SP-OM

A complex tool of the SP-OM brand is used for flushing the heating system, heat exchangers, boilers and any other heat exchange equipment. It can be used in open and closed heat exchange circuits. "SP-OM" does not destroy aluminum, polymer elements of the system, as well as rubber gaskets. It has proven itself on an industrial scale. There are various brands of SP-OM designed for specific operating conditions. Manufacturer's website - https://spomcom.ru/

SP-OM Pros

- effective removal of scale, rust and other deposits;

- in-place flushing;

- does not corrode rubber gaskets and seals;

- prevents corrosion of ferrous metals;

- may additionally include a corrosion inhibitor;

- can be used with aluminum parts.

Minuses

consultation and the services of a flushing specialist may be required.

SP-OM

Metalin T is a product based on hydrochloric acid. Removes heavy limescale deposits, rust products and organic matter in heating systems made of steel or non-ferrous metals. It is a non-flammable substance. After adding an alkaline neutralizer, it is allowed to drain the waste into the sewer. Packaged in concentrated form in containers from 1 to 30 liters.

Metalin T Pros

- non-combustible;

- fast cleansing.

Minuses

- after neutralization with alkali, discharge into the sewer system is allowed;

- not used for surface treatment of aluminum and its alloys.

It is used in the treatment of pressure boilers, tubular heat exchangers, boilers, condensers, pipelines in industry and domestic conditions. Removes various types of dirt, in particular limestone and corrosive deposits. Ideal for flushing plastic, metal, rubber pipes. Gently cleans, does not adversely affect the structure of the seals. Not recommended for cleaning systems with surfaces made of aluminum and derived alloys. A preliminary test on stainless steel treated coatings is also recommended.

SYNTILOR Watesup Pros

- does not affect the structure of metals;

- concentrated product;

- high efficiency even at low temperatures of use (20–35 ° С);

- does not damage seals and rubber gaskets;

- contains an inhibitor.

Minuses

cannot be used for products made of aluminum and derived alloys.

SYNTILOR Watesup Heating System Flushing Agent

Deoxyl-3

Deoxyl-3 is an acid-type agent for chemical cleaning of pipelines in heating and water supply systems. It is packaged in the form of a concentrate in containers of 20 liters. The liquid is not flammable, belongs to the 3rd class of toxicity. For a greater cleaning effect, it is advisable to use the additive "Deoxil NO" together with the preparation. Foaming is neutralized by the Foral PG additive. The liquid is quite aggressive, therefore, in the process of working with it, it is recommended to protect the skin and respiratory organs with protective equipment. Use strictly according to the directions on the label.

Deoxyl-3 Pros

- completely removes scale and corrosion deposits, regardless of the design features of the equipment;

- biodegradable;

- after flushing, the spent working solution can be drained into the sewer;

- the composition includes various inhibitors that prevent metal etching and the appearance of corrosion foci. Inhibitors allow not only to wash off deposits, but also to protect the metal.

Minuses

the liquid is aggressive (work with it only with protective equipment).

What would you choose from a system flush or recommend to purchase?

Deoxyl-3

75.00 % ( 3 )

Save your voting results so you don't forget!

To see the results, you need to vote

Do-it-yourself heating flushing mechanically

For self-cleaning of radiators, mechanical cleaning technology is most applicable. In this case, you do not have to use any special equipment or specific chemicals.

Before you rinse the gas boiler heat exchanger with your own hands, you should prepare the necessary materials:

- rags or old thick clothing. With their help, it will be possible to protect the bath from damage during the process of flushing radiators in it;

- fum tape or sanitary flax with a tube of sealing paste;

- a branch pipe that allows you to connect the hose to threaded connections.

From the equipment you will need the following:

- two hoses;

- keys set;

- corset;

- steel wire ruff;

- buckets, basin and rags.

The actual cleaning of the heat exchanger and lines consists of several stages.

- A hose of the appropriate diameter is connected to the drain pipe of the heating system. The other end of the hose is led down the drain.

- A second hose is connected to the highest point of the system. As a rule, such a point is either a branch to an expansion tank or a safety group. The tank or safety group is unscrewed and in their place a branch pipe is screwed onto which the hose is put on. The other end of the hose is connected to the water supply.

