Gas bottle

Gas cylinders known to all - these are metal oblong vessels of different volumes, containing compressed gases under high pressure inside. Structurally, a household gas cylinder consists of a cylindrical part, a bottom and a neck. Valves, flanges and other sealed communicators are used to connect the cylinder.

This applies to the most common types... In addition, spherical gas cylinders are produced, but they are not used for domestic purposes.

Thanks to its compactness and availability, gas cylinders are often used for domestic purposes. In addition, they are easy to transport, do not take up much storage space and are easy to use as needed. And even this is not all the advantages of a gas cylinder for a summer residence.

Independence from a centralized gas pipeline and / or power supply. Even if there are these communications on the site, you are insured in case of their disconnection, accidents and other unforeseen circumstances. By the way, this is a reason to buy a gas cylinder even if there is a gas pipeline.

Control and savings... You yourself decide and regulate how much gas to use, what the pressure will be, which devices to connect to the source. This makes sense, especially if you have a large number of tenants and / or if you are renting out the cottage.

Not only metal are produced, but composite cylinders... Not only do they weigh much less, but their walls are also transparent. And you can see how much LPG is left in stock, how soon you need to refuel the gas cylinder.

Gas bottle can be called a useful acquisition without exaggeration. But only on condition of strict observance of all safety requirements.

Decor

The design of a gas stove for a cylinder is nominal - you do not need to visit any authorities, the requirements are easy to fulfill. The first was announced - the distance to the balloon is not less than 0.5 meters. Second: to the mains - water supply, sewerage, metal heating pipes - there must be at least 2 meters. That's all.

There are two options for official design:

- When you fill up a new cylinder at a municipal filling station (not for cars, but for filling household gas cylinders), the station employee will draw up the paperwork for you. You will need to provide the address (at least approximately) and explain where the stove is and where the cylinder is located. Here you have to be careful, at least say that it is worth it according to the rules. Yes, the cylinder must be purchased in one of the Gorgaz stores and you will need the registration number of the car on which this cylinder will be transported.

Filling stations for gas cylinders

- In some localities, a car drives and replaces empty cylinders for refueled ones. These people can issue documents. The difference is that they know the address.

For many, a gas stove for a summer residence under a cylinder has been worth for years even without such a "design". But in this case, you will fill the cylinder yourself, without using the services of municipal gas stations or exchange cars. Also, if it is necessary to repair or maintain the stove, to reconfigure it, it will be necessary to somehow resolve the issue of registration (usually there are no problems) or use the services privately.

Gas in a cylinder: safety at home

Inside a household cylinder there is natural hydrocarbon gas under high pressure. Excessive pressure converts the gas into a liquid state of aggregation. When leaving the cylinder, the liquefied gas returns to its previous state.If you delve deeper into understanding this process, it turns out that:

Hydrocarbon gas Is a mixture of butane, propane, ethane and methane. A complex composition is required to create certain properties of the gas mix. Inside the balloon not all of the gas is in a liquid state. Rather, it can be called a two-phase content: liquid, and gas above it. The higher the pressure, the more fluid.

When leaving the cylinder the liquid literally evaporates, acquiring a gaseous state necessary for domestic use. Structure LPG cylinders may vary slightly. Moreover, all hydrocarbon gases are explosive and easily ignited by any careless handling.

They have a specific, recognizable odor so that you can spot the leak in time. According to the degree of toxicity, they are assigned to the IV class of hazard (“low-hazard substances”). It's true: even perfumes and deodorants use liquefied petroleum gases.

So do without gas bottle in everyday life it is not necessary. Moreover, according to the law, all produced gas cylinders undergo a mandatory technical check and receive supporting documents (the so-called "passport").

You can (and should!) Check for a stamp when purchasing a cylinder. It is located near the neck and contains information about the date of manufacture of the cylinder, expiration date, nominal volume and weight.

The main types of gas cylinder gas heaters

A gas heater from a cylinder can differ in its design and the principle of heat transfer, as well as technical characteristics, type of use and cost.

The industry produces several fundamentally different designs of such devices: a heat gun, a gas converter, a ceramic and infrared heater.

