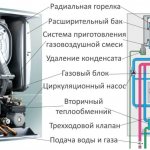

The principle of the boiler

Gas heaters may differ structurally and in technical parameters, but the principle of creating heat in a house is the same - heating the coolant (water / antifreeze) with combustion gas (natural / liquefied). The supply of gaseous fuel to a dwelling is not the easiest and safest thing to do, but consumers are attracted by gas, its comparative cheapness and versatility.

Blue fuel can be used not only for heating, but also for heating domestic water using columns or dual-circuit heater models. Modern equipment is equipped with effective security systems that prevent all possible emergencies. Nevertheless, there are operating rules that are mandatory and are a guarantee of safe operation.

Precautionary measures

Despite the desire of manufacturers for the safety of gas appliances, they can still become a source of danger. The Ministry of Emergency Situations regularly reminds the owners of any gas-powered equipment about the precautions:

- It is necessary to buy gas-fired appliances from organizations that have an appropriate sales license.

- Installation should only be carried out by qualified personnel.

- The set should include an instruction manual.

- It is forbidden to change the structure of the device in any way.

- A technical check must be carried out annually.

- It is forbidden to reduce ventilation openings in windows and walls.

- In the presence of sealed windows, it is necessary to organize the flow of air.

- Materials that can quickly ignite must not be stored in the boiler room.

- It is forbidden to increase the temperature of the heating medium over 90 ° C.

Stages of obtaining permission to operate the boiler room

Acceptance of boiler equipment and obtaining a permit for operation is carried out by state acceptance commissions in accordance with SNiP 3.01.04-87.

At the same time, it is forbidden to put into operation objects without safety automation, not provided with fire extinguishing and environmental protection systems. Before acceptance, complex tests of boilers are carried out with a working load for 72 hours.

A preliminary test run must meet the conditions to ensure the safe operation of the boiler room:

- Operative and maintenance personnel were recruited;

- instructions for operation and labor protection were approved;

- operating diagrams of the boiler room and auxiliary devices were developed;

- stocks of fuel, tools, repair kits and personal protective equipment were prepared for service personnel;

- issued permits of state supervisory authorities for operation.

The commissioning of the boiler house is carried out by the state acceptance commission in the following stages:

- Completion of commissioning works, registration of regime cards for the operation of heat power plants.

- Registration of the required package of documentation for the commissioning of the boiler house and their submission to the state service for environmental and technological supervision.

- Control by representatives of environmental and technological supervision

- Obtaining a commissioning certificate.

Accommodation rules

- The area of the room in which the heater is installed is at least 7.5 m².

- Ceilings - from 2.2 m.

- There should be a window that allows air access from the street.

- The door should open in the direction of the movement of a person leaving the room.

- It is forbidden to equip switches in the boiler room. If they are already installed, they will have to be taken out of the room.

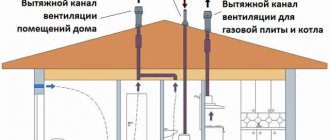

- It is necessary to equip supply and exhaust ventilation. For each m³ of consumed fuel - 15 m² of air.

- The distance from the heater to elements capable of burning is 25 cm or more. Up to non-combustible elements - 5 cm.From the chimney to combustible parts - 40 cm, to non-combustible - 15 cm.

- The device is mounted on a perfectly flat surface, without slopes.

Requirements for industrial gas boiler houses

Gas has a high flammability in connection with which the state requirements for such facilities are extremely high, and are enshrined in the joint venture 89.13330.2012.

This code defines the requirements for thermal equipment at the stages of design, installation, repair or technical re-equipment and safe operation.

Basic requirements for gas-fired boiler houses.

The operation of boiler plants is carried out in accordance with the established state regulations and rules in the field of production safety;

- Installation of boilers is allowed in detached buildings or in premises adjacent to the production building, disconnected from it by a firewall.

- It is forbidden to install gas heating units under facilities where a large number of people can be concentrated and located under a fuel and lubricants warehouse.

- The floor covering in the boiler room is made of fire-resistant materials, with a non-smooth structure.

- In rooms, for the location of heating units with a total area of up to 200 m, it is allowed to install one outlet, and more than 200 m - at least 2, located opposite.