- When everything is ready, water is supplied to the system. This way it is possible to get rid of scale and impurities deposited in the lines of the system.

- The coolant is being drained. To do this, remove the hose through which tap water was supplied. In this case, the connection to the system is not blocked. Under the influence of gravity, water begins to drain through the drain pipe at the lowest point of the line.

To completely drain the coolant, it is necessary to ensure that the outlet end of the hose is below the level of the heating system lines. In a private house, it will be possible to provide such a configuration if water is drained into buckets installed in the underground.

Radiators are removed from the dehydrated system

Be careful when doing this. It is likely that the threaded connections on them have coked up and you will have to make some effort, trying not to damage the threads. The removed radiators are transferred to the bath, previously covered with a rag or thick cloth

Here they are washed with running water, treated with a brush and a steel wire brush. After flushing the radiator, it is carefully inspected again for any remaining contamination. The radiators are installed in place.

df2185cefce037de2f4f59e24c82a23a.jpe

eea5416a8dab45beb5327b9907898e97.jpe

- Through the drain pipe, the lines are filled with fresh water. At the same time, the formation of air jams in the pipe and radiators is monitored. You can get rid of air bubbles by opening the Mayevsky taps on the radiators. As soon as the air stops hissing and water begins to ooze from the tap, it closes them. As the lines fill, it is advisable to repeat this procedure several times.

- After the actual flushing of the gas boiler heat exchanger with your own hands is completed, the heating system is started up.

- With the beginning of the circulation of the coolant, re-formation of air locks in the radiators is possible. To eliminate them, the Mayevsky cranes are re-manipulated. Part of the air will be removed on its own through the air vent.

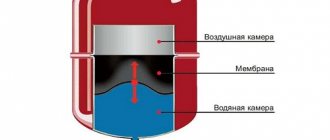

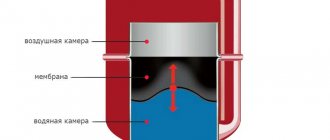

- As the pipelines and radiators become free of air, the pressure of the coolant will drop.To level it, it is necessary to make an additional pumping of water from the water supply. In addition, the pressure in the expansion vessel should be checked.

site4.ru

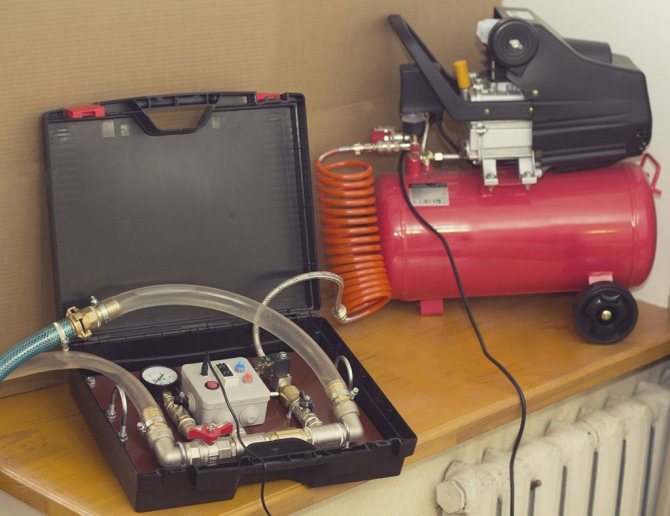

Compressed air is supplied by a compressor, which creates an air pressure of up to 0.6 MPa. A check valve is installed on the compressed air pipeline, preventing the ingress of water from the heating system into the compressor receiver, and on the supply and return pipelines - pressure gauges with a scale of up to 1.0 MPa.

Hydropneumatic flushing of the system is carried out in one of two ways: flow or filling. The flow-through method of washing is carried out as follows. The system is filled with water, with the air intake valve open. After filling the system with water, the valve is closed. Compressed air is supplied and the bleed pipe is opened. The water-air mixture is continuously fed into the pipelines, passes through the pipes and heating devices, and then is drained. Flushing is carried out until clean water flows from the branch pipe. Hot water supply systems are also washed in this way.

