Water hammer compensator in internal water supply systems FAR

—>

| Name | The size | Retail price, rub. | Discount price, rub. |

| Water hammer compensator for internal water supply systems FAR FA 2895 12 | 1/2″ |

You can download the full price list for FAR valves in Excel format here.

The phenomenon of "water hammer" occurs in the event of a sudden opening or closing of equipment (drive of a mixing valve, pump, etc.), which leads to the appearance of excessive pressure in the system. The FAR water hammer compensator takes over the excess pressure, maintaining normal operating parameters for the system components. Also, its task is to significantly reduce the noise from vibration, which occurs as a result of the closure of the water consumer.

Specifications

- Accession - НР 1/2 ″;

- Maximum pressure - 50 bar;

- Nominal pressure - 10 bar;

- The maximum operating temperature is 100 ° C.

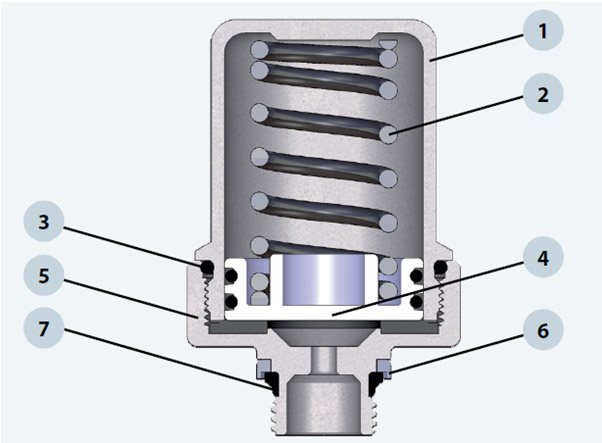

Design

1. Upper body - CW617N brass; 2. Spring - AISI 302; 3. O-ring - EPDM; 4. Disc - plastic; 5. The lower part of the body - brass CW617N; 6. Clamping ring - brass CW614N; 7. Sealing - EPDM.

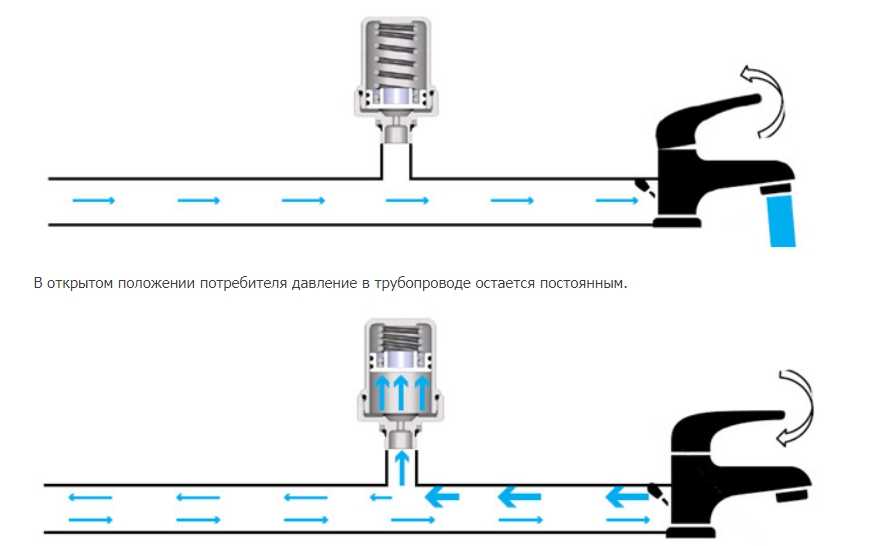

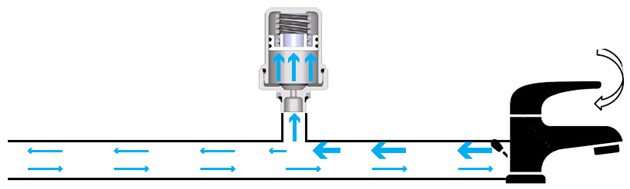

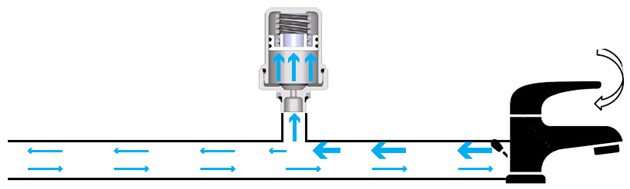

The overpressure is relieved by an air chamber and a steel spring connected to a double sealed plastic disc, which absorb most of the overpressure.