- The doors of gas boiler rooms must open outward, and be equipped with vestibules, in order to prevent the flow of cool air.

- Doors to auxiliary rooms must open towards the boiler room and have equipment for self-closing.

- All rooms are equipped with natural or supply and exhaust ventilation.

- The placement of equipment should not violate the distances for maintenance: from the front of the boiler units to the opposite one more than 2 m, free passages between the equipment - at least 1.5 m.

Chimney requirements

- Chimney material - steel. It is recommended to use stainless steel.

- Cleaning hatches and condensate drainage are required. There should be a pocket at the bottom of the chimney in which deposits accumulate.

- The chimney is equipped with external thermal insulation, which is protected from moisture (condensation, precipitation).

- Chimney height - from 5 m and at least 2 cm above the outlet.

- The chimney is installed on the receiving plate of the vapor trap.

- The expansion tank is installed at the highest point in the system.

- A safety group and a thermometer are installed on the supply pipeline.

- It is undesirable to place the device in openings, niches and other hard-to-reach places.

How to use

In modern models of heaters, human participation is minimized. Before the device is started, it is connected to:

- gas pipeline - employees of the gas service;

- heating pipes;

- water supply - representatives of organizations serving heating systems.

The first start-up is also carried out by service workers. If during connection and maintenance the requirements of the instructions are violated, the warranty will be canceled. The equipment must only be used for the purposes intended by the manufacturer.

During installation, maintenance and repair, original spare parts must be used. If a breakdown or incorrect operation is found, the user should immediately turn off the gas with a valve and call the service or gas service. It is strictly forbidden to carry out repair work on your own.

When performing any work on or near the air duct or chimney, it is imperative to turn off the gas. After completing the work, they check the functionality of the chimney and air duct and only then they start starting the device.

How to turn off the boiler correctly

If the device will not be used for a long time, perform the following actions:

- Close the gas valve.

- If the equipment is volatile, disconnect the automation and the water pump from the mains.

- Shut off the water supply and heating valves.

- If the temperature is expected to drop below zero, you will have to drain the water.

- Call a specialist to permanently turn off the equipment.

The heater is also turned off for cleaning. Clean it with a damp cloth, mild detergent and soap. It is forbidden to use aggressive substances.

Safety system

Gas powered appliances need serious monitoring. It is provided either by a person or by an automation system. The latter is capable of providing multi-stage protection that prevents dangerous situations and increases the safety of the equipment. The main task of the protection system is to turn off the device in time by stopping the fuel supply.

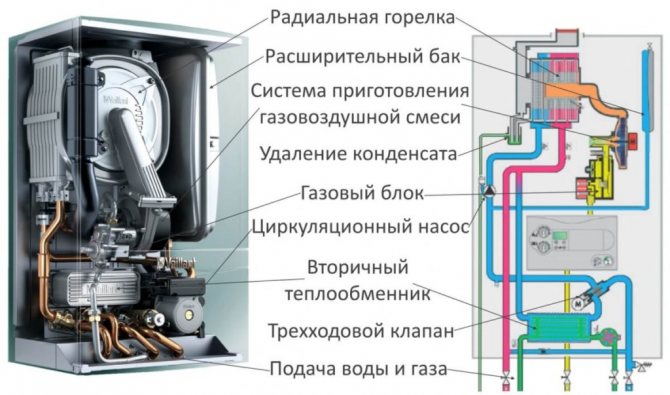

Let us consider the protection stages using the example of a floor-standing boiler "Proterm Wolf KSO". These modern devices have multi-stage protection. One of the stages is an ionization sensor that monitors the flame. If the fire goes out, a signal will be given to the control unit, it will cut off the fuel supply and prevent an accident.

The combustion chamber has a temperature sensor that monitors the heating of the coolant and does not allow the furnace to burn out quickly. "Wolves" are equipped with a KTD system - chimney draft control. It prevents the accumulation of carbon monoxide gases. If there is no draft, the accumulation of combustion products in the chimney begins, the thermostat heats up. When the temperature limit is reached, the thermostat contacts open - the flow of fuel stops.

Automatic protection

Modern heater models are saturated with electronic instrumentation that generates signals for the control unit. Automation, receiving signals from sensors, coordinates the work of all units. Safety valves, expansion tanks, air valves, smoke detectors and other devices are the elements that prevent various kinds of malfunctions and problems.