By the filling method, hydropneumatic flushing is carried out in the following sequence. The system is filled with water, after which the valve is closed. Compressed air is fed through another branch pipe for 5-15 minutes (depending on the contamination and the volume of the system being flushed). Then the supply of compressed air is stopped, the valve is closed, and water with dirt that has exfoliated during the purging of the system with air is removed through the drain pipe. The system is flushed several times until it is completely cleaned. In systems with top distribution, flushing is carried out when water is supplied from the return pipeline located at the bottom, and the drain pipe is connected to the supply pipeline.

Depending on the design and degree of contamination, the systems are flushed with risers, groups of risers, sections or the entire system. Usually, a group of two to five risers is washed simultaneously. The rest of the risers are turned off. At the end of the flushing of the first group, the risers are turned off and the next group is flushed, etc. Flushing is carried out until the removed water-air mixture is fully clarified.

Technology of application of hydropneumatic flushing:

- Inspection of the system (degree of clogging of the system with deposits);

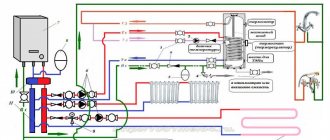

- Integration of pumping equipment into the existing system;

- Forced circulation in the system of high pressure water during the specified time;

- Dismantling of pumping and storage equipment;

- Quality control of flushing by cutting pipe sections;

- Pressure testing with prepared water.

Application period:

Once a year (inter-heating period).

Effectiveness and results of application:

- Partial restoration of the throughput of pipelines;

- Reducing the cost of heat loss up to 5%;

- Reducing energy consumption when transporting water.

Heating system flushing instructions

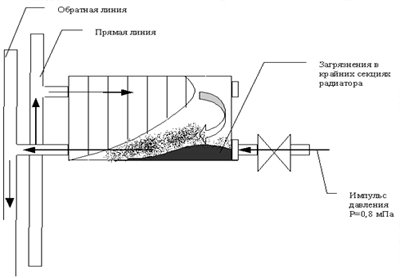

Pneumatic impulse cleaning scheme

There are 2 main methods of flushing the heating system, namely:

- using special hydropneumatic equipment;

- using chemical reagents.

Hydropneumatic flushing

Hydropneumatic flushing of heating systems - instruction Hydropneumatic flushing of heating systems - instruction

This method is actively used by domestic housing offices and is quite effective. You just need to do everything in accordance with the technology.

The principle is extremely simple: first, water is discharged from the system, then it is fed back. A special pneumatic pump is used to "adjust" the water flow. As a result, under the influence of a rather powerful pressure, scale and other deposits peel off, and when the water is drained, they are removed from the system.

To carry out such a procedure on your own, you will need a pneumatic pump capable of pumping a pressure of more than 6 kg / cm2.

The sequence of actions is as follows.

Before starting work, you need to turn off all the taps

First step. We close the "return" valve.

Heating system lines diagram

Second step. We connect the pneumatic pump to the valve installed after the valve.

Step three. We reset the "return".

Fourth step. We give the pneumatic pump to pressurize above 6 kg / cm2, and then open the valve to which it is connected.

Fifth step. We shut off all the risers one by one. We do this so that no more than 10 risers are blocked at one moment. Compliance with this rule will make the flushing procedure as efficient as possible.

Sixth step. We transfer the system to dropping in the opposite direction. To do this, do the following:

- close the discharge and close the valve connected to the pump and turn off the device;

- close the open valve, and then open a similar one on the "return";

- we reset the heating system. To do this, connect the pneumatic pump to the valve in the opposite direction, then open the valve and turn on the pump. The fluid will move in a different direction.

You can determine the required duration of flushing "by eye". A clear, clear liquid started to come out of the system? You can finish! Return the gate valves and valves to their original position and turn off the pump.

Prepare a suitable container to collect dirty water. If you wish, you can connect a hose to the battery and ensure that the dirty coolant is drained into the sewer.

