It is noteworthy that automation for a private house can be installed on almost any heating system. Despite this, many still do not understand why exactly to automate the system and what it is all about.

To order the installation of automation for a private house - call +7 495 205-205-2

Already based on the name, we can conclude that the automation is designed to minimize human intervention in the heating process. Thus, the automatic program frees the person from constantly adjusting the indoor temperature. But many neglect this and rely on manual control. On the one hand, this is a significant expenditure of personal time, and on the other hand, in most cases, automation is necessary for the safe and reliable operation of the system.

Usually, the term "automation" means a whole list of different devices that monitor the operation of the entire heating system and the boiler in particular. It should also be noted that automatic control will be more accurate anyway.

Automation for heating a private house

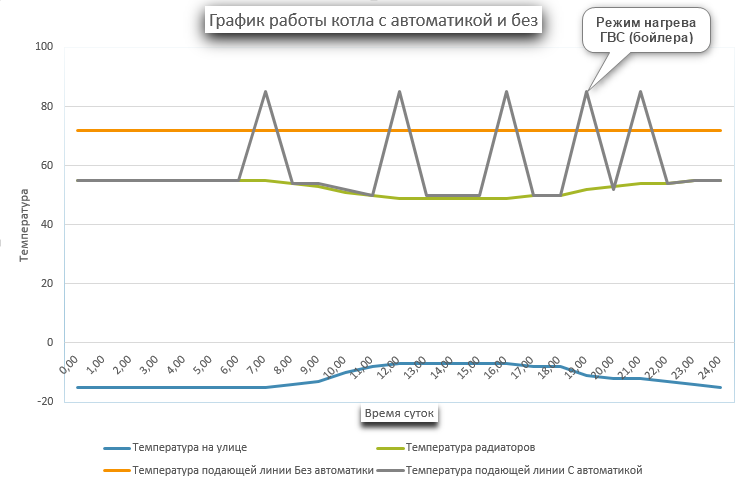

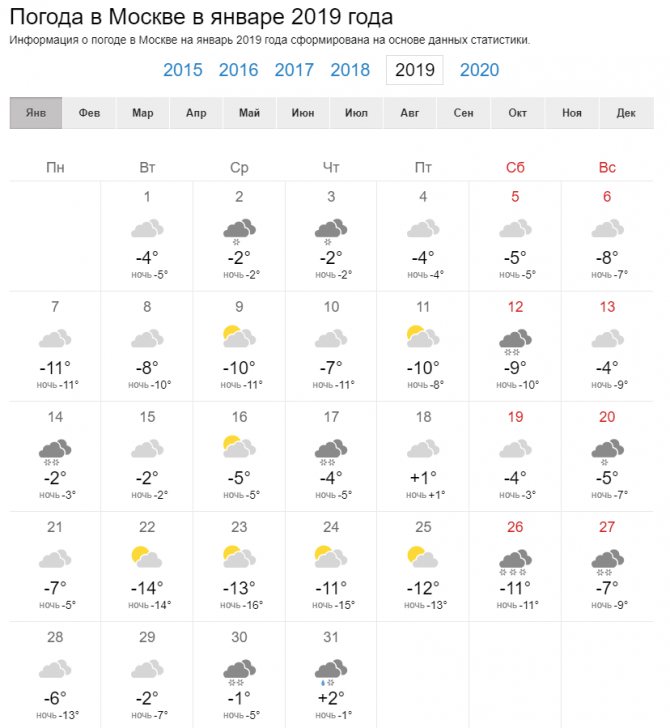

The main task for which the automation for heating a private house is responsible is to maintain the required temperature inside the premises. As you know, regulation takes place depending on the outside temperature. Thus, you can easily provide yourself with a comfortable environment inside the house.

Another benefit of automation is cost savings. Again, taking into account the fact that the temperature is adjusted depending on the outside air temperature, the system will automatically lower the heating temperature if it suddenly becomes warmer outside.

It is noteworthy, but the automatic system can increase or vice versa decrease the temperature inside the room, depending not only on the weather outside, but also on the days and hours of the week. For example, if there are few or no people in the house on weekends, then you can set the program in such a way that it does not heat the room as intensely, but at the same time maintains the optimal temperature. Of course, this will have a positive impact on cost savings.

The main advantages of heating system automation include the following:

- The program allows you to adjust the temperature inside the house at the request of the owner. If it has become much warmer outside, then you can program the system in such a way that it lowers the heating temperature, thereby maintaining a comfortable environment inside the room;

- It is possible to control the temperature depending on the day of the week or at certain hours;

- In suitable conditions, the automation will always reduce the heating temperature, thereby saving the owner's money;

- Automation of the heating system will provide reliable protection against overheating of the coolant, monitor the pressure inside the system, and also control the supply of water or gas to the system.