Gas boiler operating instructions

Autonomous heating of the house makes it possible to independently regulate the microclimate in the premises, to set the air temperature that is optimal for a particular place. Leaving on a business trip or to a resort, you can turn off the boiler or put it into a reduced consumption mode. And, accordingly, do not overpay extra money, as is the case in apartment buildings connected to a centralized steam heating system.

Since gas is a highly flammable combustible material, its use is associated with an increased level of danger. And only observance of all precautions can ensure the safe operation of the equipment for a long time.

Example of connecting the boiler to the heat supply system

To increase the level of safety, certain provisions have been adopted at the legislative level that are designed to minimize the risk of fire or carbon monoxide poisoning of users. They are set out in SNiP 11-35-76 "Boiler Plants" and SP-41-104-2000 (rules for designing autonomous heat supply systems)

First of all, these standards are related to the correct installation and connection of a gas-fired boiler. It can only be carried out by a representative of the relevant service, as a rule, an employee of a gas or regional gas or regional gas company. Independently, you can only hang (or install) the unit at the workplace and supply water to it.

Gas connection is allowed only to employees of the installation organization, who draw up a connection certificate, install seals on the boiler and put the system into operation.

Regulatory documents also regulate the methods of chimney arrangement and the requirements for the room in which the gas equipment is installed - the boiler room.

To conclude a contract with a service organization, you will need:

- Agreement on the provision of natural gas to an individual developer

- Boiler installation project, agreed with a representative of the relevant service, which has a license to develop design documentation

- Certificate of installation and connection of the boiler to the gas supply system

The conclusion on the readiness of the heating equipment for operation is issued by an engineer of the local gas organization. Before direct switching on, the pipe connection must be checked for tightness under a pressure of up to 1.8 atm., Bleed the air present in them.

In addition, it is recommended to secure the boiler against voltage drops in the network by installing a stabilizing transformer. Ideally, the best solution for problems arising in the power grid would be to connect an autonomous uninterruptible power supply.

It is forbidden to add antifreeze to the water circulating through the heating channels. This leads to rapid wear of the rubber gaskets, which act as a seal in the pipe connections. As a result, liquid leakage and violation of the specified operating mode of the heating equipment may occur.

The combustion room must have an area of at least 4 m 2, the height of the ceilings must be at least 2.45 m. The size of the entrance door must be at least 0.8 m wide. It is also necessary to have a ventilation window and free air flow. If the ventilation is insufficient, a lattice opening is installed in the lower part of the door, allowing the air to move freely. The hole size is calculated based on the norm of 8 cm 2 per 1 kW of power.

Requirements for the location of the gas boiler in the boiler room

Combustion of 2.5 m 3 of gas requires about 30 m 3 of air! In addition to sufficient air flow, a continuous exhaust gas vent is required.

The chimney is arranged according to the following standards:

- the diameter of the chimney must not be less than the diameter of the outlet from the boiler;

- more than 3 elbows are not allowed along the length from the boiler to the end point of the smoke outlet;

- the pipe umbrella must rise above the roof ridge by at least 50 cm.

Requirements for the installation of the chimney of a gas boiler

In order to prevent dangerous gas accumulation in the room, a gas analyzer must be located in the boiler room, which transmits a signal to an electric valve that stops the gas supply. Gas leakage is the most common cause of accidents associated with the operation of gas equipment.

To calculate the cost of gas used for heating, gas meters are used, which are installed on the inlet pipe in front of the boiler.

The installation of the equipment should provide for a safe positioning of the boiler away from walls and windows. If the wall is made of a combustible material (eg wood), then a sheet metal gasket with a thickness of at least 0.5 mm must be used. It is not recommended to install the boiler directly near the window.

To prevent the heat exchanger from clogging up over time, a mesh filter is installed on the pipe entering it. Ball valves on both sides will greatly facilitate further replacement and maintenance.

Terms of operation

The service life of gas equipment is determined in the technical passport of the boiler and ranges from 10 to 15 years. However, with regular maintenance and prevention, it can take much longer. On the part of the controlling services, additional requirements for the service life may be established.

