The organization of water supply in a private house has reached full automation. The minimum set of equipment and the competent use of the laws of physics - and suburban housing is already in no way inferior to the comfort of a city apartment.

Even the conventional expansion tank for water supply has been improved in such a way as to minimize user involvement in the water supply process.

- Setting the tank pressure in the water supply system

Hydraulic tanks connection diagrams

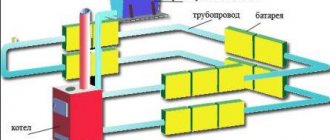

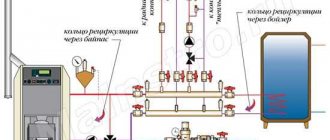

For a hot water supply system, the expansion tank is installed in the section of the circulation line, the suction line of the pump, closer to the water heater.

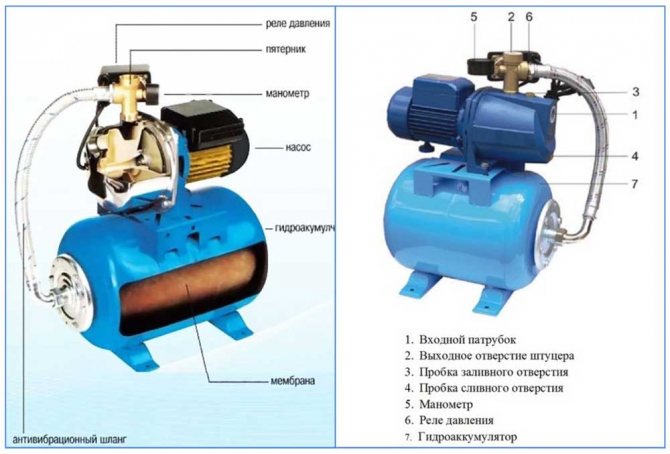

The tank is equipped with:

- pressure gauge, safety valve, air vent - safety group;

- shut-off valve with a device that prevents accidental overlap.

In a plumbing system where water heating equipment is present, the device takes over the functions of an expansion tank.

Installation diagram in the GW system: 1 - hydraulic tank; 2 - safety valve; 3 - pumping equipment; 4 - filtration element; 5 - check valve; 6 - shut-off valve

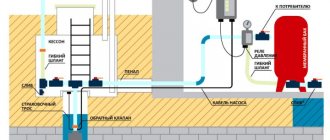

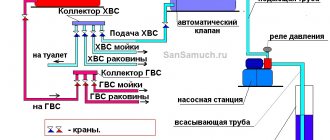

In the XB system, the main rule when installing a hydraulic accumulator is installation at the beginning of the piping, closer to the pump.

The connection diagram must contain:

- non-return and shut-off valve;

- security group.

Connection diagrams can be very different. The connected hydraulic tank normalizes the operation of the equipment, reducing the number of pump starts per unit of time and thereby extending its service life.

Installation diagram in the cold water system with a well: 1 - tank; 2 - check valve; 3 - shut-off valve; 4 - pressure control relay; 5 - pumping equipment control device; 6 - security group

In the scheme with a booster pumping station, one of the pumps runs constantly. Such a system is installed for houses or buildings with high water consumption. The hydraulic tank here serves to neutralize pressure surges, and a container of as large a volume as possible is installed to accumulate water.

Features of adjusting the accumulator

Expansion tanks for water supply are sold with the manufacturer's standard settings - often the pressure in the air compartment is already set at 1.5 bar. The permissible pressure is always indicated on the label and the manufacturer does not recommend deviating from the specified parameters, especially in the direction of increasing it.

Before proceeding with the adjustment, the system is disconnected from the mains and the shut-off valves are closed. The membrane tank is completely emptied by draining the water - an accurate pressure reading can only be measured when the water compartment is empty.