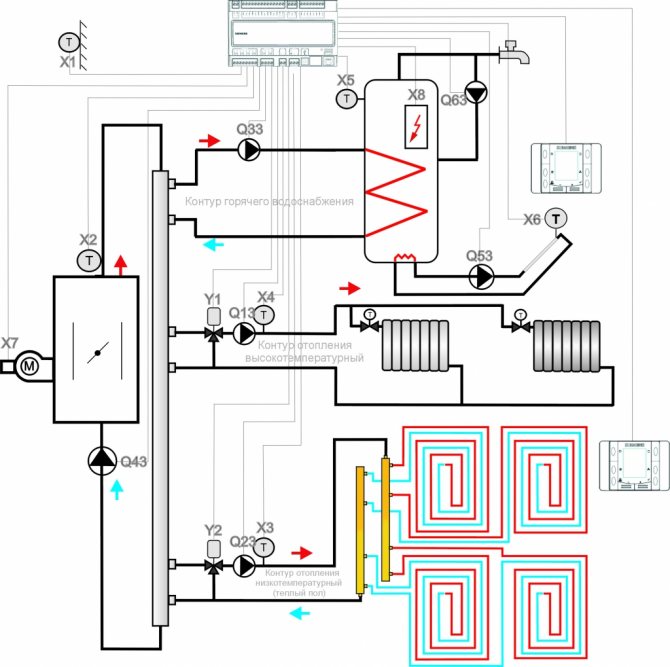

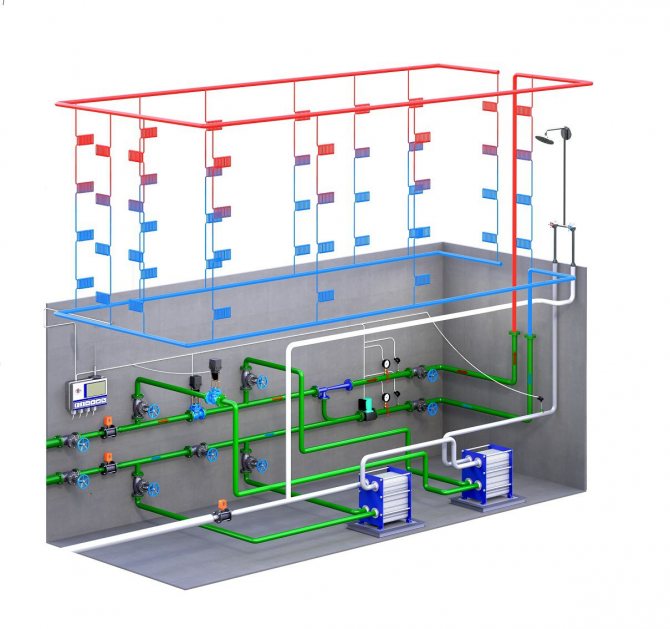

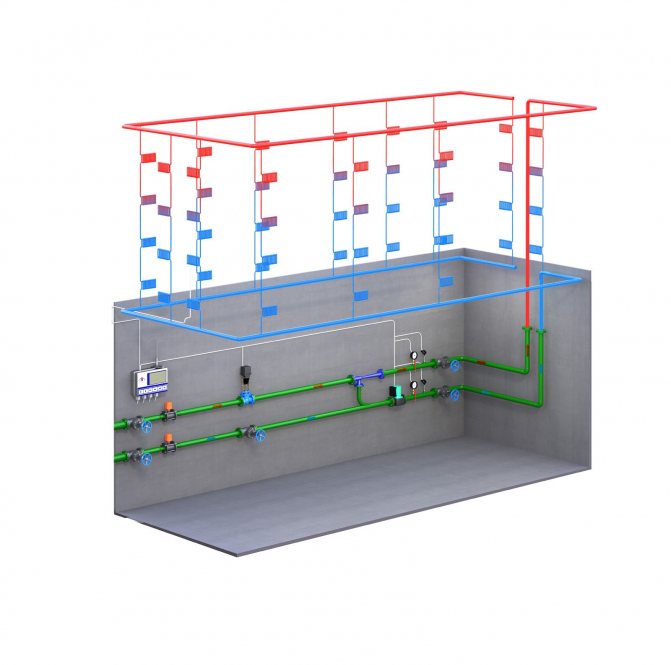

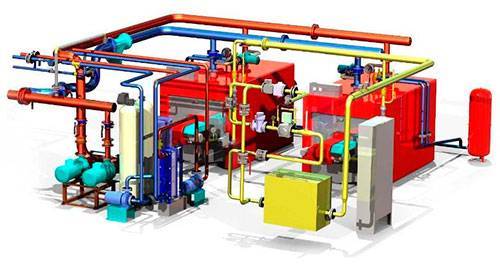

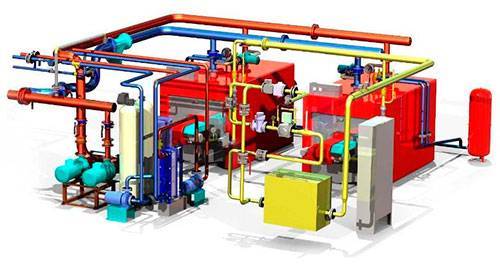

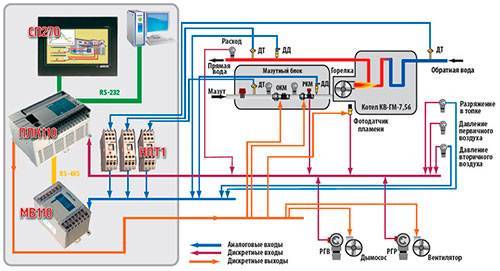

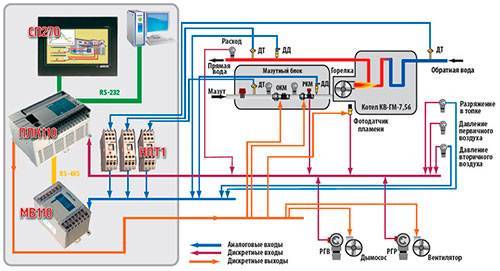

Boiler room automation - heating systems

Boiler room automation

(

heating systems

) Is a set of measures to create an automated heat supply system, the operation of which is regulated depending on the ambient temperature.

With manual control, the operator independently sets the temperature of the flow or return line of the boiler. The only benefit of manual control is the low initial cost. Disadvantages - high fuel consumption, difficulty in achieving comfort and the need for constant adjustment, since the weather conditions are constantly changing.

The inclusion of a DHW module and a room thermostat in the control system is the first step in boiler room automation

- heating systems

... The hot water preparation module, when the temperature in the boiler drops, gives a command to the boiler and the boiler loading pump to turn on. The room thermostat controls the room temperature and gives a command to the boiler to turn on if the room temperature drops below the set one.

With partial automation of heating, the convenience of preparing hot water is somewhat increased and it becomes possible to adjust the temperature in the room by means of a room thermostat. Among the disadvantages are the lack of accuracy of room thermostats, high fuel consumption and the lack of direct accounting for weather conditions. In addition, regulation in such systems is carried out according to room temperature, so the boiler turns on when the temperature in the room has already dropped.

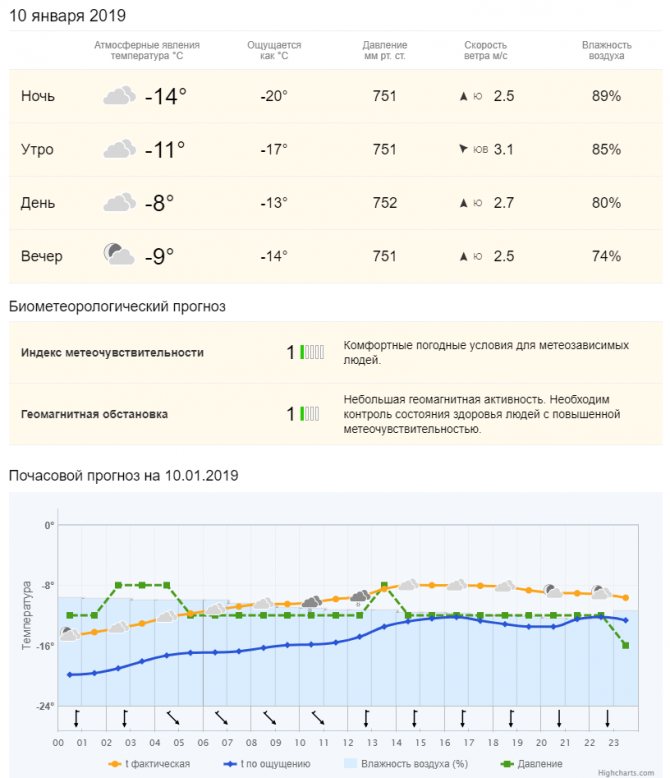

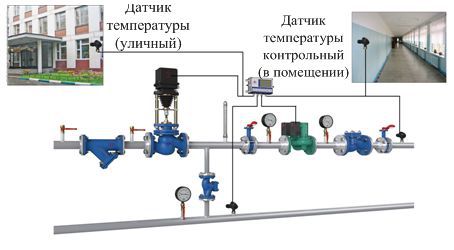

At present, weather-dependent automation of boilers and heating circuits has become widespread. Such a system monitors the temperature of the outside air and, depending on it, calculates which coolant parameters need to be supplied to the heating devices to maintain the set temperature in the room. A properly configured automatic boiler control system does not require operator intervention, but for more accurate operation, a room temperature sensor can be installed. The sensor differs from the thermostat in that it monitors not just the temperature in the room, but the dynamics of its change. Therefore, automation can predict the further state of the system and take timely measures to stabilize the temperature in the house.

