Home / Gas boilers

Back to

Published: 03/16/2020

Reading time: 6 minutes

0

361

The Italian brand Baxi is very popular in the Russian HVAC market. Gas boilers of this brand are available in several installation options: wall-mounted and floor-standing, as well as single-circuit for heating and additionally double-circuit for hot water supply.

The manufacturer's specialists made sure that the installation and operation processes were as simple and accessible to any user as possible. Therefore, to connect the Baxi boiler to work, the owner does not need to make significant efforts.

- 1 Advantages of Baxi boilers and equipment

- 2 Schemes of piping of heating systems Baxi 2.1 Two-pipe scheme

- 2.2 One-pipe scheme

- 2.3 Combined diagram of the Baksi gas heating system

- 5.1 System clogging and cleaning

Periodicity of coolant replacement

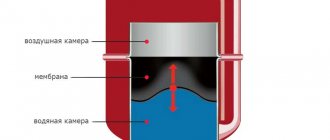

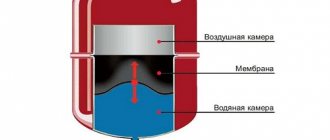

Closed heating system with water connection

During the heating season, even an initially high-quality coolant gradually loses its properties. This is due to a periodic change in its temperature, resulting in precipitation (for water) or a change in the viscosity of the substance (synthetic heat transfer fluids). If you do not fill the heating system with coolant in time, the following negative moments may occur:

- Decrease in efficiency in heating operation. This is a consequence of a decrease in the efficiency of heat transfer due to the presence of third-party elements in the liquid - lime scale and rust.

- The likelihood of failure of the heating boiler, radiators and valves. Only by filling the heating with a coolant can such problems be avoided. This is due to the gradual saturation of water with oxygen, as a result of which foam formation increases and corrosion processes on the inner surface of the steel elements of the system are significantly accelerated.

Timely filling with water of a closed heating system can be different in time. It all depends on the composition of the coolant and the temperature regime of the boiler. For distilled water, the optimum replacement interval is 1 year, i.e. before each heating season. In the case of using heat transfer fluids based on ethylene glycol, propylene glycol or glycerin, the service life is 3 to 7 years. It depends on the concentration of chemical components - the more there are in the total volume, the longer the liquid will serve.

However, before filling a closed heating system with water, you need to decide on the type of coolant - it will be ordinary H2O or improved fluids.

In order to fill or add antifreeze to the heating system of a double-circuit boiler, you need to find out if this can be done. Boiler manufacturers indicate solutions that can be used to fill the heating system.

Drip injection of medicines. Intravenous drip system assembly

Purpose: preparation for the introduction of large amounts of liquid into the patient's bloodstream for therapeutic purposes.

Equipment: sterile tray, sterile cotton balls, ethyl alcohol 70 °, gloves, disposable system for intravenous infusion, solution for intravenous drip infusion, container for waste material, containers with disinfectant solution.

Algorithm of the nurse's actions when filling the system:

- Check the tightness of the packaging bag, the expiration date.

- Read the label of the medicine on the bottle, expiration date, dosage.

- Wash your hands and put on gloves

- Open the packaging bag, take out the system (work on the desktop), put it on the sterilizer lid, on a sterile napkin, on a sterile tray.

- Treat the aluminum cap of the bottle with a cotton ball with alcohol, open the aluminum cap of the bottle with tweezers and treat the rubber stopper of the bottle with a cotton ball with alcohol.

- Rub the rubbing alcohol on your hands.

- Remove the cap from the airway needle (short tube with a filter) and insert it all the way into the rubber stopper of the bottle, fix the free end of the airway on the bottle with a plaster or a pharmacy rubber band at the bottom of the bottle.

- Close the screw clamp, remove the cap from the needle at the short end of the system and insert this needle into the vial stopper.

- Turn the bottle over and secure it to a tripod.

- Turn the dropper to a horizontal position, remove the capped needle at the end of the long system tube and open the clamp, slowly fill the dropper to half the volume.

- Close the clamp and return the dropper to its original position. The filter must be completely submerged in the transfusion liquid.

- Open the clamp, slowly prime the system until the air is completely displaced and drops appear from the connecting cannula in the rubber tube.