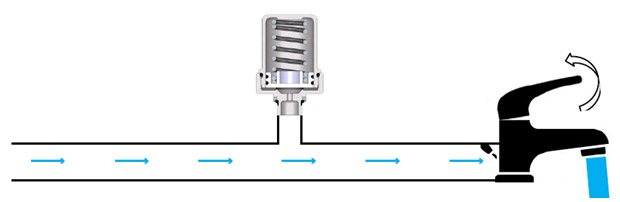

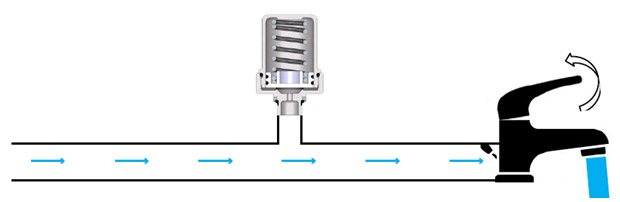

In the open position of the consumer, the pressure in the pipeline remains constant.

When the consumer is closed, the pressure in the pipeline increases and the FAR water hammer compensator absorbs the excess pressure, protecting the system components.

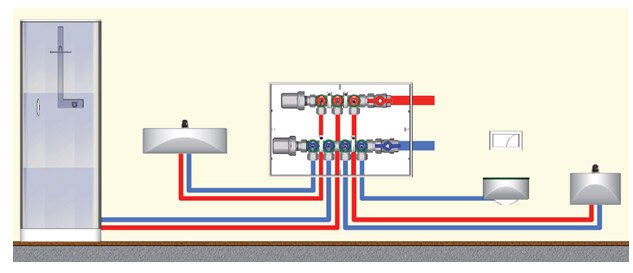

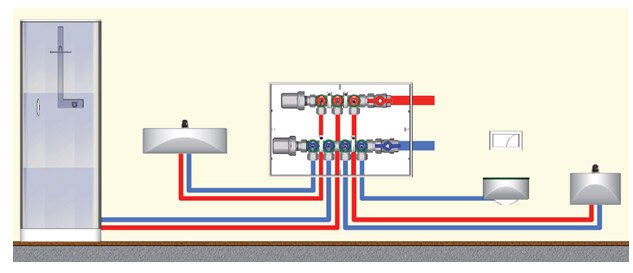

It is recommended to install a water hammer compensator at the end of the pipeline to consumers (ball valves, plumbing fixtures, motorized valves, etc.) or on manifolds.

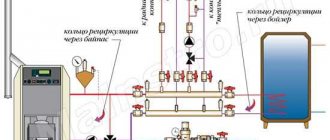

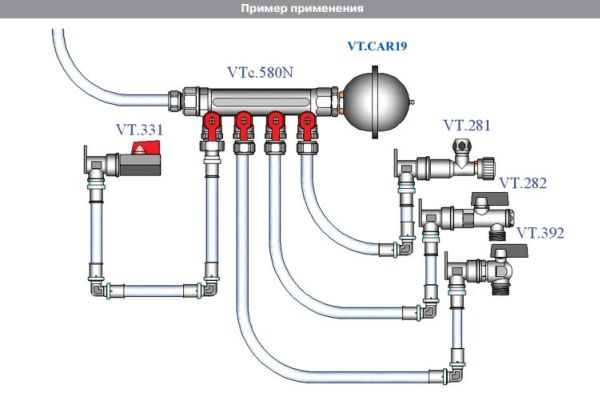

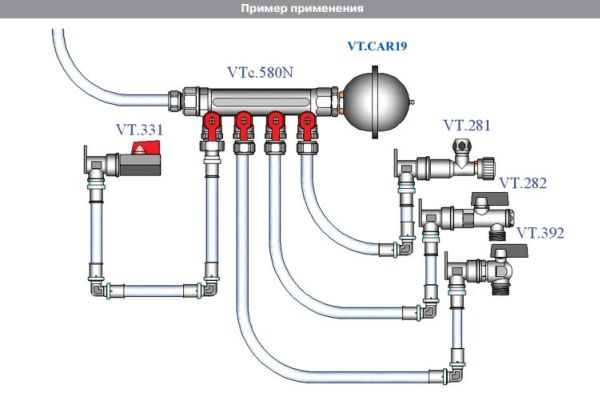

An example of installing a water hammer compensator on Multifar manifolds.

An example of installing a hydraulic shock compensator to the consumer.

