Categories of materials

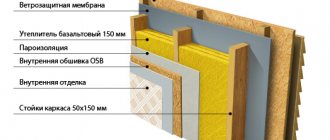

Stone wool

Heat and sound insulating stone wool slabs. Produced on the basis of basalt. Due to their low thermal conductivity, stone wool slabs retain heat in winter and cool indoors in summer. Completely safe for human and animal health. The service life of the materials is comparable to that of a building.

Areas of use

- attic;

- pitched roof;

- cold attic;

- baths;

- floors on logs;

- frame walls;

- overlappings;

- partitions;

- facades for siding;

- ventilated and plaster facades;

- other structures where the material does not perceive external loads.

* based on the results of studies carried out according to the methodology of the standard DSTU B V.2.7-182-2009

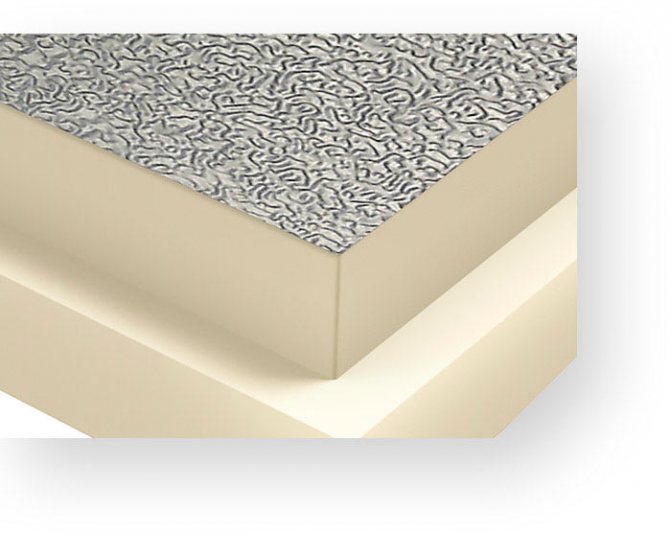

A versatile and modern material from extruded polystyrene foam. Possesses high heat-saving and strength properties. Low-thickness XPS creates a reliable thermal insulation layer, reduces heat loss and saves more usable floor space. The material is resistant to moisture, mold and mildew

Areas of use

- floor, including underfloor heating technology;

- walls from the inside;

- balconies and loggias;

- blind area and basement;

- foundations.

Innovative environmentally friendly rigid polyurethane foam insulation. Possesses high thermal insulation properties and mechanical strength at low thickness. Saves indoor space. Retains its characteristics for over 50 years. It is lightweight and easy to assemble. The double-sided foil coating additionally reflects heat and imparts water resistance.

TechnoNIKOL

In this case, the products may be well-known ... More ›

Good day. I need a commercial offer. I am building a private kindergarten in the city of Zhanaozen. Send everything you have to building materials. Tel .: 8701.144.28.92.

Release form:

in slabs

Plate width:

600 mm

Plate length:

1200 mm

Plate thickness:

50 or 100 mm

Number of plates in a package:

50mm - 8pcs, 100mm - 4pcs

Packed material area:

50mm - 5.76sq.m, 100mm - 2.88sq.m

Density:

40-45 kg / m3

Flammability class:

NG

Price: 469 rub / pack Order

TECHNOBLOK slabs are intended for heat and sound insulation of building structures of residential buildings and industrial structures, in which the insulation does not perceive external load.

Technoblock standard is one of the many heaters produced from basalt rocks under the influence of heat treatment with the addition of a synthetic binder. This type of mineral wool is widely used as heat and sound insulation for various structures in industrial and residential construction. A prerequisite for the use of plates of the Technoblock Standard is the absence of external loads on the insulation. Technoblock insulation is used to insulate horizontal and vertical surfaces of enclosing structures in buildings of any type, but it found the most widespread use in cottage frame construction.

As a thermal insulation system, filling the space between the logs, the material is used when installing floors, the covering of which is based on the logs. When constructing wooden beam-type floors with mineral wool slabs, the space between the load-bearing beams is filled. From above, the insulation should have a protective covering from the flooring. If such a covering is not provided, it is necessary to equip the overlap with walking bridges. Miniplates are indispensable for the construction of mansard pitched roofs.The structure of this material allows it to be used on inclined planes of attics, providing thermal insulation for attics.

What is stone wool?

Stone wool is made from volcanic rock. In its natural form, it is a solid material, so that it takes on a "wadded" shape, it is melted and separated into fibers. Depending on the manufacturer, one or another technology (centrifugal or spinneret drawing, blowing, swathing) can be used for this procedure. Basalt processed in this way becomes free-flowing, and so that it does not crumble, and so that a certain shape can be formed from it, the fibers are treated with a sticky substance.