Further, the pressure readings are taken using an accurate pressure gauge. To do this, remove the decorative cap from the spool and bring the device. If the pressure differs from the required one, then it is adjusted by pumping or bleeding off excess air.

Considering that the manufacturer is against deviations from the recommended pressure indicators, it is necessary at the design stage to select suitable equipment, the parameters of which will not conflict with each other.

When adjusting the pressure in the gas compartment of the tank, the manufacturer fills it with an inert gas, for example, dried nitrogen. This prevents corrosion of the inner surface. Therefore, users are also advised to use technical nitrogen to increase the pressure.

Setting the tank pressure in the water supply system

The pressure in the closed tank is always set slightly lower (by 10%) than the pressure level when the pump is started. By adjusting the pressure in the device, you can adjust the water pressure. The lower the gas pressure in the hydraulic tank (but not less than 1 bar), the more it will hold water.

At the same time, the pressure will become uneven - strong when the tank is full and increasingly weaker when it is empty. To ensure a strong and even flow of water, the pressure in the chamber with air or gas is set within 1.5 bar.

The water pressure in the water supply system is set using a relay. When setting the pressure in the expansion chamber, these values must be taken into account

Adjustment of the hydraulic tank in the piping of the water heater

The expansion tank, which is used for hot water supply, should initially be free of water. The pressure in the device is set at an indicator that is 0.2 more than the upper threshold for turning off the pump.

For example, if the relay is set to shut off the equipment at a pressure of 4 bar, the pressure in the gas compartment of the expansion vessel should be set at 4.2 bar.

Installed in the piping of the water heater, the tank does not serve to maintain pressure. It is designed to compensate for expansion when the water is heated. If you set the pressure in it to a lower value, then there will always be water in the tank.

The role of the expansion tank

- The expansion tank helps create in the water supply system enough stable working pressure, at which the optimal water pressure will be maintained both for the operation of all plumbing fixtures (water heater, washing machine, flush cistern), and for comfortable use of tap water. The indicators of the required pressure in the air chamber of the accumulator are calculated for each of the autonomous water supply systems according to certain algorithms.

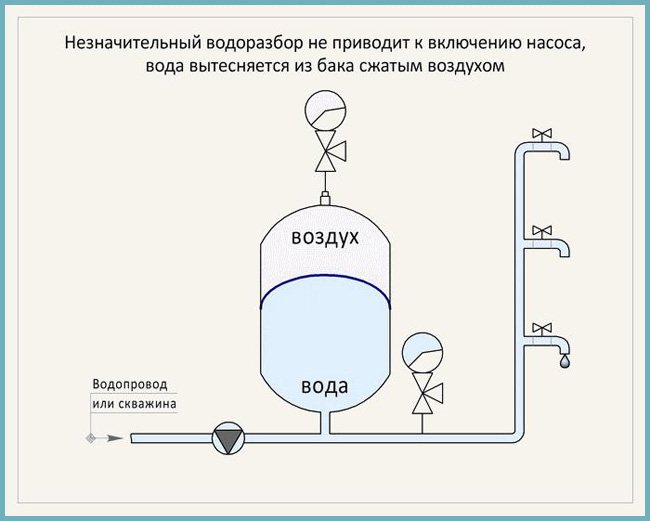

- Creates a supply of water and maintains a stable pressure in the water supply for a certain period of time. There are frequent power outages: in this case, the pump stops working and then the accumulator acts as an emergency reservoir, from which water will flow for some time under pressure. In order to increase the supply of water in the house, you can additionally connect another expansion tank without dismantling and replacing the already installed one.

- Optimizes pump function: reduces the number of times it is turned on. The larger the volume of the accumulator and the higher the maximum preset pressure threshold in the tank, the less often the pumping equipment will operate. Thus, its wear rate will be significantly reduced.