- Check for air bubbles in the system - the system is full.

- Place the needle with a cap in a sterile tissue.

- Put five cotton balls in a sterile tray, Prepare two strips of adhesive plaster, tourniquet, pillow, gloves.

Water or heat carrier: choosing the optimal filling of the system

Antifreeze for the heating system

The optimal composition of the liquid should be determined by the parameters of the heating system. The heating system is often filled with water, as it has a number of significant advantages. The determining factor is the affordable cost - they often take simple tap water. However, this is fundamentally wrong. A large number of metal and alkali elements will contribute to the formation of build-up on the inner walls of pipes and radiators. This leads to a decrease in the bore diameter, an increase in hydraulic losses in certain sections of the pipeline.

But how to properly fill a closed heating system with water to avoid such troubles? Experts recommend using distilled water. It is cleaned as much as possible from impurities, which affects for the better its physical and operational properties.

- Energy intensity. Water accumulates heat well in order to subsequently transfer it to the room;

- Minimum viscosity index. This is important for closed heating systems with forced circulation and affects the power of the centrifugal pump;

- As the pressure in the pipes rises, the boiling point shifts upward. Those. in fact, the process of transition from a liquid to a gaseous state occurs at a temperature of 110 ° C. This makes it possible to use high-temperature heating modes.

But if there is a possibility of exposure to negative temperatures, then water, as a liquid for filling heating systems, is unacceptable. In this case, antifreeze agents should be used whose crystallization threshold is significantly lower than 0 ° C. The best option is propylene glycol or glycerin solutions with special additives. They belong to the class of harmless substances and are used in the food industry. The best technical properties are possessed by solutions based on ethylene glycol. Until recently, they were used to fill closed heating systems. However, they are extremely harmful to humans. Therefore, despite all their positive qualities, it is not recommended to use ethylene glycol-based antifreezes.

But what can you fill the heating system with - water or antifreeze? If there is no chance of exposure to cold temperatures, water is the best choice. Otherwise, it is recommended to use solutions of a special heat carrier.

Car antifreeze must not be added to the heating system. This will not only lead to a breakdown of the boiler and failure of the radiators, but it will also be hazardous to health.

Types of transfusion systems

By filter mesh size, the dropper system is subdivided into infusion products:

- solutions;

- blood and blood substitutes.

A properly selected system, taking into account the size of the cells, is the key to successful therapy. For example, for the administration of a solution of glucose or electrolytes, small cells will prevent harmful impurities from entering the bloodstream. And in the case of transfusion of blood products, such cells will quickly become clogged with blood elements, and the infusion process will stop.

By the type of needle used, which is connected to a bag or bottle, systems are distinguished:

- with a metal needle;

- with a polymer needle or plastic spike.

The choice of an infusion system for a dropper in this case will depend on the container in which the drug is located. For glass containers, a metal needle is used, and for bags - a polymer needle.

Water drain technology, cleaning heating pipes

Drain valve in the heating system

Before filling the heating system of a double-circuit boiler, it is necessary to drain the old coolant. This procedure is mandatory and, despite its apparent simplicity, must be performed according to a certain technological scheme. First you need to turn off the heating and wait until the water temperature drops to room temperature. Only then can the closed heating system be properly filled with distilled water.

The drain valve is then opened, located at the lowest point in the system. After waiting for the water to drain, you need to open the Mayevsky tap, which is located at the top of the circuit. This is necessary to stabilize the pressure in the pipes. After completing these works, you need to flush the system. This is done before the heating system in a private house is filled. This requires the use of special tools and equipment. A pump is connected to the heating circuit, which pumps flushing liquid into the heating system. It also has a destructive effect on deposits in pipes. After several cycles of passage, contaminants are removed along with the liquid.

The used liquid must not be discharged into the sewer system. It must be collected in sealed containers, which are then disposed of by special companies.

Collection system for intravenous infusion algorithm. Algorithm for performing manipulation

- 1.Wash, dry your hands, put on a mask

- 2. Check the packaging of the drip system: tightness, shelf life, "sterile", visible defects.

- 3. Open the packaging in the indicated place.

- 4.Place the drip system with sterile forceps into a sterile tray.