Phenol-formaldehyde resin - this is the very adhesive, in any case, it is used more often than analogues. It glues the fibers together, making the layers of the required thickness. Then the stone wool is treated with a special oil to make it water-repellent. The last stages of production are the cutting and packaging of the insulation.

Photo insulation of the facade with stone wool

Varieties of stone wool

Stone wool comes in different types. Basically, it is divided into types by density.

- Soft cotton wool, it is also a roll insulation. Its density ranges from 10-50 kg / m. cub. The thermal conductivity coefficient is 0.033 W / m * C. It is used to improve pipelines, frames, ceilings, partitions.

- A semi-rigid board can have a density of 60 to 80 kg / m3. cub. The thermal conductivity coefficient is 0.039 W / m * C. It is often used for facades, roofs, ceilings or sandwich panels.

- The rigid slab has a density of 90-175 kg / m. cub. The thermal conductivity coefficient is 0.046 W / m * C. This insulation is used for surfaces that are subject to significant mechanical stress. This can be the floor, roof, foundation, underground pipelines, etc.

TechnoNIKOL

Insulation tehnoblok standard is used as a heat-insulating filler when erecting walls of residential buildings from piece materials using the technology of lightweight well masonry. When installing ventilated hinged facade systems, the Technoblock slab serves as the main insulation for the outer walls, and hinged decorative panels provide reliable protection against possible loads and damage. Also, miniplates of this type are used for thermal insulation of industrial equipment, the temperature range of which is in the range from -60 ° С to + 400 ° С.

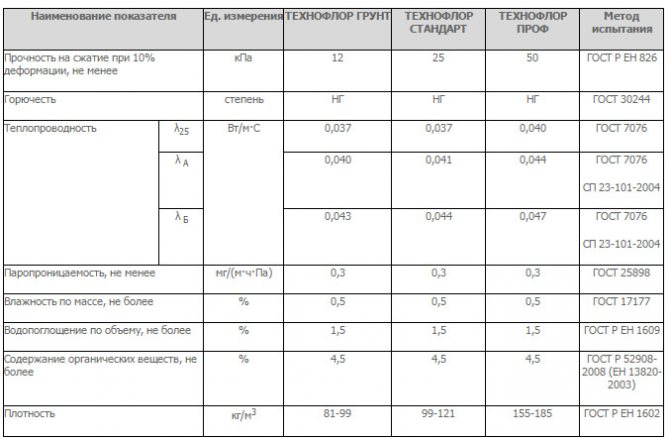

Characteristics of the TECHNOBLOK Standard slab

- The density of the insulation is 45kg / m3;

- Moisture, based on the weight of the insulation - no more than 0.5%;

- Vapor permeability of the slab> 0.3 mg (m.h. Pa);

- Compressibility Reviews about Technonikol building materials stores

Its peculiarity is in the minimum content of phenol, therefore, at elevated temperatures, this insulation does not emit harmful chemical compounds, which favorably distinguishes it from a number of other heat insulators. And given the sufficient density of Rocklite, it becomes clear that it also provides good noise absorption. It goes on sale in polyethylene packaging in the form of plates having 2 standard sizes (in cm) - 100x50x5 and 120x60x10. The price of the product is quite reasonable, which makes it popular among the widest sections of the population.

An objective analysis of all the properties and characteristics of this basalt insulation shows that Rocklight is somewhat hydrophobic. Judging by a number of reviews, this is positioned as a minus of the product. However, if you make a small review of articles on the topic of construction and repair, then waterproofing surfaces is always one of the mandatory stages of work. Moreover, any insulation based on basalt wool needs protection from direct contact with liquids.

Properties and characteristics of stone wool

Stone wool is often compared to other types of similar material.Namely, with glass wool, slag and mineral wool. Below are comparative characteristics that allow you to navigate in one or another parameter of all types.

| Parameter | Stone wool | Mineral wool | Glass wool | Slag |

| Average fiber diameter (μm) | 5-15 | 4-12 | 4-12 | 4-12 |

| Fiber length | 20-50 | 16 | 15-50 | 16 |

| Thermal conductivity (W / m2 * k) | 0,033-0,046 | 0,077-0,12 | 0,038-0,046 | 0,46-0,48 |

| Usage temperature | -190 to + 700 ° C | -60 to + 600 ° C | from -60 to + 450 ° C | -60 to +250 |

Advantages and disadvantages

Experts note both the advantages and disadvantages of stone wool, so before buying it for insulation, it is necessary to weigh the pros and cons. What are the advantages of stone wool?