When using automated weather-dependent control systems, the disadvantages of "partial automation" disappear. Such systems automatically maintain the required coolant temperature in the boiler and in each heating circuit. At the same time, fuel consumption is reduced by 15-20%. The main disadvantage of weather-dependent systems is the high cost. However, operating costs will be significantly lower due to savings in fuel and electricity.

When automating boiler rooms, attention should be paid to safety automation, which prevents the operation of boiler equipment in unacceptable modes, ensures the safety of the heating system and the safety of personnel. Make the right choice!

Make the right choice!

Automation of the heating system of a private house

In addition to all the listed advantages, automation of the heating system of a private house also has several disadvantages:

- The main disadvantage is its price. If we compare the cost of automation with the cost of a conventional thermostat, then the latter will cost literally "pennies";

- In order to save on heating at a certain time of the day, while having manual control, it is necessary to independently carry out all the manipulations with the system, which is not always convenient and possible. In order to fully automate this process, you can buy or order weather-dependent or programmable equipment for a specific system. But it is worth noting that it will not be possible to find it inexpensively, since it costs a little more than conventional equipment;

- If heating is carried out with the help of a gas boiler, then the fuel consumption will increase when the heating is switched on and off periodically. Saving fuel in this case is much more difficult than with other modern heating boilers.

System operation modes. Work in the building automation and dispatching system

Heating control systems can operate in the following modes.

Manual mode... In this case, setting the operating modes, switching equipment from the main to the backup and many other functions is carried out by the operator manually, it does not matter if he presses the buttons on the automation panel or on the PC, this is a manual mode.

Automatic offline mode... In this case, the system is turned on and off by the operator, then the system works according to a given algorithm and transmits information about its state to the operator or dispatcher.

Auto as part of an automated building management system. In this mode, the operation of the heating system is synchronized with other life support systems of the building, the operator or dispatcher does not take part in the control.

Heating system automation in a private house

Even at the stage of the future construction of a private house, the question arises of which heating to choose in order to provide a comfortable environment in the house and minimize the cost of maintaining the entire heating system. Usually, the choice of heating a private house comes down to three main aspects of the choice:

- Which boiler to choose;

- What will be the configuration of the heating system;

- Heating system automation in a private house.

As for the choice of the boiler, which is the main source of heat in the house, there are three main types that are most popular among consumers. Each of the types has both advantages and disadvantages.

- Gas boiler. This will be the most profitable option if there is a main fuel supply line. In the absence of this line, you can use liquefied gas in cylinders, but this does not reflect in the best way on the cost of servicing the heating system;

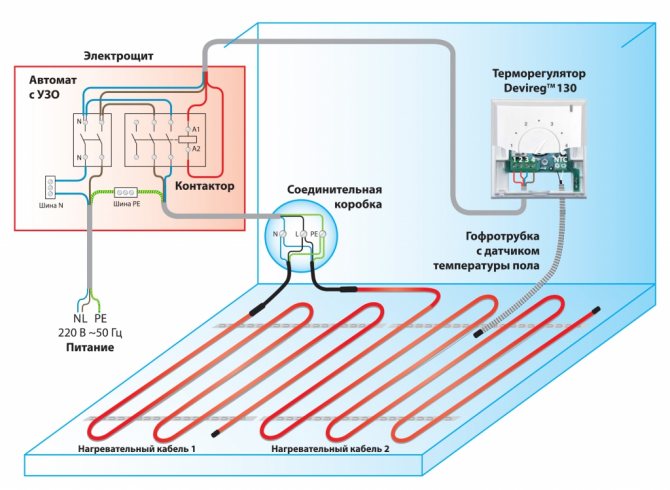

- Electric boiler. This is a rather expensive option and requires a lot of electricity. To minimize costs and provide a comfortable stop in the room, they resort to installing electric underfloor heating, which is much more economical;

- Solid fuel boilers. It is very popular among consumers, as it makes it easy to organize an autonomous heating system. But there are some nuances: the maintenance of such a system causes some inconvenience. In addition, such boilers are best used to heat small houses or use it depending on the season.