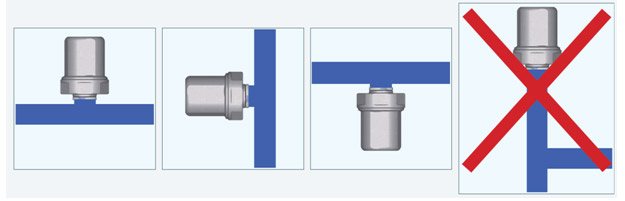

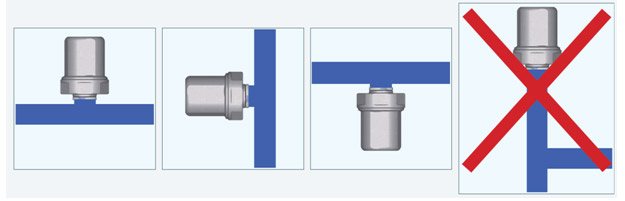

The water hammer compensator can be installed vertically or horizontally.

When installing a water hammer compensator, make sure that its location does not create areas where water stagnation can occur, which leads to the growth of bacteria. For example, installing the expansion joint at the top of the riser should be avoided.

Diaphragm expansion joint model overview

Comparison of the technical characteristics of different models of devices helps those who first encountered the need to use them to make the right choice. The same can be said for membrane expansion joints. The Valtec Car 19 model is ideal for residential use in apartments.

Its main purpose is to compensate for variable pressure values in water pipelines and heating systems. The valtec models are often used exclusively as an expansion tank. The compensator body is quite durable, moreover, it is made of stainless steel. With a water hammer, the reservoir is capable of accepting 162 g of water. But this is not such a low indicator, since the pressure in the line at this time is from 10 to 12 bar.

When installed, the nominal pressure in the tank is 3 bar, which in most cases is suitable for many systems without reconfiguration. Some models are equipped with pressure gauges for more convenient adjustment of the compensator.

The FAR FA 2895 12 model from FAR has conquered its niche in the compensating device market due to its reliability at a relatively inexpensive cost.Temperature and pressure indicators allow the compensator to work both in industrial systems and in systems for home use.

The device of the reservoir is practically no different from analogues. A brass alloy is used as a material, and the membrane is made of durable plastic. So that this plastic does not deform under the influence of air when the tank is empty, but is held by springs. The undoubted quality of far models is their small size, they are easy to install even in tight spaces.

The manufacturers Reflex and caleffi specialize in the production of fittings for water pipes. They offer a whole line of expansion joints, which differ in that they are used in larger systems. The Reflex tank can be up to hundreds of liters. Often, such devices become hydraulic accumulators capable of storing a huge amount of water. These batteries ensure the integrity of the pumps when the water supply is cut off.

The availability of devices and flexible pricing policy of manufacturers allows you to protect water supply systems not only in large enterprises, but also in ordinary households. The listed devices have a sufficiently high resource, provided that all technical parameters are selected in the correct way.

Source: silphon.ru

What is a water hammer in a pipeline, the causes of

Water hammer - This is a sharp increase in pressure in systems transporting fluid, which occurs when a sharp change in the speed of fluid movement. A pressure surge can cause the destruction of some elements of the system. Failures occur if the tensile strength of the joint or material is exceeded.

If we talk about our houses and apartments, water shocks occur in heating and water supply systems. In heating systems of private houses - at the start or stop of the circulation pump. Yes, by itself it does not create pressure. But a sharp acceleration or stop of the coolant is the load that acts on the pipe walls and nearby devices. In closed-type heating systems, there is an expansion tank. It compensates for water hammer if the pump is nearby. In this case, additional devices may not be needed. You can check the need to install a compensator on a pressure gauge. If the needle does not move or moves only slightly, everything is fine.

In centralized heating systems, water hammer occurs when the damper is suddenly closed, when the taps are quickly opened to fill the system after repair / maintenance. According to the rules, it is necessary to do it slowly and gradually, but in practice it happens differently ...

In the water supply, water hammer occurs even when the tap or other stop valves are suddenly closed. More pronounced "effects" are obtained in airborne systems. When driving, water hits the air locks, which creates additional shock loads. We may hear clicks or crackles while doing this. And if the water supply system is divorced with plastic pipes, during operation, you can see how these pipes are shaken. This is how they react to water hammer. You've probably noticed how the metal braided hose twitches. The reason is the same - pressure surges. Sooner or later, they will lead to the fact that either the pipe will burst at its weakest point, or the connection will leak (which is more likely and more common).

Why hasn't this phenomenon been noted before? Because now most of the taps have a ball valve and the flow closes / opens very abruptly. Previously, the taps were of valve type and the damper was lowered slowly and gradually.