- The material is lightweight, which allows it to be easily carried and laid during the insulation of the room.

- This is a time-tested insulation.

- High insulating properties.

- Stone wool is not afraid of temperature extremes. Regardless of the weather, it does not expand or contract, it keeps its shape and retains its properties.

- The basic characteristics are the same regardless of the manufacturer. So, for example, insulation from Rockwool and Isobox have similar parameters and qualities, but differ in terms of price, additional raw materials used for production and other parts. Hence the price difference.

- The material is not flammable.

- Depending on the quality of the insulation, vapor permeability can range from 0.3 to 0.55 mg / m hPa. The higher the indicator, the better this property is expressed.

- Laying stone wool is pretty easy, even without practice.

Now about the disadvantages of stone wool.

- Contrary to misconceptions, it does not scare away rodents. Mice and rats are not afraid of it and can live peacefully in it.

- The sustainability of stone wool is often questioned due to the fact that the fibers are held together with resins during production. Manufacturers rarely explain what these resins are, their exact composition and whether they are harmful, so the question remains open.

- During the laying of stone wool, dust appears, which is strongly recommended not to inhale. Therefore, you can work with it only in a respirator.

Photo of stone wool Technonikol and Rockwool

Do-it-yourself floor soundproofing

You can isolate the floor from acoustic and impact noise from below by yourself. The choice of tool and the order of installation will depend on the material used. For apartment buildings, the installation of a floating floor on a dry screed is relevant.

The finish coating, laminate flooring, parquet does not come into contact with the load-bearing walls, this ensures complete cut-off of structure-borne noise, which is transmitted through the floors. Expanded clay for dry screed, extruded polystyrene foam are used as the main noise absorber.

Preparatory work

Before installing the floating floor, it is necessary to clean and level the surface of the base plate.

- The old floor covering is removed.

- Holes and cavities in the concrete slab are sealed with cement mortar. It is better to use a special leveling compound for the floor.

- The surface is treated with construction soil, checked for level, the permissible difference in height is 10 mm.

- After preparatory work, the base is dried and rubbed.

Required tools

A floating floor is one of the simplest technologies. If there is no experience in construction work, then installation of sound insulation on a screed will be the best solution when arranging an apartment in a multi-storey building or a brick structure with a concrete slab overlap. For work you will need:

- building level;

- trowels;

- a knife or saw for cutting panels or sheets of noise insulation;

- sand, cement for screed;

- vibration absorber: glass, basalt wool, foamed polymers to cut off noise around the perimeter.

Stacking materials

Regardless of the type of finished floor: carpet, laminate, parquet, rough work on the installation of floor sound insulation will be the same. Work order:

- Install wooden formwork around the perimeter of the walls or lay damping tape.

- Install the floor sound insulation panels.

Masters recommend to lay a polyethylene film in two overlap layers on top of the noise insulation under the screed, to glue the joints with tape.

- Install beacons on soundproofing plates, lay a reinforcing mesh.

- Pour with cement mortar, level the surface, maximum screed layer 40 mm. To increase the strength, building mixtures of basalt or propylene fiber are added to the cement slurry. 1 kg of mixture is used per 1 cubic meter. meter of solution.

- After the subfloor has dried, the topcoat and the finishing floor are laid.

Seamless concrete flooring technology or wet screed is more commonly used under laminate flooring. The base is completely flat, which allows you to quickly lay the decorative coating.

Laying decorative coating

The finished floor is part of the overall soundproofing system of the room. Soundproof mats installed under the parquet floor cut sound by 80%. Substrates and panels Texound, Penoplex are used under the laminate. If it is not possible to make a flat surface with a dry screed, the floor is poured with cement mortar.

Decorative coverings made of soft material do not require the floor surface to be completely flat. This is the advantage of carpet, which can be laid on fiberboard, and stone wool, Technonikol, Regupol panels can be used as an insulator.

Soundproofing a house is a set of measures to protect an apartment from extraneous noise, it is necessary to equip the floor, strengthen the walls, and carry out acoustic insulation of the ceiling.

Where is stone wool used?

Since the 20th century, stone wool has become widespread. Due to the fact that it is 95% natural material, it is used for insulation of various types of buildings.

- Walls. As a facade insulation, this material is very popular. Thermal insulation properties help prevent heat loss in winter and keep cool in summer.

- The floors are often insulated with them. It allows you to make screeds, provides sound insulation.