Do-it-yourself home heating control automation. Part 1

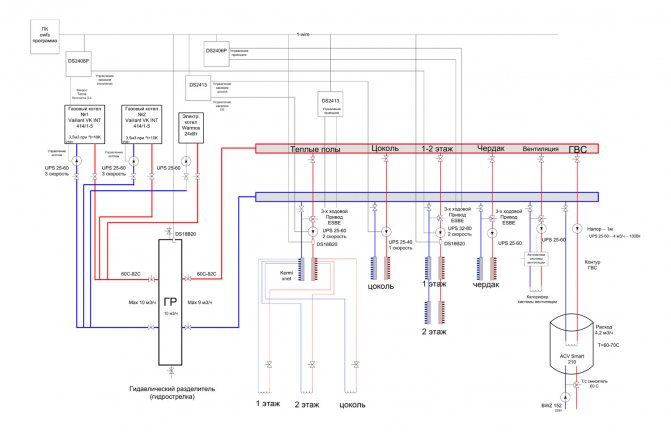

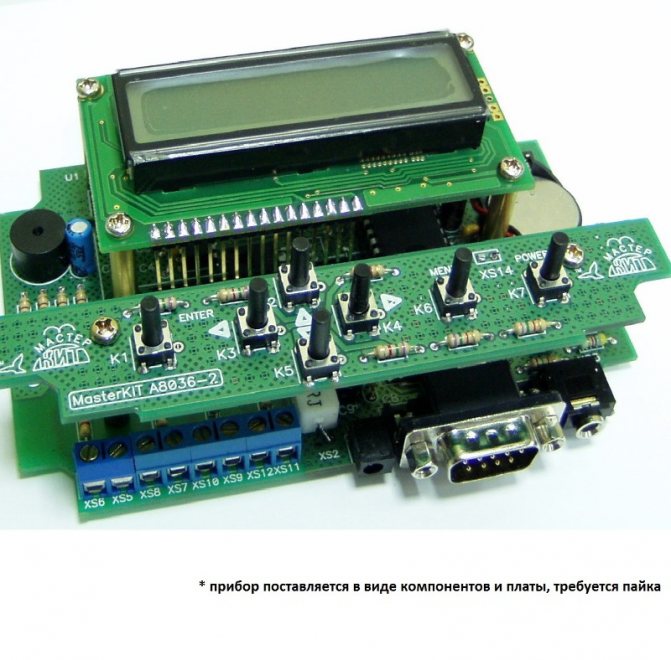

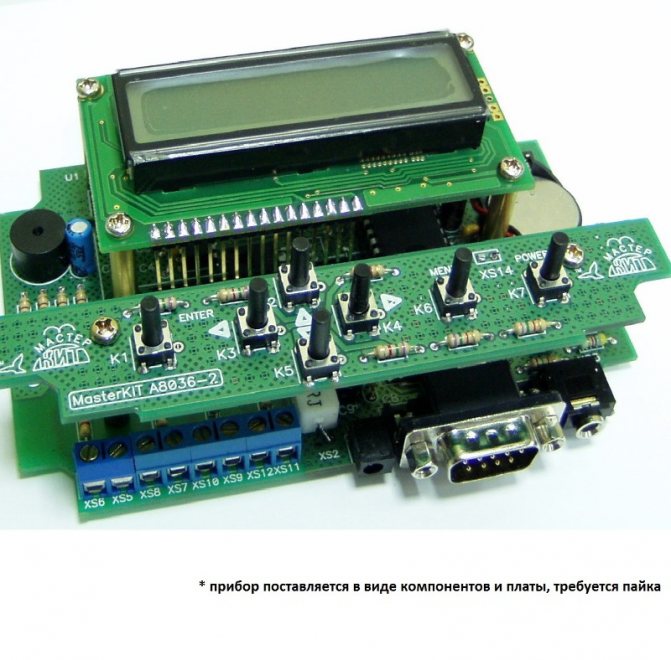

The multifunctional devices BM8036 and NM8036 from Master Kit can be used as the central part of a control system for heating, cooling, ventilation, etc. Based on NM8036, one of our buyers decided to make a home heating control automation and described in detail the process of implementing his idea:

“In my article Automation of heating for home, I wrote about what kind of automation is needed for a heating system with a water heat accumulator (BTA). Based on the desired algorithm and the peculiarities of the operation of a heating system of this kind, I came to the conclusion that a programmable control unit is needed that performs not only the functions of a thermostat, but also a timer with a calendar. In principle, you can just take an old computer, some kind of Pentium 2, write a program for it that will perform all the desired functions - and that's the end of it. I confess that I still have not lost this mood. However, I suddenly remembered a company where you can buy a lot of different kits for a wide variety of tasks. This is Master Kit.

And I must say that this company supplies various kits for the assembly of electronic devices. What is a kit? This is usually a printed circuit board and a set of parts for assembly. True, there are already assembled, ready-made devices. I, in fact, used this service before, collected something ... And now, after rummaging through its catalog quite a bit, I found a device that, on the whole, quite meets my requirements.This is a 4-channel timer-thermostat NM8036.

There is also an analogue of such a thermostat in the catalog, but already for 8 channels: BM8036.

* the device is supplied soldered with installed power switches complete with a housing and 8 temperature sensors

If you take a closer look at both options, then personally my choice: 4-channel. Why? It can be easily expanded to 12 channels. More precisely, both devices can be converted into a 12-channel version. That is, set 12 devices under his control. And this is not my invention, the Master Kit website says all this. My choice fell on the NM8036, as it is cheaper. However, the use of one or another option depends on the tasks, the ability to solder, etc. (for someone it will be easier and more convenient to use the finished device).

What kind of devices could it be? Well, for example, the electrovalves of the heating system, circulation pumps, electric heaters, fans, electrically controlled valves ... Eka blew me away. Gate valves, fans ... Duc, I'm already considering that this thermostat will not only control the heating system, but also maintain the storage temperature in the basement that is optimal for vegetables.

It is not superfluous to note at the same time that a huge number of temperature sensors can be connected to the inputs of this device. Digital sensors with high accuracy. And for gourmets from electronics, it is also possible to connect a couple of analog sensors to the ADC inputs.

But the highlight of this unit is not even that. Its software core allows you to program work without knowing any programming languages. Everything is at the level of human understanding in Russian. Although, of course, a person who is far from such things will probably find it difficult to cope with it. At least not right away, not from a raid.

But what I especially liked was the fact that this device can be connected to a computer and scammed over it no longer with the help of its standard buttons, but with the computer keyboard. Viewing the program, changing it, uploading new firmware versions ... Is it difficult, Master? I don’t know, I don’t think so. Today, the age is such that 12-year-old grandchildren, no longer looking at the buttons on the keyboard, beat. And what am I, dumber than them, or what? Dudki, they won't catch up with us!

Well, in short, I assembled and debugged this device. Now there is a trifle left: to place the temperature sensors in their places and create a program according to the algorithm that I need for the system to work. And this is not at all a pipe-work. Look, Master, read how many people are already using this thermostat. I did not make any discovery here, I just found what I needed and at an affordable price.

So what is required to fully assemble my control unit? I figured it out on my Wishlist-motels and decided to use all 12 channels at once. Maybe not right away, but the control unit must be assembled complete. Therefore:

1. Timer-thermostat NM8036 1 piece 2. Block of executive relays NM4411 3 pieces 3. Power supply unit PW1220D 1 piece 4. Digital temperature sensor DS1822 4 pieces

I bought all this in an online store. Temperature sensors, in fact, come with a timer, there are already 4 of them. But I took 4 more for the expansion. They will not be superfluous. And at the local store I looked at a case for the control unit, where you can stick all these components.

The Master Kit himself is not engaged in trade, it is done by various dealers-shops, including online stores. There are no supermarkets in my village, so I use online stores.

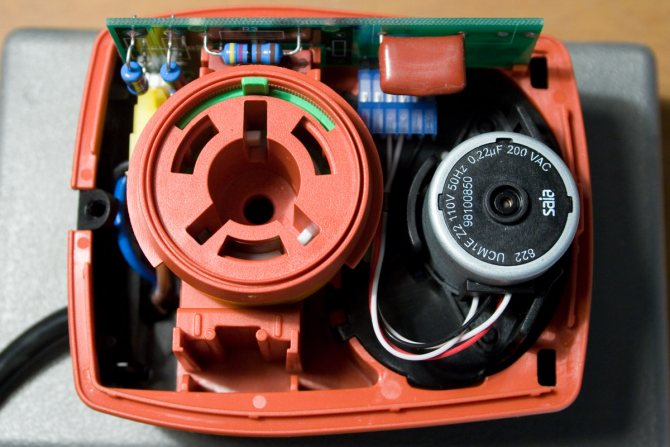

Here is the build process

Now let's talk about the assembly and start-up of the heating control unit based on NM8036.

The Master Kit has very good instructions for working with the kit. There is a link at the end of the kit description page.

But today I didn’t start a story to repeat this instruction. There are various pitfalls and boulders, which are not mentioned in the instructions, but in my practice I either stumbled upon, or miraculously avoided one, but could have stumbled upon. I’ll talk about this.

I will not tell and show how to solder elements to a printed circuit board. Of course, this is not done with a blowtorch and a certain minimum skill is of course highly desirable.Here the rules are simple: neatness and attentiveness, conclusions and contact pads, try not to overheat.

There are diagrams with sets, lists of elements are nested, names on the elements are written - have, as they say, eyes and hands. But I want to remind you of one thing: after assembly, cleaning and rinsing, do not rush to turn it on right away. Take, Master, a larger magnifying glass and carefully check each solder. EVERYONE! So that the circle is even, so that the closing snot of the solder does not extend from it to other contacts. The lion's share of malfunctions arises precisely from poor-quality soldering.

Insert the processor (controller) correctly into the socket. This is the largest microcircuit, it has a notch at the end, which indicates the beginning of the conclusions. The wiring diagram shows where this notch should look.

Collected? Check it out? Now check it again. Control shot before launch. Shot? Well, cross yourself on the image and poke the power connector. Just keep in mind that if you insert it in the wrong place, the pleasure will be dubious, and the result is not the same.