How to deal with water hammer in heating and water supply? You can, of course, teach the inhabitants of an apartment or house not to turn the taps abruptly. But a washing machine or a dishwasher cannot be taught to be careful about pipes.And the circulation pump cannot be slowed down during the start and stop process. Therefore, water hammer compensators are added to the heating or water supply system. They are also called absorbers, shock absorbers.

|

|

|

|

Our company has been actively working on the Moscow construction market for 20 years. The main specialization is design, installation and commissioning of engineering systems of modern energy-rich buildings. These are power supply systems, heating, ventilation, air conditioning (air conditioning), water supply and fire extinguishing systems, sewerage systems, as well as a modern heating point, which plays an important role in the effective functioning of all these systems.

A special unit of our company, relying on considerable experience in the field of real construction, carries out complex supplies of equipment for third-party customers with the analysis and adjustment of projects. An example of such work is a complex supply of the largest object of Russian-Belarusian cooperation "Radiological Dispensary" in Gomel (Republic of Belarus).

Over the past decade, there have been fundamental changes in the nomenclature of materials, equipment and technologies used in construction in general, and in the areas of our specialization in particular. The Moscow construction market is full of new advertised equipment and materials, which are very difficult to understand. Our experts will study your task and offer the best solution, both at the level of the project and its specific implementation. We will not keep you waiting, we will not let you spend extra money, and you will not have problems with equipment incompatibility.

We would like to specially highlight our production program. We successfully manufacture and sell two types of installations at our and third-party facilities:

- Pressure boosting stations with frequency control of pump motors rotation speed. In water supply systems with a variable water flow, the station maintains a constant pressure.

- Station for maintaining constant pressure in closed heating and air conditioning systems.

The imported analogs of the equipment we produce are extremely and unreasonably expensive, which is the reason for our activity in this direction. Today we offer the customer development for specific tasks, production in the shortest possible time from imported components, delivery, installation and commissioning of the mentioned stations, as well as warranty and post-warranty service. The price of the product depends on many parameters and wishes of the customer and is communicated by us upon your specific request. We are confident that you will be pleased with our prices and quality.

Alfa Laval heat exchangers, Grundfos pumping equipment, Danfoss automation systems, Broen shut-off and control valves

successfully operates in the Russian market. Here you will find the necessary heating equipment from the world's leading manufacturers used in your heating units. Heat exchangers Alfa Laval (Sweden-Russia), pumps Grundfos (Denmark), shut-off and control valves Broen (Denmark), Zetkama (Poland), Polna (Poland) and much more. We specialize in the sale of exceptionally high-quality equipment, which is why we have products from world-renowned manufacturers: one of the best examples of this is Danfoss automation systems that work reliably and without interruption.

We provide the best equipment because our specialists know a lot about their business: for example, they are well aware of all the properties of Alfa Laval heat exchangers or Grundfos pumps. And they are always ready to share their knowledge and tell you about the optimal choice of the system, about its setup and operation on the basis of Danfoss systems equipment, Broen valves and any other products we offer.Contact for advice and find out which Grundfos pump or Alfa Laval heat exchanger should be purchased in this or that case. Greentek specialists take an individual and attentive approach to each order - this is a guarantee that the right equipment will be chosen correctly.

We guarantee objective, competitive prices for Alfa Laval heat exchangers, Grundfos pumps and any other equipment

Naturally, the cost of equipment is very important, because in many ways the design depends on how much it costs to buy Danfoss systems, Broen fittings and all equipment in general. Moreover, if the allocated budget is limited, but in this case, the purchase of high-quality Alfa Laval heat exchangers, Grundfos pumps and other devices can be affordable. Contact Greentek - with us, the purchase of Danfoss or Broen products will take place in the shortest possible time and on the terms available to you.

- After all, we offer all the equipment at an objectively formed cost - look at the catalog and you will be convinced that the Alfa Laval heat exchanger or the Grundfos pump can be purchased at the manufacturer's price list.

- In addition, we offer the most economical options for equipping the premises - Greentek specialists are ready to advise the optimal configuration of Danfoss automation systems or Broen valves, taking into account what budget needs to be met.

In a word, the purchase will take into account the interests of the customer as much as possible - contact us and be prepared for the fact that you will be pleasantly surprised by the final price of Alfa Laval heat exchangers, Grundfos pumps and other equipment.

Related services for the purchase of Danfoss and Broen

We not only sell high-quality equipment at fair prices, but also provide assistance at all stages of its acquisition. The optimal choice of equipment, delivery in the shortest possible time and shipment from a warehouse in Moscow - by contacting Greentek, you can count on the following related services:

- Design - every single Alfa Laval heat exchanger or, for example, a Grundfos pump will be allocated the optimal place, taking into account all the characteristics of your room.

- Delivery to the site - the ordered Danfoss automation system, Broen fittings and any other equipment purchased from Greentek will be delivered in a short time. Our warehouse is located on the Moscow Ring Road, so it won't be difficult for us to get anywhere in the capital.

