What's special?

Briquettes are an environmentally friendly type of fuel, because it is produced without the addition of various chemicals and adhesives. Natural base and contributes to the widespread distribution of this material. The second important point is that when briquettes are burned, no harmful substances are released that can affect the state of man and nature as a whole.

Due to their low sulfur content, the combustion of biomass does not generate pollutants. Briquettes for heating received good reviews and due to the fact that they are easy to ignite, they burn for a long time (twice as long as wood).

Third, it is much easier and safer to feed such material into the firebox than to use non-briquetted waste. Fourth, no sparks are formed during combustion, which also indicates a high level of safety.

The consumption of briquettes for heating is small, which means that you can save on energy costs. So, due to the greater efficiency of combustion in the boiler furnace, very little ash is formed, and it can be used as a potash fertilizer. In addition, briquettes will not spontaneously ignite at high temperatures, since there are no hidden pores in them.

Industrial models

An industrial boiler operating on peat briquettes is characterized by a higher efficiency and a higher level of automation of combustion processes. Close attention is paid to operational safety. Typically, industrial boilers have multi-level protection against overheating and unexpected fires.

solid fuel boiler Proton KVu-1,5AMT with automatic loading

The differences between these units are as follows:

- New solid fuel industrial boilers are launched on the market with built-in automation for fuel loading.

- The furnace is connected to a belt or auger conveyor. Peat is fed from mechanized niches, often undergoing initial preparation in auto mode.

- Now for the ash removal system. Domestic long-burning boilers on peat have a grate with special holes for cleaning. A brush in the form of a hook is pushed through these holes into the furnace and ash residues are manually removed. Industrial peat boilers have a self-cleaning system and movable grates. When the fuel is burning, the grate bars toss and turn from time to time and thereby dump soot down into the ash pan. Plus, there is a pneumatic self-cleaning system function.

- The heat exchanger here is a niche through which many tubes with a heat carrier moving along them stretch. A two-way, as well as a three-way system of heat accumulation of smoke gases is used. There are industrial boilers that function both for heating the coolant and for producing steam.

Now more and more often you can find the automation of the supply and cleaning of the boiler and in household models.

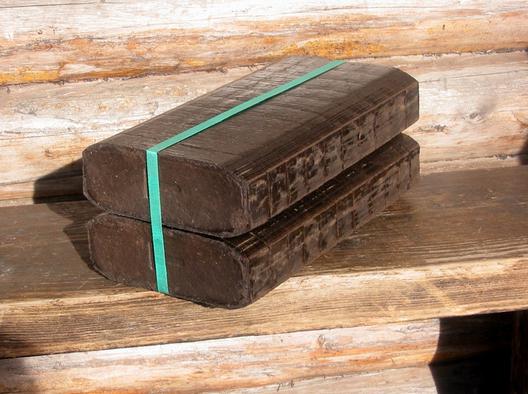

Peat briquettes

Peat briquettes for heating receive numerous and good reviews. Dried and compressed peat is used to create them. The manufacturing process involves drying and pressing under high pressure. As a result, the raw material is compressed into small briquettes that are easy to transport and store. You can use such fuel when heating a house with stoves, boilers, fireplaces, as well as for lighting a fire.

Prices for our products and delivery

invites you to buy peat briquettes in Moscow and the Moscow region. We have been carrying out activities for the production and sale of various heating materials since 2004, bringing warmth and comfort to your homes.Our company does not unreasonably overstate the prices for peat briquettes for heating, offering a loyal and attractive price.

Peat briquettes are packed in p / prop. bags of 25 kg

Delivery from 1 to 5 tons is paid separately

| № | price rub / ton | Scope of delivery |

| 1 | 250 rub / bag | less than 500 kg |

| 2 | 9000 rub / ton | more than 0.5 tons. |

| 3 | negotiable | 20 tons |

Buying our products, you get a highly professional service, because we care about the interests of our customers and are well-versed in the heating raw materials market. The peat briquettes produced by our company, the price of which is indicated in the corresponding table of this section, are of impeccable quality and meet all the requirements and standards imposed on them.

delivers peat briquettes throughout Moscow and the Moscow region using its own vehicles, thanks to which you can significantly save money by choosing this service. There is also an option for self-delivery of ordered products.

Peat briquettes, which are much more profitable to buy from us than from other companies, can be ordered by contacting the specialists at the contacts indicated on the website.

Positive properties of peat briquettes

Peat briquettes for heating, reviews of which are mostly positive, have the following advantages.

