Is it possible to insulate the facade in winter?

Wise customers think about the thermal insulation of their building in advance, i.e. in spring and summer. During this period, it is possible to quickly carry out work and prevent heat loss. Unfortunately, not everyone remembers this and realizes his condition with the first cold weather. It is during this period that the excitement begins and most of the customers wait for their turn until winter.

Yes, insulation of the facade is possible in winter, but the weather: low temperatures, wind, snow, dampness significantly complicate and delay the work. Added to this are the nuances associated with the characteristics of the materials and tools used (weather tolerance). The choice of thermal insulation must be carried out carefully: give preference to moisture-resistant and non-responsive specimens. \

Is it possible to insulate the house in winter outside the basement of the building

Proven technology allows you to thermally insulate the lower part of the building, observing the following sequence of operations:

- Prepare a pit around the perimeter of the building.

- Place moisture barrier in the trench.

- Pour expanded clay.

- Waterproof insulation.

- Add sand and concrete.

Read also Types of wood-burning stoves for home

Self-performance of work is not difficult.

Is it possible to insulate the walls outside in winter with penoplex

It is allowed to perform thermal insulation of the walls and the base of the building with penoplex. For thermal insulation of the walls, glue the penoplex and plaster the surface.

The algorithm for warming the foundation is as follows:

- Dig a trench around the foundation.

- Apply bitumen to the surface of the base.

- Stick on penoplex.

- Waterproof insulation.

- Fill in the pit and make a blind area.

Penoplex provides a high level of thermal insulation.

If it is necessary to insulate the outside of a wooden building in winter, remember about the change in the properties of materials under the influence of natural conditions

Wet facade in winter - technology

At temperatures up to minus 5 degrees Celsius, you can make a wet facade in winter. Technological sequence of works:

- Clean the surface.

- Fasten the heat insulator.

- Reinforce the surface with mesh.

- Apply plaster.

- Paint the walls.

Use a special primer to protect the façade.

We insulate a building made of wood from the inside of the building

Thermal insulation of a building from the inside cannot be compared in efficiency with external thermal insulation, which protects the base and walls from freezing. Consider the features of the use of various heat insulators.

Using expanded clay for internal thermal insulation of the base

The use of expanded clay for interior work allows:

- insulate the base of the building;

- insulate the floor of the room.

Sequencing:

- Form a moisture-wicking layer.

- Pour expanded clay.

The gap between the floor and the expanded clay layer promotes moisture removal and ventilation.

The use of mineral wool for insulating the inside of the basement

Insulate with mineral wool as follows:

- Make grooves at the bottom of the walls to collect moisture.

- Waterproof the surface.

- Slice and secure the mineral wool.

- Moisture up the mineral wool.

Due to the increased hygroscopicity, mineral wool needs reliable protection.

Wet facade technology

One of the most common technologies for insulating and cladding buildings. The device of the insulated facade by the "wet" method implies the use of liquid materials. To begin with, the thermal insulation slab is attached to the wall with glue or dowels, and reinforced with mesh on top, plastered. Among the advantages of this method:

- Suitable for any building;

- Does not carry a significant load;

- Choosing an adhesive type of fastening, you can even mount it on a hollow base.

- The result is a smooth, seamless finish that is easy to repair even on your own.

- Unfortunately, the method has its downsides:

- Not used at temperatures below + 5 ° C;

- Not applicable for timber structures;

- Installation is quite laborious.

The modern construction market is replete with claims that there are frost-resistant additives that facilitate the hardening of the plaster layer, allow outdoor work even at -15 ºС. Yes, it is possible to carry out the installation of insulation and plastering of the building in winter, but this is far from the best option.

Features of house insulation in winter

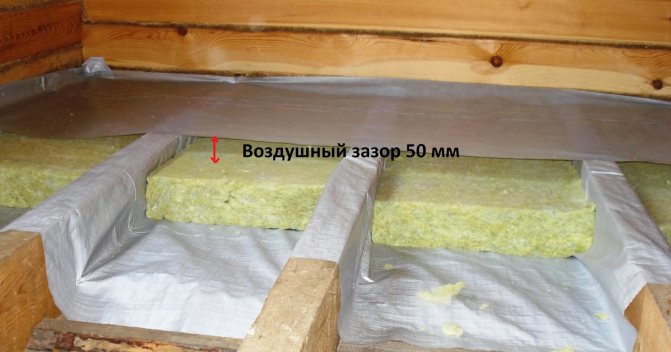

To insulate the facades of houses, 2 methods are used - ventilated and non-ventilated. To implement the second method, an adhesive solution is required, with the help of which the insulation plate is attached. It is he who will not tolerate low temperatures and will not be able to solidify. Therefore, it is possible to insulate a house in winter only by one method - a ventilated facade. The features and advantages of this method are as follows:

- All parts of the structure are fastened with dowels;

- There is a free space between the wall and the cladding, which does not interfere with vapor permeability;

- For installation, you can use expanded polystyrene, which is not afraid of installation in the winter season - the lowest budget option;

- Or you can use basalt insulation - also loyal to winter temperatures, but also very resistant to fire.

