Akterm Anti-condensation

The material prevents the formation of condensation on all types of surfaces, including concrete, brick, metal. The scope is wide:

- interior work in the room (walls, ceiling, floor);

- containers, tanks;

- pipelines;

- metal structures;

- outbuildings - garages, cellars, cellars.

The application of 2 mm paint 100% guarantees the absence of condensation during the operation of surfaces in the temperature range of -60 ... + 150 degrees. Indoors, this helps to create a comfortable microclimate, provide protection against mildew and mold.

![]()

The material is diluted with water, can be easily applied with a brush, airless spray. Drying time - 24 hours.

How comfortable is AKTERM Concrete liquid insulation in operation?

The application of AKTERM Concrete thermal insulation is carried out with the same degree of comfort as the use of conventional surface paint. So, all you need is:

- ordinary spatula;

- an apparatus for spraying means of an airless type.

A sheet of thermal insulation applied to the surface to be treated acquires such properties as:

- flexibility;

- elasticity;

- clear adhesion.

Therefore, it is also convenient to operate it later, since the maintenance procedures for this material are reduced to zero.

It should also be said that the application of AKTERM Concrete as thermal insulation not only deprives you of the need to pay substantial heating or electricity bills, but also prevents the formation of the following on the treated surfaces:

- fungus;

- condensate;

- mold.

When located in the external environment, AKTERM Concrete, daily encountering natural factors negatively affecting it, with full preservation of its properties, can be used for at least 10 years. If we are talking about the use of material inside rooms, then the desired indicator can be safely doubled, and added to the resulting value for another 3-5 years. The thing is that in the form applied to the wall, the desired coating shows resistance to:

- ultraviolet radiation;

- an increased level of air humidity;

- temperature jumps.

At the same time, no additional layer to protect the thermal insulation is required, since this composition is able to cope with all the "attacks" of the environment itself.

This liquid insulation can be applied both on flat and embossed surfaces, the final effect will not suffer from this.

Akterm Standard

It is a universal liquid heat-insulating material, most in demand in everyday life and at work. The paint is suitable for all types of surfaces, even plastered ones. Can be used for:

- insulation of internal and external surfaces in apartments, houses, on balconies and loggias;

- hydro and noise insulation of any structures;

- protection against UV radiation, other atmospheric factors;

- handling of transport, containers, pipes, metal structures.

"Akterm Standard" is sold in convenient packages with a volume of 5.10.20 liters, its consumption does not exceed 1 liter / sq. m of surface. Application of paint is standard - by spray or brush.

Application conditions

- AKTERM BetonTM is applied in layers of 1 mm at an ambient temperature of + 7 ° C to + 45 ° C on a surface with a temperature of + 7 ° C to + 45 ° C. After drying of all layers of the coating, the surface can be used in the temperature range from -60 ° C to + 140 ° C. The time for complete drying of one insulating layer is 24 hours at an air humidity of no more than 65% and an air temperature of at least + 7 ° C.On the finished coating, you can apply plaster, putty, wallpaper or paint in a decorative color.

- The recommended thickness of the finished AKTERM BetonTM coating is 1.5 mm.

- AKTERM BetonTM consumption is 1 liter per 1 m2 of surface with a layer thickness of 1 mm.

- After drying, the color of the coating is white.

Actor Metal

Liquid ultra-thin insulation "Akterm Metal" is specially designed for thermal insulation of metal substrates. perfectly protects surfaces from aggressive factors - sunlight, wind, moisture. A unique property of the paint is protection against burns in contact with heated metal. Due to the environmental friendliness of the composition, the material is widely used inside production facilities and workshops. Other possibilities of operation:

- steam pipelines;

- hot and cold pipelines;

- tanks and hangars;

- storage facilities and cold storage facilities;

- air conditioning systems;

- trailers and refrigerators.

In addition to metal, paint will help protect glass and plastic surfaces from damage and heat loss. The minimum layer of material is 1 mm, the peak application temperature is +260 degrees for 2 hours.