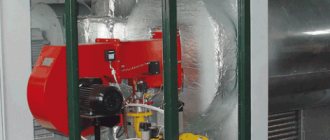

Heat gun for giving

A heat gun is a heat ventilator that uses the combustion gas as a heat source. Structurally, heaters of this type are a streamlined metal case with openings for hot air outlet. The housing contains: a fan, a gas burner, a heat exchanger, devices providing ignition and combustion control, as well as monitoring the safety of the unit.

By design features, heat guns are classified into devices with direct and indirect heating.

Direct air heating models have an efficiency of 100%, but their disadvantage is the combustion of oxygen in a heated room.

In models of indirect heating, fuel is initially burned, and then the products formed during its combustion, which is carried out using a ring-type heat exchanger. Indirect heating models are environmentally friendly devices, however, their significant disadvantage is the limited mobility caused by the presence of a chimney that serves to remove exhaust gases.

The heat gun is a heat fan The heat gun works as follows:

- when the gas supply valve installed on the gas cylinder is opened, the gas flows to the gas burner;

- the ignition device ignites the gas;

- when gas is burned, the air in the heat exchanger heats up;

- a working fan sucks in cold air from the room and directs it to the heat exchanger, and the heated air, in turn, enters the heated room;

- to protect against overheating and damage, the units are equipped with thermostats.

IMPORTANT!

When using a heat gun, it must be remembered that for its operation it is necessary to have an electrical network, from which the fan of the device operates, and also gas is ignited.

As a rule, models intended for domestic use are equipped with a handle for carrying them and wheels for moving on the floor surface. These are mobile devices powered by separately located gas cylinders.

Stationary models have an already installed gas cylinder in their design, they are more powerful and have larger overall dimensions and weight.

Gas cannons used in the country are of two types according to the type of fuel used: they work on liquefied gas (butane / propane) and universal ones, capable of working on liquefied and natural gas.

IMPORTANT!

To connect a gas cannon to a natural gas main, the model must be equipped with a pressure stabilizer that ensures the normal operation of the unit from a similar source of combustion fuel.

The criteria for choosing a heat gun are:

- unit power;

- area (volume) maximum allowable for heating;

- the type of heat exchanger that determines the heating method (direct / indirect);

- overall dimensions, weight and shape of the case;

- the manufacturer's brand that ensures the quality of the product;

- cost.

A heat gun for a summer residence is a simple and economical source of thermal energy in operation, which is a good alternative to stationary heat sources.

Heat guns do an excellent job of heating premises

Gas convector for summer cottages

Any convector, regardless of the type of primary energy converted into heat, involves the circulation of air flows due to the temperature difference in the lower and upper air layers.

Warm air rises up, and when it cools down, it goes down, which causes its circulation. This principle is incorporated in the design of the gas converter, in which the air is heated by burning gas.

Structurally, the gas converter consists of the following components:

- body - can be made in various types of execution (mounted, mobile, stationary);

- heat exchanger;

- a heating element;

- automation, control and protection devices.

The gas converter operates as follows: when fuel is burned, the air in the heat exchanger heats up and rises up through the holes in the housing. At the same time, cold air enters from below, which is due to its circulation in an enclosed space.

Units of this type can operate on liquefied and natural gas. In the variant of summer cottage use, as a rule, it is liquefied (propane / butane) gas. The design of the gas convector can have exhaust systems or be of an open type.

Some models of such devices are equipped with a fan, which increases their performance and extends the service life.

Heats by circulating hot and cold air

Catalytic type gas heater

A catalytic heater (including a gas-fired one) is a unit used to heat the ambient air by oxidizing a catalyst plate, which is the main element of such a device. The catalyst plate, as a rule, is made of fiberglass with the addition of platinum powder, upon contact with fuel and heat energy is released.

On the surface of the plate there are a large number of small holes through which gas enters and burns, an oxidation reaction occurs on this surface, and as a result, heat energy is released. This combustion mode is called flameless, although there is little flame on the surface of the plate.

The work of a catalytic gas heater is as follows:

- when the heater is turned on, the surface of the catalyst plate heats up;

- an air-fuel mixture is prepared and heated in a separate chamber of the device;

- vapors of the combustible mixture are supplied to the heated plate, which, when burned, release heat, which is transferred, in turn, to the surrounding air.

