Calculation of the flow through the heat meter

The calculation of the flow rate of the coolant is carried out according to the following formula:

G = (3.6 Q) / (4.19 (t1 - t2)), kg / h

Where

- Q - thermal power of the system, W

- t1 - temperature of the coolant at the inlet to the system, ° C

- t2 - temperature of the coolant at the outlet from the system, ° C

- 3.6 - conversion factor from W to J

- 4.19 - specific heat capacity of water kJ / (kg K)

Calculation of the heat meter for the heating system

The calculation of the flow rate of the heating agent for the heating system is carried out according to the above formula, while the calculated heat load of the heating system and the calculated temperature graph are substituted into it.

The calculated heat load of the heating system, as a rule, is indicated in the contract (Gcal / h) with the heat supply organization and corresponds to the heat output of the heating system at the calculated outside air temperature (for Kiev -22 ° C).

The calculated temperature schedule is indicated in the same contract with the heat supply organization and corresponds to the temperatures of the coolant in the supply and return pipelines at the same calculated outside air temperature. The most commonly used temperature curves are 150-70, 130-70, 110-70, 95-70 and 90-70, although other parameters are possible.

Calculation of a heat meter for a hot water supply system

Closed circuit for heating water (through a heat exchanger) a heat meter is installed in the heating water circuit

Q - The heat load on the hot water supply system is taken from the heat supply contract.

t1 - It is taken equal to the minimum temperature of the heat carrier in the supply pipeline and is also specified in the heat supply contract. Typically it is 70 or 65 ° C.

t2 - The temperature of the heating medium in the return pipe is assumed to be 30 ° C.

Closed water heating circuit (through a heat exchanger) a heat meter is installed in the heated water circuit

Q - The heat load on the hot water supply system is taken from the heat supply contract.

t1 - It is taken equal to the temperature of the heated water leaving the heat exchanger, as a rule it is 55 ° C.

t2 - It is taken equal to the water temperature at the inlet to the heat exchanger in winter, usually 5 ° C.

Calculation of a heat meter for several systems

When installing one heat meter for several systems, the flow through it is calculated for each system separately, and then summed up.

The flow meter is selected in such a way that it can take into account both the total flow rate during the simultaneous operation of all systems, and the minimum flow rate during the operation of one of the systems.

Selection of a circulation pump

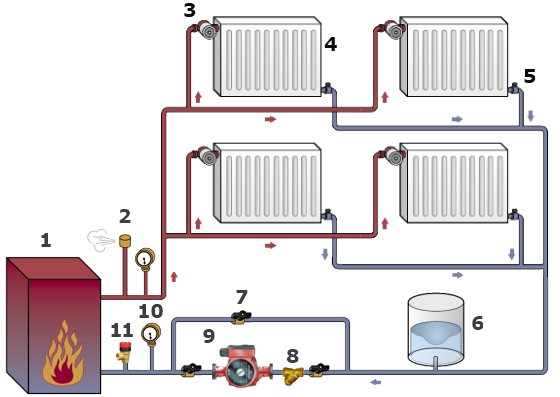

Circulation pump installation diagram.

A circulation pump is an element, without which it is now even difficult to imagine any heating system, is selected according to two main criteria, that is, two parameters:

- Q is the flow rate of the heating medium in the heating system. Expressed consumption in cubic meters for 1 hour;

- H is the head, which is expressed in meters.

For example, Q to denote the flow rate of the coolant in the heating system is used in many technical articles and some regulatory documents. The same letter is used by some manufacturers of circulation pumps to indicate the same flow rate. But factories for the production of shut-off valves use the letter "G" as a designation for the flow rate of the coolant in the heating system.

It should be noted that the designations given in some technical documentation may not coincide.

It should be noted right away that in our calculations the letter "Q" will be used to indicate the flow rate.

Heat meters

In order to calculate thermal energy, you need to know the following information:

- Liquid temperature at the inlet and outlet of a certain section of the line.

- The flow rate of the liquid that moves through the heating devices.

The flow rate can be determined using heat meters. Heat metering devices can be of two types:

- Vane counters. Such devices are used to meter heat energy, as well as hot water consumption. The difference between such meters and cold water meters is the material from which the impeller is made. In such devices, it is most resistant to high temperatures. The principle of operation is similar for the two devices:

- The rotation of the impeller is transmitted to the accounting device;

- The impeller starts rotating due to the movement of the working fluid;

- The transmission is carried out without direct interaction, but with the help of a permanent magnet.

Such devices have a simple design, but their response threshold is low. And also they have reliable protection against distortion of readings. The anti-magnetic shield prevents the impeller from braking by the external magnetic field.