Chemical washing

Scheme of chemical flushing of pipes

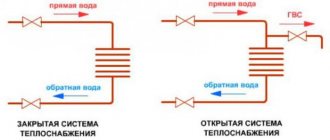

This method can be used only in two cases, namely:

- if necessary, cleaning the natural circulation heating system, built with the use of steel pipes. It is advisable to use chemical reagents in situations where, for any reason, there is no desire to flush the entire system. Most often, blockages are deposited in heat exchangers. The system can get silted up along the entire perimeter. In the second case, there will be no special sense from chemical washing;

- if it is necessary to restore the old heating system. Over decades of operation, pipes can become clogged and overgrown so that the power of the pneumatic pump will not be enough for effective cleaning. You could, of course, take a more powerful pump, but no one will give guarantees that the pipes will not burst under such a pressure.

Reagent for washing

The principle of flushing is simple: instead of a coolant, a special solution containing acid and alkali is poured into the system. Then the mixture is circulated for 2-3 hours (if the line with natural circulation is not cleaned, for this it will be necessary to connect a pneumatic pump), after which it is drained and the pipes are filled with a standard coolant.

Reagents for flushing and protection of heating systems

Never use such chemical mixtures for cleaning aluminum pipes. If the products remain intact after such a rinse, they will serve much less.

It is recommended to flush the system of a private house at least once every 7 to 10 years.

Flushing the heating systems of an apartment building

Flushing of heating systems in apartment buildings can be done by the following methods:

Chemical rinsing

This method of purification consists in supplying special chemical reagents in the form of alkalis to the system.

Then, due to special pumping equipment, a continuous circulation of the liquid is carried out for several hours. After that, the solution is completely drained and the system is pressurized.

Hydropneumatic flushing

This flushing method is very often used when cleaning heating systems in apartment buildings. The effectiveness of flushing depends on the correct cleaning job.

Algorithm of actions for hydropneumatic flushing:

Shut-off of the valve in the return pipeline. Connecting the compressor to the metering valve in the flow after the house valve. After the pressure in the ballast tank of the compressor reaches the level of 6 kgf / cm2, it is necessary to open the valve to which the compressor is connected. Then you need to block the risers

It is very important that no more than ten risers are open during the overlap. This will ensure that all risers and radiators connected to them are flushed efficiently.

Duration - this flushing can be determined independently - if the liquid in the riser becomes transparent, then you can start flushing the next pipe.

At the last stage of cleaning, you need to correctly switch the heating to reset in the opposite direction:

- To begin with, the discharge and the valve are closed.

- Then the house valve closes at the feed, it opens during processing.

- Ultimately, the discharge from the serve opens. The compressor must be connected to a metering valve in the return line. After that, you need to open the compressor.

Hydropneumatic flushing and pressure testing of the heating system

Heating devices in a residential building are complex structures connected to an autonomous or centralized network. Long-term and uninterrupted operation of engineering equipment depends on the operating rules. If the conditions of use are not followed, the devices begin to clog, the quality of space heating decreases. To prevent breakdowns and for preventive purposes, mandatory hydropneumatic flushing and pressure testing of the heating system is required.

The importance of regular maintenance

The accumulation of scale in pipelines not only reduces the efficiency of work, but can also lead to an emergency. The smallest amount of deposits, 1 mm thick, reduces the level of heat transfer in an apartment building by 20%. Sediment is a specific insulator that retains energy. Layers can act on the inner surfaces of pipes and heating devices, causing corrosive processes and the formation of fistulas. To improve the quality of equipment operation, it is important to carry out hydropneumatic and hydraulic flushing at regular intervals, at least once a year.

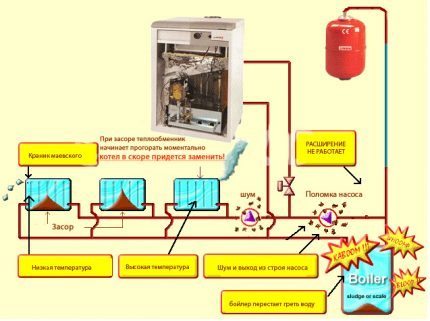

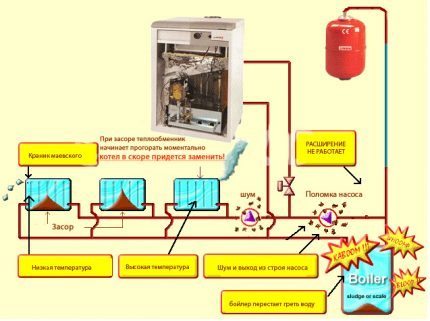

To determine the condition, diagnostics are carried out. In apartment buildings, when replacing sections of the centralized network, scale and rust gets into the pipeline, which is deposited in the devices. If the analysis is carried out independently, the following indicators can be attributed to the number of obvious signs:

- Whistling, gurgling and other sounds coming from instruments.

