;

- frameless.

One chiller is sufficient to supply chilled liquid to ten fan coil units. In addition, you can configure the operation of fan coil units both in general mode and in stand-alone mode for each.

Chiller and its differences from fan coil unit

The term chiller comes from the English chiller, which literally means "cooling machine". Where and how is this unit used? Almost everywhere. It cools the filling water or non-freezing liquids. The installation is essential for industries such as mechanical engineering, metalworking, food processing, winemaking and others, as well as where air conditioning systems operate.

This type of climatic equipment is a rather bulky apparatus. The chiller cooler, both domestic and industrial, consists of three parts:

- capacitor;

- compressor;

- evaporator.

Refrigerant circuit

The refrigerant circulates inside the chiller. Its movement along the refrigeration circuit is carried out using a compressor, which, in fact, plays the role of a pump. The refrigerant pumped by the compressor has high pressure (up to 30 atmospheres) and temperature (about 70 ° C).

Then the temperature is released in the condenser: the refrigerant flowing through the pipes is blown by the outside air. At the same time, the refrigerant changes its state of aggregation: it goes from a gaseous state to a liquid state.

However, the refrigerant pressure remained high. The cooled high-pressure freon passes through the control valve, where it expands. The refrigerant pressure drops sharply.

This process is similar to the delivery of breathing gas for a scuba diver: from a cylinder where the gas is stored under high pressure, it flows to a person who breathes a mixture at normal atmospheric pressure. At the same time, the temperature of the respiratory mixture decreases markedly.

Likewise, the refrigerant after the control valve loses not only pressure but also temperature. Thus, its temperature is reduced to only a few degrees. It can now cool the water flow of the building's cooling system. This takes place in the evaporator. The refrigerant then flows back into the compressor and the cycle closes.

Principle of operation

The principle of operation is to convert the energy of the cooled liquid into a vapor state. The heat from the liquid is taken off in the evaporator and in the vapor state it is transferred to the compressor. Then it goes to the chiller motor, cooling its winding. The refrigerant is then cooled in the condenser by air currents, converted to liquid and returned to the evaporator.The cycle is repeated anew.

Summary

Euler's circles are a very useful technique for solving problems and establishing logical connections, and at the same time an entertaining and interesting way to spend time and train your brain. So, if you want to combine business with pleasure and work your head, we suggest taking our Neurobics course, which includes a variety of tasks, including Euler's circles, the effectiveness of which is scientifically substantiated and confirmed by many years of practice.

We also advise you to read:

- Golden ratio

- Learn to Learn: Some Tips from Coursera's LH2L Course

- 7 popular pseudosciences

- How to Switch to Creativity: Right Brain Workout by Betty Edwards

- Logical paradoxes

- TRIZ exercises in pedagogy

- Eugenics: in simple words about the most important

- Mathematical thinking

- Cognitive development. Part 1

- Solving non-standard Fermi problems

Keywords: 1Cognitive science

Chiller types

Industrial chillers come in different types. They can be classified into four groups according to different criteria.

- By the type of cooler.

- Fan type.

- By the way of cooling.

- According to the features that the chiller design has.

Chillers are air-cooled or water-cooled. An air cooler is similar in principle to a conventional air conditioner, where a fan blows a stream to air-cool the condenser. In a cooler where water is cooled, the design is simpler, the unit itself is smaller and lower in cost than air. But the air one is self-sufficient and works autonomously, and the water one requires the supply of water from the outside using a special additional installation.

Chiller installation on site

The chiller is installed on a strictly horizontal open area, which must be able to withstand the weight and dynamic loads of the equipment with a margin. For the installation of monoblock units on the roofs of buildings, a support frame is used; for the installation of chillers in ground rooms, a special foundation is prepared, in which channels for condensate drainage are provided in advance.

The base foundation or support frame is designed to evenly distribute the weight of the chiller, increase the inertia of the equipment and reduce vibration loads.

To minimize vibration loads on the supporting structures of the building, the chiller is installed on special vibration mountings (spring or rubber) that damp equipment vibration. Depending on the location, vibration mounts experience different loads - the most powerful springs are installed from the compressor side, and weaker supports are installed on the opposite side. For correct installation, all springs are marked accordingly.