- High heat dissipation.

- Long burning.

- Ease of use, because the product is already ready for use.

- The ash that forms after combustion can be used as a phosphorus or lime fertilizer.

Peat briquettes for heating are a profitable alternative to conventional solid wood, while you do not have to think about the time-consuming firewood harvesting.

Advantages and disadvantages

Peat briquettes for heating have a number of undeniable advantages, namely:

- safety of use - sparks are not formed, during combustion there is no release of carcinogenic and toxic fumes;

- the combustible quality of peat fuel has been preserved for several years;

- peat bars - a natural bioproduct with minimal additives;

- storage requires a much smaller area compared to traditional fuels (coal, firewood);

- the wholesale purchase of peat briquettes is much cheaper than the purchase of diesel fuel, gas, coal;

- the calorific value of peat briquettes occupies an intermediate position between wood and black coal.

But one drawback still exists. It is flammable. Therefore, for the purpose of fire safety, peat fuel is strictly prohibited to be left near fire or heating appliances.

Coal briquettes

Another popular type of raw material for heating is coal briquettes. It is a synthetic fuel obtained from compressed coal screenings. First, the material is crushed, then pressed, with the addition of binders. This approach makes it possible to obtain easy-to-use coal briquettes for heating. In accordance with European standards, this fuel is a smokeless compound, in addition, it meets environmental safety requirements. For your information, you can even cook food on the basis of coal briquettes!

Positive properties of coal briquettes

The use of this type of raw material is absolutely safe, since no carbon monoxide is emitted during combustion. It is no coincidence that coal briquettes for heating are widely used in home and country heating based on various types of systems: boilers, stoves. The distinctive features of raw materials include:

- high density;

- low moisture content;

- control of fuel consumption and maintenance of the combustion process;

- due to the complete combustion of the product, all the thermal energy is released into the room, respectively, it will be possible to warm up the house much faster;

- ease of transportation, during which the material is not crushed;

- during combustion, only ash is formed, which can be easily removed.

All these positive properties explain the popularity of such material as coal briquettes for heating. Reviews often mention the availability of the material.

Wood briquettes

This fuel has a cylindrical shape and a characteristic color. Briquettes are created on the basis of woodworking industry waste - sawdust, dead wood, shavings and substandard materials. The waste is first heated and then compressed under high pressure. As a result, the natural glue lingin is released, thanks to which the material becomes stronger and becomes resistant to deformation. In addition, this type of heating material has the following features.

- Low moisture content - only 10% (compared to 40-60% of conventional solid wood).

- Heating efficiency.

- Uniform and constant density, while in ordinary wood it depends on the type of wood.

- When burning, fuel cells do not spark, emitting a minimum amount of smoke. The combustion process takes at least 4 hours.

- After the briquettes are burned, coals are formed, which can also be used as raw materials for ignition.

- Environmental Safety. Wood briquettes for heating (reviews about them are very common), when burned, emit 50% less carbon dioxide.

- Due to the correct form, such firewood will take up little space, while you can transport them with maximum convenience (reviews also say about this).

Design features

Peat is a cheap and renewable solid fuel. It is clear why now more and more coal-fired boiler houses are being converted to peat briquettes. Although, theoretically, nothing prevents the owner from using this type of fuel in a classic unit, in practice everything turns out to be somewhat more complicated than it seems.

The device of the solid fuel boiler KLIVER-25P

There are the following nuances to this:

- Peat in a standard wood-fired or coal-fired boiler burns with a steady blue flame and generates a lot of heat. However, during the combustion process, soot remains on the surface of the fuel, which prevents oxygen from entering. Peat burns longer, but the heat transfer becomes much lower.

- The ash residue is characterized by a high density, because of this, the combustion products, when burned out, do not crumble through the grate into a special niche for ash, but accumulate on the grate, and thereby impede air circulation.

- Peat has a relatively high moisture content. This disadvantage must be eliminated by manufacturers of heating equipment. In nature, peat has a moisture content of about 85-90%. After drying, the percentage is 30-60% (depending on the variety).

In a solid fuel boiler, peat briquettes can be used, which are made from small particles of raw materials by pressing. After being processed, peat has already other indicators: lower moisture content, ash content. This makes it possible to use peat briquettes in classic units.