Some manufacturers add electric heating elements to the design of individual models, which serve to heat the catalyst plate, as well as fans that improve air circulation in the heated room.

The selection criteria for catalytic heaters are the following:

- heated area;

- electric power;

- gas consumption at various operating modes;

- availability of automation and control systems;

- overall dimensions and weight;

- device reliability (manufacturer's brand);

- cost.

A gas catalytic heater is a progressive type of heating units that is confidently gaining its place in the market of devices used for heating buildings and structures for various purposes.

The catalytic heater looks good in the interior

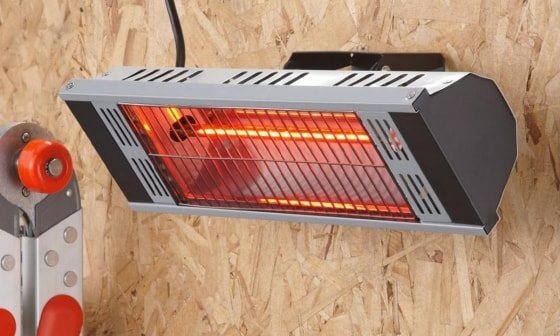

Infrared gas cylinder-operated heater

The principle of operation of a gas infrared heater is based on the fact that infrared rays heat the objects in the room, and the building structures of this room (walls, ceiling, etc.), and they, in turn, give off their heat to the surrounding air.

IMPORTANT!

When using gas infrared heaters to increase the heated area, they should be positioned as high as possible above the floor surface. A heater of this type consists of the following elements: a body made, as a rule, of metal, a heat exchanger, a splitter and a reducer, as well as a control and protection unit.

The operation of a gas infrared heater is as follows:

- gas from a separately installed cylinder enters the reducer, where its pressure decreases, then the gas enters the heater nozzle;

- in the splitter, the gas is mixed with air, after which it enters the ceramic panel, where it is burned (gas-air mixture);

- when heated, the ceramic panel emits infrared rays, which are distributed in the heated room.

IMPORTANT!

A distinctive feature of an infrared heater is its ability to start heating the heated room immediately after it is switched on, which significantly saves the fuel used.

The selection criteria for heaters of this type are: power, moisture resistance, type of exhaust gas discharge, as well as the presence of automation and protection systems.

Stoves with a small gas cylinder

A small stove, paired with a small gas cylinder, is a mobile and compact heater used to heat small rooms (up to 10 m²) in buildings and structures for various purposes.

In addition, heaters of this type are used to heat temporary structures (tent, hut, etc.) used by people leading an active lifestyle, as well as hunters and fishermen (winter huts, fisherman's and hunter's houses, etc.).

The combustion principle of this type of heater is a closed type stove. The furnace body, as a rule, is made in the form of a rectangle, on the reverse side of which there is a fitting for connecting a gas hose. A hose connects the oven to a gas cylinder through a reducer installed on the latter.

Outdoor gas heater

An outdoor gas heater is intended for outdoor use. These can be gazebos and terraces, verandas, etc. Externally, heaters of this type resemble street lamps or illuminating columns. Gas cylinders in outdoor heaters are mounted in their legs, the method of heat transfer is infrared radiation.

The heater resembles a luminous column

Choosing and buying a safe gas cylinder for a summer residence

Of course acquire and use only cylinders that have passed a full test and provided with an official stamp are allowed. But it cannot be otherwise if you buy gas cylinders only from legal suppliers. You must be presented with a license. After that, you can safely explore the range.

By volume gas cylinders can be very small (5 liters), as well as 5, 12, 27 and 50 liters.

When choosing, take into account the number of appliances to which you will connect the gas (stove, heater, etc.); the number of people in the house; free space for safe storage of the cylinder (we will talk about this in more detail in the next part of the article).

Cylinder material... The usual option is a metal cylinder, one-piece or with welded seams.