- Devices with a differential recorder. Such counters work according to Bernoulli's law, which states that the rate of movement of a liquid or gas flow is inversely proportional to its static movement. If the pressure is recorded by two sensors, it is easy to determine the flow in real time. The counter implies electronics in the construction device. Almost all models provide information on the flow rate and temperature of the working fluid, as well as determine the heat energy consumption. You can configure the work manually using a PC. You can connect the device to a PC via the port.

Many residents are wondering how to calculate the amount of Gcal for heating in an open heating system, in which hot water can be taken off. Pressure sensors are installed on the return pipe and the supply pipe at the same time. The difference, which will be in the flow rate of the working fluid, will show the amount of warm water that was spent for domestic needs.

Targets of the energy saving program of regulated organizations

| P / p No. | Activity / target name | Unit measurements |

1. | Thermal energy production | |

| 1.1. | Reduction of heat energy consumption for own needs | Gcal,% |

| 1.2. | Reduction of specific consumption of equivalent fuel for heat generation | kg.c.f. / Gcal,% |

| 1.3. | Reducing the specific consumption of equivalent fuel for the supply of heat energy from collectors | kg.c.f. / Gcal,% |

| 1.4. | Reducing the specific consumption of electrical energy for the supply of heat energy from collectors | kWh / Gcal,% |

| 1.5. | Reduction of water consumption for heat energy supply from collectors | cub. m / Gcal,% |

| 1.6. | Increase in the share of heat energy supply to consumers by metering devices | % |

| 1.7. | Equipment of buildings, structures, structures owned by the company and / or on another legal basis, with metering devices for the energy resources used: water, natural gas, heat energy, electric energy | % |

| 1.8. | Reducing the specific consumption of electrical energy in buildings, structures, structures owned by the company and / or on other legal basis | kWh / sq. m,% |

| 1.9. | Reducing the specific consumption of heat energy in buildings, structures, structures owned by the company and / or on other legal basis | Gcal / cubic meter m,% |

| 1.10. | Reducing the specific consumption of fuels and lubricants used by the company in the provision of services for the transmission of electrical energy (power) | toe / km,% |

2. | Heat transmission services | |

| 2.1. | Reduction of heat energy losses in heating networks (survey) | Gcal,% |

| 2.2. | Reducing the specific consumption of electrical energy for the supply of heat energy to the network | kWh / Gcal,% |

| 2.3. | Increase in the share of heat energy supply to consumers by metering devices | % |

| 2.4. | Equipment of buildings, structures, structures owned by the company and / or on another legal basis, with metering devices for the energy resources used: water, natural gas, heat energy, electric energy | % |

| 2.5. | Reducing the specific consumption of electrical energy in buildings, structures, structures owned by the company and / or on other legal basis | kWh / sq. m,% |

| 2.6. | Reducing the specific consumption of heat energy in buildings, structures, structures owned by the company and / or on other legal basis | Gcal / cubic meter m,% |

| 2.7. | Reducing the specific consumption of fuels and lubricants used by the company in the provision of services for the transmission of electrical energy (power) | toe / km,% |

3. | Heat production and transmission | |

| 3.1. | Reduction of heat energy losses in heating networks | Gcal,% |

| 3.2. | Reduction of heat energy consumption for own needs | Gcal,% |

| 3.3. | Reduction of specific consumption of equivalent fuel for heat generation | kg.c.f. / Gcal,% |

| 3.4. | Reducing the specific consumption of equivalent fuel for the supply of heat energy from collectors | kg.c.f. / Gcal,% |

| 3.5. | Reducing the specific consumption of electrical energy for the supply of heat energy from collectors | kWh / Gcal,% |

| 3.6. | Reduction of specific water consumption for heat energy supply from collectors | cub. m / Gcal,% |

| 3.7. | Increase in the share of heat energy supply to consumers by metering devices | % |

| 3.8. | Equipment of buildings, structures, structures owned by the company and / or on another legal basis, with metering devices for the energy resources used: water, natural gas, heat energy, electric energy | % |

| 3.9. | Reducing the specific consumption of electrical energy in buildings, structures, structures owned by the company and / or on other legal basis | kWh / sq. m,% |

| 3.10. | Reducing the specific consumption of heat energy in buildings, structures, structures owned by the company and / or on other legal basis | Gcal / cubic meter m,% |

| 3.11. | Reducing the specific consumption of fuels and lubricants used by the company in the provision of services for the transmission of electrical energy (power) | toe / km,% |

