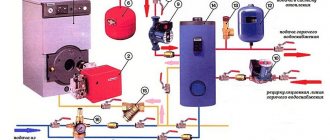

The heating system of private houses and country cottages needs regular monitoring of the technical condition and preparation for operation in anticipation of the cold period.

In order for the system to function without interruption, it is necessary to periodically perform pressure testing, which helps to detect defects and identify leaks before the start of the heating season.

- 2 Features of the operation

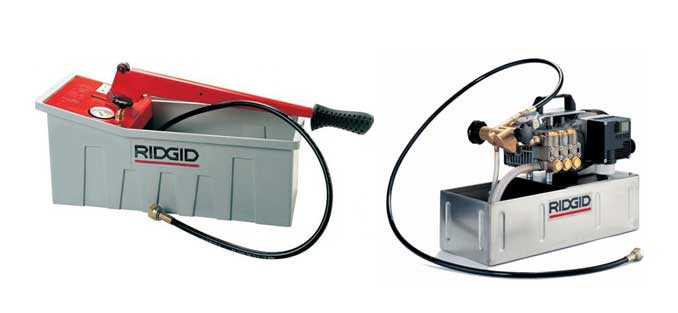

- 3 Pumps

- 4 Types of equipment

4.1 Electric pump

- 4.2 Mechanical

The essence of crimping

Pressure testing is a special test of the building's heating system for tightness and strength by means of high pressure, which is created after pumping the pipeline with liquid.

Since the heat carrier in the pipes is under constant pressure, therefore, all components of the circuit are subjected to systematic stress.

Often during the heating season, air masses penetrate into the system, leading to hydraulic shocks. As a result, various leaks appear, which are not always fixed. For example, in certain areas of the system in underfloor heating.

It is for this reason that the heating system must be pressurized before connecting the heating. In addition to detecting damage, pressure testing helps to clean the pipeline from accumulations of debris, rust, air residues, dirt and other deposits that impede the free movement of fluid.

A defect in the pipeline can lead to a rupture of the pipe, a large leak and the impossibility of shutting off the water flow.

What is the function of a pressure pump?

Directly, the crimping operation is calculated to detect leaks and deviations in pressure drops. However, pumps for pressure testing heating systems have a wider functional range. They also act as a means of preventive examination of a specific section of the line. This is important in terms of ensuring timely repair operations. Most often, the need to use such a revision arises after the completion of installation or repair activities.

In the rules for the operation of heating systems, some paragraphs contain instructions according to which the crimping procedure is mandatory. For example, you cannot do without it when putting an object into operation. It is also common practice to use pressure testing equipment before the onset of the heating season, when it is necessary to check the reliability of the connections in the pipeline.

Features of the operation

The first time the pressure test should be carried out before connecting the pipeline to the centralized system.

In the future, prophylaxis is performed every 5 years. It depends on the quality of the source material and components (constipation, pipes, pumps).

Steel pipes are connected by welding and threads, polyethylene modifications - with fittings, and propylene ones using low-temperature brazing. Any connector is considered a potential leak point.

To determine the damage, hydraulic pressure is created in the system. Its coefficient must be greater than the maximum possible working pressure in the pipeline. So, if the system can withstand a hydraulic load of 16 atmospheres, then the pipes can also withstand the standard pressure of 8 atmospheres.

In addition, pressure testing is mandatory after repair work or prolonged downtime, as well as after replacing radiators or heating risers.After all, it is better to detect a violation in the system in the off-season than during the first frosts.

Hydraulic tests in a private house

In the heating circuits of private houses, the operating pressure is not more than 1.5 - 2.0 atmospheres. Therefore, pressure testing of the heating system, for which it is necessary to create in the range of 1.8 - 4 atmospheres, is easily carried out using manual or electric pumps. The system is filled before testing from below, through a specially provided valve, and air is removed through the air valves at the top of the fuel system.

The standard time for pressing the heating system is 30 minutes.

There is another, simple, alternative method for crimping a home heating system. The heating system circuit is connected to the water supply network. The water supply pressure reaches 3 atmospheres, and it is sufficient for testing.

Pumps

Pressure testing of the heating system is carried out by means of pressure pumps simulating a situation similar to a water hammer.

A pressure pump is a kind of press that is used for hydraulic testing of plumbing, engineering and communication systems.

This mechanism connects directly to the loop. With its help, the controlled pressure created in the pipes is increased. After connecting the device, the working substance begins to be supplied to the system under a certain pressure, then the readings of the manometer are taken.

The pressure is applied until its level exceeds the operating value by 3 times. The verification procedure takes 2-3 hours. All this time, the readings of the manometer are monitored.

If during the process there is a sharp drop in pressure, then the tightness of the pipeline is broken. In this case, it is necessary to identify the location of the leak, carry out repair work and start a new test. Stable readings indicate the tightness of the heating system.

Equipment types

Depending on the technical parameters, all crimping pumps are classified into two groups: electrical and mechanical.