It is necessary to protect not only the chiller from increased vibration, but also its piping - refrigerant pipelines. In this case, pipe vibration isolators are used to reduce vibration. In this case, all pipelines must be properly supported so as not to put stress on the equipment.

Finally, the unit is attached to the support only after checking its position - it must be strictly horizontal. The chiller is fastened with anchor bolts to a concrete base or nuts to a metal profile frame support.

Chiller characteristics

The main characteristic of a cooling machine is its capacity. It can vary between 5 kW - 9000 kW. Low-power ones are suitable for offices, more powerful ones are used in industry and manufacturing.

Other characteristics

| Characteristic | The values |

| Model | Depends on the manufacturer |

| Cooling capacity | Measured in kW, it can be from 10 to several thousand |

| Rated power | Also measured in kW, has values in the range from 30 to 200 |

| Dimensions (edit) | From 500 to 4000 mm in width, length and height |

| The weight | 100 to 2000 kg |

| Compressor, evaporator, condenser type and body color | Depends on the manufacturer |

Chiller capacity

Power and efficiency are not only the number of kW, but the aggregate in the sum of various terms. When calculating the capacity of the chiller, the following indicators are taken into account:

- Heat entering windows through fences.

- Heat from people in the room.

- Heat energy generated by lighting and other equipment.

All heat inflows are summed up, and thus the total heat load that the room is carrying is determined. Then the loads of all rooms served by the chiller are summed up.

Since the cooling process is accompanied by the release of condensate, and the moisture content of the air changes, the power is calculated according to a special formula, providing up to 20% of the power reserve.

Chiller cost

The cost of a refrigeration unit is made up of several parameters. The price is influenced by both technical indicators and the name of the manufacturer's brand. Also taken into account:

- additional power steps;

- complete set of pipes for connecting the unit with fan coil units;

- The material from which the pipes are made (metal or plastic);

- axial fan configuration (standard or modified blade configuration);

- > additions in the form of drainage, heated trays and others.

After evaluating all the parameters of the room, calculating the required power according to the formula, you can choose the best option for the chiller, not only in terms of performance, but also at the price, which includes the cost of maintenance.

The nuances of choosing a chiller

Tip 1. If you are going to place the cooler indoors, do not forget to measure the width of the doorway beforehand. It often happens that the purchased unit simply does not fit into the door, which becomes a serious problem for its installation.

Advice 2. It is necessary to ensure sufficient air exchange in the installation room, which corresponds to the parameters and characteristics of the unit producing free cooling.

Advice 3. If the chiller is installed outdoors, on the street, be sure to consider the following issues:

- protection of the unit from external influences and vandalism;

- the possibility of using anti-freezing liquids.

Advice 4. Before buying, even at the selection stage, you need to accurately determine the flow rate of the cooled water (liquid) in order to calculate the pressure required for its cooling.

Tip 5. When choosing an installation filled with antifreeze liquid, you need to calculate the capacity of the water-cooling evaporator.

Question answer

Question:

What do chillers work on?

Answer:

The main working medium of the chiller is the refrigerant. Freon is most often used as a refrigerant. It circulates around the circuit of the device and evaporates in the heat exchanger due to the heat received from the cooled liquid. Cold transfer is carried out using a coolant (water, ethylene glycol).

Refrigerant circulation is provided by a compressor, the smooth operation of which depends on many factors. Thus, the operation of the chiller is impossible without refrigerant and refrigerant.

Question:

What is better freecooler (cooling tower) or chiller?

Answer:

The freecooler provides cooling of water or other refrigerant in the radiator to the level of heat in the ambient air. For this, fans are used. Freecooling technology does not include a compressor module. Thanks to this feature, they consume much less electricity than chillers.

Disadvantages of freecoolers: the impossibility of their full use in hot weather, since the cooling occurs to the air temperature level.Freecoolers can be easily integrated into existing air conditioning units, so they can be conveniently used in combination with chillers that operate independently of the outside temperature.

