Many craftsmen in their practice are faced with the need for new devices, such as a waste oil burner. For workshop and garage owners, this will replace a stove for heating the room, especially if there are decent reserves of used oil and other fuels. Burners, if you understand the principle of their operation, can be adapted for mixed fuel.

Waste oil burner can be used to heat technical rooms

Varieties of Russian-made waste oil burners

In the cold season, not only residential, but also auxiliary premises need heating. At the moment, devices for heating are used on different types of fuel, including waste or used technical oil. On the Russian market, you can find devices that process different fuel bases, as well as having a narrow specialization. By the type of fuel burned, such devices are:

In terms of functionality, the torches for testing are not only heating, but also welding and lighting

- gas;

- on liquid fuel;

- combined.

The simplest and most economical device for heating a room is considered to be a working burner. In terms of functionality, burners are divided into 3 subspecies:

- welding;

- lighting;

- heating.

The principle of operation of these devices was borrowed from primitive kerosene gas back in the 50s. Quite quickly, the simplest burners became popular, they began to be purchased for heating country houses and garages. In those days, any fuel was inexpensive, but over time, zealous owners, inventors and innovators began to look for a replacement for gasoline, diesel fuel and kerosene. Fuel oil and waste oil were used, which is now used as a full-fledged fuel. Today, the device is still relevant, moreover, it is an excellent way to preserve the environment.

Important! In the room where any liquid-fueled apparatus will be used, whether it is a home-made gasoline burner, an apparatus for testing or a diesel fuel burner with your own hands, there must be a fire extinguisher!

Burners for working out are of the type available on liquid fuel, gas and combined

The difference between a Babington torch and a blowtorch

Quite often, burners that operate on the blowing principle are compared to a blowtorch. Their devices have some similarities. Whereas the principle of action is different. In a blowtorch, fuel, namely gasoline, is in a closed container. It is exposed to high air pressure, which is provided through the use of a hand pump. Air is not mixed with fuel, the latter is pushed upward. On the way, the gasoline warms up, gradually evaporating in the pipe. After that, it is pumped into the nozzle orifice. After leaving it, gasoline mixes with air, burns and forms a sufficiently powerful torch. A self-made burner for mining operates on the opposite principle. Air is blown through the nozzle, not oil. In this case, the fuel does not evaporate, but is heated to a temperature of 70 degrees, but no more.

The liquid does not completely ignite, some volume goes into the sump. A home-made burner for working off cannot be made from a blowtorch, since it is very difficult to evaporate and feed oil through the nozzle into the combustion zone. It is worth considering before making such a design that refueling the described unit with gasoline is ineffective and rather dangerous.