- Plays the role of a water hammer damper... At any start of the pump, there is always a sharp jump in pressure in the water supply system - sometimes it reaches ten atmospheres. The result of such a sharp drop can be a rupture of pipes and fittings, valves; connected plumbing equipment and instrumentation may fail. In this case, the expansion tank takes the shock load on itself: it dampens the wave force - and the system is safe.

In cases where there are risks of exceeding the design pressure with a water hammer of 20 bar (maximum allowable value), it is necessary to install the pipeline in such a way that a separate damper tank can be installed in some of its sections for reliable protection against water hammer.

So, the expansion tank (accumulator) in the water supply system protects it from water hammer, ensures the correct operation of all equipment and household appliances connected to the water supply system, and creates a reserve supply of water.

Hydraulic tank maintenance rules

Routine inspection of the expansion tank is to check the pressure in the gas compartment. It is also necessary to inspect the valves, valves, air vent, check the operation of the pressure gauge and water pressure switch. To ensure the integrity of the tank, an external inspection is carried out.

During preventive maintenance, the pressure in the hydraulic tank should be measured and corrected if necessary.

Despite the simplicity of the device, expansion tanks for water supply still do not last forever and can break. Typical reasons are diaphragm rupture or air loss through the nipple. Signs of breakdowns can be determined by the frequent operation of the pump, the appearance of noise in the water supply system. Understanding how the accumulator works is the first step to proper maintenance and troubleshooting.

We offer:

- - replace the hydraulic accumulator assembly 24 liters 4000 rubles

- - replace the hydraulic accumulator assembly 50 liters 6,000 rubles

- - replace the hydraulic accumulator assembly 80 liters 8000 rubles

- - replace the hydraulic accumulator assembly 100 liters 8800 rubles

- - replace the hydraulic accumulator assembly 150 liters 12,500 rubles

- - replace the hydraulic accumulator assembly 200 liters 18,500 rubles

Our proposals take into account the use of original tanks and membranes AQUASYSTEM (Aquasystem).

We will also service hydroaccumulators REFLEX, VAREM, WESTER, Jileks or replace it with a new one.

House heating:

- Water supply pump repair The pumping equipment system is the heart of your home's engineering system. And if some of its elements start to work incorrectly or fail, then life in the house stops. Water no longer flows from the taps, the sewerage ceases to function, and heating interruptions are possible. Note that if you do not carry out regular maintenance, the most frequent failures are: [...] ...

- Water supply pressure gauge maintenance ...

- Replacing the water expansion tank A drop in pressure in the heating system may indicate a problem. In such cases, even with an increase in power, normal operation of the device cannot be achieved in such situations. If the equipment does not maintain the pressure in the heating system, the expansion tank must be replaced. There is a possibility of rupture of the tank membrane. In the cold season, it is necessary to act as quickly as possible, when the equipment comes out [...] ...

- Water supply expansion tank maintenance ...

- Replacing the water supply accumulator A well-designed and properly installed water supply system can operate smoothly for years, much depends on the correct choice of components. This review will focus on hydraulic accumulators, their principle of operation, installation options, repair and maintenance. Why does a pumping station need a hydraulic accumulator The main function of a pumping station is to continuously supply the consumer with water, while ensuring the required operating pressure range both for the points of water intake and for operation [...] ...

- Maintenance of a water supply accumulator Many people mistakenly think that the main task of a hydraulic accumulator is to serve as a storage tank. In fact, it is too "expensive" device for simple water storage. The task of the accumulator is to maintain a constant water pressure in the system within the limits of the pressure switch adjustment, as well as to eliminate water hammer in the water supply system. To cope with these tasks, the hydraulic tank is helped by a rubber bulb located inside [...] ...

- Maintenance of water supply automation During operation, water supply systems can become clogged, lose their tightness and no longer function properly. To restore the previous efficiency, it is necessary to carry out the appropriate service, which implies the following works: Cleaning the caisson from debris and dirt Visual inspection of the equipment Checking the operation and adjusting the automation Contac pulling Checking the pressure in the expansion tank Our experts when performing [...] ...