- Installation and commissioning - we will install an Alfa Laval heat exchanger, a Grundfos pump and any other system we offer. The help of qualified Greentek specialists is a guarantee that you will not have any problems using products from Danfoss, Broen and other brands.

We can guarantee an individual approach, qualified consulting and service assistance, a flexible system of discounts to end consumers. Whatever product you need, be it an Alfa Laval heat exchanger, a Grundfos pump, a Danfoss automation system or Broen fittings, it can be easily found at Greentek.

What is a water hammer compensator: types, design, principle of operation

There are two types of water hammer compensators: diaphragm and spring-loaded valve. They perform the same function: they take in excess fluid, thereby reducing the load on other elements of the system. Since these devices are small in size, they protect those devices that are located in the immediate vicinity.

How the membrane expansion joint works and works

A membrane hydraulic shock absorber is a container that is divided into two parts by an elastic membrane. One of the parts is filled with air, the other is normally empty. The air in the filled part is pumped under a certain pressure. For checking / pumping up pressure in this part of the body there is a spool (nipple). The products are supplied from the factory with an initial pressure of 3 bar.This is the “standard” value for most heating systems in single-storey private houses. If the pressure needs to be changed, a pump is connected to the nipple and brought to the required value. This value is 20-30% higher than the worker in a particular system. But it should be well below the performance limit of the compensator itself.

As long as the pressure in the system does not exceed the pressure in this part of the reservoir, nothing happens. When a water hammer occurs, the membrane stretches under the influence of the increased pressure, part of the liquid enters the reservoir. As it normalizes, the elastic membrane tends to return to its normal state, pushing fluid back into the system. Thus, the jump is smoothed out.

Features of the spring water hammer damper

The second type of water hammer compensators works on the same principle: liquid is passed into the body when the pressure rises. But the access to the container is blocked by a plastic disc, which is supported by a spring. The pressure at which the liquid begins to flow inward depends on the spring force. There is no way to regulate it (in any case, so far no regulated models have come across), so you have to select a device with suitable parameters.

Related article: Connecting to the water supply of a private house

The principle of operation of this damper is similar to that described above. As long as the pressure in the system is normal, the spring presses the disc against the body. When a water hammer occurs, it is compressed, water enters the body. As the pressure decreases, it becomes less than the spring force. It gradually expands, returning fluid to the pipeline.

As you can see, both devices work in a similar way. Spring models are considered to be more reliable, since the working elements in them are less susceptible to wear (metal spring and durable plastic). But membranes are also made of materials that do not lose their elasticity for a long time. An additional plus is the ability to set the pressure at which the membrane will begin to stretch. But the disadvantage can be considered the need to regularly check the pressure and, if necessary, pumping.

Ways to prevent water hammer

Below are several methods aimed at reducing the force of a water hammer or neutralizing it.

Smooth overlap

Special standards for the operation of a water utility and heating systems describe their correct switching on and off - it should be smooth. These rules, although developed for heat and water suppliers, also apply to people using autonomous circuits. The essence of this method of protection is that the water hammer is "stretched" over time, reducing its strength. A smooth decrease in pressure, volume and velocity, and the same increase in them, helps to protect the pipeline from damage.

System modernization

The first way to avoid water hammer is to install shock-absorbing devices directed in the direction of fluid movement.

In simple terms, this is the replacement of the pipe in front of the thermostat with the same product made of a softer material: heat-resistant reinforced rubber or elastic plastic. A characteristic such as elasticity will help to spontaneously reduce the force of the water hammer at the point at which the pressure is at its maximum value. Basically, a segment of 20-30 cm is enough for such manipulation, but you can take more.

The second way is to add a shunt with a maximum clearance of 0.4 mm to the thermostatic valve.

On the side from which the liquid enters the thermostat, it is necessary to place a tube with a cross section of 0.2-0.4 mm. This clever move allows you to reduce the pressure at the moment of its critical value, while the functionality of the entire system will not suffer. This work should be done by a person who thoroughly knows the design of the thermostat.

Shunting to protect the water supply from water hammer can be used in autonomous networks, made not so long ago and from high-quality materials, since rust and other debris will quickly clog a small hole.

Mounting the thermostat with protection

These devices have spring mechanisms located between the thermal head and the valve. When the pressure rises, the spring prevents the valve from closing, and when it decreases, it allows it to spontaneously lower. The installation of such thermostats should be carried out strictly in the direction indicated on the body. Be careful, as not all thermostat models are equipped with this protection.

Automation

There are special pumps, in which smooth opening and closing of engineering systems is performed automatically. A correctly programmed device is able to independently track changes in the water supply and regulate them.

So we considered several ways to protect our water supply system from unwanted influences. By using one method or another, you will prevent future accidents.