Scope and features of thermal insulation Akterm

Universal liquid thermal insulation Akterm Standard.

Thermal insulation of this type is used to cover any kind of surfaces: metal, wood, concrete. It has sound and heat insulating properties. Also, Akterm liquid thermal insulation can be easily applied to surfaces of any shape.

Used on pipes, walls, roofs and vehicles. Due to its properties, thermal insulation significantly reduces heat loss in the room. It prevents the walls from freezing and helps to significantly reduce the cost of heating. It prevents condensation from forming on pipes and any steel surfaces.

Existing types of insulation:

- standard;

- facade;

- north;

- NG;

- volcano.

"Standard" is used for thermal insulation of building facades, interior decoration of premises and insulation of concrete floors. Also used for coating surfaces on roofs. Such ultra-thin thermal insulation Akterm is used for pipes for hot and cold water supply.

If you cover the wall with a thin layer of Akterm insulation, it will cease to freeze and become covered with condensation. 1 mm of insulation can replace a 2.5 mm polystyrene layer.

A more effective insulation is "Facade". It can be applied in thick layers, which is a godsend for concrete surfaces. It has a high coefficient of heat reflection and is used to insulate walls and facades of buildings. For work at low temperatures, the "Nord" type is suitable. It is often used to insulate rooms outside, as well as heating pipes or any metal containers.

At facilities where it is necessary to use non-combustible materials for thermal insulation, the "NG" type is used. For cases with a high thermal regime up to +600 degrees, the Akterm liquid insulation of the "Volcano" type is used.

Liquid thermal insulation does not reduce the usable area of the room.

The features of the insulation are:

- thermal insulation;

- thermal mirror;

- anti-corrosion;

- use in hard-to-reach places;

- anti-fungal coating;

- does not reduce space;

- high temperature resistance;

- reduces and eliminates the formation of condensation.

- adhesion (or adhesion) to almost any material.

If you cover the walls of the building from the outside, then in summer this material will reflect heat, and in winter, on the contrary, return it inside the room. Thus, it functions as a thermal mirror. Indoor wall covering will not only provide excellent thermal insulation, but can also act as a finishing and anti-fungal coating. About Akterm liquid thermal insulation reviews, for the most part, leave good ones.And not only due to excellent insulation, but also the possibility of application in hard-to-reach places.

The use of thermal insulation Akterm will not reduce the usable area in the apartment.

The use of this thermal insulation significantly reduces the risk of rust, as it prevents condensation. High heat resistance (up to +260 degrees) and the ability to apply to any objects distinguish it favorably from other heat-insulating materials.

Regulatory documents, according to which pressure testing of the heating system is carried out: SNIP, GOST, sanitary standards.

There is special equipment for flushing and pressure testing of heating systems. Some cleaning methods can be performed manually. More details here.

Akterm (Facade) Concrete

Liquid insulation is designed to insulate and decorate the facades of buildings, structures and premises from the inside. It is ideal for surfaces made of bricks, concrete and other materials. Thanks to antifungal additives, you do not have to worry about removing mold - its appearance is excluded. The antiseptic additives included in the composition eliminate harmful bacteria, which helps to improve the indoor climate.

The heat-insulating layer will also protect against freezing and condensation of moisture on the walls. The product will retain its attractive appearance for a long time, because it is resistant to UV radiation. After drying, the paint does not require additional processing, it is used for:

- insulation of premises from the inside;

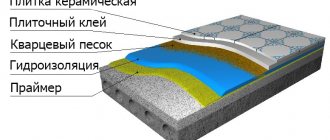

- floor insulation under the screed;

- insulation of loggias, balconies, basements;

- as a vapor barrier for underfloor heating;

- insulation of facades of residential and industrial buildings and structures;

- elimination of condensate, fungus;

- thermal insulation of surfaces of household and industrial facilities;

- thermal insulation of children's rooms, schools, hospitals and other social services. institutions;

- thermal insulation of interpanel seams, facades;

- protection of walls, floors from freezing;

- insulation and insulation of window slopes.