Forms of fuel briquettes

This heating raw material is available in several varieties. So, round briquettes are made in the form of a cylinder, have a diameter of 60-90 mm and a length of up to 350 mm. High pressure mechanical or hydraulic presses are used for their production. Fuel briquettes in the form of bricks are also made from sawdust, wood chips, while no harmful chemicals are added to them. Pini-key briquettes are made in the shape of a polyhedron, which have a dark crust and a hole in the center. These varieties are not only pressed, but also subjected to firing, due to which they become stronger and more resistant to moisture. Such Eurowoods look modern, but at the same time they are more expensive. As a rule, they are bought for heating fireplaces, since the pini-key burns very beautifully.

INNOVATION FOR BUSINESS

Avoiding these disadvantages allows the creation of an innovative technology for the manufacture of peat briquettes, including mixing peat and a binder - oil sludge until a homogeneous mass is obtained, pressing it into peat briquettes by molding in a piston screw unit with heating the body, and drying the peat briquettes in a drying chamber.

The solution to the problem of obtaining an effective substitute for natural fuel is the use of a compressed mixture of peat and waste oil products, as one of the energy components of solid fuel, for use as the main type of fuel or a high-calorie additive to the fuel of small boiler houses.

The technical result of using the proposed technology is to reduce the energy consumption of the process.

The technical result is achieved by the fact that in a method for the manufacture of peat briquettes, including mixing peat and a binder - oil sludge until a homogeneous mass is obtained, pressing it into peat briquettes by molding in a piston screw unit with heating the body, drying the peat briquettes, use peat with a moisture content of 30--65%, volume ratio peat and oil sludge (4 × 10): 1, the said body is heated to 65-80 ° C, and the drying process is carried out with additional sorption of oil sludge from the surface of peat briquettes.

To implement the method, an installation has been created that is compact, mobile, has the ability to move and work in any, including field, conditions, for example, on spills of oil products, cleaning the contaminated surface.

The method has a low fire hazard.

This method makes it possible to produce peat briquettes with specified parameters (dimensions, calorific value).

The proposed technology consists of the following operations:

1.mixing until a homogeneous mass of oil products (oil sludge) and pre-prepared peat (cleared of stones, metal and large wood inclusions) is obtained, having a moisture content of 30–65%, with a volumetric ratio of peat and oil products in the ratio (4–10): 1;

2. loading a homogeneous mass through a dosing feeder into a piston screw unit;

3. molding the mixture in a piston screw unit to obtain peat briquettes at the outlet;

4. additional drying of peat briquettes with additional sorption of oil sludge from their surface; for this, the surface of the peat briquettes is sprinkled with finely ground peat.

Peat briquettes are formed in the form of cylinders with a diameter of 40-60 mm, length 100-200 mm, calorific value up to 4800 kcal / kg; ash content 6%.

Process flow diagram for the production of peat briquettes with the addition of petroleum products:

An example of the implementation of the proposed technology:

To implement the method, a piston screw unit and a feeder-dispenser are used.

To obtain peat briquettes, low-lying peat with an average degree of decomposition was used, with an ash content in a dry state of no more than 15%, and a moisture content of 50%.

Peat was mixed with oil sludge in a volume ratio of 6: 1.

To obtain peat briquettes, the optimal operating mode of the unit was chosen: the screw rotation speed is 180 rpm; the location of the auger from the extremely extended position - 60 mm (within 50-70 mm); heating of the screw body - 70 ° С; nozzle diameter of the branch pipe - 60 mm; uniform supply of peat to the auger.

The finished briquettes were dried in places protected from external precipitation (snow, rain) getting on the briquettes, with additional sorption of oil sludge from their surface (the surface of peat briquettes is sprinkled with finely ground peat).

The calorific value of briquettes is comparable to the calorific value of Kuzbass coal.

Peat briquettes are produced moist and plastic, but due to the previous thermomechanical and thermochemical processing of a mixture of peat with oil sludge in the unit, they noticeably harden within a few hours and partially lose moisture, and additional sorption significantly accelerates the hardening process.

Features of the technological process

Fuel briquettes are a modern material that has great prospects. Due to their compactness, environmental friendliness and ease of use, they are becoming more and more popular, and the manufacture of briquettes for heating is a profitable business.This raw material is effective because it burns longer and heats the room longer, because heat is generated continuously. There is practically no smoke when they burn. Briquettes with a through hole in the middle promote better fuel combustion. The use of this material is advisable in those countries where climatic conditions are severe.

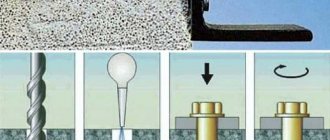

The production of briquettes for heating is carried out on the basis of the following equipment:

- a machine for shredding wood waste;

- press;

- a machine that packs finished products.