Where and how to install: installation recommendations

The water hammer compensator is small in size, only a small amount of water can fit in the body (less than 200 ml usually). It is installed in the immediate vicinity of the source of the appearance of a water hammer: a ball valve, a water comb, on a hose to a washing machine or dishwasher, after a circulation pump, on a comb for underfloor heating.

You can fix it in any position: up, down, to the side. For membrane models, it is only important that there is free access to the nipple. Regardless of the design, it is not recommended to install the device on long branches from the line. The supply pipe section should be as short as possible.

When choosing, pay attention to the maximum working and compensated pressure. The second point is the connection diameter. Usually it is 1/2 ", but there are also 3/4 and" inches.

When connecting a washing machine and / or dishwasher, a tee is installed on the hose. One free outlet of the tee goes to the machine, the second is equipped with a water hammer compensator.

Other ways to deal with water hammer

One of the possible options for neutralizing the water hammer has already been announced - to close the taps smoothly. But this is not a panacea, and it is inconvenient in our fast-paced times. And there are also household appliances, you cannot teach them. Although, some manufacturers take this point into account, and the latest models are made with a valve that smoothly shuts off the water. That is why expansion joints and neutralizers are becoming so popular.

You can fight water hammer using other methods:

- When installing or reconstructing water supply or heating, insert a piece of elastic pipe in front of the source of the water hammer. It is reinforced with heat-resistant rubber or PPS plastic. The length of the elastic insert is 20-40 cm. The longer the tube, the longer the insert.

- Purchase of household appliances and valves with smooth valve travel. When it comes to heating, problems with a warm water floor are often observed. Not all servos run smoothly when closing the flow. The way out is to install thermostats / thermostats with a smooth piston stroke.

- Use pumps with soft start and stop.

Water hammer is a really dangerous thing for a closed system. He breaks radiators, breaks pipes. To avoid problems, it is better to think over the control measures in advance. If everything is already working, but problems have appeared, it is wiser and easier to install expansion joints. Yes, they are not cheap, but repairs will cost more.

Manufacturers, characteristics, prices

It is best to buy a water hammer compensator from well-known companies. This is not the area where it is appropriate to save. The most popular are several companies:

- FAR. The compensator of this company is without a diaphragm, with a spring and a shut-off disc. Connecting thread 1/2 ", maximum pressure 50 bar, nominal - 10 bar.Temperature resistant up to 100 ° C. Price from $ 30.

- Uni Fitt. Same design with spring loaded disc. There are two body options: brass and brass with nickel plating. 1/2 inch connection. Maximum temperature 90 ° C, nominal pressure 10 bar, peak pressure 20 bar. The length of the protected pipeline is 10 m. The price is from 15 $.

There are other firms, but they are not as popular. some are overpriced, others have not won credibility. For now, anyway.

What is water hammer and why are they afraid of it

Water hammer is a sharp and very strong pressure surge in pipes. Able to break the joints and pipes themselves, rip valves and cause a flood. Small water hammers act gradually, over and over again squeezing out the gaskets, slowly but surely deforming and destroying the water supply and heating pipes with microtraumas.

Pressure, as one of the parameters of the heating and water supply system, plays a key role. It is due to the pressure difference that the fluid flow is formed. Modern heating systems use hydraulic pumps. The flow rate, head and volume depend on the pressure indicator. In open systems, which were commonly used in the past, the fluid pressure was equal to atmospheric pressure, so an increase in the temperature of the carrier was accompanied by a fluid overflow into the expansion tank.

The disadvantage of such a system was the gradual evaporation of the liquid, the impossibility of raising the boiling point, and the lack of protection from hydraulic shocks.

The liquid is practically not compressed. When the layers are compressed, elastic forces of large magnitude arise, which can be transmitted at high speed in the medium. A sharp change in pressure in one part of the apartment line could lead to the destruction of pipeline elements in another part.

Opening the tap or any valve can provoke a water hammer. A striking example is the destruction of a newly laid line at its first start, when the water supply opens with the valves of the mixers closed.

What is water hammer

Water hammer is a short-term pressure surge in a system filled with liquid. A similar phenomenon occurs if the fluid flow unexpectedly collides with an obstacle that appears in its path. This happens when, for example, a shut-off valve is suddenly closed, or the pressure pump suddenly stops.

After a collision with an obstacle, the water flow continues the inertial flow at the same speed, however, new flow layers are injected, compacting the layers that have already collided with the obstacle. This rapidly increases the pressure in the pipes, which expand and can break at any time. The occurrence of a problem may be preceded by extraneous noises, clicks and knocks in the pipes, as well as a characteristic hum.