Modern version: Composite balloon, lightweight and transparent to control the amount of content. Composite cylinders are considered safer (less risk of explosion). But these advantages will have to be paid for about three times more than metal cylinders of similar volume can cost. Even the smallest, 5-liter, gas cylinder will come in handy at the summer cottage if the house is not heated there. This fully applies to cabins, log houses, block containers and even logs. With the help of gas, you can both heat the house and create comfortable conditions in it (heating water, cooking, etc.).

Safe storage and operation of a gas cylinder

Even initially serviceable A gas cylinder can be dangerous if used incorrectly. And rightly so - it's not difficult at all. Here are the basic conditions:

Passport stampassigned to a cylinder in production does not guarantee eternal preservation. In particular, the gas cylinder can be damaged during transportation, from impacts and / or falls.

A sign of such damage is dents, deep scratches, cracks, other violations of the integrity of the cylinder or its parts (neck, valve, etc.). It is dangerous to use such a bottle or even leave it in the house.

Temperature regime very important for gas cylinders. Do not store, use, move them at temperatures over 45 ° C. Exceeding this line can lead to a jump in internal pressure and an explosion of the gas cylinder. Sudden changes in temperature are fraught with the same consequences. And too low ambient temperature makes the walls of the cylinder brittle.

Gas cylinder you need sufficient storage space, and it depends not only on the dimensions of the cylinder itself. First, you need free access to the cylinder, as well as the ability to take it out of the room. Secondly, in order to comply with the temperature regime (see paragraph above), it is imperative to move the cylinder away from all devices that can heat it (2 meters from the stove, 1 meter from batteries and heaters). Storage room and the operation of the gas cylinder must meet certain requirements. Thus, the balloon should not be exposed to direct sunlight. Do not leave the cylinder in the aisle, where it can be touched, moved, dropped.

Gas cylinders small volumes (5 and 12 liters) can be stored in a common room. There can be only one cylinder with a volume of 27 or 50 liters in a room, regardless of the size of this room.

Often per balloon girdle rubber rings are worn for safety. They are usually used for transportation, but they will not interfere with the cylinder set on the floor. Many owners store gas cylinders in a residential building or shed for easy access to them.

But in fact, according to the rules, gas cylinders must be installed outdoors: on the street, in a tightly closed metal cabinet or booth. Always upright! Make sure that there is no sunlight and precipitation inside.

Read more about the shtil chainsaw and its repair with us.

Are you decorating a barbecue area in the country? With these tips - get it right!

Build your own dog house by following these important guidelines.

Refueling and connecting a gas cylinder to household appliances

Gas bottle can serve as a source of fuel for heaters, water heaters, kitchen stove. To securely attach the cylinder, you will need:

- special flexible gas hose. The admissible hose diameter is from 6 to 9 mm;

- a clamp for fixing the hose to the cylinder and a clamp for fixing the hose to the device;

- reducer type RDSG 2-1.2 (for a cylinder with a valve) or RDSG 1-1.2 (for a cylinder with a valve).

It is highly desirable that installation performed by specialists. Moreover, you still have to invite a master from time to time to fill an empty gas cylinder for a summer residence. Refueling gas cylinders - this is the specialization of professional licensed companies, only in this case you can count on the safety of both the process and the result.

And in no case should you try to get by on your own. Refueling gas cylinders refueling is strictly prohibited! If you cannot wait long for the visit of the master, keep spare gas cylinders for the summer cottage. Because this is precisely the situation where caution is never over-cautious.

And for those who like to know more, we suggest that you familiarize yourself with the video about gas cylinders

Gas composition

The efficiency of gas consumption and the very possibility of the burner operation directly depends on the temperature of its use. For a long time, the composition of the gas mixture did not allow the burners to work correctly at low temperatures, because when cooled, the gas is compressed and no longer effectively evaporates through the open valve. The situation changed only in 1986 when MSR released cylinders containing a gas mixture of isobutane, propane and butane. All gases in it have different boiling points, therefore, they allow the burner to operate efficiently over a wide temperature range (up to -15 ° C, depending on the purity of the fuel).

Today, the widest range of gas mixture choices belongs to the Swedish company Primus, which has been in the portable fuel equipment market for over 100 years. The latest innovations in the design of gas cylinders are also associated with it. Using the example of the Primus range, you can consider the choice of a gas mixture for specific operating conditions.