- 5. Check the bottle with the medicinal solution: name, tightness, shelf life, "sterile", transparency, visible defects.

- 6. Open the central part of the metal disc from the bottle cap with non-sterile tweezers.

- 7. Treat the rubber stopper of the bottle with a sterile cotton ball moistened with 70% alcohol.

- 8. Take the drip system from the tray into your hand with sterile forceps.

- 9.Close the roller clamp.

- 10. Remove the injection needle (in a protective cap) with sterile tweezers and place in the tray.

- 11. Remove the protective cap from the vial needle and insert it all the way into the rubber stopper of the vial.

- 12. Turn the bottle over and fix it on a tripod.

- 13. Squeeze the dropper and fill it halfway with the solution (up to the mark).

- 14.Open the roller clamp.

- 15.Fill the system with the solution until the air is completely displaced and drops appear from the connecting cannula.

- 16.Close the roller clamp.

- 17.Take the injection needle (in the protective cap) from the tray with sterile forceps and attach it to the connecting cannula.

Filling methods - built-in mechanism and pumps

Heating filling pump

How to fill the heating system in a private house - using a built-in water connection with a pump? It directly depends on the composition of the coolant - water or antifreeze. For the first option, it is enough to pre-flush the pipes. The instruction for filling the heating system consists of the following points:

- It is necessary to make sure that all shut-off valves are in the correct position - the drain valve is closed as well as the safety valves;

- The Mayevsky valve at the top of the system must be open. This is necessary to remove air;

- Water is filled until the moment when water flows from the Mayevsky tap, which was opened earlier. Then it overlaps;

- Then it is necessary to remove excess air from all heating devices. They must be fitted with an air valve. To do this, leave the system filling valve open, make sure that air comes out of a particular device. As soon as water flows from the valve, it must be shut off. This procedure must be done for all heating devices.

After filling the water in a closed heating system, you need to check the pressure parameters. It should be 1.5 bar. In the future, pressing is performed to prevent leaks. It will be discussed separately.

Filling the heating with antifreeze

Before proceeding with the procedure for adding antifreeze to the system, you need to prepare it. Usually 35% or 40% solutions are used, but to save money it is recommended to purchase a concentrate. It should be diluted strictly according to the instructions, and only using distilled water. In addition, a hand pump must be prepared to fill the heating system. It is connected to the lowest point of the system and the coolant is pumped into the pipes using a hand piston. During this, you need to monitor the following parameters.

- Air outlet from the system (Mayevsky valve);

- Pipe pressure. It must not exceed 2 bar.

All further procedure is completely similar to the one described above. However, one should take into account the peculiarities of the operation of antifreeze - its density is much higher than that of water. Therefore, special attention should be paid to the calculation of the pump power. Some glycerin-based formulations can increase the viscosity index with increasing temperature.

Before pouring antifreeze, it is necessary to replace the rubber seals at the joints with paronite ones. This will greatly reduce the likelihood of leaks.

Automatic filling system

For double-circuit boilers, it is recommended to use an automatic filling device for the heating system. It is an electronic control unit for adding water to pipes. It is installed on the inlet pipe and works in fully automatic mode.

The main advantage of this device is the automatic maintenance of pressure by the timely addition of water to the system. The principle of operation of the device is as follows: a pressure gauge connected to the control unit signals a critical drop in pressure. The automatic water supply valve opens and remains in this state until the pressure stabilizes. However, almost all devices for automatic filling with water in a heating system are expensive.

A budget option is to install a check valve.Its functions are completely similar to the automatic filling device of the heating system. It is also installed on the inlet pipe. However, the principle of its operation is to stabilize the pressure in pipes with a water make-up system. If the pressure in the line drops, the pressure of the tap water will act on the valve. Due to the difference, it will automatically open until the pressure stabilizes.

In this way, it is possible not only to feed the heating, but also to fully fill the system. Despite the apparent reliability, it is recommended to visually monitor the coolant supply. When filling the heating with water, valves on the devices must be opened to release excess air.

End of procedure

After the end of the procedure, close the clamp on the infusion tube, remove the adhesive plaster, cover the venipuncture site with a sterile cotton ball and pull the needle out of the vein and skin. After that, the patient should bend his arm at the elbow, holding a cotton ball in place of the skin puncture. In this position, the hand must be held for at least 3-5 minutes to prevent the formation of a hematoma at the site of the vein puncture.