This may be due to the presence (or absence) of spare parts that are needed in the process of maintaining the boiler in full operation.If some part is required during the repair, and the manufacturer has stopped producing them, it may be necessary to replace the boiler as a whole, with a more modern one and provided with spare parts.

Service

The current technical maintenance and repair of boilers is undertaken by a company that supervises the safety of using this type of equipment. This is reflected in the contract concluded between the consumer and the local gas office. As a rule, an inspection is carried out once a year, before the start of the heating season. The service representative is obliged to test the operation of the main technical units of the unit and draw up an inspection report, a copy of which remains in the hands of the consumer. If any deviations from normal operation are detected, the task of the inspector is to draw up an order, which reflects the essence of the problem and the timing of its elimination.

In order for the boiler to work properly and without failures, certain rules should be adhered to, which are easy to follow, but neglecting them can lead to serious and unpleasant consequences.

Extreme situations associated with the operation of gas installations

If you smell gas:

- turn off all electric heaters;

- do not use electrical light switches, do not light lamps;

- increase ventilation in the room, open all possible windows and doors;

- turn off the gas shut-off valve to the “CLOSED” position (perpendicular to the pipe on which it is installed);

If you smell carbon monoxide:

- suspend the operation of the boiler;

- increase ventilation by opening as many windows and doors as possible;

- call an emergency gas service.

It should be borne in mind that the phone also operates on an electric current, so you need to make calls at a safe distance from a gas-polluted or smoky room.

During maintenance of the boilers, for example, replacing fuses in the electrical supply system, the boiler must be completely disconnected from the mains. Only by removing the cord from the outlet, you can proceed with further actions.

In the event of a leak in the heating pipes and carrying out restoration work, it is necessary to drain all the water from the boiler. The boiler can be restarted only after the leak has been eliminated and air has been bleed from the pipes.

In the cold season, when the outside air temperature drops to low levels, icing can form on the chimney, which, falling off, can cause harm to human health. To prevent this from happening, special ice traps are installed on the roof or on the pipe itself.

The general rules for the installation of boilers also stipulate that their placement is possible only in rooms protected from freezing. It is forbidden to store and use substances with an increased level of explosiveness in the boiler room, such as gasoline, solvents, paint or varnish.

To care for the boiler, use only damp cloths and mild detergents. The area under the boiler casing may only be cleaned by a specialist.

Correct regulation of the heating mode significantly reduces costs.

Heat distribution in rooms is carried out in two ways:

- manual adjustment of thermostats directly on the radiators;

- using a remote control system, by installing climate control sensors.

A good help in saving money is a device that provides a decrease in temperature at night. A change in temperature by 1 degree changes the gas flow rate by 5–7%.

For effective air circulation around heating radiators, it is necessary to create favorable conditions. Heavy curtains covering the radiator housing prevent this and, accordingly, increase energy consumption.At the same time, curtains that tightly cover the glass of the windows help to reduce the cooling of the air in the room in winter. By correctly selecting the size and location of the curtains, you can further reduce gas consumption.

Design of a niche for a heating radiator

Economical heat distribution is facilitated by such seemingly insignificant trifles as thermal insulation of niches for the location of batteries and painting them in light colors. It is estimated that these measures will reduce gas consumption by up to 3%.

In addition, if it is necessary to ventilate the rooms, short-term but frequent opening of doors and windows is recommended. With prolonged airing, the walls that accumulate heat cool down and after that they have to be reheated.

A lot of excess energy is taken by the excess air in the heating pipes. Removing it from the closed system in a timely manner will ensure cost savings. For the same reasons, it is not recommended to overheat the liquid until it boils. In addition to the formation of steam bubbles, this condition is fraught with an excess of the nominal pressure and additional load on the joints. Micro leaks can form at the pipe joints, through which water will ooze over time.

It is advisable to use a hot water recirculation pump. The optimal form of its connection is a connection through a time relay, which can be programmed in accordance with the hours of active consumption of hot water.

Using a shower instead of a bath reduces hot water consumption by up to 30%.

An important factor in energy saving is the sealing of window gaps and entrance doors. Modern means of sealing make it possible to eliminate the movement of cold air even in old cracked windows.

In order to prevent the wick from blowing out on the boiler operating in automatic mode, there should be no stable drafts in the boiler room. The device itself should be located at a distance from doors or windows, so that when the door is slammed, the air wave cannot extinguish the flame of the wick.