Look, near the COM connector there are two smaller connectors - on the right and on the left. The one on the right is the sensor connector. And the power connector is the one to the left of the COM. So, the power connector pokes very well into the sensor connector. Be careful, otherwise you run the risk of running into trouble.

COM connector. For what? To connect to a computer ... and more. The controller outputs are connected to the contacts of the same connector for controlling the loads OUT0, OUT1, OUT2 and OUT3 (see the XS1 connector on the diagram). That is, these 4 outputs can be used directly from this connector.

Not bad, of course, but if you don't use them here, and only use the connector to connect to a computer, then don't try to use any cable for the connection. This cable can also solder wires to the output pins. It is not known how this could end. It is said in the instructions how to unsolder the cable to connect to the computer - so do it.

Further. These blue terminal blocks (XS6 - XS9), which are to the left of the connectors, can not be installed at all if you intend to use NM4411 sets for control. Moreover, you can also not solder all the elements that are provided in these output stages. Everything that is on this fragment of the NM8036 circuit (there are also 8 resistors and 4 optocouplers).

These elements are not needed (less rations - a more reliable device). So how do you connect the controller outputs to the NM4411 inputs? Duc, like ... directly.

After all, I said that there are only 4 outputs in this set as standard, to which, accordingly, only 4 loads can be connected. And the software and firmware of the controller can provide work with 12 loads. In this case, each of them is connected directly to the controller's contacts (although, of course, the first 4 can be taken from the COM-connector as standard).

How directly?

If you look at the NM8036 board from the side of the rations, then its appearance will be approximately the same as in this figure (click on it to enlarge). Control channel outputs from 1 to 12 are numbered with corresponding numbers. Two analog inputs (A1 and A2) are also numbered, which are also processed by the new firmware of the controller.

If, Master, you watched the video of the assembly, then, of course, you noticed a bundle of wires soldered to the terminals of the controller on the back of the board. Using this bundle, I connected the indicated pins to the connector on the additional board.

And there already went another harness, from this connector to the boards of the NM4411 executive relays and two switches, which were connected to the analog inputs of the controller. What are switches for? I put them to switch the operating modes of the heating system.

Heating control of a private house with a boiler and a heat accumulator cannot be solved unambiguously.It's not just "on-off" here. The operation of the boiler for the accumulation of heat energy is already a separate mode, different from the mode of heat consumption. My first switch is to enable / disable the "Boiler" mode, which exactly corresponds to the operation of the boiler.

The second switch in my case turns on the heating of the bath. In standby mode, the temperature in the dressing room, sink and sauna rooms is maintained at 16 degrees. When the heating is turned on, the temperature in the sink rises to 35 degrees.

The mode switch circuit is simple, it is a pair of 1 kΩ resistors soldered to the toggle switch. The top resistor is connected to pin 10 of the controller (VCC, power + 5V), and the bottom resistor is connected to pin 11 (GND, common).

It remains to supplement this article with considerations for choosing a case. In my case, the choice of a plastic case, which I got in one of the local electrical goods stores, turned out to be very successful. Some crampedness in it was fully compensated by a rather appropriate transparent window for placing an NM8036 unit with a display under it. It also houses the power supply and 3 NM441 control boards, 4 channels each.

The keyboard and toggle switches of the mode switches were fixed on the inside of the lid. Thus, it turned out to be a good control unit for heating a private house.

To be continued…"

Heating automation

In order to increase the efficiency of heating, as well as the ease of use of the entire heating system, heating automation is used. This includes the following components:

- Thermostatic valve;

- Thermoregulator;

- Room regulator with thermo-valve and more.

The use of such equipment will ensure more efficient operation of the system, as well as reduce energy consumption, while this will not affect the comfort of the residents. Thanks to such devices, it becomes very easy to control the heating system, and the temperature inside the house will always meet the needs of the residents.

Automation processes

It is becoming so clear that all the automation of the heating systems of a private house works with the help of auxiliary devices, let's look at how this is done.

- Control only on the heating boiler. Thus, only the temperature in it is regulated, and, accordingly, external factors are taken into account, such as the temperature of the room where the equipment is located. Naturally, by adjusting and monitoring the boiler, the temperature of the heat carrier in it and at the outlet is monitored.

Heating boiler automation

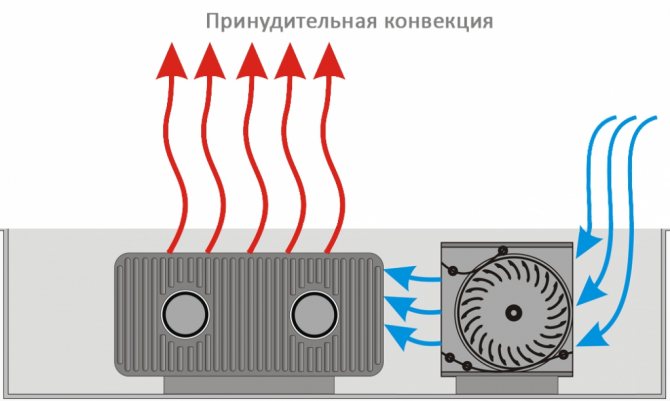

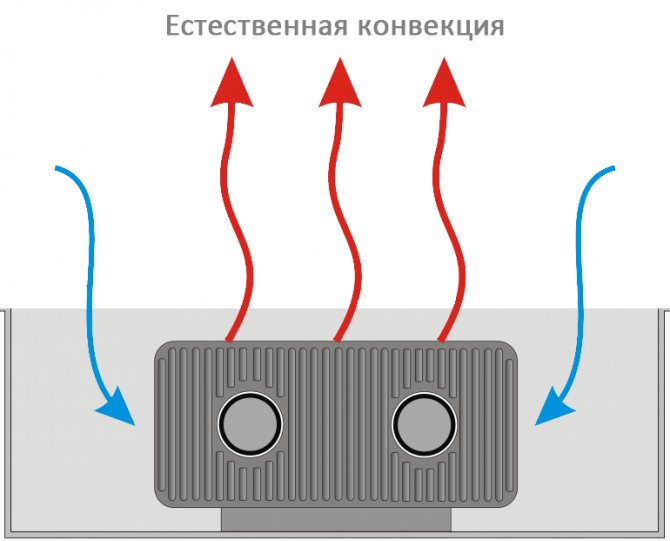

- Valve thermostat. The simplest device that is installed on each individual radiator. This thermostat sets the temperature you need, and it reacts in the future to all changes inside the heating radiator itself and outside it. This valve, if the temperature has reached the limit, closes the access to the heater, and in reverse order at a low temperature of the room or radiator, it spins back up.

Such technologies are used independently, and do not in any way provoke the economy of resource consumption, because they do not regulate the consumption thereof in any way.

There is a third automated approach for heating a private house, a special room box with data - a room temperature controller. He already controls the circulation of the heater, its temperature, and provides the desired mode. Roughly speaking, he alone does what the two previous ones do, and it is used not for temporary "summer cottage" use, but on a permanent basis.