- Long period of time for heating.

- Hot condition of pipes with cold batteries.

- Increased energy consumption.

- Cleaning is also necessary when replacing the boiler.

When flushing internal heating systems using the hydropneumatic method, carried out by specialized organizations, a special procedure is noted. The equipment is examined with an assessment of the technical condition. The primary pressure test in an apartment building should show a pressure with a minimum value of 2 atmospheres. This is necessary so that the detected defects are eliminated before starting work.

Professionals draw up an act of work taking into account hidden procedures, for example, dismantling the radiators of the heating system. By identifying the condition of the pipes and the amount of scale, the method of flushing is determined with the customer. Hydraulic technology is most often used, less often chemical cleaning. Draw up an estimate, sign a contract, which includes deadlines. After that, they start cleaning, then carry out a secondary pressure test. This is necessary to check the functionality of the equipment in a residential building.

Do-it-yourself chemical washing

For chemical cleaning, it is important to select the correct product and carefully study the instructions before starting work. For self-cleaning of the heating system in a private house, you need:

- pump;

- container for liquid;

- cleaning agent;

- hoses.

Most chemicals are diluted with a certain volume of water before use. In stores, if desired, you can purchase ready-made liquid, which is the best option for flushing a small system. For large stand-alone systems, it is recommended to purchase a concentrate. The cleaning procedure is as follows:

- drainage of water from the heating network;

- filling the tank of the treatment plant with the prepared composition;

- switching on using the pump nozzles and filling the heating system elements with a chemical composition.

Usually 2-3 hours are enough for the destruction of scale. The circulation is carried out until there are no deposits in the filter tank. Flushing of the heating system with water is mandatory to completely remove the chemical reagent

Please note that the spent chemical solution must not be disposed of down the drain

When carrying out work, pay attention to the precautions with the chemical. Precautionary measures:

- when working with a solution, it is imperative to wear gloves;

- the concentration of the reagent can be very dangerous for humans, therefore, before starting work, it is necessary to protect the mucous membranes with a respirator.

The main advantages of this method are

- High-quality removal of limescale and rust on the inner surface of pipes.

- No need for complete dismantling of the heating system.

- Uniform heating of radiators after flushing.

- Reduced fuel consumption and, as a result, savings.

- Extending the life of the heating system.

Disperse washing

Our company, for high-quality work such as cleaning pipes and disinfection of pipelines, has developed its own reagent that does not enter into a chemical reaction with deposits, but penetrates into their structure and weakens molecular bonds. Loose deposits are washed away by the coolant flow. The flushing agent contains a corrosion inhibitor that prevents the destruction of the metal of the system itself and substances that form a protective film on the inner surface of the pipeline, preventing further formation of deposits. In addition, the reagent has disinfectant properties. The spent reagent is disposed of into the sewage system without damage to biological treatment facilities. For the use of our reagent, a method for cleaning pipes was developed and patented, which allows it to be used both in open and closed heating systems. Moreover, flushing can be carried out all year round, without disturbing the temperature regime.

Heating system flushing frequency

According to SNiP, flushing of the system is required annually.But cleansing is carried out of different types. Conventional hydraulic is carried out annually, with the addition of air - once every 2-3 years, and chemical - as needed, but not more often than once every 5-7 years.

How far the operating organizations adhere to such recommendations is difficult to say. But in individual systems, no one bothers to flush the heating system every two to three years. There is no need for annual processing. After the end of the season, you can drain some of the coolant to assess its condition. If there are no "aromas" and no precipitation, the time has not yet come to flush the heating.

Hydropneumatic flushing and flushing of heating systems

Flushing of heat supply systems is necessary for efficient space heating. This procedure is recommended to be carried out once a year, before hydraulic tests. In extreme cases, it is necessary to flush the heating system at least once every few years - this will help to increase the heating efficiency. Private home owners will also be able to reduce heating costs and extend the life of their piping.