Video: gas double-circuit boiler NAVIEV 24, review and recall

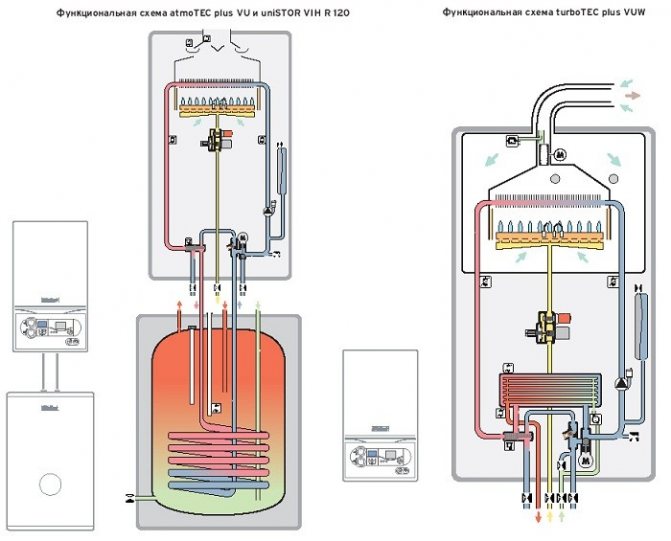

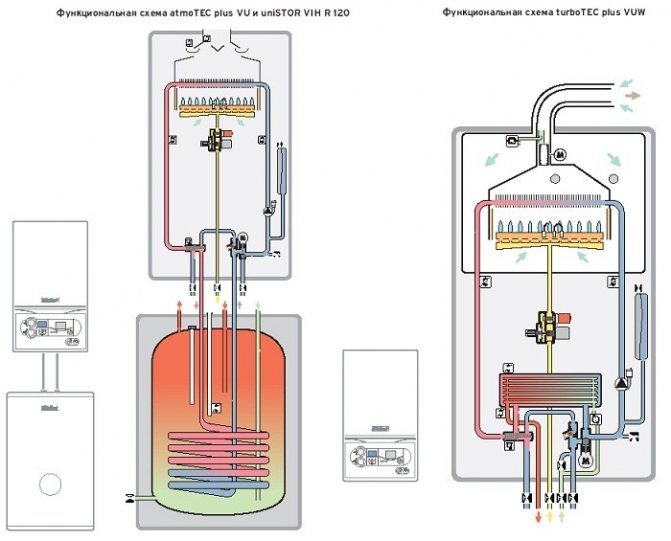

There are a great many varieties of models of heating boilers. They differ in size, power and purpose. There are purely heating units, and there are double-circuit boilers that combine the function of heating a room with the supply of hot water for domestic needs. Depending on the brand, they may differ in equipment, the presence or absence of automation and various kinds of adjustments. Some are designed for small rooms and are mounted on brackets to the wall, while others are installed on the floor, have large dimensions and are designed to heat large areas.

Each type has its own operational features, which are described in the technical documentation. A careful study of the passport and the manual for the product will allow everyone to understand all the nuances of connecting and using exactly the model that is selected.

Video: starting and turning on the gas boiler AOGV-8-1 "Gazovik"

What to do if malfunctions appear

Let's consider situations with breakdowns using the example of Italian Baxi boilers. Italian wall and floor heaters are an example of quality and efficiency. But even with proper use, malfunctions may occur that require prompt elimination.

The following problems may appear in Baksi models:

- the burner does not ignite;

- while working in the firebox, pops are heard;

- the boiler has overheated;

- the device makes a lot of noise;

- the sensor is out of order.

The probable causes of breakdowns are associated both with violations of the operating rules and with reasons beyond the control of the user:

- moisture has entered the device;

- low quality of the coolant;

- decreased pressure in the gas pipeline;

- voltage drop in the power grid;

- errors were made during installation.

Violation of at least one rule or norm leads to breakdowns, incorrect operation and unnecessary costs.

The main errors in the operation of the boiler and options for elimination

All errors are recognized by sensors and displayed as a code.

Major mistakes:

- E01-Lack of ignition of the flame. Check the sensor, gas presence and burner condition.

- E02-Thermostat overheating. The water supply may be interrupted or scale build up.