Room temperature controller

Heating automation

Today, heating automation in a wide range is represented by thermostatic valves. This device is designed specifically to be able to regulate the air temperature inside each individual room in the house.This device can be installed either on a heating radiator or on a floor heating circuit. Its functioning is quite simple. The owner will only have to turn the thermo head of the valve to the figure that is needed and the device will quickly raise or lower the temperature to the set level. This is where human intervention in work ends.

The rest of the process is carried out automatically. After the temperature in the room rises above the set value, the valve will close the circulation of water to the heating radiator. After the temperature drops below the specified level, the supply of the heating medium will be restored again. In this case, the valve is constantly in operation, and its action is quite simple.

It is worth noting that such a scheme will continue to function regardless of whether the coolant supply in the boiler is regulated or not. This does not depend on the boiler used. Such valves can be installed in those heating systems that use a gas or solid fuel boiler. And even if we are talking about an electric boiler, then thermo valves will not be superfluous here either. Best of all, such a device manifests itself with solid fuel boilers. It is known that regulating the temperature with such boilers is not only difficult, and sometimes impossible.

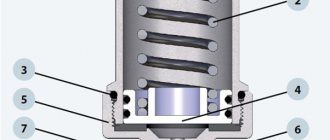

Sensors

The sensors are designed to control the pressure and temperature in the room, outdoors and the coolant in the heating system pipelines.

Temperature sensors are:

Submersible... Designed for taking readings about water heating in pipes. Their installation is carried out in certain areas of the system. These sensors are bimetallic and alcohol

Remote... This type of sensor is installed outside the heating system. Recently, wireless models have been popular, which transmit information using auxiliary electronics, which makes it possible to install them almost anywhere - in a separate room or on the street.

Pressure Sensors are mechanical - pressure switches (mechanical measurement of differential pressure and electrical conversion) and analog pressure sensors (conversion of pressure directly into an electrical signal, for example, using piezo elements).

Heating automation in a private house

It is worth noting that in this case, the automation of heating in a private house does not imply savings, since the thermostatic valve simply does not allow this. And there are several main reasons for this:

- Using such a device, the power of the heater increases by approximately 15%. If you do not use such a device, then it is possible to choose a weaker radiator. We can say that in this case, the device played not a good joke. The higher the power, the more expensive the heating device;

- In this case, the heating boiler will not be in the most comfortable conditions for it. This will be reflected in the increased fuel consumption, as well as in its operational period. It is very difficult to imagine how many times a day a gas boiler can turn off and turn back on. Of course, this does not reflect in the best way on its service life. With solid fuel boilers, things are even worse, since here the likelihood that the boiler will simply boil increases significantly;

- There is one more point that already requires human intervention. In order to save on fuel, it will be necessary to manually lower the temperature of the coolant when there is no one in the house. This can be done in two ways: the first is to cut the amount of fuel for the boiler, and the second is to set a reduced temperature indicator on each separate thermo-valve. As practice shows, many simply forget about this, so the issue of saving is not resolved here;

- The cost of such equipment is far from small.In addition, the final amount will vary depending on the heating batteries. We multiply their number by the price of one thermostatic valve and we get a pretty solid amount.

What do we know about automation

Under this name, in most cases, they mean a certain number of different devices, the purpose of which is to monitor the operation of the heating boiler. Almost the very name of the process shows that the complex of devices allows you to create different jobs without an operator.

The instruction recommends setting the necessary parameters yourself, and the system will adhere to them, which is very comfortable and does not take up your free time. As a result, the control takes place as accurately and without errors, which cannot be ruled out in the case of "anthropogenic factor".

Now it is possible to automate any process, based on this, heating was no exception in this idea. In addition, automation can be used for the entire circuit at once, as well as for its individual elements, for example, radiators.

As mentioned above, automatic heating control is a control over the temperature in the boiler and in the premises. This is its main function, based on this, the most questions arise for devices.

The market is saturated with a wide range of control and monitoring devices that differ in functionality, performance and accuracy of readings. Based on this, we will consider this issue in more detail.

Thermostatic valve

- Designed to control and regulate the temperature in every room of the house.

- Installation is carried out on a battery or underfloor heating circuit.

- To turn the device into operation, it is enough to unfold its thermal head, on which there are numbers of the required temperature.

- Other work is carried out in automatic mode, based on this, when the air temperature in the room drops, the valve opens the supply of the coolant to the radiator, if it is exceeded, it closes.

- The operation of the circuit does not depend on the temperature in the heat generator and the type of domestic boiler of the heating system.

- Much more often the equipment is used with gas, liquid and solid fuel devices for heating the coolant. In the latter case, this is most appropriate, since it is difficult or unrealistic to create temperature control in the heat generator.

When choosing this automatic device, take into account that it is not recommended for saving. Let's explain below:

| Power | When installing a thermostatic valve, the heat output of the radiator immediately increases by about 15%. Based on this, if it is not installed, the heating device can be selected with a lower power. In practice, we will need to purchase a battery at a higher price. |

| Boiler operation | The heat generator will need to work in a mode that is not very comfortable for it, which will affect:

He will need to turn on and off several times daily, which is much worse than if he had to work in one mode. Solid fuel heat generators are even more troublesome. It is practically unrealistic to adjust the fuel supply to them, so there is a danger of the coolant boiling. |

| Anthropogenic factor | To save energy, you will need to lower its temperature when you are not at home. There are two methods to do this:

|

The price of a quality thermostatic valve cannot be low. If you install it on all radiators in the house, the amount will be quite important.

Room temperature control

- One of the modern automation devices for heating.

- Installed on a wall in a room and is a whole complex of devices:

- turning on and off the fuel supply (for electric and gas boilers),

- regulating the operation of the circulation pump in systems with a solid fuel unit.

Let's define the advantages of this automation:

- The ambient temperature in the room is controlled, and not the coolant in the radiators. Based on this, there are no sudden changes in temperature.

- The boiler will not turn on and off quite often. That is why it is possible to reduce energy costs by almost 30%.

- The regulator is programmable. Based on this, it will be very easy to set the minimum temperature regime for 7 days, in case you need to leave home. Before your return, the system will be able to warm up the airspace in the room to normal within an hour.

Advice: we recommend using this method, as any lower degree can give 6% fuel savings.

- Regulators with two sensors - in the house and outdoors, are able to control the mode in the room from the outside temperature. They are called weather-dependent, and their price is possibly 6 times higher than a simple one.

- This automation can be controlled not only manually, but also via SMS messages or via the Internet.

Tip: automation of heating systems for residential buildings - articles on the topic, detailed diagrams and tips for an independent installation, you have the opportunity to find our portal.

Thermo valve with room regulator

An entertaining option, which you should be sent to chat about in more detail in order to find out whether it is possible to benefit from such a combination in the form of savings in heating costs.

Experts say the costs will be significantly reduced. This will happen not only due to the lower consumption of energy sources, but also due to the purchase of inexpensive thermostatic valves.

In this case, you need to correctly distribute functions between devices, based on the importance of each:

- the room controller should be used as the main element, under the control of which it is also regulating the operation of the heat generator... Based on this, the main adjustment will depend on it,

- thermo valves are needed as additional equipment, which can be used to adjust the temperature in roomsbased on the conditions created in each.