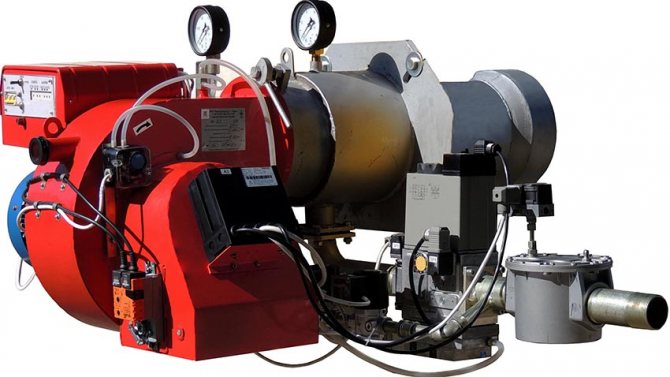

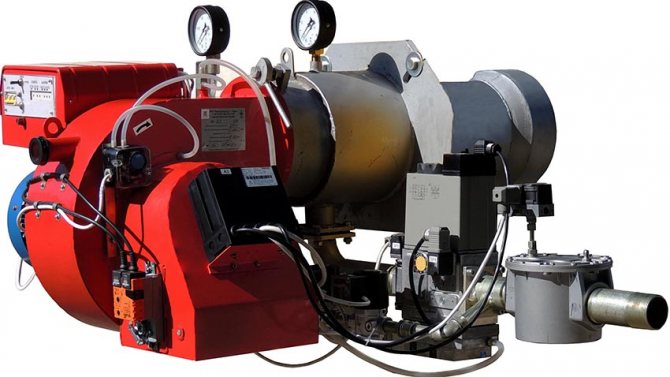

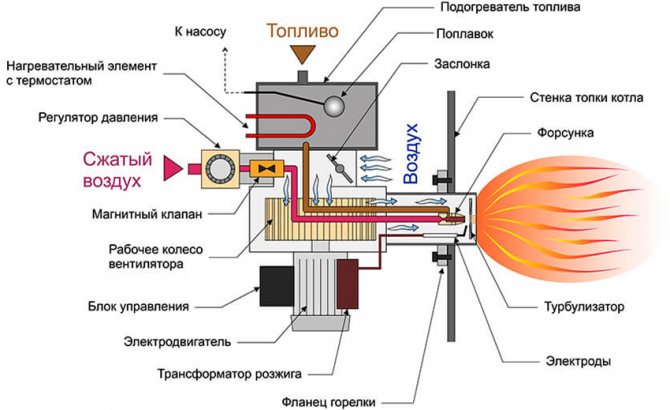

Construction of a finished waste oil burner

When buying gas burners and similar equipment, people are often interested in one or another element and its purpose in the overall design. For example, they want to know where the oil should flow from and where, how it ignites, and so on. When they think about how to make a burner at home, looking for a sample for building a homemade analogue, even more questions arise. Most often they are interested in replacing nozzles and oil containers with something suitable from the available tools.

Having at his disposal photos, diagrams and drawings of a waste oil burner, not every master will immediately get down to business. The main reason is the large number of specific details.

Note! It doesn't matter what the device was built from - the principle of operation of all burners is approximately the same: filtered and heated oil is supplied from the main tank and burned in the combustion chamber.

The multicomponent process consists of several stages, and the success of its operation will depend on the quality of the constituent parts of a drip burner on waste oil with your own hands:

Waste oil burner operating principle

- collection and filtration of mining;

- pumping and heating of purified oil;

- combustion process to obtain heat.

Filtration as the beginning of the burner operation during the development

Enterprises that produce ready-made devices that run on liquid fuel or mining are equipped with additional options that purify the oil. These are the so-called intake floats, which take the purest portion of the substance from the surface for heating. This principle of sampling mining is currently inherent in the overwhelming majority of manufactured products belonging to this category.

Further, through a hose made of material that is resistant to an aggressive environment, there is a portioned supply of used oil. The tube is usually submerged approximately to the middle of the main container, so the solid suspension remains at the bottom, and a cleaner layer is used for heating and processing. At this stage, it is possible, without additional efforts, to filter the fuel of a fairly high quality. Dirty impurities, sand and other insoluble components remain at the bottom.

Important! The duration of the operation of the burner for the waste oil burner with your own hands largely depends on the purity of the fuel. Therefore, it is worth taking care of at least a rough cleaning of the oil fraction supplied to the furnace.

In order for the burner to work for a long time, it is necessary to take care of the cleaning of the fuel.

As you know, filters are single and reusable. Sifting of coarse particles can be done through several layers or filter elements, as in the ready-made heating pads of the Smart Burner company. The traditional configuration of different products is about the same: ready-made devices are rarely produced without a filter or elements replacing it.

The small transfer pump is a standard component for the smooth flow of oil. If you organize the supply for a stationary unit according to the principle of communicating vessels, then in a home-made burner it can flow to the nozzle by gravity.

Warming up used oil before burning it

An equally important stage in preparing the device for operation is the heating of the waste oil before complete combustion to generate heat. When heated, the oil becomes more liquid and plastic, as a result of which the optimal consistency is excellently burned.

A preheating tank or heating coil is needed for any do-it-yourself waste oil burner - the drawings show an intermediate location. Usually this is a separate chamber or a small volume capsule hidden in the middle of the body. Purpose - to warm up the fuel as efficiently as possible before the combustion process.Finished products most often have a temperature switch that monitors the heating level. As a rule, they operate in the operating range of 0-150 ° C.