4. | Electricity and heat productionin combined generation mode | |

| 4.1. | Reduction of electricity consumption for own needs | kWh,% |

| 4.2. | Reduction of losses of electrical energy in the electrical network | kWh,% |

| 4.3. | Reduction of heat energy consumption for own needs | Gcal,% |

| 4.4. | Reducing the specific consumption of equivalent fuel for the supply of electrical energy from tires | g.f. / Gcal,% |

| 4.5. | Reducing the specific consumption of equivalent fuel for the supply of heat energy from collectors | kg.c.f. / Gcal,% |

| 4.6. | Reduction of water consumption for heat energy supply from collectors | cub. m,% |

| 4.7. | Reducing water consumption for the supply of electrical energy from tires | cub. m,% |

| 4.8. | Reduction of specific water consumption for electricity supply from tires | cub. m / kWh,% |

| 4.9. | Reduction of specific water consumption for heat energy supply from collectors | cub. m / Gcal,% |

| 4.10. | Increase in the share of electricity supply to consumers by metering devices | % |

| 4.11. | Increase in the share of heat energy supply to consumers by metering devices | % |

| 4.12. | Equipment of buildings, structures, structures owned by the company and / or on another legal basis, with metering devices for the energy resources used: water, natural gas, heat energy, electric energy | % |

| 4.13. | Reducing the specific consumption of electrical energy in buildings, structures, structures owned by the company and / or on other legal basis | kWh / sq. m,% |

| 4.14. | Reducing the specific consumption of heat energy in buildings, structures, structures owned by the company and / or on other legal basis | Gcal / cubic meter m,% |

| 4.15. | Reducing the specific consumption of fuels and lubricants used by the company in the provision of services for the transmission of electrical energy (power) | toe / km,% |

5. | Electricity transmission services | |

| 5.1. | Reduction of losses of electrical energy in networks | kWh,% |

| 5.2. | Reducing the consumption of electrical energy for own needs | kWh,% |

| 5.3. | Increase in the share of services for the transmission of electrical energy (power) by metering devices | % |

| 5.4. | Equipment of buildings, structures, structures owned by the company and / or on another legal basis, with metering devices for the energy resources used: water, natural gas, heat energy, electric energy | % |

| 5.5. | Reducing the specific consumption of electrical energy in buildings, structures, structures owned by the company and / or on other legal basis | kWh / sq. m,% |

| 5.6. | Reducing the specific consumption of heat energy in buildings, structures, structures owned by the company and / or on other legal basis | Gcal / cubic meter m,% |

| 5.7. | Reducing the specific consumption of fuels and lubricants used by the company in the provision of services for the transmission of electrical energy (power) | toe / km,% |

6. | Cold water services | |

| 6.1. | Reducing water losses in water supply networks | cub. m,% |

| 6.2. | Reducing the consumption of electrical energy for own needs | kWh,% |

| 6.3. | Reducing the specific consumption of electrical energy for cold water supply | kWh / cu. m,% |

| 6.4. | Increase in the share of water supply to consumers by metering devices | % |

| 6.5. | Equipment of buildings, structures, structures owned by the company and / or on another legal basis, with metering devices for the energy resources used: water, natural gas, heat energy, electric energy | % |

| 6.6. | Reducing the specific consumption of electrical energy in buildings, structures, structures owned by the company and / or on other legal basis | kWh / sq. m,% |

| 6.7. | Reducing the specific consumption of heat energy in buildings, structures, structures owned by the company and / or on other legal basis | Gcal / cubic meter m,% |

| 6.8. | Reducing the specific consumption of fuels and lubricants used by the company in the provision of services for cold water supply | toe / km,% |

7. | Wastewater services | |

| 7.1. | Reducing the consumption of electrical energy for own needs | kWh,% |

| 7.2. | Reducing the specific consumption of electrical energy for wastewater disposal | kWh / cu. m,% |

| 7.3. | Equipment of buildings, structures, structures owned by the company and / or on another legal basis, with metering devices for the energy resources used: water, natural gas, heat energy, electric energy | % |

| 7.4. | Reducing the specific consumption of electrical energy in buildings, structures, structures owned by the company and / or on other legal basis | kWh / sq. m,% |

| 7.5. | Reducing the specific consumption of heat energy in buildings, structures, structures owned by the company and / or on other legal basis | Gcal / cubic meter m,% |

| 7.6. | Reducing the specific consumption of fuels and lubricants used by the company in the provision of wastewater disposal services | toe / km,% |

8. | Hot water supply | |

| 8.1. | Reducing the consumption of electrical energy for own needs | kWh,% |

| 8.2. | Reducing the specific consumption of electrical energy for hot water supply | kWh / cu. m,% |

| 8.3. | Equipment of buildings, structures, structures owned by the company and / or on another legal basis, with metering devices for the energy resources used: water, natural gas, heat energy, electric energy | % |

| 8.4. | Reducing the specific consumption of electrical energy in buildings, structures, structures owned by the company and / or on other legal basis | kWh / sq. m,% |

| 8.5. | Reducing the specific consumption of heat energy in buildings, structures, structures owned by the company and / or on other legal basis | Gcal / cubic meter m,% |

| 8.6. | Reducing the specific consumption of fuels and lubricants used by the company in the provision of hot water supply services | toe / km,% |

9. | Solid Waste Management | |

| 9.1. | Reducing the consumption of electrical energy for own needs | kWh,% |

| 9.2. | Equipment of buildings, structures, structures owned by the company and / or on another legal basis, with metering devices for the energy resources used: water, natural gas, heat energy, electric energy | % |

| 9.3. | Reducing the specific consumption of electrical energy in buildings, structures, structures owned by the company and / or on other legal basis | kWh / sq. m,% |

| 9.4. | Reducing the specific consumption of heat energy in buildings, structures, structures owned by the company and / or on other legal basis | Gcal / cubic meter m,% |

| 9.5. | Reducing the specific consumption of fuels and lubricants used by the company in the provision of services for the disposal of solid municipal waste | toe / km,% |

Read: developing an energy saving program for a regulated organization.