In order to comply with infectious safety, you need to disconnect the dropper system from the medicine bottle, cut it with scissors and place it in a container with a disinfectant solution (needles - separately, cut tube - separately). The nursing staff can then remove their gloves and wash and dry their hands.

In the log of manipulations and procedures, as well as in the assignment sheet, a note should be made about the manipulation performed.

Heating system pressing

Heating system pressing

Before filling the heating system with coolant, it is necessary to check the tightness of all joints and connections. For this, pressing is performed - creating excess pressure in the pipes, i.e. a situation of destabilization of the system is artificially created.

This can be done in two ways - by pumping air or a coolant. This must be done even before the heating system of the double-circuit boiler is filled. This procedure can be carried out using a mechanical (electrical) pump or by connecting the water supply. The latter option is not recommended, as it will be very difficult to control the process. The order of execution is as follows:

- Preliminary visual inspection of joints and joints;

- Connecting the mechanism to the inlet pipe of the system;

- Creation of excess pressure, the value of which should exceed the norm by 1.5 times.

The condition of the heating elements must be checked. In the event of a leak, the process stops immediately and can only start when the defect has been eliminated.

General preparation

The preparation algorithm is as follows:

- Wash your hands thoroughly with warm water, always with soap.

- Put on gloves, then carefully treat them with a ball of alcohol, without missing a single fragment.

- Check the tightness of the packaging of the disposable medical instruments used, the system for infusing the liquid must be one-piece, the equipment must not let you down.

- Check the status of the medications. The algorithm is simple: first check the name to see if there is any confusion, then the expiration date, then the transparency level.

Quality control of heating filling

Before filling a closed heating system with water, make sure that all protective elements are present. These include Mayevsky taps, bypasses, and control devices - thermometers and manometers. They are necessary not only to control the pressure in the pipes during the supply of the coolant, but are also the main safety measures during the operation of the heating. This is how you can properly fill the heating radiator with water.

During the correct filling of a closed system with water, the following parameters must be monitored:

- Pressure. Manometers must be installed in key places of the system - extreme radiators of heating, and the highest point. After the final air outlet, the pressure on all pressure gauges should be the same;

- No leaks.

Only in this way can a stable pressure be achieved. However, the main check process takes place when the boiler is turned on. The thermal expansion of water at maximum operation should not affect the integrity of the piping of the heating elements.

Dropper preparation

If it is necessary to make a one-time setting of the dropper, then the algorithm for this will be as follows:

- Open the injection system with scissors and place it on a sterile tray in an accessible area.

- Remove the foil from the packaging of the drug to approximately the middle of the stopper.

- Treat the cork with a ball that was previously moistened with alcohol.

- Remove the needle cap from the airway.

- Insert the needle into the sample as far as it will go. Then close the air duct tube so that its end is approximately at the bottom of the bottle.

- Then remove the clamp, remove the cap from the needle that is designed to connect to the bottle. After that, insert the needle into the bottle cork until it stops.

- The bottle is turned over, fixed on a tripod prepared in advance for it. The cap is removed from the injection needle.

- The dropper is rotated so that it is now in a horizontal position. After that, it slowly fills up to half of its volume.

- The clamp closes, the dropper returns to the position it was in before. Please note that the filter at this stage must be filled entirely.

- The clamp opens and the entire device slowly fills until all the air has escaped and a drop of liquid emerges from the needle. After that, the clamp is closed, and the cap is put on the needle. The system is ready for introduction.

At this stage, it is very important to make sure that there is no air in the pipe of the fixture.