Some burner models are equipped with an electric heating element for heating oil

Attention! Burners adapted for combined slurries usually have a heating vessel. Diesel fuel does not need to be heated in self-made diesel burners.

Manufacturers decide differently how to organize this stage. The Gnome burner on waste oil (and other similar models) has a small electric heating element inside the tank, which is responsible for heating the mining to the desired level. In the same way, as in this case, each manufacturer decides in his own way and the issue of oil supply. Often, float switches and pumps are responsible for the flow rate. The system switches itself off when the preheating tank is full.

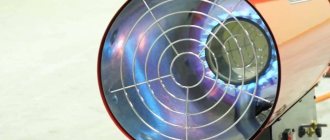

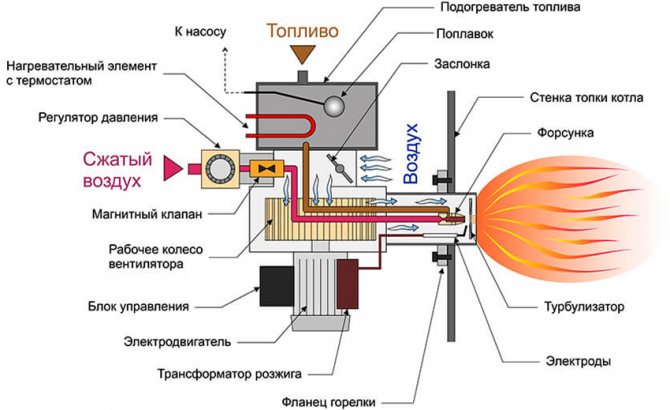

Compressed air supply for waste oil disposal

Compressed air is required to prepare the oil mixture for combustion by spraying it. This transport is directed to the nozzle, which is carried out under pressure. Due to the supply through a separate channel, oxygen ensures the combustion process in any device, including a do-it-yourself Babington burner on waste oil. Although the device was originally patented as running on diesel fuel, it was also adapted for industrial oil.

Successful air delivery requires a mini-compressor built into ready-made oil fired fixtures. It can be transported in other ways, for example, according to the pneumatic principle. In the absence of compressed air, the nozzle may not work correctly.

Compressed air in the burner is required to prepare the oil for combustion

Useful advice! The working pressure is monitored by a small pressure gauge, thus maintaining the parameters necessary for the full operation of the entire apparatus.

Air flow regulation is provided by a special solenoid valve on the body. The expensive equipment also includes air filters for air purification. They will be useful in dusty mini-workshops, boiler rooms or other rooms where the air taken for the combustion process has a lot of impurities. To operate the waste oil burner nozzle with your own hands, you need an adjustable secondary air supply. The following burner parts are responsible for the synchronous operation of all units:

- nozzle (nozzle);

- fuel compartment;

- heating tank;

- air supply valve;

- oil supply regulator;

- pressure gauge (it may not be there);

- blower (fan).

In ready-made devices, ignition is provided by electrodes. The compressed air is supplied through the air duct, from there it enters the nozzle. Waste oil also goes there after heating. If the nozzle is clean, it produces a high-quality ignition of fuel, suggesting the appearance of an even continuous flame.