As a result of hydraulic flushing, various deposits are removed from pipes and radiators: scale, rust, scale, etc. Sometimes they occupy more than 2/3 of the pipeline diameter. The thicker the layer of deposits, the more the amount of thermal energy transferred into the room decreases. You can see how the pipes with deposits look in the photo.

The heating systems must be flushed by the ZhEK employees, and every year. But in practice this is not always done. As a result, hydropneumatic flushing of heating systems is carried out by specialized companies, to which the residents of the houses apply.

The ways

Typically, flushing is done in the following ways:

- Water-pulsating mixture. This flushing method is carried out using pulsating water and compressed air. Due to this, sediments, rust, plaque, silt, sand are removed in the pipes. This flushing method reduces energy costs and extends the life of the heating system elements. However, special equipment must be used to carry out this flushing.

- Biologicals. The use of biological products during flushing ensures deep penetration into clogged areas and complete dissolution of all deposits. When flushing with biological products, it is not necessary to turn off the entire heating system. Water-based supercleaners are mainly used as biological products. The principle of action of these drugs is based on loosening scale, oil-mud, hard crystalline, corrosive and organic deposits.

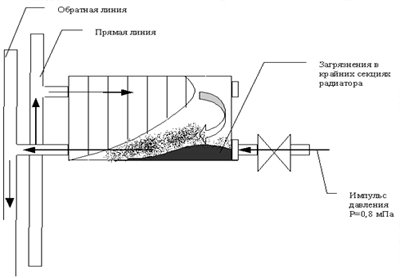

- Pneumohydroimpact. During flushing in this way, special equipment is used. This method is very convenient since you do not need to disassemble the battery assemblies. Also, there is no need to use special cables and chemicals. With the help of the equipment, a pneumohydraulic impulse is supplied to the system. The main blow falls on the main column of the coolant with deposits. Due to this, the deposits quickly break down and dissolve. The efficiency of this method is very high. In addition, ruptures and cracks in pipes are excluded.

- Chemicals. This cleansing method is based on the use of preparations containing organic and inorganic acids. The preparations, getting into the pipe, completely dissolve scale, rust, and deposits in the form of salts.

Hydropneumatic flushing methods

Even if you have the necessary equipment, you still need to take into account the individual characteristics of the heating system. The chosen method depends on many factors, including the following:

- whether it is an apartment building or a private sector;

- how many floors the house has;

- what liquid was used as a heat carrier;

- how long has the service or cleaning been carried out;

- what material the pipes are made of;

- what year the system was installed.

Depending on all these factors, the specialist must conclude that it is necessary to choose one or another washing method.

Flow-through washing method

This method of cleaning pipelines of the heating system from slags consists in the following stages:

The heating system must be completely filled with water, leaving the air intake valve open.

After filling the system, the valve must be tightly closed

Hydropneumatic flushing scheme

A stream of compressed air is supplied to the system, at the same time the discharge branch pipe is opened

Until clean water emerges from the drain pipe, an air-water mixture continues to be supplied to the system. Please note that the volume of the flushing mixture can be quite large, so take care of where the waste fluid is drained off in advance.

Flushing with filling the heating system

In this case, it is necessary to carry out the following sequential operations:

- Fill the heating system with water with the valves closed.

- Compressed air is supplied through the inlet with the closed outlet for 5-1 minutes.

- After stopping the air flow, the outlet pipe opens and the water-air mixture with the torn off scale is drained from the system.

Please note that the volume of the supplied air-water mixture is calculated individually for each heating system, depending on its volume. Otherwise, with an illiterate calculation, you can get not clean, but broken pipes.

Instructions for carrying out hydropneumatic flushing

- Remove the nozzles and diaphragms from the hydraulic elevator, if available in the system.

- Drain the circuit into the sewer to drain the contaminated water.

- Conduct a thermal imaging survey of the internal surfaces of the radiators, if special equipment is available.

- Close the heat valve located on the "return" pipe.

- Fill the system with water to remove air from it, with the air collector valve open. As soon as the system is full, the valve is closed.

- Connect the compressor to the metering valve, open the “return” drain.