- E03-Problems in the fan operation, diagnose or replace.

- E05-Failure of the extract air temperature sensor.

- E06-Malfunction of the DHW sensor.

- E10-Drop in coolant pressure, cause of leakage in the circuit.

- E25-26-Failure of the circulation pump or failure of the sensor.

- E35-Pseudo combustion signal. There are several reasons for the ingress of water on the board before the sensor closes.

- E96-Fall of electricity.

The first step of the owner when an error occurs is to reset to do this, press the R button and hold it for 3 seconds. If the error does not disappear on the display, contact a specialist.

Frost protection

One of the important rules for operating heating systems is to ensure the minimum permissible temperature of the coolant. If water is poured into the system, then at low temperatures freezing occurs, pipes and radiators become unusable. In modern models, this problem is solved - the user is relieved of the need to monitor the coolant.

So, for example, in boilers of the South Korean] Navien [/ anchor], reliable protection against freezing is provided. "Navien" is cheaper than European counterparts, but these boilers have all the necessary protection functions, which greatly simplifies use.

When the temperature of the heating medium drops below 10 ° C, the circulation pump starts automatically. If the coolant cools down to 6 ° C, the burner automatically turns on, heating the coolant to 21 ° C.

Features of the

In the Baxi Main 24 Fi double-circuit boiler, the number 24 is an indicator of the boiler power (24 kW), which is enough for the uninterrupted supply of hot water for the operation of heating systems or the operation of a warm floor, and the letters Fi are turbocharged mode in the combustion chamber.

The design of the combustion chamber is made of a closed type, which ensures tightness and cleanliness of the surrounding air.

In the Baxi Main 24 Fi design, two separate heat exchangers are combined into one, unlike other versions.

The design is a pipe in a pipe, made in the form of a diamond. Due to the design feature, where the coolant passes through the outside and hot water through the inside, the boiler has acquired convenient adjustment and adjustment, and has also become more compact.

Ignition instructions

Heaters differ in the type of ignition, so there are nuances when starting different modifications. Before turning on the device, you need to read the ignition instructions in order to do everything right. Let's consider firing up on the example of the Italian boiler "Ariston". It is important to check the system for leaks before switching on. For this purpose, the thermostat is turned on to the maximum so that the changeover is automatically triggered. Ariston ignition process:

- the device is connected to the mains, and the heating regulator is set to the desired temperature value;

- a small noise is heard when the pump is turned on;

- when all air jams are eliminated in the pipes, the noise will disappear;

- electric ignition is triggered - the boiler turns on independently.

Self-diagnosis

The operation of the heaters is simplified if they have a self-diagnostic function. Almost all European manufacturers have equipped their products with it.

So, for example, German heaters "Bosch", displaying error codes on the display, allow the user to quickly understand the cause of the problem and take measures to eliminate it. If code A7 appears on the screen, it is clear that the hot water temperature sensor is faulty.

If A8 is highlighted, the connection to the BUS bus is broken.This function greatly simplifies the use of gas equipment, makes it easier and more comfortable.

Dangerous situations

The greatest risk is burner malfunction. If the flame goes out, gas can accumulate in the room, which will subsequently cause an explosion. Reasons for extinguishing the fire:

- the gas pressure has dropped below the permissible rate;

- there is no draft in the chimney;

- the supply voltage has disappeared;

- the igniter went out.

In an emergency, it is necessary to immediately shut off the fuel supply to the burners - automatically or manually. Modern versions are equipped with automatic devices necessary for prompt shutdown of equipment. The operation of such devices is not only convenient, but also safe.

How to prevent gas build-up in a room

Modern safety standards provide for the installation of gas analyzers in boiler rooms, they are necessary for signaling when gas appears in the room. A special electronic valve reacts to their signals, automatically stopping the flow of fuel to the burners.

7.