The operating temperature of the finished coating is not as high as that of the previous materials - up to +140 degrees. The color of the film is white, the paint can be applied manually or mechanically.

Liquid insulation AKTERM Beton - insulation of an apartment from the inside

Arrangement of thermal insulation for residential and industrial premises is one of the most important stages of finishing work. If you do not pay enough attention to this issue, in winter the walls will freeze through and through, despite the heating, and the corners will be constantly covered with condensation, the presence of which, ultimately, will lead to the spread of disease-causing mold. However, the development of building technologies does not stand still, and today you can equip the most reliable thermal insulation in your home or office thanks to AKTERM Beton, without damage to your wallet and high labor costs.

Actorm Nord

A universal heat paint for application at low temperatures down to -35 degrees, it is used on all types of substrates, and the addition of special components gives exceptional frost resistance and anti-corrosion properties. Akterm Nord is intended for outdoor use as it includes a number of solvents. The heat-insulating layer easily tolerates even the most severe winters, therefore the scope of the paint:

- insulation of residential and non-residential buildings and structures;

- insulation of the outer part of the building object: facades, interpanel seams, roofs;

- vehicles;

- containers, cisterns, reservoirs;

- household and industrial pipelines;

- insulation and anti-corrosion protection of metal structures;

- hangars, garages, warehouses;

- thermal protection of vehicles, containers.

The product has excellent adhesion to concrete, wood, brick, and plastered surfaces. Its consumption is higher than that of other materials in the line - 1.2 l / sq. m. Apply by brush or airless spray.

AKTERM cost

Price for 1 liter in 10l buckets.and 20 liters. - 320 rubles. per liter

Price in a container of 1 liter. 2L. 5l. - 350 rubles. per liter

RECOMMENDED FOR HEAT PROTECTION

- garages (doors, walls, cellar hatches);

- pipelines;

- air conditioning systems;

- hangar roofs;

- lower parts of bridges (reduces freezing);

- piles in permafrost (slows down thawing);

- the tops of the roofs of buildings;

- industrial freezers;

- hydrants;

- external parts of bulkheads, lintels, canopy roofs;

- water heaters for preparing hot water;

- hulls of ships;

- water storage tanks;

- internal and external walls of houses from freezing, condensation, the appearance of fungus, mold;

- insulation of foundations from the inside;

- roofs of residential premises, you can insulate the ceiling;

- metal roofs;

- cars, trailers, wagons and other vehicles;

- storage tanks for nitrogen;

- oil and gas pipelines (underground or aboveground, non-combustible insulation is recommended);

- oxygen pumping pipelines;

- steam lines;

- drinking water tanks;

- reflective walls in steel mills.

For all questions regarding the purchase of materials, please contact our specialists.

Actor Volcano

Unlike the previous paint, the liquid ultra-thin insulation "Akterm Vulkan" is a high-temperature modification of insulation, including organosilicon additives. The paint is applied to metal and brick substrates. Its distinctive feature is protection against scalding when in contact with a hot surface. The scope of the tool is as follows:

- heat pipelines in everyday life and industry;

- chimneys;

- product pipelines;

- engine parts;

- transport and ship hulls;

- roofing and metal structures.

Thermal insulation can be used on any substrates exposed to heating up to +450 degrees, as well as to the influence of aggressive substances: petrochemicals, salts, oils. For a short time, exposure to temperatures up to +600 degrees is allowed. The paint is applied with a brush, foam roller, pneumatic spray. It is recommended to apply 2-3 layers of coating.