- Open the valve when the pressure on the compressor reaches 0.6 MPa;

- Close the risers and flush them one at a time. Flush until purified water flows out of the hose.

- Switch the heating circuit from supply to return. Flush all risers in the opposite direction.

After completing the flushing process, the system must be filled with water, as its pipes must not be kept empty.

Hydropneumatic flushing of heating systems - instruction

- Flushing of the heating system is carried out in the presence of a representative of the power supply organization.

- The foreman of the district heating unit is invited to the start of flushing, and in his presence, flushing work begins.

- At the time of flushing, the heating system is disconnected from the quarter heating network by valves 1, 2, 3, 4. If the closure tightness is not enough in the valves, additional blinds (plugs) must be installed, made of 3mm sheet steel.

- By the beginning of the new heating season, these valves must be revised.

Preparatory work

Rubber hoses are connected to the flushing fittings. Hoses (rubber hoses) are connected using ROT half-nuts (according to GOST 2217-76). Check valves must be installed on the air and water inlets, which will be used for flushing.

Remove the nozzle from the elevator before flushing.

- The system is filled with cold water through the valve 19 with an open valve 21 of the air collector and open valves 22 and 24, as well as closed valves 1; 2; 3; 4; 18; 20 and 23. After water appears in the valve 21, this valve and valve 19 must be closed.

- Purge air on each riser in the heating system.

- To do this, close all 24 valves on the risers. Open air damper 18.Sequentially opening the taps 22 on the heating risers, the risers are purged with air from the bottom up.

- To drain the waste water after the stormwater drainage system, a flexible rubber hose must be put on the fitting 20.

- Starting from the far riser, all risers are hydropneumatically flushed sequentially.

- To do this, open the valve 22 and 24 in succession on the risers with the air valve 21 open, then open the water valve 19 and air valve 18.

Then to carry out flushing

- consistently fill the risers with water;

- close taps 21 and 23;

- open the water drainage through the 20th valve.

Turn on the air with the valve 18. With the valves 19 and 20 open, turn on the risers in series, opening the valves 24, starting from the farthest riser.

Heating system diagnostics

To identify the need for hydropneumatic flushing of the heating system, it is necessary to conduct an initial diagnosis. It can be carried out in a domestic environment without resorting to the services of expensive specialists. It is on the basis of the diagnostic results that it is necessary to resolve the issue of flushing. In addition, after carrying out routine maintenance, gently expose the heating system to anti-corrosion treatment - this will reliably protect the walls of the pipelines for the next operational period.

So, the main signs that your heating system needs hydropneumatic flushing are the following:

- Your heating boiler is making unusual sounds that you have not heard before,

- The time it takes to warm up the system to a working state is significantly increased.

- One of the main signs is the uneven heating of the heating system elements. So, if the pipeline system is hot to the touch, and the radiators are much colder, it is necessary to urgently flush.

- An indirect sign of a clogged heating system is an increase in energy consumption when the same temperature is reached and in the same weather outside.

How is hydropneumatic flushing carried out and what equipment is needed?

The main essence of hydropeneumatic flushing of the heating system is cleaning the pipeline system and heating radiators with compressed air pressure... In this case, the coolant remains in the system, that is, water. The beginning of this process dramatically increases the speed of fluid movement in the system, and compressed air gives the water increased turbulence, that is, uneven movement and the formation of vortices. From the action of a mixture of air and water, scale and deposits formed on the inner surface of the system are loosened, carried away by the water-air flow and removed from pipes and radiators to the discharge point.

compressor

With this type of flushing, the discharge point of loosened deposits is a drain pipe or a specialized valve. In the absence of these elements in the heating system, they must be cut in before starting cleaning.

If there is an elevator in a heating system with a liquid heat carrier, it is dismantled before flushing to avoid damage.

Air is supplied to the heating system from the compressor to create a powerful water-air flow with swirls. This device should show a pressure of 0.6 MPa at the outlet. In order to prevent the ingress of water from the system into the compressor receiver, a check valve is installed at the point of its connection with the pipeline system.

A good compressor with a powerful and even air supply delivers an air-water mixture to the pipelines, which loosens and knocks down scale deposits inside the pipes. The compressor must operate in a uniform pulse mode, creating not just a constant air flow, but a series of air-water jolts. This is exactly how the scum-loosening swirls are formed.