BOILER EMERGENCY STOP IN THE BOILER ROOM

7.1. In an emergency, the maintenance personnel is obliged to immediately stop the boiler and inform the head (manager) of the boiler room or the person replacing him about it, in particular in cases where:

a) more than 50% of safety valves or other safety devices replacing them have ceased to function;

b) the pressure has risen above the permitted by more than 10% and continues to grow, despite the interruption of the fuel supply, the decrease in draft and blast, and the increased supply of water to the boiler;

c) there was a leak of water from the boiler (below the lower edge of the water-indicating glass). It is strictly forbidden to make up the boiler with water;

d) the water level drops rapidly, despite the increased water supply to the boiler;

e) the water level has risen above the upper edge of the water-indicating glass and by blowing the boiler it is not possible to lower it;

f) the operation of all feeding devices is terminated;

g) all water indicating devices are no longer valid;

h) in the main elements of the boiler (drum, collector, chamber, flame tube, fire box, furnace casing, tube sheet, external separator, steam line, etc.) cracks, bulges, gaps in welded seams, breaks of two or more a number of connections;

i) a gas contamination of the boiler room with boilers operating on gaseous fuel was detected, the gas supply was stopped, an explosion of the gas-air mixture occurred in the boiler furnace or gas ducts;

j) the power supply has been interrupted during artificial draft, as well as the elements of the boiler and its lining are damaged, creating a danger for the service personnel or the threat of destruction of the boiler;

k) a fire broke out in the boiler room or soot or fuel particles in the gas ducts caught fire, threatening the maintenance personnel and the boiler.

7.2. The reasons for the emergency shutdown of the boiler must be recorded in the shift log.

7.3. If a leak appears in riveted seams or in places where pipes are rolled, fistulas on the pipes of the heating surfaces of the boiler, & also in case of other damage and malfunctions of the boiler, fittings, pressure gauges, safety devices and auxiliary equipment that do not require an immediate shutdown of the boiler, the service personnel is obliged to immediately report this administration.

7.4. In case of emergency shutdown of the boiler, it is necessary:

a) stop the supply of fuel and air, sharply weaken the draft;

b) remove burning fuel from the furnace as soon as possible; in exceptional cases, if it is impossible to do so, burning

fill the fuel with water, making sure that the water jet does not hit the walls of the boiler and the lining;

c) after stopping combustion in the furnace, open the smoke damper for a while, and in manual furnaces - the furnace doors;

d) disconnect the boiler from the main steam line;

e) release steam through raised safety valves or emergency exhaust valve, except as specified in clause 7.1 (e, f).

7.5. When stopping the boiler due to the ignition of soot or entrainment of fuel in the economizer, superheater or gas ducts, immediately stop the supply of fuel and air to the furnace, stop the draft by stopping the smoke exhausters and fans, and completely shut off the air and gas dampers. If possible, fill the flue with steam and, after stopping the combustion, ventilate the furnace.

7.6. In the event of a fire in the boiler room, the personnel must immediately call the fire brigade and take all measures to extinguish it, without stopping the supervision of the boilers.

In the event of a fire in a boiler room with boilers operating on gaseous fuel, it is necessary to immediately turn off the gas pipeline of the boiler room using a valve installed outside the boiler room.

If a fire threatens the boilers and it is impossible to extinguish it quickly, it is necessary to stop the boilers in an emergency manner, intensively feeding them with water and releasing steam into the atmosphere (outside the premises).

8. FINAL PROVISIONS

8.1. The management of the establishment should not give instructions to personnel that contradict the instructions related to their work, and may lead to an accident or accident.

8.2. Workers are liable for violations of instructions related to the work they perform, in the manner prescribed by the internal labor regulations of enterprises and the criminal codes of the union republics.

table of contents .. 91 92 ..

What other safety rules are there?

- Do not disassemble or dismantle gas appliances yourself.

- Handle the power cord with care.

- Do not place foreign objects on top of the appliance.

- Do not step on the boiler. Do not step on chairs, tables or other unstable objects to clean the wall-mounted kettle.

- Watch the coolant, add it to the system in time.

- Be careful - in some modifications the use of antifreeze is prohibited.

- If you smell gas, immediately turn off the gas, open windows and doors. Exit the boiler room and call the gas service.

In order for the operation of a household gas boiler to be safe and uninterrupted, the user must familiarize himself with the instructions for it in advance. Choosing models equipped with automation, the consumer increases the comfort of use and safety. Observing the rules for the use of gas appliances in everyday life, for their installation and maintenance, the number of emergencies can be minimized.

Gas boiler: operating rules

Major mistakes

Most of the possible problems are associated with poor-quality installation of equipment and the first launch... Trying to save money, you cannot trust the installation to specialists without sufficient knowledge, who do not know regulatory requirements and have not undergone specialized training from equipment manufacturers.