Energy saving program of a regulated organization RUB 18,000.

Learn more

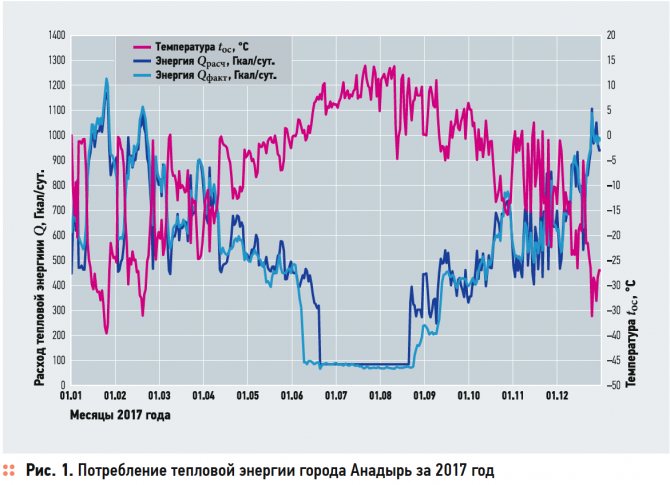

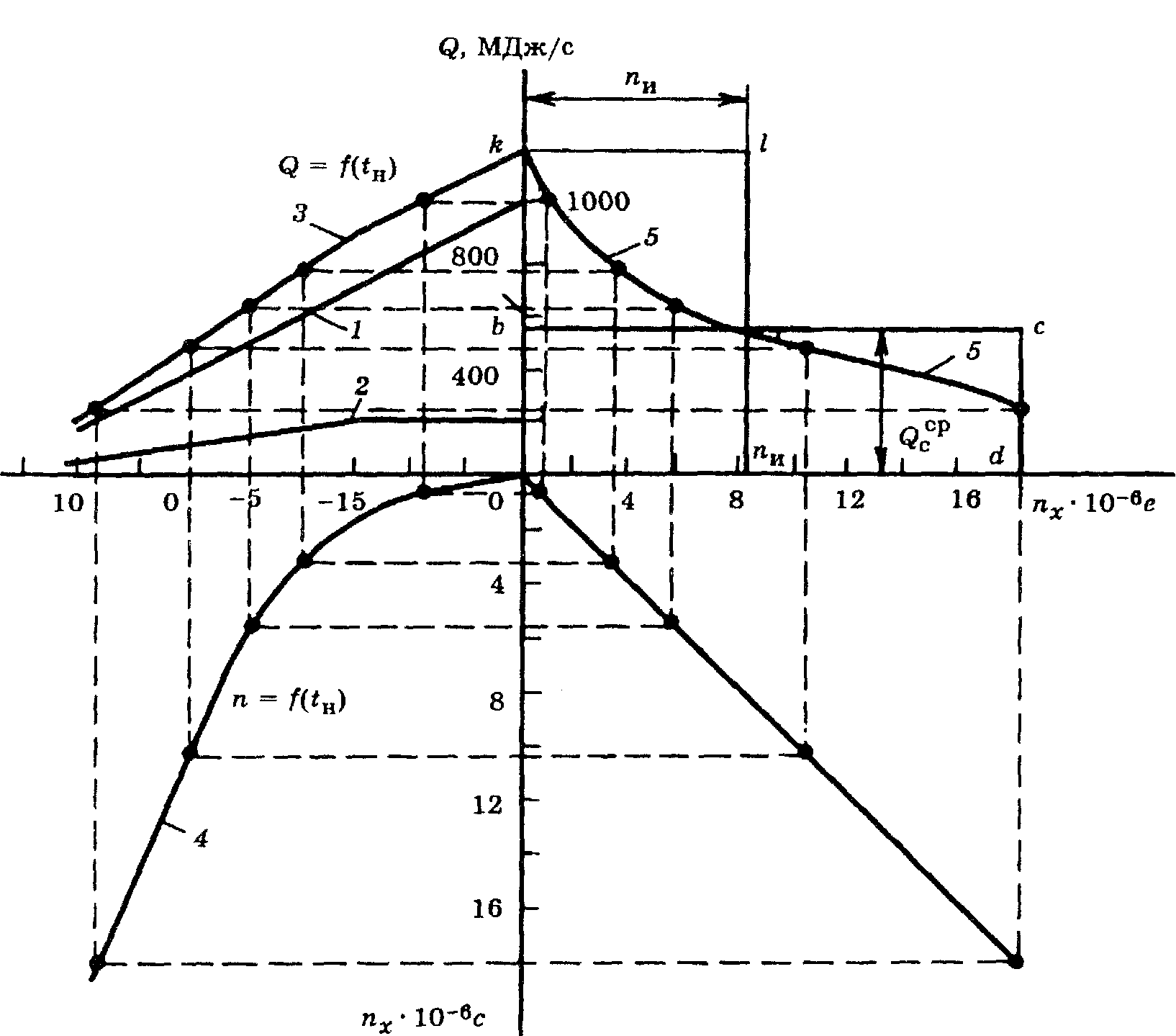

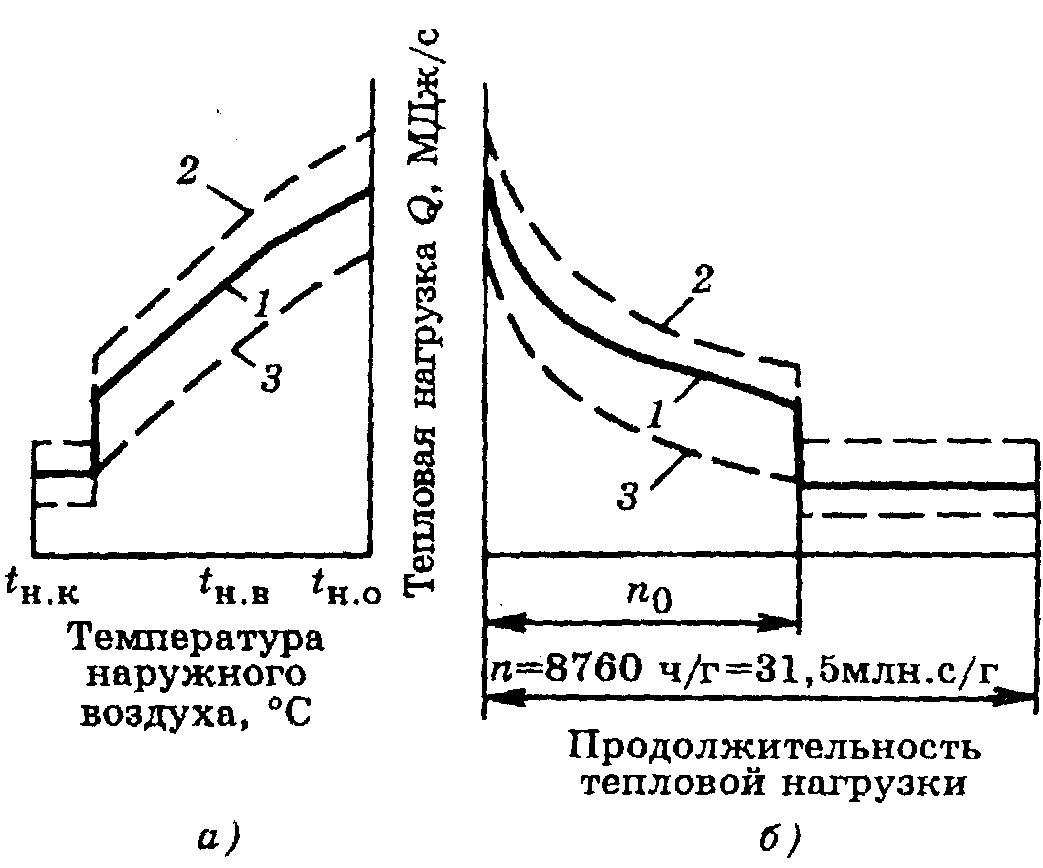

Heat load duration graph

To establish an economical mode of operation of heating equipment, to select the most optimal parameters of the coolant, it is necessary to know the duration of operation of the heat supply system under various modes throughout the year. For this purpose, graphs of the duration of the heat load are built (Rossander graphs).

The method for plotting the duration of the seasonal heat load is shown in Fig. 4. Construction is carried out in four quadrants. In the upper left quadrant, graphs are plotted depending on the outside temperature. tH,

heating heat load

Q,

ventilation

QB

and the total seasonal load

(Q +

n during the heating period of outdoor temperatures tn equal to or lower than this temperature.

In the lower right quadrant, a straight line is drawn at an angle of 45 ° to the vertical and horizontal axes, used to transfer the scale values P

from the lower left quadrant to the upper right quadrant. Heat load duration 5 is plotted for different outdoor temperatures

tn

by the points of intersection of the dashed lines that determine the thermal load and the duration of the standing loads equal to or greater than this one.