There are also automated lines for the production of briquettes, while the variety of equipment allows you to optimize this process, which is simple.

Features of the firebox

As we have already said, ease of use and affordability are the main indicators that distinguish briquettes for heating. Reviews about them focus on the high quality of combustion. The heating process is also simple, especially if wood briquettes are used - they are simply put in the oven. When creating peat products, they first get rid of moisture, after which they are crushed.

During briquetting, the material is compressed, as a result of which the substances contained in the wood are released, binding the material into a single piece. At high temperatures, moisture evaporates from the wood, however, if this is too intense, so-called steam pockets can form. That is, the material will expand, which means that the briquette will collapse.

Can you make briquettes yourself?

It is quite possible to create briquettes for heating with your own hands, especially if you have access to free sawdust or other woodworking waste. At the same time, you will receive environmentally friendly, and, importantly, cheap raw materials for heating a house or summer cottage. By the way, for the manufacture of Euro wood, you can use not only chips and sawdust, but also husks, straw and many other materials at hand.

Clay can be used as a binder for future briquettes at the rate of: 1 kg of clay - 10 kg of the material itself. To make the resulting briquettes conveniently stored, you should give them a certain shape, for example, using homemade forms from boards.

DIY briquettes for heating are created as follows.

- We take a container, into which we pour the previously prepared consumables, clay and water. The mass should be well molded.

- Pour the resulting solution into the mold.

- We press it thoroughly.

- Dry.

To make the briquettes stronger, you can cover each product with paper, rags, and then press it.

Method of making peat briquettes

The invention relates to the fuel industry, in particular to the production of peat briquettes using oil sludge. The technical result of the invention is to reduce the energy consumption of the process. In the method of making peat briquettes, including mixing peat and a binder - oil sludge until a homogeneous mass is obtained, pressing it into peat briquettes by molding in a piston screw unit with heating the body, drying peat briquettes, peat with a moisture content of 30-65% is used, the volume ratio of peat and oil sludge (4 h 10): 1, the said body is heated to 65-80 ° C, and the drying process is carried out with additional sorption of oil sludge from the surface of peat briquettes.

The invention relates to the fuel industry, in particular to the production of peat briquettes using oil sludge. The use of the proposed technology contributes to the purification of the environment.

Known methods of obtaining peat briquettes by pressing peat chips or dust with various binders (see, for example, USSR AS No. 157961, published in 1962). The disadvantage of these methods is high energy consumption and the complexity of technological processes.

A known method of disposal of peat waste by pressing them with a binder by obtaining fuel briquettes with a high calorific value, and as a binder used wastes of watered fuels and lubricants fuels and lubricants, which are filtered through a layer of peat or peat waste, after which the resulting product is dried and briquetted (RF patent No. 2021324, 15.10.1994).

The disadvantage of this method is that to obtain a uniform impregnation of peat, it is necessary to pre-irrigate the peat mass with heated fuels and lubricants.

This method requires additional equipment for collecting fuels and lubricants that have passed through the peat layer on the conveyor, as well as equipment for drying and briquetting.

The closest analogue of the invention is a method for the manufacture of peat briquettes, including mixing peat and a binder - oil sludge until a homogeneous mass is obtained, pressing it into peat briquettes by molding in a piston screw unit with a housing heating of 120-150 ° C, drying peat briquettes in a drying chamber (RF patent No. 2100414, 27.12.1997).

The technical result of the invention is to reduce the energy consumption of the process.

The technical result is achieved by the fact that in the method for the manufacture of peat briquettes, including mixing peat and a binder - oil sludge until a homogeneous mass is obtained, pressing it into peat briquettes by molding in a piston screw unit with heating the body, drying the peat briquettes, use peat with a moisture content of 30 ÷ 65%, volume ratio peat and oil sludge (4 ÷ 10): 1, the said body is heated to 65-80 ° C, and the drying process is carried out with additional sorption of oil sludge from the surface of peat briquettes.

To implement the method, an installation is sufficient, which is compact, mobile, has the ability to move and work in any, including field, conditions, for example, on oil spills, cleaning the contaminated surface.

The method has a low fire hazard.

This method makes it possible to produce peat briquettes with specified parameters (dimensions, calorific value).