- Roofs (flat and pitched) are partially insulated with this insulation. It is true that it is not recommended to use only stone wool, but it is suitable as part of protection.

- Partitions inside rooms are often made with the participation of this material. It provides additional sound insulation.

- Bearing beams and columns, reinforced concrete floors, transit air ducts, cable and pipe passages can be made using stone wool. This provides fire protection and additional safety for the occupants of the premises.

The best stone wool manufacturers

Stone wool is produced by many manufacturers, but not all of them guarantee quality and durability. In order not to regret buying in the future, you should focus on leading manufacturers.

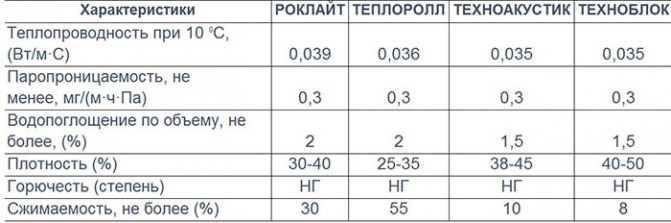

- TechnoNIKOL - a well-known manufacturer. Stone wool Technonikol comes out in series. For example, Rocklight - slabs cost from $ 12 per cubic meter. Teploroll - a roll, priced up to $ 23 per cubic meter. Technoacoustic - has excellent sound insulating properties. Price from $ 45.

- Isover Is a French manufacturer. Famous lines - Isover>

Photo of wall insulation with stone wool

Features of thermal insulation of the TechnoNIKOL company

Can I buy a ticket for December 26 at the box office now? How much is the ticket Moscow-Bolakovo? Thanks.

| The operator just drops the phone. | |

| It is impossible to return a ticket through the website! There is no Return button, although the operators claim that it is. Fix the software, it's not serious | |

| Hello! I really like your service! But why haven't you made the mobile app yet !? | |

| Thanks for the good service. | |

| Hello! How many days will the testing stage pass and when will the function of booking tickets through the website be activated? | |

Stone wool reviews

It cannot be said that any stone wool is good for use and durable. There are both positive and negative customer reviews.

- Mikhail Pavlov: “Stone wool was required to insulate the house last year. The choice fell on Technonicol. This is a relatively inexpensive type, so in total you can say that it saved. Cotton wool was used quickly, without problems. Of the shortcomings, I can note that it is very loose, although I took it of medium density. So when choosing, you should be careful. As for the qualities, the house has become warmer, this was noted already in the first year after insulation. "

- Dmitry Zaitsev: “Rockwool is a well-known stone wool brand. Indeed, the material is of high quality, very good. After insulation, the house is warm, comfortable, there are no drafts, and even the dampness has disappeared. However, anyone planning to buy this product should also purchase a pair of protective suits for work. This is a really dangerous insulation. On the skin it caused irritation, redness, itching, constant sneezing, shortness of breath. In general, nothing good - you can't work with him without protection! "

- Elena Alexandrova: “Isobox stone wool is our choice for home insulation. Throughout the summer, she was engaged in insulation of the house, both inside and outside. This insulation has both advantages and disadvantages. It insulates sound really well, retains heat, and the price is affordable. As for the problems, there is a lot of dust flying from the stoves, which causes irritation, so it is better to use a respirator. The downside is that the insulation has an uneven density over the entire surface. It crumbles a lot, breaks down and I am sure that this will affect the service life. "

| Sintering temperature | 700-1000 | 600 | 450-500 | 250-300 |

| Heat capacity | 500-800 | 1050 | 1050 | 1000 |

| Compressibility (%) | Up to 40 | 40 | 60 | 60 |

| Elasticity | 71 | 60 | 55 | 50 |

| Flammability class | NG - non-flammable | NG - non-flammable | NG - non-flammable | NG - non-flammable |

| Sound absorption | 0,87-0,95 | 0,75-0,95 | 0,8-0,92 | 0,75-0,82 |

| Vibration resistance | No | No | No | No |

| Binder (%) | 2.5 to 10 | 2.5 to 10 | 2.5 to 10 | 2.5 to 10 |

| Moisturizing per day (%) | 0,035 | 0,095 | 1,7 | 1,9 |

| Chemical resistance to water | 1,6 | 4,5 | 6,2 | 7,8 |

| Chem. alkaline resistance | 2,75 | 6,4 | 6 | 7 |

| Chem. acidic resistance | 22 | 24 | 38,9 | 68,7 |

| Release of harmful substances | Yes, if there are harmful binders | Yes | Yes | Yes |

| The need for binders | Yes | Yes | Yes | Yes |

| Taunt | No | No | Yes | Yes |