Area under the curve 5

the duration of the heat load is equal to the heat consumption for heating and ventilation during the heating season Qs.

Fig. 4. Plotting the duration of the seasonal heat load

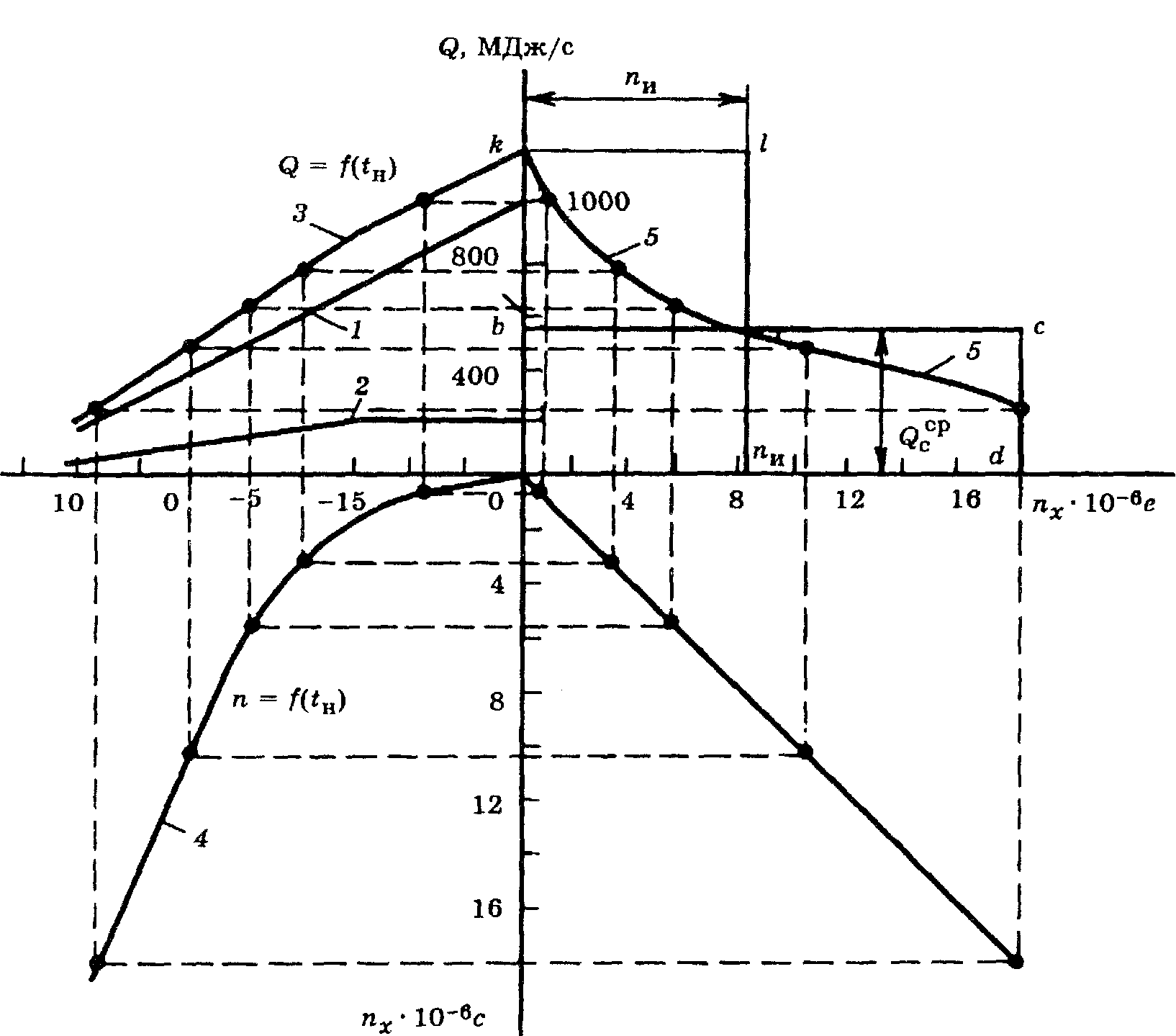

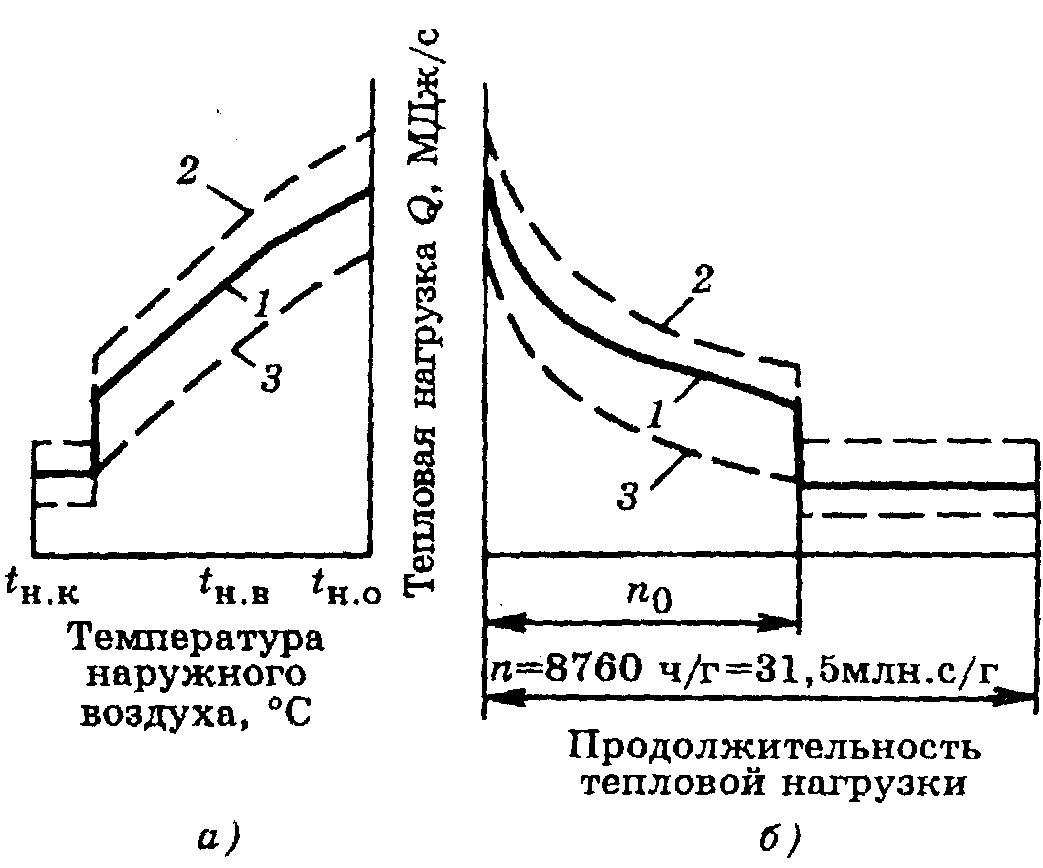

In the case when the heating or ventilation load changes by hours of the day or days of the week, for example, when industrial enterprises are switched to standby heating during non-working hours or ventilation of industrial enterprises does not work round the clock, three curves of heat consumption are plotted on the graph: one (usually a solid line) based on the average weekly heat consumption at a given outside temperature for heating and ventilation; two (usually dashed) based on the maximum and minimum heating and ventilation loads at the same outside temperature tH.

Such a construction is shown in Fig. five.

Fig. 5. Integral graph of the total load of the area

but

—

Q

= f (tн);

b

- graph of the duration of the heat load; 1 - average weekly total load;

2

- maximum hourly total load;

3

- minimum hourly total load

The annual heat consumption for heating can be calculated with a small error without accurately taking into account the repeatability of the outside air temperatures for the heating season, taking the average heat consumption for heating for the season equal to 50% of the heat consumption for heating at the design outside temperature tbut.

If the annual heat consumption for heating is known, then, knowing the duration of the heating season, it is easy to determine the average heat consumption. The maximum heat consumption for heating can be taken for approximate calculations equal to twice the average consumption.