If the pipe still bursts, an extremely dangerous emergency situation is created, from which the following may suffer:

- equipment (pipelines and heating devices);

- property (the room is flooded, furniture and other things deteriorate);

- people in the apartment (a break in the heat supply system threatens with serious thermal burns).

Closed heating system

If the pipeline is made sealed, then when the liquid heats up, pressure will rise sharply, which can cause pipes or connections to begin to collapse. However, pressures above atmospheric pressure provide many advantages.

- As you know, the boiling point rises, therefore, the support can be used more efficiently.

- Increased pressure increases the efficiency of the hydraulic pump.

- The sealed system does not need periodic recharge.

The pressure regulator in a closed system combines the functions of a diaphragm expansion joint and an expander. It is a container divided into two parts by an elastic partition.

In one part, there is air under pressure, and the other part is connected to the line. During thermal expansion, the liquid presses on the membrane, as a result of which it sags into the area filled with air. With a decrease in air volume, its pressure increases and begins to compensate for the excess fluid pressure.

When the apartment heating system is in working order, the membrane expansion joint is in dynamic equilibrium. Each increase in fluid side pressure is accompanied by an increase in air pressure. But it turns out that such a system is not only capable of damping thermal expansion, but also works as a water hammer damper.

Types of expansion joints for pipelines

In modern practice, 4 types have gained popularity expansion joints for pipelines:

- stuffing box;

- bellows;

- lens;

- anti-vibration.

The selection of the model is carried out depending on the characteristics of the system, pipe materials, equipment features. In our catalog, the class of devices is widely represented, which will allow you to easily choose the right equipment for compensation.

Stuffing box

One of the first types of equipment - stuffing box expansion joint for the pipeline. Its use is possible with the following network characteristics:

- medium - water, steam;

- pressure - no more than 25 kgf / sq. cm (2.5MPa);

- temperature - up to 200 (water) or 300 degrees above zero (steam).

To the pluses of the stuffing box expansion joint for pipes include high compensation ability and durability. Disadvantages of the stuffing box type: expensive maintenance, complicated repairs, requirements for the qualifications of employees involved in servicing the stuffing box device, and low efficiency in preventing leaks. The stuffing box equipment is not designed for angular stresses. This significantly limits the scope of its application (according to the project plans for the pipe route).

Bellows

Bellows expansion joint is devoid of the shortcomings of the stuffing box, and therefore is very popular in critical industries (petrochemical and chemical industry, oil refining, gas industry, energy). The use of a bellows device provides compensation for:

- defects due to temperature changes;

- misalignment of pipelines;

- a wide range of vibrations.

The advantages of a bellows expansion joint for pipelines are practicality, reliability, compact size, high compensation ability. This type is designed for serious loads and can be used in pipeline systems with complex layouts (including those with the location of pipes in hard-to-reach areas). With the right choice, you can add here the simplicity and speed of installing bellows types of equipment

Lens

Lens types of compensators for piping are used in systems with relatively high pressure levels. Can be performed with 1–4 lenses. Their application gives:

- compensation for expansion due to temperature rises;

- stiffening pipes;

- equalization of pressure in boilers.

Pros: high strength, ability to withstand significant stresses (including axial and angular). There are also disadvantages: low self-compensation ability, complex design with a large number of welded joints and (as a result) low reliability in comparison with bellows analogs.

Anti-vibration

Anti-vibration compensators or flexible expansion joints restrain expansion and elongation of pipes, prevent the development of corrosion (electrolytic) and reduce the force of water hammer. Application - to compensate for vibrations and reduce the noise level of the pipeline. Pros - efficiency and affordable price. Minus - limited scope.

Diaphragm expansion joint device

In the market of building materials and parts for heating systems, the expansion tank is known as a membrane hydraulic shock absorber. It can be installed not only in the heating system, but also in the water supply system. The main purpose of the tank is to unload the system in the event of an increase in pressure.

The diaphragm, made of elastic material, is a pressure regulator. The shape of the tank is not subject to standardization. The choice of external form depends solely on the conditions of the surrounding space and aesthetics. The most common expansion joints are in the form of a cylindrical balloon.

The half of the tank where the air is located has an outlet with a spool. Through it, you can add or reduce the amount of air in the tank. When buying a membrane expansion joint, the air is under pressure equal to tenths of atmospheric pressure. During commissioning, this pressure increases according to the performance of the system. The compensator has only one connecting pipe, because there is no through flow of liquid.

Water hammer is a big danger for water supply and heating systems

- Photo: Water hammer - a great danger to water supply and heating systems

Within the limits of an apartment and a private house, extraneous knocks and sounds similar to them are often heard, which come from the water supply or heating system. Most people believe that this is a temporary nuisance and this is facilitated by a foreign object accidentally trapped in the pipes. But most often the water hammer is the culprit. It can cause serious damage to plumbing equipment and cause cracks in the piping.