The claimed method consists of the following operations:

1.mixing until a homogeneous mass of oil products (oil sludge) and pre-prepared peat (cleared of stones, metal and large wood inclusions) is obtained, having a moisture content of 30 ÷ 65%, with a volume ratio of peat and oil products in the ratio (4 ÷ 10): 1;

2. loading a homogeneous mass through a dosing feeder into a piston screw unit;

3. molding the mixture in a piston screw unit to obtain peat briquettes at the outlet;

4. additional drying of peat briquettes with additional sorption of oil sludge from their surface; for this, the surface of the peat briquettes is sprinkled with finely ground peat.

Peat briquettes are formed in the form of cylinders with a diameter of 40-60 mm, length 100-200 mm, calorific value up to 4800 kcal / kg; ash content 6%.

An example of the implementation of the method:

To implement the method, a piston screw unit and a feeder-dispenser were used.

To obtain peat briquettes, low-lying peat with an average degree of decomposition was used, with an ash content in a dry state of no more than 15%, and a moisture content of 50%.

Peat was mixed with oil sludge in a volume ratio of 6: 1.

To obtain peat briquettes, the optimal operating mode of the unit was chosen: the screw rotation speed is 180 rpm; the location of the auger from the extremely extended position - 60 mm (within 50-70 mm); heating of the screw body - 70 ° С; nozzle diameter of the branch pipe - 60 mm; uniform supply of peat to the auger.

The finished briquettes were dried in places protected from external precipitation (snow, rain) getting on the briquettes, with additional sorption of oil sludge from their surface (the surface of peat briquettes is sprinkled with finely ground peat).

The calorific value of briquettes is comparable to the calorific value of Kuzbass coal.

Peat briquettes are produced moist and plastic, but due to the previous thermomechanical and thermochemical processing of a mixture of peat with oil sludge in the unit, they noticeably harden within a few hours and partially lose moisture, and additional sorption significantly accelerates the hardening process.

A method of making peat briquettes, including mixing peat and a binder - oil sludge until a homogeneous mass is obtained, pressing it into peat briquettes by molding in a piston screw unit with heating the body, drying peat briquettes, characterized in that peat with a moisture content of 30 ÷ 65% is used, the volume ratio of peat and oil sludge (4 ÷ 10): 1, the said body is heated to 65-80 ° C, and the drying process is carried out with additional sorption of oil sludge from the surface of peat briquettes

What's the price?

How much do briquettes for heating cost? Eurodrova (namely, wood briquettes) are very popular precisely due to the fact that their purchase will be cheaper. For comparison: 1 m3 of briquettes will require 5 m3 of birch firewood. In this case, the cost will be 5500 rubles against 7000 rubles for ordinary firewood. Why are the savings being made? Firstly, there are no costs for logging, for its delivery to the site, sawing and splitting. Briquettes are created, as already mentioned, from wood waste at the factory (and even with their own hands, if there is anything) and do not require large transportation costs, since they take up little space.

On the other hand, many people say that peat-based fuel briquettes are only good advertising, in fact it is not profitable to buy them. You can give the following table, which will reveal the features of peat products and ordinary birch firewood.

Comparative characteristics

| Peat briquettes | Birch firewood | ||

| Kindling features | Melt equally well with paper or birch bark | ||

| Combustion | They burn slowly, the inner layers do not ignite until the top layer is burned out | Burn well and evenly | |

| Flame | Ugly and small | Decorative flame | |

| Warmly | A little heat is released, vigorous combustion is noted if the briquettes are placed vertically | There is a lot of heat when burning | |

| Burning duration | Briquettes burn for a long time - about 2 hours | Firewood burns out in an hour | |

| Storage | Take up little space | Requires a lot of space | |

| Firewood preparation | Ready already, thanks to the standard shape they fit well into the oven | It is required to split, respecting the dimensions of the firebox | |

| Ash amount | After the combustion of briquettes, about 2% ash remains | After burning wood ash about 10% | |

Popular models

The modern market of heating units is overflowing with offers of highly efficient models of boilers operating on peat and peat briquettes. Let's note some of them.

The solid fuel peat boiler of the Ukrainian company Kliver is characterized by impeccable quality, 100% guarantee and high efficiency up to 92%. It can operate on all types of solid fuels, including peat briquettes. They are used for heating large houses in the countryside and industrial enterprises. Kliver can heat up to 300 m². The structure only takes up 0.5 m² and does not require a dedicated installation room. The approximate price of a 30 kW Kliver is 42,000 rubles.

Peat boiler Aremikas Candle S 18 kW

Lithuanian boiler Aremikas Candle works on peat briquettes, is used for heating individual housing buildings, as well as for heating premises for production. The price for Aremikas Candle with a capacity of about 20-35 kW is 120,000 rubles.