16

Option 3

We are left with the last option, during which we will consider the situation when there is no thermal energy meter on the house. The calculation, as in the previous cases, will be carried out in two categories (heat energy consumption for an apartment and ODN).

Derivation of the amount for heating, we will carry out using formulas No. 1 and No. 2 (rules on the procedure for calculating heat energy, taking into account the readings of individual metering devices or in accordance with the established standards for residential premises in gcal).

Calculation 1

- 1.3 gcal - readings of an individual meter;

- 1 400 RUB - the approved tariff.

- 0.025 gcal - standard indicator of heat consumption per 1 m? living space;

- 70 m? - the total area of the apartment;

- 1 400 RUB - the approved tariff.

As in the second option, the payment will depend on whether your home is equipped with an individual heat meter. Now it is necessary to find out the amount of heat energy that was consumed for general house needs, and this must be done according to the formula No. 15 (the volume of services for the ONE) and No. 10 (amount for heating).

Calculation 2

Formula No. 15: 0.025 x 150 x 70/7000 = 0.0375 gcal, where:

- 0.025 gcal - standard indicator of heat consumption per 1 m? living space;

- 100 m? - the sum of the area of the premises intended for general house needs;

- 70 m? - the total area of the apartment;

- 7,000 m? - total area (all residential and non-residential premises).

- 0.0375 - heat volume (ODN);

- 1400 RUB - approved tariff.