Question:

Which chillers are better water or air chillers?

Answer:

By the type of condenser cooling, chillers can be water or air. Devices that use water for these purposes are suitable for operation throughout the year. They are more compact, can be installed inside a building, but they are much more expensive than equipment where the temperature is reduced by a directed air flow.

Air installations are offered at a low price, but their installation requires vast areas to accommodate all units and modules. For example, the cooling system is often installed outdoors. This allows more rational use of space inside the building, but reduces the functionality of such equipment.

Question:

What is the difference between chillers with and without a heat pump?

Answer:

Devices in which a heat pump is installed can not only cool, but can also heat the surrounding space or provide hot water. This useful function allows such installations to be used for heating large public or industrial premises. Equipping with a heat pump increases the cost of the equipment, but significantly expands its functionality.

Question:

What is the principle of operation of absorption chillers?

Answer:

Absorbed devices use waste heat in factories as the main energy. In such systems, the main working substance contains several components. The solution consists of an absorbent and a refrigerant. The absorber is lithium bromide, and the refrigerant is water. It enters the low pressure evaporator, from where it exits cooled and is absorbed by lithium bromide. The liquid is concentrated in a condenser and then the refrigerant is piped to the end users. Absorbed chillers do not have a compressor module and therefore consume a minimum of electricity.

Question:

What is the cost of modern chillers?

Answer:

The cost of modern chillers depends on their design features and power. These are industrial air conditioning systems that are designed to serve large industrial or public buildings, so the price of new units starts at 100 thousand rubles. The cheapest are low-power mini chillers, and the most expensive ones have an output power measured in thousands of kW, and their cost is several million rubles. Many suppliers, upon request of the customer, provide a cost estimate after specifying the main required characteristics and functions.

Fancoil what is it

In one bundle, a fan coil unit and a chiller, they allow you to create independent temperature control in several different rooms at once. As a result of this advantage, the fan coil system has found wide application in industrial enterprises, as well as in large premises, which are used for offices, hotels, warehouses, etc.

The operation of the fan coil is designed in such a way that the device can be switched on and off automatically, as well as maintain the required heat and cooling capacity.

Equally important is the fact that the fan coil system makes it easy to expand the number of installed equipment, depending on the number of consumers, the required power and other features.

Chiller-fan coil system and its advantages

The main advantage of the chiller-fan coil system is the flexibility of operation to ensure high-quality air exchange in various rooms.A large number of fan coil units of different power operating independently of each other can be connected to the chiller, which is designed to prepare the heating medium.

In addition, using the chiller-fan coil system, it is possible to control separately the operation of each fan coil connected to the chiller, both from the built-in and from the remote control panel. If there is such a need, it is possible to program the fan coil system into a single thermal mode.

An indisputable advantage is also the rather simple possibility of increasing the power of the system, which significantly expands the scope of application of fan coil units. Well, among other things, it is worth noting the technical capabilities of installing a chiller and a fan coil: the distance between them can be almost unlimited, everything largely depends on the capacity of the pumping station.

Fan coil types

So what is a fan coil unit - what is it? How does it work and what types of fan coil units are there?

The fan coil unit includes a heat exchanger and an electric fan, a filter with a control panel, which allows you to adjust the settings of this climatic equipment. An electric fan in a fan coil unit is designed to blow air into the room through the ventilation duct system, and the heat exchanger to cool it to the required temperature.

As mentioned above, today there are different types of fan coil units. The simplest design has a cassette fan coil unit, which is mounted on a suspended ceiling. Fan coil units differ in design, installation method and other features that allow them to be seamlessly connected with various climatic equipment.

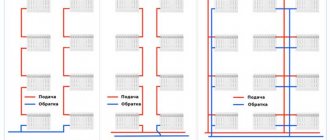

Depending on the number of heat exchangers installed, the following types of fan coil units are distinguished:

- Two-pipe fan coil units;

- Four-pipe fan coil units.

According to the place and method of installation, fan coils are cassette, duct, ceiling, wall and floor. In addition, fan coil units can be either enclosed in a case or without it - open-frame fan coil units.