The Czech model Dakon DOR F12 is independent of electricity, has a power of 13.5 kW. It is characterized by a unique newest design, improved mechanism for holding the firebox door, and the absence of an upper facing cover for easy fuel loading. The price is about 60,000 rubles.

Technological processes for the combustion of biofuel are developing every day, peat has excellent consumer qualities, so this fuel is highly valued by scientists and specialists. The extraction and use of peat is considered the most promising direction for the development of energy in the future.

What are buyers saying?

Feedback from those who already use various types of fuel briquettes can be summarized as follows.

- It is an economical and environmentally friendly fuel that is popular in Europe. It can be used to heat both apartments and country houses. Thanks to the thoughtful production of sawdust, briquettes are not deformed, simply transported, and show good thermal insulation characteristics.

- Another review says that in cottage settlements in many houses they switch to heating with briquettes pressed from birch dust, which remains from the grinding of plywood. In terms of the degree of efficiency, this method of heating does not come out cheaper, but the higher heat transfer justifies the high cost. In addition, the briquettes are completely dry, little smoke is generated during their combustion, and it is much more convenient to use such firewood. The only drawback is that high-quality storage is required, since Eurowood quickly damp in the open air.

- Heating with briquettes, many users say, is really convenient and simple. The cost of fuel depends on the raw material used to create briquettes.

Peat briquettes (reviews, application)

Peat briquettes are natural, natural and environmentally friendly natural fuel, which is produced on modern equipment. Also, in the production process, the latest technologies and methods of peat processing are used. Peat briquettes are ignited effortlessly, and give an even, continuous fire. They can be used for kindling fireplaces, various types of stoves, in saunas, greenhouses, baths, greenhouses. In addition, houses and stoves are heated with peat briquettes today. This type of fuel is very popular today due to the rise in prices for gas and electricity.

This combustible material comes from marsh plants that have been preserved. Plants, due to the fact that there is no access to oxygen, do not decompose and turn into fuel. If we take into account the chemical composition of peat, then it is composed of carbon. That is why peat briquettes are considered environmentally friendly and during combustion it almost does not form ash. The peculiarities of the peat structure do not allow it to burn quickly, which facilitates the maintenance of the boilers, since the frequency of loading this material into the furnace is reduced. Due to the ease of extraction and availability, peat briquettes will cost less than firewood or coal (photo 1).

Peat is harvested on swampy soils in forest zones using special equipment - combines. After it is dried to a moisture content of about ten or thirty percent, and subjected to pressing. So it turns into briquettes. According to experts, such briquettes are no different from coal. They also burn well and even surpass it in some characteristics. In addition to the briquette, manufacturers offer milled and crushed peat for combustion. In shape, peat can be rectangular (RUF-briquette, brick), hexagonal or tetrahedral with a radial hole (also called Pini-Key), as well as cylindrical without a through hole or with it (Nestro, Nielsen). It is worth noting that pressed briquettes surpass both firewood and coal in terms of thermal conductivity (photo 2).

So, when burning a kilogram of peat briquettes, heat is released in the amount of 4500-5600 kcal, when burning firewood - about 3400 kcal, coal - 3800-6000 kcal. In the peat briquette, ash is not more than twenty one percent. Humidity is no more than fifteen percent. The sulfur content is minimal - 0.2%.The advantages of such a fuel are obvious. It is convenient to store it. The fuel is compact and clean in shape. When used, there is no soot and grime. One peat briquette burns for about six hours. It has been proven that those boiler houses that operate only on such fuel emit less sulfur dioxide into the air (photo 3).

Another advantage is that peat briquettes do not require additional processing. For example, when preparing firewood, they still need to be chopped additionally. In some regions that are close to the site of peat development, sometimes it is much easier to buy peat briquettes to heat your home than to buy firewood, coal or gas. The environmental friendliness of the product and the absence of dust make it popular among the population (photo 4).

It is worth noting that peat briquettes also improve the combustion of coal and firewood, excellently ignite in stoves and fireplaces. In terms of thermal conductivity, one ton of peat briquettes is equal to four cubic meters of firewood. A small amount of ash generated during combustion can then be used as fertilizer. There will be no slag in the boiler during the combustion of such fuel. Manufacturers today offer peat briquettes in propylene bags, in bulk. There is a package of big bags (from five hundred to one thousand kilograms), and a pallet (photo 5).