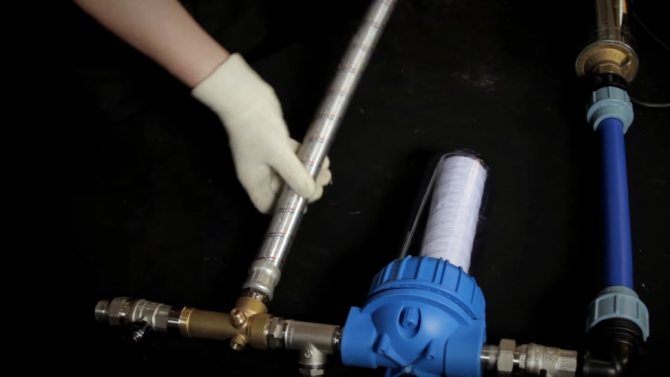

- Replacement of water supply filters Our company sells and installs branded water purification equipment for private houses and individual city apartments. The list of services includes maintenance of ATOLL and ANGSTRA water purification systems. The service contract is concluded even if the installation of the equipment was carried out by specialists from other companies. Conclusion of a service agreement allows: not to worry about [...] ...

- Service of water supply filters We will perform service of water purification systems of any complexity, installed both by our masters and by any other company. Scheduled maintenance will prevent malfunctions in the operation of complex technical units, will allow timely replacement of worn-out mechanical parts of the system. List of works: Checking the performance of filters: iron remover, softener, coal, sedimentary and aeration complex; Setting or changing the automatic filter program [...] ...

- Replacement of water supply pressure switch Production, repair, maintenance of wells is the work of professionals. Even a skilled electrician is not able to perform all types of electrical work on a well pump! An artesian well can perfectly solve the problem of independence from centralized water supply. Its owner will have his own source of high-quality deep water all year round. A well is a complex technical structure. In its composition, it contains pumping equipment operating from [...] ...

- Maintenance of the water supply pressure switch The pressure switch is responsible for the correct operation of the borehole pump. As a rule, it is installed on the accumulator or directly on the pipeline, but at a distance of no more than 3 meters from the accumulator. It is the pressure switch that gives the command to turn the pump on and off. Very often the relay fails due to burning of the contacts. This occurs when the power supply to the pump [...] ...

- Maintenance of water supply systems Water supply is one of the main engineering systems of a country house. The system includes pipelines and various equipment, including water treatment and water treatment. The main conditions for the reliable operation of the system, as well as the compliance of water with sanitary standards, is the timely service of the water supply. Before listing the main work performed during maintenance, we will give a short list of equipment and communications [...] ...

- The main functions of automation units for pumps A large number of suburban areas are equipped with wells and wells. Owners strive to have an autonomous water source. More often it is a technical resource that is used for irrigation. But also as drinking water such water is used quite actively. In terms of chemical composition, it can significantly surpass tap water, especially if the intake is carried out from a great depth. In order for the process to be optimal in [...] ...

- Types of protective automatics for a borehole pump When choosing an automation unit for a borehole pump, you should pay attention to the voltage indicator recommended for the normal operation of the latter, and to the permissible deviations. To protect the device from running out of water, a U-shaped relay must be installed.This element will turn off the pump if no water is supplied to it. Modern manufacturers offer several types of protective mechanisms to ensure the safe operation of pumps: starting protection, [...] ...

- Maintenance of water supply shut-off valves ...

- Replacement of water supply shut-off valves ...

- Repair of the water supply pressure switch After connecting the pressure switch. it may need to be adjusted - adjust the on and off pressures. By default, it has factory settings, you can clarify them in the passport of the device, usually they are set like this: turning on the pump at a pressure below 1.4-1.8 bar and turning it off at a pressure above 2.5-3 bar. To adjust the pressure switch, you first need to know [...] ...