Each mining burner must be equipped with an air supply valve

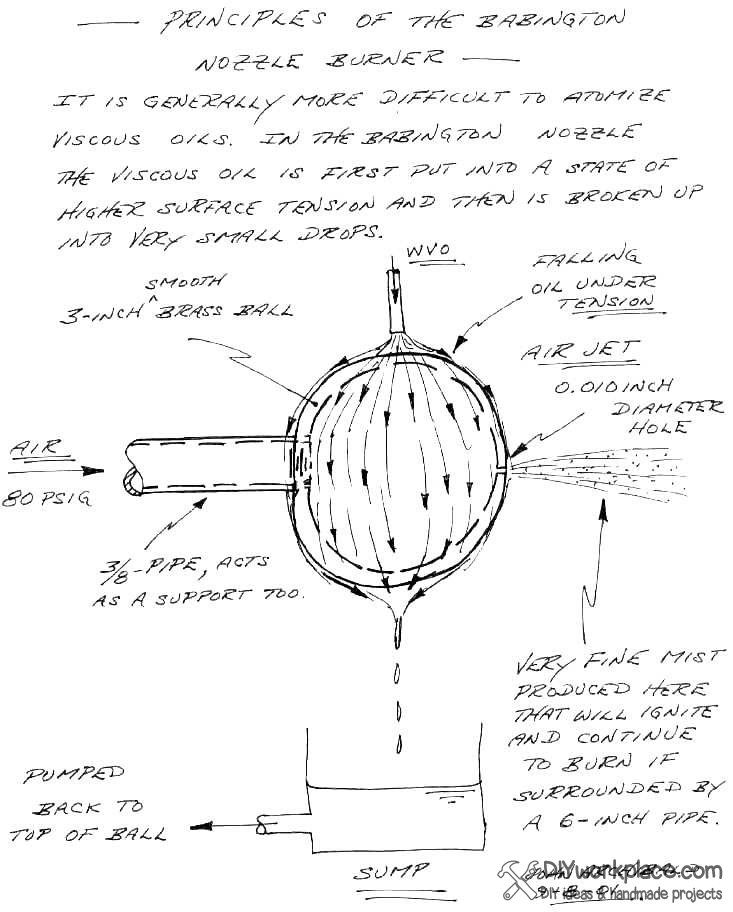

What is Babington's famous invention

Each invention has its own author, even if his name is undeservedly forgotten by descendants. For example, the British inventor Robert Babington received a patent in 1969 for a diesel-fueled stove that resembled a kerosene-fired light kerosene gas. The design of Robert Babington was originally designed for kerosene, then it was adapted for diesel fuel. When the number of cars increased disproportionately, the used oil had to be disposed of somehow. Therefore, innovators were looking for devices suitable for these purposes.

First, based on the patented invention of R.Babington's own diesel burner appeared, then it was adapted for burning oil and other fuels. The device, functioning in development, appeared much later than the diesel design, but in terms of popularity and safety it surpassed its predecessor.

After some time, a similar device was proposed again, since the first patent had expired, and the liquid fuel furnace did not lose its relevance. Similar devices were repeated in different versions, while not only self-taught craftsmen, but also design bureaus of reputable enterprises tried to assemble the Babington burner with their own hands.