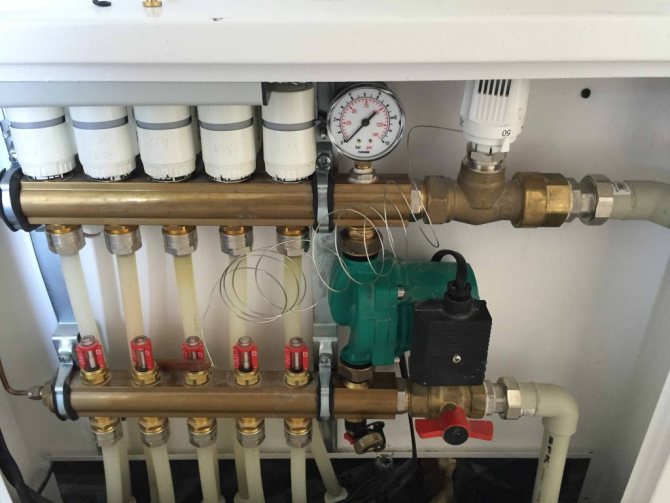

Heating systems automation

If more modern automation of heating systems is needed, then today manufacturers offer rather unique devices that will distinguish all the requirements of our time. This includes a room temperature controller. Basically, such devices are installed right in the room. It is wall-mounted and allows you to control the room temperature. The uniqueness of such a device lies in the fact that it performs a whole range of different tasks. It can turn on or off the fuel supply, when it comes to gas or electric boilers, and also turn on and off the sediments for the circulation of the coolant, when it comes to solid fuel boilers.

What and how to automate? Basic principles

Depending on the type of heating medium heating system, the control will differ and the parameters controlled by the automation system.

In general, the operator sets the desired room temperature through the control panel or PC, through the control panel in a separate room, etc.

The heating automation system, based on data on the air temperature in the building, the outside temperature, the time of day, the presence of people in the room, selects the operating mode and transmits control signals to the actuators, which may differ:

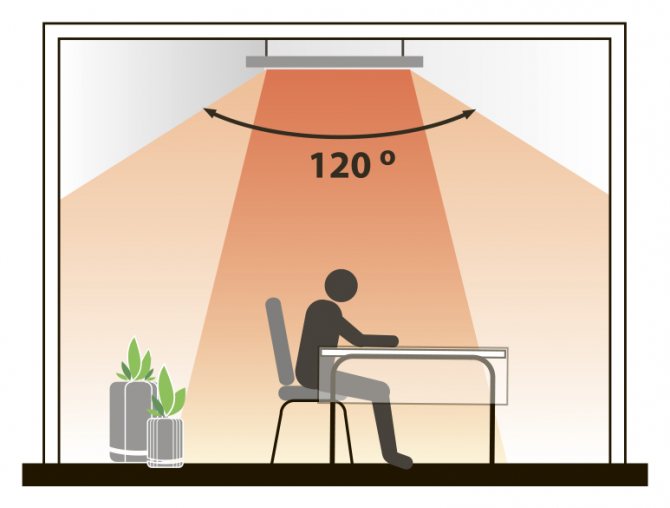

A) To control the electric heating system, devices that control the power of electric current are used: bimetallic thermostats operating on the "on / off" principle, or thyristor voltage regulators, with the help of which, when the voltage decreases, the power consumption of the device is also reduced. As an example, we can recall an electric convector, the user sets the required temperature, and the thermostat maintains the temperature by turning on and off the power supply to the device.

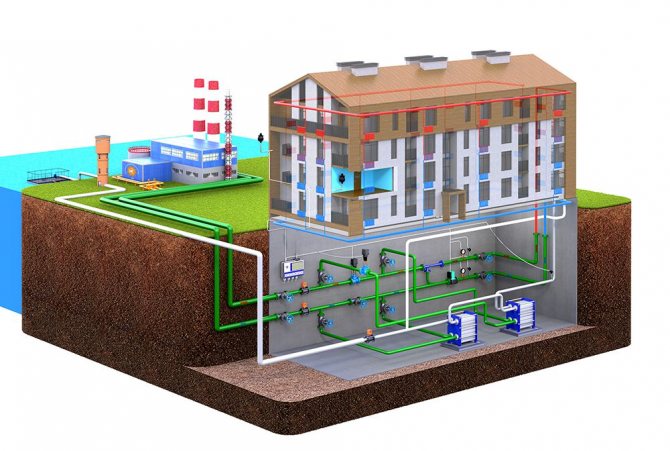

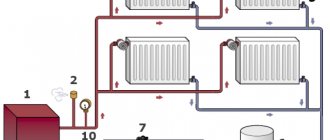

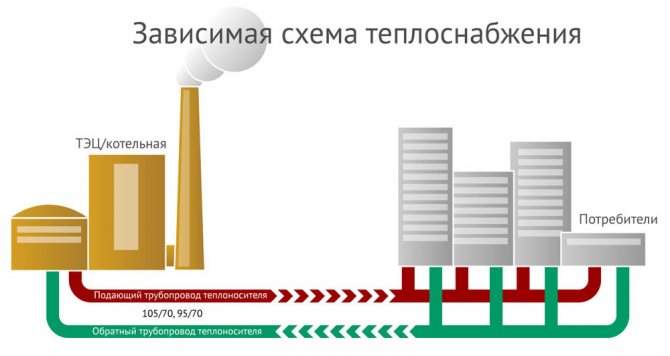

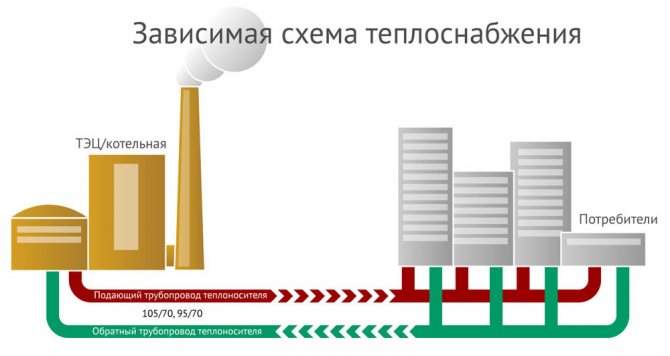

B) To control the heating system with a coolant circuit, devices are used that regulate the temperature and flow rate of the coolant. At the same time, the regulation of the coolant temperature is possible only in autonomous systems with boilers and heaters, for example, in private houses; for centralized heating systems, the temperatures of the incoming and outgoing coolant flows are set by the graphs:

- from large thermal power plants: 150/70 ° С, 130/70 ° С or 105/70 ° С;

- from boiler houses and small thermal power plants: 105/70 ° С or 95/70 ° С.

Thus, in large objects, room temperature control can be carried out only with the help of devices that change the flow rate of the coolant in the heating network and maintain it at a given level so as not to go beyond the temperature schedule.