As a result of the calculations, we found out that the full payment for heating will be:

- 1820 + 52.5 = 1872.5 rubles. - with an individual counter.

- 2450 + 52.5 = 2 502.5 rubles. - without an individual counter.

In the above calculations of payments for heating, data were used on the footage of an apartment, house, as well as on meter readings, which may differ significantly from those that you have. All you need to do is plug your values into the formula and make the final calculation.

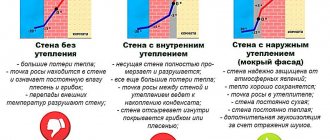

Calculation of heat losses

Such a calculation can be performed independently, since the formula has long been derived. However, the calculation of heat consumption is rather complicated and requires consideration of several parameters at once.

To put it simply, it boils down only to determining the loss of heat energy, expressed in the power of the heat flow, which is radiated into the external environment by each square m of the area of walls, floors, floors and roofs of a building.

If we take the average value of such losses, then they will be:

- about 100 watts per unit area - for average walls, for example, brick walls of normal thickness, with normal interior decoration, with double glazed windows installed;

- more than 100 watts or significantly more than 100 watts per unit area, if we are talking about walls with insufficient thickness, not insulated;

- about 80 watts per unit area, if we are talking about walls with sufficient thickness, with external and internal thermal insulation, with installed double-glazed windows.

To determine this indicator with greater accuracy, a special formula has been derived, in which some variables are tabular data.

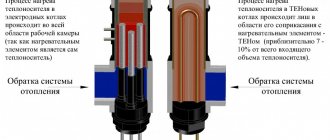

How to calculate the consumed heat energy

If a heat meter is absent for one reason or another, then the following formula must be used to calculate heat energy:

Let's see what these conventions mean.

one.V denotes the amount of hot water consumed, which can be calculated either in cubic meters or in tons.

2. T1 is the temperature indicator of the hottest water (traditionally measured in the usual degrees Celsius). In this case, it is preferable to use exactly the temperature that is observed at a certain operating pressure. By the way, the indicator even has a special name - this is enthalpy. But if the required sensor is absent, then the temperature regime that is extremely close to this enthalpy can be taken as a basis. In most cases, the average is about 60-65 degrees.

3. T2 in the above formula also denotes the temperature, but already of cold water. Due to the fact that it is quite difficult to penetrate into the line with cold water, constant values are used as this value, which can vary depending on the climatic conditions on the street. So, in winter, when the heating season is in full swing, this figure is 5 degrees, and in summer, with the heating turned off, 15 degrees.

4. As for 1000, this is the standard coefficient used in the formula in order to get the result already in giga calories. It will be more accurate than using calories.

5. Finally, Q is the total heat energy.

As you can see, there is nothing complicated here, so we move on. If the heating circuit is of a closed type (and this is more convenient from an operational point of view), then the calculations must be made in a slightly different way. The formula that should be used for a building with a closed heating system should already look like this:

Now, respectively, to decryption.

1. V1 denotes the flow rate of the working fluid in the supply pipeline (not only water, but also steam can act as a source of thermal energy, which is typical).

2. V2 is the flow rate of the working fluid in the "return" line.

3. T is an indicator of the temperature of a cold liquid.

4. Т1 - water temperature in the supply pipeline.

5. T2 - temperature indicator, which is observed at the exit.

6. And finally, Q is the same amount of heat energy.

It is also worth noting that the calculation of Gcal for heating in this case from several designations:

- thermal energy that entered the system (measured in calories);

- temperature indicator during the removal of the working fluid through the "return" pipeline.

The procedure for determining the amount of transferred heat energy when calculating with RSO

A management company in the field of housing and communal services (MC) applied to our organization for legal assistance in connection with a dispute with a resource supplying organization (RSO) over the volume of heat supplied to provide public services to the population. Our company was tasked with checking the legality and validity of the calculation of the RNO, as well as the compliance of the concluded heat supply agreement with the current legislation.

Having studied the documents presented by the Criminal Code, we found the following. Under a heat supply agreement, the MC purchases thermal energy from the RNO for the provision of utility services for heating and hot water supply (DHW) to the owners and tenants of residential premises in apartment buildings. In accordance with this agreement, the MC ordered a certain amount of heat energy from the RNO, calculated on the basis of the established consumption standards for heating and hot water supply for the population. However, RNO supplied heat energy in a larger volume than stipulated by the contract, citing the fact that the outside air temperature in winter was significantly lower than expected, which led to the need to supply heat in a larger volume. The RSO determined the volume of supplied heat energy based on the readings of common house and group metering devices, and for houses that do not have such devices - by calculation (based on the total heat supply from the CHPP).At the same time, the RNO changed the readings of common house and group metering devices, increasing or decreasing them by the amount of losses and the volumes of consumption of other persons under the control of these devices, and also applied penalties for the underutilization of thermal energy - the return of excess hot water to the return pipeline.