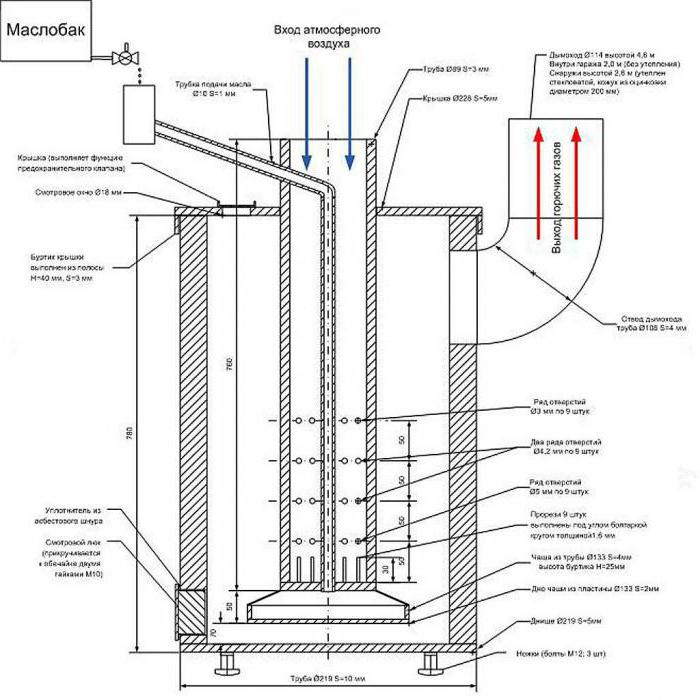

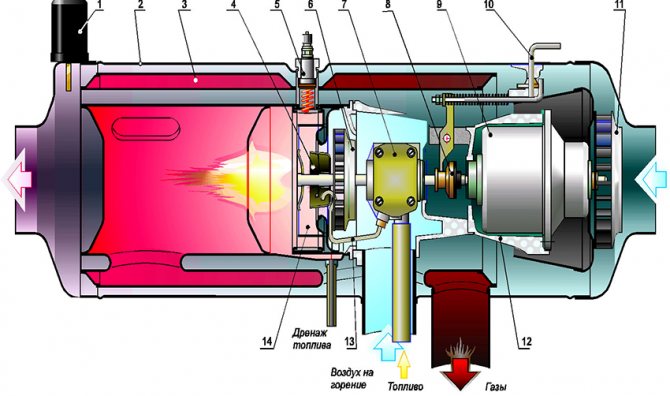

The burner, according to its constructive solution, belongs to simple devices, therefore, it is successfully manufactured at home. It is distinguished by a fairly high efficiency in terms of generating heat required for heating:

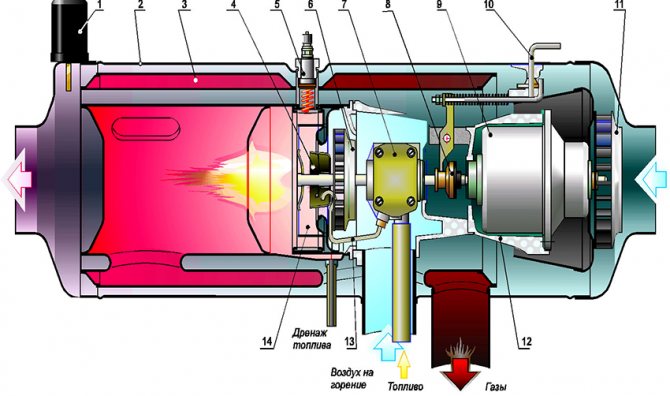

Burner diagram according to the Babington principle, where 1 is a heating sensor; 2 - casing; 3 - heat exchanger; 4 - fuel atomizer; 5 - glow plug; 6 - supercharger; 7 - fuel pump; 8 - friction clutch; 9 - electric motor; 10 - lever for switching operating modes; 11 - fan; 12 - skeleton; 13 - fuel pipe; 14 - combustion chamber

- technological installations;

- small workshops;

- workshops;

- garages;

- warehouse and utility rooms.

Useful advice! You should not adapt a home-made burner with your own hands for heating your home, since burnt oil has a specific smell.

Blitz Tips

- If you adjust the fuel supply correctly, then the Babington burner is very economical and consumes only 0.5-1 liters per hour. And the air consumption is only a few liters per hour.

- If additionally add a chimney to the scheme, a combustion chamber with a water jacket, then such a burner can be used as a full-fledged boiler for heating a private house.

- As a device for blowing air you can use a compressor from an old refrigerator.

- Such a system works stably even on a mixture of various waste oils containing gasoline., diesel fuel, various additives and even antifreeze, which undoubtedly gives it an advantage over factory counterparts.

- The heat from such a burner is very strong., and the power, depending on the configuration, is more than 10 kW.

Already several decades ago, in summer cottages and in utility rooms, it was possible to find burners operating on waste oil.

The reasons for the popularity of the units are understandable - they worked not just on "waste" fuel, but even helped with the disposal of accumulated waste.

Its construction was developed by craftsmen on the basis of kerosene gas. And in our time, the device has not lost its relevance. Let's figure out how a burner is made for testing with our own hands.