Heating system automation

Such automation of the heating system, which is represented by room temperature controllers, has the following advantages:

- The device is responsible for controlling the temperature in the air, not inside the coolant. Considering the fact that the volume of air is greater than the volume of water, there will be no sudden temperature jumps. This will have a positive effect on the operating period of the boiler, since there will be much less shutdowns and shutdowns. Experts note that the use of such automation allows for 30% savings;

- The device is programmable. It can be installed in such a way that the same air temperature will be kept until the evening, and before the arrival of residents, it will rise. Savings in this case are obvious. It is noteworthy that each lower degree of air temperature provides 6% fuel economy;

- There are also more functional sensors, which consist of two devices, one of which is installed directly inside the house, the second on the street. This is necessary so that the temperature in the house is completely dependent on the temperature outside. Such devices are called weather-dependent;

- With the help of such a device, you can control the process of heating water in the boiler, as well as control the circulation of the coolant along the circuits on different floors, as well as in the underfloor heating system. Another big plus of such a system is that it can be controlled via the Internet or via SMS chat.

How is the heating system regulated?

- Weather-dependent automatic control according to the temperature graph of the dependence of the coolant temperature on the outside air temperature;

- Regulation of heat consumption to maintain the set air temperature parameters in rooms with central heating.

- Programmed reduction of heating agent consumption for heating at night, weekends and holidays.

- Limitation of the temperature of the return network water according to the schedule of its dependence on the outside air temperature in accordance with the requirements of the heat supply organization in heating systems

The heat carrier from the central heating system comes to you in the IPT, to the control unit. Then the coolant enters the home heating system. Having passed through all the batteries, the coolant from all risers is collected in the return pipe and again enters your control unit. The automation controller analyzes the temperature parameters on the street, the supply pipeline (supply), the return pipeline (return) and automatically adjusts the coolant consumption, determining how much of the coolant and what temperature must be supplied to the house heating system, according to the built PID coefficients. The PID coefficients are adjusted by service engineers when tuning the system.

PID coefficient - Proportional-integral-differentiating coefficient.It is used in automatic control systems to calculate the control signal in order to obtain a high process accuracy.

Heating network automation schemes.

| First heating circuit - 150/70 ° C | Second heating circuit - 95/70 ° C |

|

|

|

|

Variants of the location of the ATS temperature sensors.

| The best option for installing temperature sensors | Incorrect installation of temperature sensors |

|

|

Service and maintenance of ACS, APCS.

- adjustment of day / night settings, weekend / working day

- lubrication of movable valve mechanisms

- checking the operation of check valves, shut-off valves

- in manual mode, control of valves, pumps

- verification of readings of temperature sensors with a reference

- analysis of archived data

- maintaining the settings of the automation system within the limits set by the technical conditions

- diagnostics of technical condition and prevention of failures of control systems and equipment

Next to the unit there is a diagram of a substation in A3 format and an instruction manual for the ATS.

With a competent organization of the process of servicing the APCS, it is possible to transfer from the system of scheduled preventive maintenance to carrying out work in accordance with the actual state of the equipment.

Service cost 480 rubles / month.

Get a service engineer consultation!

Heating control automation

As for the price of a room regulator, such automation for heating control will directly depend on the chosen model. You need to understand that the difference in cost is quite noticeable. If you choose a weather-dependent thermostat, then it will cost 5-6 times more than a regular one. But there is an effective way to solve this problem. For this, a thermostat can be installed in one of the rooms, and thermostatic valves can be installed on the radiators in all the others. You need to set the required temperature on the thermostat, and turn the valves manually.

Heating system automation

What is the advantage? The fact is that expensive automation for the heating system will affect the operation of the heater itself, constantly turning it on and off. As for the thermo valves, they will have nothing to do with the boiler, since they will only monitor the temperature in the room where they were installed. But there is one small drawback here. For example, in one room, where the room temperature controller is installed, several people have gathered. Of course, the temperature in this room will begin to rise rapidly. Accordingly, the automation will react to these changes and the fuel supply to the boiler will be sharply reduced. Naturally, this will lead to the fact that the temperature throughout the house will begin to decrease. If in the room where people are gathered, it will be quite comfortable and warm, then in other rooms it will become much cooler.

A completely logical question may arise - how quickly the automation will react to temperature changes. If we take into account the fact that a person emits about 100 watts of thermal energy, this indicator needs to be multiplied by the number of people and we will get the desired result. As practice shows, in an average room, where about 5 people have gathered, the air temperature will increase by 1 degree in half an hour. It is also worth considering the moment with the location of the room where the regulator is installed. If the room is on the south side, then it will always be warmer than in other rooms. All this must be taken into account before buying an automatic thermostat.

Technology features

When organizing an intelligent control system, the features of the building's architecture, materials for making walls, the purpose of the premises and other nuances are taken into account. It is also important to provide for the integration of the heating system with ventilation and air conditioning systems.These utilities must work together for greater efficiency and better indoor climate control.

Automation means must provide control of all devices in the system, be it radiators, convectors, boilers or other equipment. For this, electric drives, thermostats and other devices are used, thanks to which the corresponding adjustment is carried out. The reference point for the automation equipment is set by the temperature sensors located in the premises. They are used to control the current climatic conditions.

When combined into a single system, competent heating automation solves several important tasks at the same time.

- All heating zones in the house are monitored and managed.

- It is possible to pre-program the temperature change in the room by hours of the day, days of the week or by separate dates.

- It is possible to envisage an increase in the consumption of hot water in the morning and evening hours.

- If there are most empty guest rooms, the heating mode can be adjusted accordingly to ensure savings.

- For bedrooms, children's rooms, kitchens and other rooms, you can adjust the heating mode in accordance with their purpose.

Automation in a private house

In addition, automation in a private house can be simultaneously represented by a room regulator and a thermo valve. This combination has already been discussed a little higher. But is this "symbiosis" really as effective as they say? Practice shows that the savings are really significant. And this fact is influenced not only by a decrease in the energy carrier, but also by the lower cost of thermo valves.

The functions in this case are allocated based on the importance of each of the devices used. The room temperature regulator will be the main one of the whole chain, which will control and regulate the operation of the boiler. In simple words - he will carry out the basic work adjustments. As for the three valves, they will be a kind of additions that can correct the temperature in the rooms where they are installed.

As for the cost of automation, it is also influenced by the type of heating, as well as the presence of underfloor heating, etc. Using a combined type of automation, the price for it will increase. Despite this, its presence will reduce costs, which directly depend on the gas pipeline, as well as on the location of all the necessary authorities. Before making your choice in the direction of a particular device, you must be well acquainted with all types of automation of the heating system. This will allow you to select the correct type of device, as well as calculate its approximate cost and future savings. If it is difficult to do this on your own, then for help you can turn to a specialist who will do all the work for you. In this case, the risk of spending even more personal funds, which were allocated for the arrangement of the automation of the heating system, is significantly reduced.

Automatic regulation of heat, heating, heat supply.

To create comfortable heating in an apartment, an obligatory element involves the use of automation. You will not constantly sit at the heating point and manually control the operation of the heating unit. And it is better to provide comfortable conditions in the house not with open vents, although no one has canceled the ventilation in the rooms, but by setting the desired temperature. It is not easy to create a mild climate in the house, with sharp fluctuations in room temperature and frequent drafts. These tasks are performed by the automation of heating systems.

Heating automation has never been so affordable, see for yourself!

The technical feasibility of installing the automation is determined by the heating engineer on site. The visit of a specialist is free and does not oblige you to anything.

Find out the possibility of installation!

Order a free engineer visit!