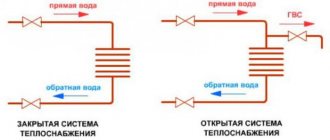

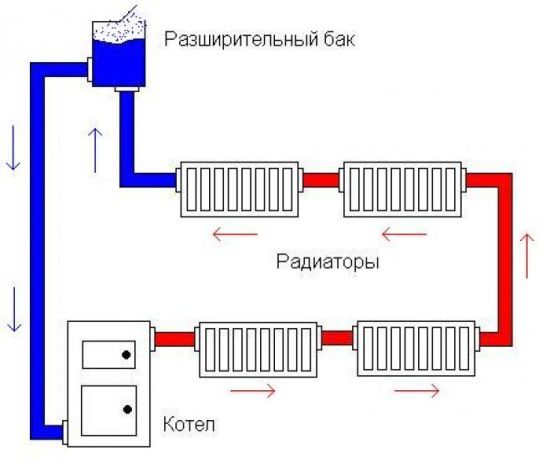

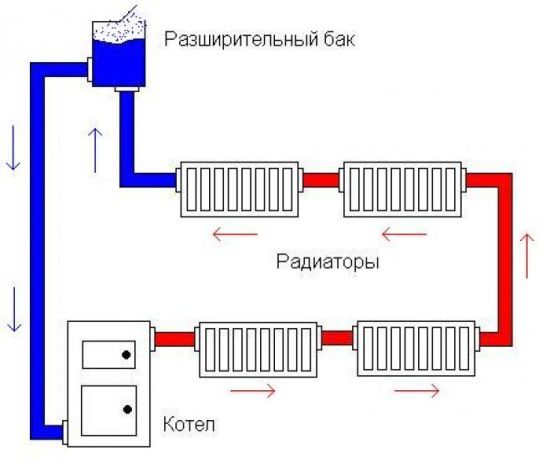

Open heating system

Open heating system

If the filling of an open-type heating system in a private house is performed, then the procedure for performing the work is somewhat different. The peculiarity lies in the fact that the pressure in the pipes is equal to atmospheric. Therefore, the main control element is the expansion tank, which is installed above the other heating devices.

In this case, the order of filling the heating system is as follows:

- The old coolant is drained and the pipes are cleaned.

- Mayevsky's tap opens on all heating devices.

- The flow of liquid for filling the heating system can be carried out through a return pipe.

- As soon as all the air has left the system, the water level in the expansion tank is checked. It should be 2/3 full.

It is noteworthy that with the help of a hand pump used to fill the heating system, you can also add a coolant.

No overpressure is allowed for an open heating system. Otherwise, it can lead to incorrect operating temperature.

Indications and contraindications

Intravenous drip administration of drugs is indicated for restoring circulating blood volume, removing signs of intoxication, normalizing electrolyte balance, restoring acid-base balance in the blood, parenteral nutrition, and general anesthesia.

With the help of a special device for dripping fluids (system), it is possible to ensure the flow of solutions into the bloodstream at a rate of 20 to 60 drops per minute.

Contraindications to the setting of droppers are lesions of the skin and subcutaneous tissue at the site of venipuncture, phlebitis of the vein intended for injection. If there are local contraindications for intravenous injection, another vein is chosen.

How to top up the coolant

In addition to instructions for filling the heating system, it is necessary to know the correctness of the procedure for adding a coolant. This situation can occur 2 or 3 times during the heating season. It is important to determine in time that the volume of water has fallen below the critical value. Depending on the type of heating, there are different procedures for filling the heating system.

Closed heating system

The main indicator is a decrease in the pressure level in the pipes. For timely monitoring, several pressure gauges are installed in the system. One of them is necessarily located immediately after the exit of the hot coolant from the boiler. Also install a pressure gauge on the upper air valve. The drop in pressure in the system is the result of 2 factors - the occurrence of an emergency (leakage) or natural evaporation of the liquid. If this process occurs very quickly, it is most likely that the pipe has burst. A gradual decrease in pressure indicates a second factor.

The method of adding liquid completely repeats the procedure for filling with water any closed heating system. To do this, you can use hand pumps to fill the heating system (antifreeze), or use the central water connection.

Open heating system

It is recommended to fill an open heating system with water through an expansion tank. This can be done even with a relatively high temperature of the water in the pipes. This method has several advantages - controlling the level of the coolant in the system during filling and improving circulation due to the difference in water density.

There is a risk of failure of the boiler or heating radiators if additional filling of the open heating system with coolant occurs while the boiler is running. Therefore, this procedure is recommended to be performed when the water in the pipes reaches room temperature.

To choose antifreeze, we recommend that you familiarize yourself with the video material.