Do-it-yourself burner for working off: the principle of operation

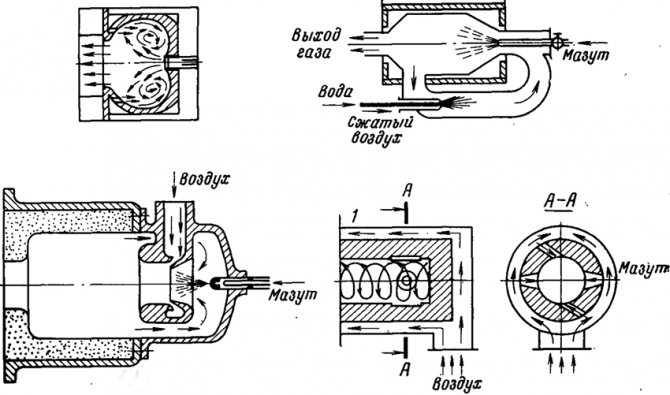

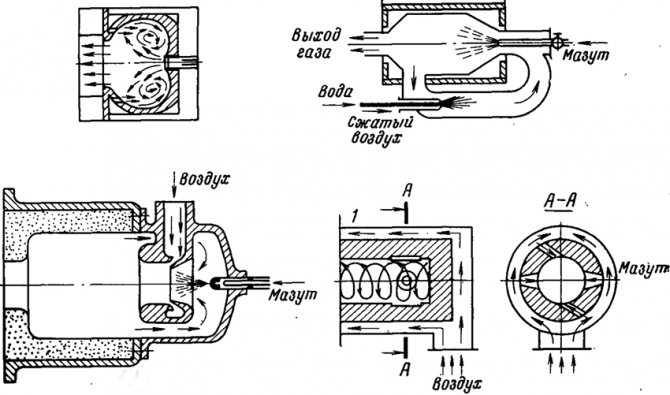

If you look at photos, drawings and drawings, it becomes obvious that secondary oil forms a thin film on a curved surface. Gas or air is fed into the container through the groove under low pressure. After heating, the oil is sprayed with this air stream, ensuring high-quality ignition.

It was this method of ignition that became the basis for inventions that became widespread in home-made apparatuses and drip burners on waste oil, produced at the factory. Waste oil is, in fact, free fuel, a spent suspension. Therefore, it is considered more advantageous against the background of other heat sources:

The waste oil burner can be made by hand

- solid fuel and briquettes for a homemade pellet burner;

- gasoline and diesel fuel;

- electricity;

- natural gas;

- kerosene;

- fuel oil.

Useful advice! Although mining remains the cheapest basis for generating heat during utilization through incineration, it is still recommended to prepare oil contaminated with impurities - to achieve water settling and filtering out of heavy suspension.

The first devices on kerosene, diesel fuel and oil smoked heavily and gave off an unpleasant odor. Later they offered a do-it-yourself gasoline burner and devices on other combustible raw materials, but an active search for budget fuel was carried out. The oil proved to be a suitable source of heat, but the smoke and smell negated the benefits.Therefore, all the efforts of the inventors were spent on eliminating the indicated disadvantages of the burner for waste oil boilers. This should have been facilitated by full combustion, heating and filtration of contaminated fuel.

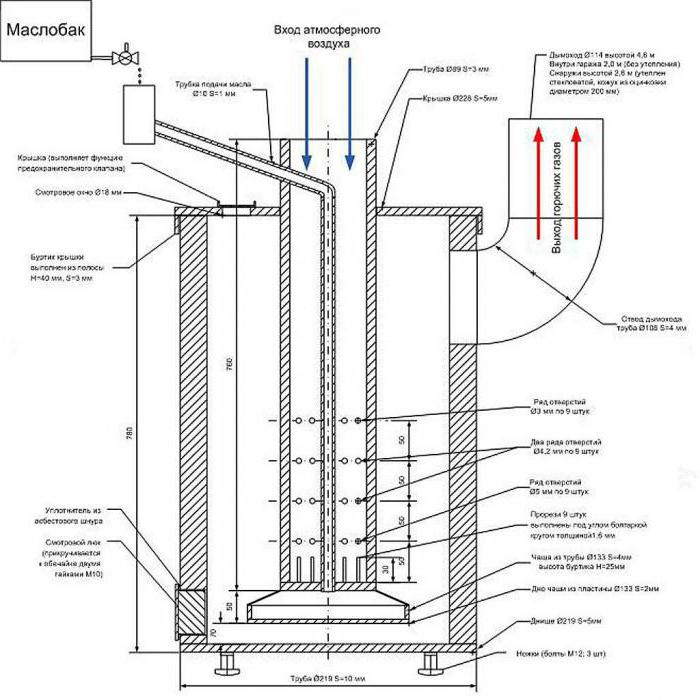

How to build your own apparatus on the principle of a Babington burner: drawings

The principle of operation of a home-made burner, made on the basis of the idea of Robert Babington, is clear from the drawings, where the components of the unit are visible:

Waste oil burner drawing according to Babington

- used oil tank;

- pallet for working off;

- fuel supply pipe;

- small fuel pump for supplying portions of oil;

- spraying hemisphere with a small hole;

- a heating chamber with a heating element (may not be available).