Characteristic

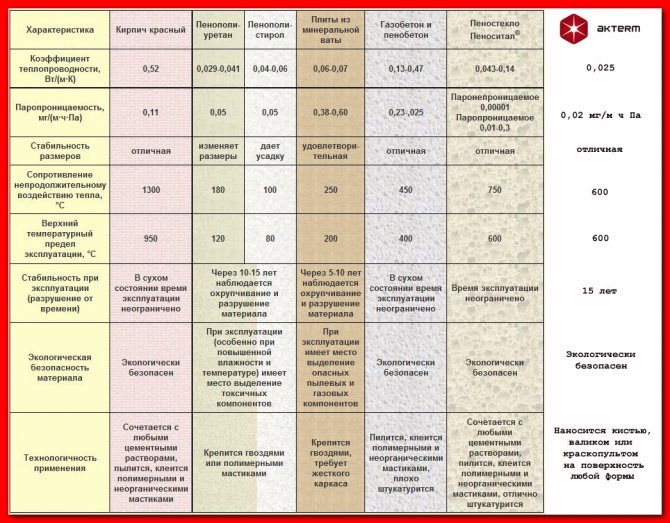

This liquid ultra-thin insulation is produced by the Russian. Can a thin layer of this substance protect against the cold? Yes, because only 1 mm of paint is equal to 5 cm of mineral wool insulation.

Material features

This is an excellent material for use as an additional insulation, it also serves as protection against moisture and corrosion. It is enough to touch with your hands the surfaces painted with ordinary paint and Akterm insulation in order to feel the effect. The composition is a thick liquid consistency. It is applied as usual paint. The drying time of the layer is at least 24 hours, although it is allowed to apply the next layer after a few hours: the substance dries quickly. You can work in an unventilated area.

Benefits:

- ease of use. It is easy to restore the damaged layer: it is enough to paint the area again. Retains access to pipe controls, saves space;

- the composition is gray or white, sprayed with a special device (spray gun) or applied, as usual, with a brush, roller, creating a uniform layer;

- the thicker the layer, the better the protection;

- when it is necessary to insulate hard-to-reach places, the paint penetrates into all cracks, pits, folds on any surface;

- strong protection against corrosion, absorbs noise.

It is used for thermal insulation of roofs, facades (topcoat); protection of walls, ceilings, floors, from the inside during freezing; additional protection of window slopes; prevent the formation of condensation on the pipes. Serves as a heat-reflecting shield for surfaces behind radiators or in a warm field.

All kinds of joints in the house (interfloor, corner, etc.), pile ends, basement walls, pipes, gas pipelines, as well as valves, roofing are treated with paint. It is also possible to process frames of prefabricated buildings, loggias, balconies, masonry joints.She insulates the walls adjacent to the cold staircase.

It is also used as a protection against rust, for example, on metal furniture; it handles ventilation systems, as it absorbs noise well. The main condition for application is the maximum cleaning of the treated surface from fine debris and moisture. Insulation Akterm is ideal for insulating plastic windows.

Such additional insulation increases the efficiency of the main one at times. The heat does not escape through the composition, but returns back. It is capable of reflecting infrared rays and 80% of heat rays.

The minimum service life is 10-15 years. The paint is able to retain up to 70% of the heat generated by the object.

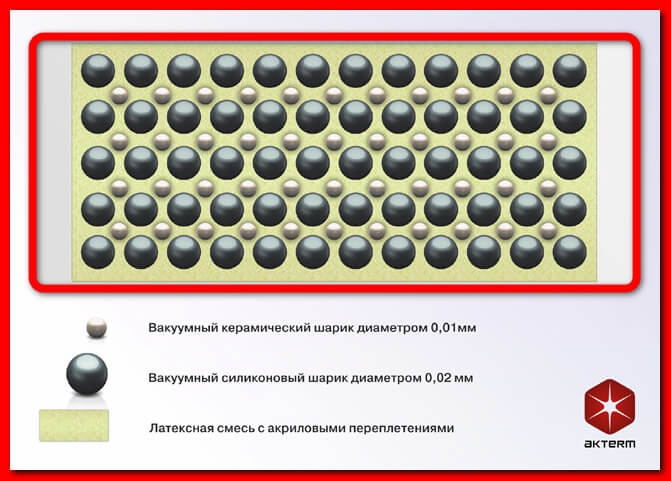

Structure

Liquid insulation Akterm consists of hollow microscopic and silicone balls with a vacuum inside: they are combined into a kind of matrix. Its principle of operation is based on the minimal properties of vacuum to conduct heat and cold.