The first start-up of the boiler is allowed only by a technician. (engineer) of an authorized service center. He will check the correctness of the installation work of the entire system: „„

- connection of cold water and hot water supply hydraulic systems, heating systems to the boiler; „„

- the presence of mud filters and the necessary shut-off valves on the connection pipelines.

Makes calculations and checks:

- „„ Cold water pressure in front of the boiler, in the heating system and compares with the data of the boiler characteristics;

- „„ Compliance of the quality of cold water and heat carrier with the requirements of the manufacturer;

- „„ The quality of the boiler power supply and its compliance with the PES requirements;

- correct installation of smoke exhaust and air supply systems, their maximum permissible lengths and diameters;

- supply and exhaust ventilation system;

- „„ Correct installation and tightness of the gas pipeline.

If there are no comments, the engineer will proceed to the commissioning procedure itself, which includes various checks and settings of the boiler control systems, adjusts its automation to the client's needs, taking into account various factors: the heat loss of the building, the type of heating system, the area of the heated rooms, etc.

The second biggest problem is the neglect of annual maintenance., because of which, after a while, various failures begin to arise. This may be due to contamination of the combustion chamber, smoke exhaust fan in boilers with a closed combustion chamber, the formation of carbon deposits on the ignition electrodes and other natural contaminants arising during operation. If you call a service engineer and fix such problems in a timely manner, the equipment will last a long time.

Work before the start

What to do before the heating season if the house already has a heating system, which, in addition to the boiler, includes heating devices, supply pipes, shut-off valves, and a smoke exhaust system? Diagnostics, adjustment and the first start-up of the boiler must be entrusted to qualified professionals, the rest can be checked and prepared for the upcoming cold weather on your own.

Before starting, it is necessary to check the heating system for leaks - whether there are leaks at the joints, recheck the shut-off and control valves, remove and wash the mud filters on the cold water supply and the heating system return supply, check the operation of the voltage stabilizer and the boiler grounding. It is also necessary to check that birds have not built nests in the smoke exhaust system.

When starting the boiler on its own with a closed heating system, make sure that the pressure in the heating system is within the range approved by the manufacturer. If the pressure drops during the downtime of the equipment, it is necessary to feed the boiler (add a coolant to the heating system to the appropriate starting pressure), not forgetting to open the Mayevsky valves to remove air. Modern boilers have automation that independently monitors the state of the boiler. If necessary, informs about possible errors in the operation of the equipment, and subject to annual maintenance, it will work for many years.

Setting up a modern boiler with an electronic control unit, connecting smoke exhaust systems and any repair work should be carried out only by specialists of service organizations. By law, only persons authorized to work with gas can repair gas equipment! The boiler must be serviced annually.

What to do if there is no boiler yet

First, you need to determine what the boiler is needed for: only for heating or for heating hot water. Choose a model - single-circuit or double-circuit. Understand what area, taking into account future extensions, is planned to be heated, where it is planned to divert the combustion products, how the boiler should behave in your absence.

Recently, wall-mounted gas boilers have been very popular. They represent a small boiler room - a complete product, which must be adapted to a specific heating system during installation and first start-up. To calculate the power of a heating boiler, use the proportion: 1 kW of power per 10 m2 of area. With the calculation of the power for heating water, it is necessary to take into account the number of consumers and draw-off points.

Approximately, to wash the dishes, you need 6-7 liters of hot water per minute, and for a shower - 11-12. There are models on the market that produce up to 20 l / min. Pay attention to the speed of DHW heating and the technologies by which the boiler operates silently. By the way, the built-in programmer will help to significantly save on energy resources (when you are not there, the boiler lowers the temperature on its own, saving gas).

When choosing smoke exhaust systems and ensuring air flow to the boiler, pay attention to insulated coaxial kits. They have proven themselves well at negative temperatures: they prevent condensate icing and guarantee stable boiler operation even at –50 ° С. If the length of the chimney is more than 5 m, a separate insulated system can be used, which will also prevent the formation of condensation inside the room.

Entrust the choice of boiler equipment to professionals. They will make a calculation, recommend equipment, draw up a project and ensure the launch of equipment.