Note! The nozzle on working off for the organization of the process of even combustion is not an obligatory element. It will be successfully replaced by a nozzle - a small hole for supplying an air jet and fuel. So that it does not clog up, you need to monitor its serviceability.

The used oil evaporates and flows down the hemisphere. These oily vapors mix with the air mass to form a fuel mixture. The remaining oil, which did not have time to be disposed of, flows into the sump, and from there - through a pipe back to the fuel tank.

This unit, based on the Babington patent for burning liquid fuels, is quite simple. Therefore, it is available for reproduction from scrap parts in a home workshop. Success depends on the exact correspondence of the details to their purpose and on the well-coordinated work of all units. Therefore, before making a burner with your own hands, you should carefully calculate all the parameters.

The design of the burner is rather simple, so it can be made from improvised means

Useful advice! If we take as a basis any one option, for example, the Gnome burner, using ready-made drawings and recommendations of the masters, it is difficult to make a mistake in the size and functionality of the parts.

Diy Babington burner

Another type of flare burner available for home manufacture is the Babington spherical burner.

Her device includes:

- a tee with a diameter of two inches;

- metal tube for fuel supply;

- fitting to the size of the thread of the tee used;

- hollow steel ball;

- air compressor;

- metal corners;

- thick wire.

Diy Babington burner

Construction diagram

The tee is the heart of the appliance.

- A squeegee is screwed into it with a hole drilled on the side of 15 - 20 mm (for ignition) - we get a burner with a nozzle.

- A hole is drilled on top of the letter "T" formed by the tee to connect the pipe supplying liquid fuel. It is wound in the form of a spiral around a nozzle heated by a flame. This is necessary to achieve the required temperature and viscosity of the oil.

- And under the outlet of the supply tube, inside the tee, a ball or hemisphere is fixed, with a calibrated hole of 0.27 mm ± 0.02 mm, oriented strictly in the center of the nozzle. You can use a jet of the specified size to simplify the task.

- Air is supplied from the compressor with a pipe connected to the back of the ball.

- Excess oil is drained through the lower branch of the tee.

- The oil supply container is fixed further from the burner (and above it) to ensure the required pressure.

- The entire apparatus is mounted on legs that can be made of thick wire. It must be very stable!

The device works like this. Oil is supplied to the spherical surface by gravity or by means of a pump. From the inside of the ball, flowing in oil, the air pumped by the compressor comes out under pressure.

It sprays oil and forms a torch that is directed into the nozzle. This design is mounted inside the tee. Excess oil and impurities are collected in a sump located below. To avoid fire, it must be positioned as far away from the torch as possible.

Advantages and disadvantages of a do-it-yourself burner

Each technical device has a number of useful qualities and shortcomings. Obviously, there are more pros than cons to this device. The main advantage is the utilization of waste materials with the greatest benefit. Other advantages of equipment for the disposal of oils and liquid fuels:

- burning mining contributes to the preservation of the environment;

- ease of use and high energy efficiency;

- the manufacture of the device is available in ordinary household conditions;

- obtaining heat at a minimum cost of raw materials;

- a simple scheme for the manufacture of a structure, understandable drawings;

- a homemade device can be made from improvised means;

- application in workshops and at enterprises where a lot of processed raw materials are accumulated that require disposal;

- the small dimensions of the burner allow it to be moved if necessary;

- mining and the lowest-grade oil go to the furnace;

- device functionality;

- relative fire safety;

- reuse of used oil.

The main plus of the burner is the utilization of used oil with benefit.

Disadvantages:

- not recommended for summer cottages and living quarters due to burning and smell;

- the need to equip the premises with a fire extinguisher;

- be sure to follow all the recommendations for the manufacture of the burner;

- the nozzle or nozzle should be periodically checked (whether the holes are clogged with solid particles);

- sensitivity of the nozzle or nozzle to dirt;

- additional power supply of the components of the apparatus (pump, compressor).