- Repair of water supply filters Any mechanical equipment requires maintenance. Water treatment equipment is no exception! Here are a few answers why it is required to carry out maintenance of water treatment: - control and maintenance of equipment in working condition; - verification of water indicators by express analysis at the outlet of the installation; - replacement of consumable components. Here are some examples of installation before performing preventive maintenance and after work: Basic list of works for the service of water treatment: [...] ...

- Repair of water supply automation As is known through practice, the main reasons for the failure of a deep ECV pump is long-term operation in the "dry" mode. This term means that the ECV pump worked without water, which leads to breakdown. This reason is more common than unstable energy saving or poor maintenance, and as a result, the repair of a borehole pump will be much more difficult. In principle, a dry run will bring [...] ...

- Repair of water supply equipment In order for water supply systems to work effectively, providing access to hot and cold water, it is necessary to periodically diagnose and repair them. If you neglect preventive work, then shut-off valves, pipes and couplings at the joints may become unusable. This is due to metal corrosion - the threads at the joints are oxidized, rendering individual parts of the system unusable. Holding company [...] ...

- Repair of a water supply accumulator Autonomous water supply, which is based on a pump that pumps liquid from a well or well, in some suburban settlements is the only way to provide a private house with water. It works as needed to use water: opening the tap, turning on the pumping device, the flow of liquid. In order to reduce the number of switching on and off of the pumping unit, which reduce its operational resource, a hydraulic accumulator is mounted in the water supply network. [...] ...

- Repair of water supply shut-off valves Shut-off valves are an essential element of any pipeline. It does not matter whether it is a household water supply system or an industrial pipeline for pumping technical liquids, a malfunction of such a device can lead to emergencies with sad consequences. That is why it is necessary to carry out preventive maintenance and repair of valves, without waiting for the appearance of emergency leaks. TYPES OF SHUT-OFF VALVES To be precise, [...] ...

- Repair of a water supply water heater Hot water in a house or apartment is the norm for a modern person, so everyone strives to provide himself with it. If connection to the central water supply for hot water supply is not possible, then water heaters are used. Different models solve this problem in different ways. To meet everyday needs, instantaneous gas or electric water heaters are very popular, which are economical and [...] ...

- Water supply boiler repair Many modern people cannot imagine their life without water heaters. Often, devices serve their owners for quite a long time, but sooner or later they fail. The simplest, but most expensive, repair method is to call the master. Alternatively, you can repair the boiler yourself. The procedure is not particularly difficult, you just need to understand the device [...] ...

- Water supply water heater flushing ...

- Replacing the water heater ...

- Water boiler maintenance ...

- Replacing the water heater ...

- Water supply water heater maintenance ...

- Automatic control system for a submersible pump The automatic control system that regulates the operation of the pump consists of several elements. The main one is the control relay, which is supplemented by the electrical part. Depending on the features of the configuration, two principles of device operation are distinguished. Regulation of water pressure in the pipeline. It works when water is supplied from a well and the system has a hydraulic tank. After the first ascent, it fills the container, then it is fed into the system [...] ...

Previous post Repair of a water supply accumulator

Next post Repair of water supply pressure gauge

Open type hydraulic tank installation

An open-type device is used less and less, since it requires constant user intervention in its work. An open expansion tank is a leaky container that serves to build pressure in the water supply system, accumulate water, and also serves as an expansion chamber.

Connect to the tank: a drain valve, branch pipes for recirculation and supply pipes, control and overflow pipes

The tank is installed above the uppermost plumbing point, for example, in the attic, water enters the system by gravity. Each meter the device rises increases the pressure in the water supply by 0.1 atmospheres.

To automate the process of providing water, the tank is equipped with a float switch and an automatic relay is installed that will turn on and off the pump.

The container is mounted in a frost-free room, covered with a lid from dust and debris, the walls are wrapped with mineral wool or other insulation

This method of organizing water supply requires regular monitoring by the user, otherwise the water at negative temperatures may freeze (if the room is not heated). The liquid will evaporate, so you will have to constantly top up.