A smart solution is to use a compressor that can add disinfectants and cleaning agents to the air stream. In addition, such a device must be protected from spontaneous shutdown, be compact enough and, preferably, have an alarm about the level of the consumed flushing liquid and the displayed pressure parameters.

Hydrodynamic type of flushing

The scheme for flushing heating in a similar way involves an active effect of water on scale and deposits. This happens due to a stream of water, which is directed to the desired area under strong pressure.

Water is supplied through special nozzles of the required size and diameter. This type of washing is more expensive than chemical washing, but the result is much more satisfactory.

Scheme of using the hydrodynamic method of cleaning the heating system. Click to enlarge.

This type of flushing is best suited for batteries made of cast iron. Removing scale from cast iron using chemicals is very problematic due to the properties of the material itself, and sometimes even impossible.

However, the hydrodynamic system does an excellent job in such cases.

Another undoubted plus is the environmental friendliness of such washing, since no acids and solvents are used. But only water.

To achieve the desired effect, specialists must have a special mechanism that will create a pressure of two hundred or more atmospheres.

Naturally, all scale is removed exclusively by exposure to water. No additional fluids or reagents are needed.

But here, too, everything is not as simple as it seems. Before flushing with this method, it is necessary to take the radiator to a service. There it will have to be treated with a special liquid so that the layer that needs to be removed becomes softer and more pliable.

Only then can the walls be treated with a pressurized water jet. Using this method, you can remove almost everything: grease, scale, rust, dyes, carbon deposits, etc.

Flushing Signs

For the normal functionality of the heating system, nothing should interfere with the movement of the coolant through the channels built for it.

It can be diagnosed by carefully monitoring the operation of the entire system and the appearance of a number of indirect signs:

- the system warms up longer than before (for autonomous heating systems);

- the operation of the boiler is accompanied by sounds uncharacteristic for it;

- increased consumption of gas or electricity; the temperature in different parts of the radiators varies significantly;

- radiators are noticeably cooler than the supply pipes.

However, weak or uneven heating of batteries is not always a sign of clogging. Perhaps they were airborne. In such a situation, it is enough to dump the airlock through the Mayevsky crane.

In houses with a centralized heating system, it should be flushed by employees of the heat supply company. In a private house, this procedure is carried out by the owners or invited specialists.

For example, in district heating systems, the coolant must go through a water treatment cycle, which reduces the degree of pollution. True, this rule is not always fulfilled. And the system itself is often in operation for the third or fourth decade and the amount of garbage circulating inside increases every year.

But for both centralized networks and stand-alone systems, it is recommended to flush annually. Which, by the way, is confirmed by the requirements of building codes.It is this period that is considered critical for the accumulation of the amount of debris inside the circuit, which significantly reduces the efficiency of work.

If the system is not flushed before the start of the heating season, the pipeline is clogged, devices and heating equipment fail prematurely

Why do you need to flush the heating system

The water that flows through the heating pipes is far from distilled. What is not in it:

- mechanical impurities: rust, sand, scale and other dirt;

- chemical impurities: metal salts, especially calcium and magnesium;

- microbubbles of dissolved air and other gases.

Together with temperatures up to 100 ° C and high pressure, all this forms a "hellish" mixture. Chemical reactions take place around the clock, the main result of which is the formation of scale, corrosion of heat exchangers and communications.

The water entering the system must not only be filtered from mechanical impurities, but also lead to the required chemical and physical characteristics, that is, to comply with the water treatment standards in thermal systems.

Important: corrosion in the heating system occurs for several reasons. Two main ones:

- Air microbubbles: they contain more oxygen than free air - up to 35% (oxygen corrosion).

- Increased acidity of water - pH

If you do not take action in a timely manner:

- the heat transfer of the system is noticeably reduced;

- energy consumption increases;

- the walls of the pipes and the boiler become thinner and destroyed, leaks are formed in various elements of the pipeline.

There are several ways to remove harmful deposits. Of these, hydropneumatic flushing of the heating system is the most radical and effective. It is used in both private and multi-storey buildings.