There are several modifications of electro-hydraulic pumps, however, they are used somewhat less often.

Although the principle of operation of the pumps is different, the functional purpose is almost identical: pressure testing of the system, finding leaks, preventive maintenance and commissioning. Before using the equipment, you must read the attached instructions.

If you wish, you can design a homemade pump, especially if you need it for crimping a private house. This will require copper pipes, plugs, a check valve, a pressure gauge and a fitting through which the pipe must pass.

All elements are assembled in a specific sequence using welding. Linen strands are used to seal the joints. The cost of such an installation will be much cheaper than analogues, however, certain skills and knowledge are required for its manufacture.

Electric pump

The device is equipped with a motor and operates from a 220V network. This unit is used for testing heating, plumbing and oil systems.

Electric models are used in professional activities with intense loads.

The main advantages of an electric pressure test pump are:

- Easy to operate and maintain. To connect the mechanism, you just need to press a button on the control unit.

- High level of performance. Thanks to the electric drive, the maximum pressure is generated very quickly.

- Long service life due to high-quality and reliable housing.

- Convenient pressure regulation with a bypass valve.

- The presence of special protection against overheating.With strong heating, it automatically lowers the pressure level, causing the device to cool down.

- Mobility. The device can even be carried in the trunk of a car.

The disadvantages of an electric pressurizer include its high cost, dependence on the electrical network and a solid weight.

Mechanical

The hand crimper consists of a pressure pump handle, indicator, hose and housing.

These devices are often used as clamps or hydraulic lines. They are indispensable for use in places where there is no electricity or water supply.

The mechanism has many advantages:

- compactness, mobility;

- can be used in a limited area, when carrying out small-scale work;

- long service life with careful maintenance, the possibility of repair;

- safety in operation, due to the absence of rapidly rotating elements;

- acceptable cost.

The disadvantages of a mechanical pump are low pressure delivery rates and the need for constant monitoring. In addition, working with the device requires some physical effort.

Important instrument parameters

The maximum possible pressure level in the heating system depends on the power of the installation.

Therefore, pressure testing equipment can be systematized into several categories:

- pressure varies within 30 bar;

- pressure reaches 60 bar;

- maximum pressure level 100–120 bar;

- over 150 bar.

The functional component of the unit is of no small importance. It depends on the pump model and determines the volume of fluid that the mechanism can pump. The weight of the pump and the volume of the reservoir for storing the working fluid are important.

Also, when choosing a certain modification, it is worth considering the working environment in which the pump can operate.

Compactness and ease of use. Features of the hand pump for pressure testing the heating system

Crimping is a parallel validation test procedure for the strength and tightness of the heating system by creating high pressure.

The first pressure test is carried out immediately after the installation of the pipeline on the site... This is done to identify potential leaks.

Mechanical pumps are most often used for domestic purposes. Such units have a lower cost, they are compact, and it is easy to work with them. Their feature is in ease of use and in the ability to work in confined spaces without access to the electrical network.

ontakte

Odnoklassniki

Pressurizing pumps and filling equipment do not have significant differences. Often, one and the same unit is used both for checking the strength of the system and for filling it.

Photo 1. This is how a hand pump for crimping looks like. ...

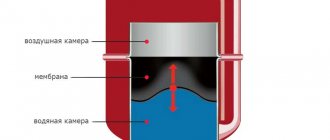

Modern pressure and injection pumps differ in the type of drive. It can be electric or manual. By the principle of action equipment is subdivided into the following types:

- membrane;

- lamellar-rotary;

- piston.

The principle of operation of the crimper

The principle of operation of a manual crimper is quite simple. Water is poured into the tested heating system up to the maximum possible level. After that, by pressing the lever, the pressure level required for the test is reached (2-3 times higher than the working norm). When the required pressure is obtained, the ball valve on the unit is closed. The operator monitors fluctuations on the pressure gauge.

Attention! In order to prevent excessive pressure inside the heating system during pressure testing, the pumps are equipped with special overflow valve.

If the pressure starts to drop, then the pipe is leaking. Described the procedure is repeated several times. If a defect is detected, work stops until it is eliminated.

The first pressure testing is carried out immediately after the completion of installation work. Then the check is repeated every 5 years after flushing the pipeline aggressive chemicals.

Benefits of manual pressure testing pumps

Mechanical crimping unit has a number of advantages:

- Low weight and compact dimensions

The low weight and compactness of the equipment allow you to easily carry and transport devices without using lifting devices.

The units are used even in confined spaces.

- High accuracy of the results obtained

The accuracy rate largely depends on the power of the device itself. When choosing a specific model of equipment, you need to understand that using a low-power pump increases the time required for verification. In addition, if a leaky joint is detected, the test results may be distorted.

Unlike electrically powered models, hand crimpers are suitable for use away from the electrical supply.

Handheld devices are simple in design and do not require qualified personnel to service them.