In addition, such a container is bulky and not aesthetically pleasing, for it you must definitely have an attic room in the house. But the main drawback of the device is that the tank is not adapted to work under conditions of high water pressure in the system.

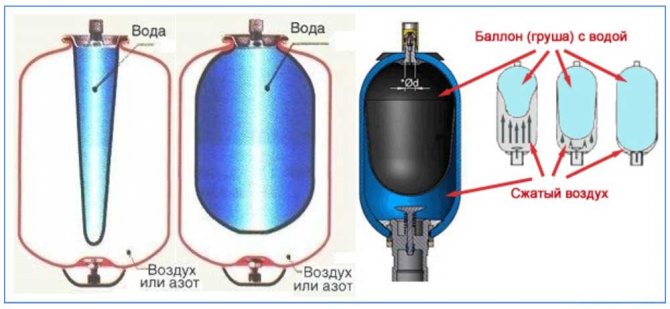

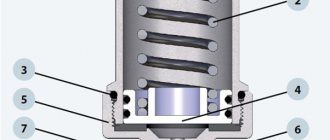

Functions and working principle

The diaphragm tank is a sealed, predominantly metal tank, consisting of two separated chambers: air and water. A special rubber membrane acts as a separator - as a rule, it is made of strong butyl, which is resistant to the development of bacterial microorganisms. The water chamber is equipped with a pipe through which water is supplied directly.

The main task of the expansion membrane tank is to accumulate a certain volume of water and supply it at the user's request under the required pressure. But the functions of the device are not limited to this - it also:

- protects the pump from premature deformation: thanks to the water reservoir, the pump does not turn on every time the tap is opened, but only when the tank is empty;

- protects against water pressure drops when using several taps in parallel;

- protects against water hammer that can potentially occur when the pumping unit is turned on.

Operation of the device

The principle of operation of the tank is as follows. When the pump turns on, water begins to be pumped into the water chamber under pressure, and the volume of the air chamber decreases at this time. When the pressure reaches the maximum allowable mark, the pump turns off and the water supply stops. Then, as water is taken from the tank, the pressure decreases and when it decreases to the minimum allowable mark, the pump turns on again and resumes pumping water.

Advice. During the operation of the tank, air can accumulate in the water chamber, which provokes a decrease in the efficiency of the equipment, therefore, at least once every 3 months, the compartment must be serviced - to bleed excess air from it.

Conclusions and useful video on the topic

Movie # 1. Everything about expansion tanks - classification, purpose, adjustment and signs of problems:

Movie # 2. Incorrect operation of the pumping station is often associated with malfunctions of the accumulator:

Movie # 3. The nuances of choosing hydraulic tanks for water supply:

Even at the planning and development stage of the water supply system, it is necessary to think through all the fundamentally important points and calculate all the parameters. If you are not sure of the infallibility of your calculations and the correct choice of a hydraulic tank for water supply, it is better to contact a specialist.

Most firms that sell professional equipment provide advice or even carry out calculations for free. This will help you avoid mistakes and unnecessary expenses.

We are waiting for your comments with stories about our own experience in using the expansion tank, with questions that arose during the review of the information provided. We are interested in your comments and possible suggestions. You can comment on the material in the block below.

Range of application of the diaphragm tank

The use of an expansion tank is possible not only in the heating system, but also in water supply and water treatment. In this case, hydraulic accumulators, which are water tanks, are used as accumulating liquid in order to supply it under the right pressure at a certain moment. Hydraulic tanks are often used in industrial and agricultural water supply systems.

Expansion tanks can also be used to prevent complete destruction of the system in the event of a water hammer. In addition, they are indispensable when used as a container with water in a fire extinguishing system, as well as in the form of reserve tanks in the event of a power outage.