Application plan

Let's imagine a step-by-step process of using the composition:

- the surface is being prepared. It is carefully cleaned and should be as clean and dry as possible;

- it is advisable to prime the object (although you can simply apply on a clean material). All seams, joints, cracks must be processed;

- all parts that will not be painted are glued;

- the container is opened, the paint is mixed for 20–40 seconds (it is not necessary to stir for a long time, as the structure of the substance is destroyed);

- the composition is applied with a spray gun, roller, brush like ordinary paint, but it must be taken into account - this is, first of all, a coating, not a paint;

- hard-to-reach places are processed first, then large spaces;

- Akterm is applied in an even layer, the maximum thickness of which is 0.5 mm. Usually 4-5 passes are enough for this. On vertical surfaces, paint is applied in a layer of 0.23–0.25 mm, so it will not drain;

- the second layer is applied after 1–5 hours.

Actor can be tinted with ordinary acrylic paints if several layers are applied, but the first layer should always be unpainted.

Akterm NG - non-flammable paint

Liquid insulation "Akterm NG" has the qualities of paint modification "Standard" and corresponds to the class of flammability NG (KM0). Recommended for use at facilities requiring increased fire safety measures. The paint has high adhesion rates to surfaces made of concrete, brick, wood, metal, and can be used as a finishing layer for the purpose of fire protection. "Akterm NG" is applied in a standard way - with a brush or pneumatic spray. It is sold in containers of 10-20 kg, the consumption is increased - 1.2 l / sq. m. After drying, the operating temperature is from -60 to +200 degrees.

Liquid insulation technology

It is quite easy to work with liquid insulation, so you can handle the procedure with your own hands, without the involvement of specialists. To do this, it is recommended to adhere to some recommendations:

- it is better to eliminate the unevenness of the wall with the help of a grinder with a brush attachment;

- metal surfaces are pre-cleaned of dust and degreased;

- the gloss is removed from the glossy metal and treated with a primer;

- the composition is prepared immediately before use;

- a liquid insulation is applied in layers, each of them should dry well and harden.

Each type of thermal insulation has its own rules, which are familiarized with before insulation measures.

Tools and materials

Due to the fact that liquid thermal insulation is available in different forms, the equipment for its application and accompanying tools with materials may also differ. For work you will need:

- spray gun for applying warm paint;

- electro-pneumatic installation of low or high pressure;

- roller, brush;

- container for the material, if it is not in disposable cylinders;

- chisel, hammer;

- protective clothing, respirator, goggles.

A spray gun is required for liquid thermal insulation

Usually, on the packaging with the composition, manufacturers indicate in what way and with what tools it should be applied.

Preparatory activities

Preparation for applying liquid insulation begins with cleaning the walls. Remove dirt, dust, serious bulges from the surface, which will prevent normal adhesion of the material to the wall. Cracks and crevices of more than 5 mm must be covered with cement mortar.

Next, you need to make a wooden or metal frame into which the insulation will be poured. The racks of the crate should be placed strictly vertically and have a single plane.

Immediately before use, the insulating mass is kneaded. To do this, calculate the required amount of material and dilute it with 5% distilled water. Stir the insulation with a construction mixer or drill. The maximum number of revolutions should be in the range of 150-200 rpm. If the speed is exceeded, the probability of violation of the integrity of the structure of the liquid mass increases.

Insulation of the outer walls is carried out in dry weather. If it rains, it is better to postpone the procedure until a more appropriate time. Optimum conditions are a sunny, but not hot day, the surface temperature should not exceed 30 degrees Celsius.

Stages and instructions for application

Depending on the type of insulation, use a brush or spray gun. The material is applied in thin layers. Each of them dries out within 24 hours, provided that the temperature of the treated surface is not lower than 70 degrees and the air humidity is not more than 80%.

It's best to do three layers. When using a spray, the pressure should not exceed 80 bar. If a roller is used, then the heat paint is poured into a low container. The tool is dipped into the composition and wait for the paint to completely saturate the fabric. After that, the wall is treated with uniform movements, movements from top to bottom.