What is a water hammer in a heating system? A sudden pressure drop in a pipeline system is called water hammer. It occurs as a result of a lightning-fast change in the speed of the water. Usually, the coolant or cold water begins to be supplied with a high pressure, and the pipes, expanding, emit a kind of rattle.

Depending on the direction of the jump, water hammer is divided into two types:

- Negative

... Occurs as a result of a drop in pressure. It can be the result of opening a special damper or turning off the pump. - Positive

... Appears after turning on the pump or abruptly shutting off the pipeline.

The last variant of water hammer in the water supply and heating system is the most dangerous. It can damage pipes, create cracks on their surface and disrupt the operation of equipment (heat exchanger or pump). This primarily applies to pipelines that have a small pipe diameter (4-102 mm) and are used for long wiring. At shorter pipe lengths, water hammer in the heating system is practically not noticeable. To prevent this phenomenon, some plumbers immediately advise installing expansion joints or buying pipes made of elastic materials.

Reasons for the formation of a water hammer These include the following factors:

- Breakdown or unplanned shutdown of the pump;

- Abrupt closing of stopcocks;

- The system was not vented before starting the water. For these purposes, special cranes must be provided.

Most often, the causes of a water hammer in the water supply system are reduced to a sharp closure of taps. In the past, the mixers were only of the screw type, and when they were opened and closed, the water smoothly flowed into the apartments. With the advent of more convenient ball valves, the picture has changed for the worse - the likelihood of an increase in the critical pressure limits in the pipeline has increased.

Varieties

There are several types of device classifications in force. The most practical is the grouping according to the types of membranes used. Today, almost all devices are manufactured with a diaphragm membrane. Non-separable cylinder made of durable steel. Usually consists of two hemispheres, welded together.The membrane is mounted in such a way that the reservoir cavity is divided into two parts. The connecting pipe remains in one part and the spool in the other.

The balloon membrane must be replaced. But modern materials are able to withstand increased loads for quite a long time without loss of integrity and elasticity, so the need to replace the membrane has practically disappeared. The reservoir for the balloon membrane is collapsible. The water is in the rubber chamber and does not come into contact with the inner walls of the tank. The spherical membrane is practically not used today, it is considered a rarity.

Classification

Compensating parts are classified according to various factors and factors. They can all be divided into two large groups:

- natural - shock-absorbing products;

- parts made of elastic materials.

Products of the first group may differ from each other in shape, purpose:

- U-shaped - used for the installation of cold water supply pipelines (liquid temperature up to 50 degrees).

- L-shaped - designed for installation in pipe bends.

- Annular - this shape provides a high rate of compensation for the thermal expansion of polypropylene.

- Z-shaped - used when installing additional circuits to the main pipeline.

The second group of high-tech parts is divided into several subgroups:

- Stuffing boxes - are installed on systems in which the temperature of the liquid changes very often. If the product has a movable glass, they can work in two directions.

- Bellows - installed on heating systems, pipelines for hot and cold water supply. Reliably protect the pipeline from water hammer, vibration, thermal expansion.

- Lens - suitable for household pipelines operating with cold, hot water.

- Flanged - made of sanitary rubber. They are installed on highways, in which water hammer often occurs.

Bellows expansion joints are divided into several more subgroups:

- Shear - parts that consist of two working elements. Made of stainless steel. They do not allow the occurrence of deformations on polypropylene pipes in two directions.

- Universal - used to compensate for any type of deformation. The stroke of the working elements is angular, transverse, axial.

Bellows devices not only compensate for thermal expansion, but also dampen vortex flows that form in the pipeline.

Installation rules

If earlier certain installation requirements were imposed on the expansion tank, then in a closed system the compensator can be installed anywhere. However, this is only a theoretical assumption. The requirements for location at the highest point are no longer relevant, since, according to Pascal's law, the pressure is the same everywhere.

The compensator is mounted where there are plumbing units, inputs or interconnections.

- On the one hand, this is due to the fact that nodes are a frequent cause of water hammer, therefore, it is more expedient to install a device that extinguishes excess pressure in the immediate vicinity of taps and valves.

- On the other hand, aesthetics play a significant role here. Against the background of straight pipes, neatly laid around the perimeter of the room, the balloon will not look well.

An important condition for installation is the absence of a long or curved outlet to the cylinder. Since water does not circulate in the outlet, this can lead to stagnation and, as a result, to the multiplication of microbes. Bends should be short and straight.

From these considerations, it is worth choosing the place of localization of the compensator.