A ventilated way of insulating a house is the most optimal for work in the winter. If you still want to use a wet facade - a system of non-ventilated insulation - you will have to invest a little more time and money.

"Dry" facade

Thermal insulation of the facade with the "dry" method is universal. This method works for any weather and any foundation. The main distinguishing point is the absence of liquid components.

A prime example is the fastening of extrusion or rock wool insulation to a prepared wood or metal frame. From above, the insulation is covered with a windproof membrane.

Among the disadvantages of the design:

- significant weight, which requires carrying out calculations of the bearing capacity;

- many types of structures that cannot be assembled on their own.

Let's give an example of two special cases of dry thermal insulation of a building.

So when is it better to insulate the facades of houses?

As you can see from the description above, starting from March you can safely insulate houses and apartments. Moreover, in summer, at high temperatures (and this is no longer a rarity), the adhesive properties of adhesives will deteriorate (above + 35 degrees Celsius).

One more argument can be made in favor of spring - the companies performing insulation works are not yet loaded with orders. This will have a positive effect on the quality of work and their cost.

In connection with the constant rise in the price of energy resources, the issue of the effectiveness of insulation today is more acute than ever. One of the most effective and affordable ways to reduce the cost of heating a room in winter and air conditioning in summer is to insulate the outer walls. The effectiveness of the work performed depends on several factors: materials, adherence to technology and even the season. If you are wondering how to insulate external walls, then this article will be very useful. In it, we will consider in detail the main points regarding the presented problem.

Thermal insulation of wooden structures

Special attention is paid to the insulation of a frame or wooden house. Wood is a natural material and is easily exposed to atmospheric influences: it dries out, absorbs moisture, and eventually becomes unusable. It is important to insulate the house made of wood and provide it with additional protection in the form of cladding. You already know that insulation of a wooden and frame house with subsequent plastering is not carried out. Therefore, the insulation is fixed with a wooden frame.

Preparation for insulation is, first of all, preparation of walls (cleaning from dirt, dust) and anti-mold treatment. After the walls are completely dry, a waterproofing film is mounted, which will not let steam from the premises into the insulation. The insulation itself is selected based on the customer's requirements. Considered: ecowool, mineral wool and expanded polystyrene. To fix the slab, you need to build a wooden frame or crate. It is mounted vertically to the bar wall. Between these bars, a heater is laid with an overlap and secured with front dowels. To protect the insulation from the outside, a windproof film is attached to the crate. Siding is perfect as a finishing layer.

Warming a house in winter - characteristics of the used heaters

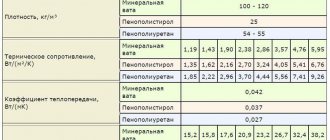

Various materials are used for thermal insulation of buildings. The main characteristics of heat insulators:

- density. With a decrease in the specific gravity, the thermal insulation characteristics increase;

- thermal conductivity. It is expressed by a coefficient characterizing the ability of a material to conduct heat;

- vapor permeability. Promotes the unhindered exit of the generated vapors from the room;

- fire resistance. Allows to ensure safe operation, avoid fire hazardous situations;

- frost resistance. Provides the integrity of the insulation during deep freezing and thawing;

- strength. Characterizes the ability of the material to perceive mechanical loads and not collapse;

Today, there are many methods of insulating the foundations of different buildings, which helps to save the energy that is spent on heating.

- moisture resistance. Determines the possibility of using the material in high humidity conditions;

- durability. The properties of the insulation should ensure the possibility of its operation for a long time.

These parameters are basic, but you should also pay attention to the following properties:

- resistance to damage by rodents;

- ease of cutting during installation;

- method of attachment to the surface;

- soundproofing characteristics;

- ease of transportation;

- ecological cleanliness.

The stores offer various thermal insulation materials:

- expanded polystyrene (penoplex). Differs in low water absorption, environmental friendliness and durability. Surpasses foam in strength characteristics, has a reduced thermal conductivity, is resistant to atmospheric factors;

- Styrofoam. It is widely used in the construction industry due to its affordable price. Lightweight material can be easily fixed to the surface with an adhesive or special mastic. The disadvantage is flammability and the possibility of damage by rodents;

After completing the work on insulation of the foundation, for example, with foam plastic, more drainage is needed to remove excess moisture from the insulated walls

- mineral wool. It is a heat insulation material that provides effective thermal insulation. The material needs protection from moisture when used in rooms located below the zero mark;

- expanded clay granules. Expanded clay is made from environmentally friendly raw materials, used in various types of thermal insulation measures. It has a low weight, frost resistance and improves thermal insulation performance.

The decision to use a specific insulation is made depending on the tasks.

Ventilated facade

The device of a ventilation facade in the cold season is the best option for thermal insulation. The structure is a rigid frame fixed to a load-bearing wall, insulation and cladding. The subsystem is designed in such a way that there is a gap between the cladding material and the thermal insulation, where air circulates. These streams remove all excess moisture from the insulation and ensure its long service life.

Installation of the ventilation facade is carried out in any weather. Today on the market there are many different options for the design of a ventilation facade for different cladding materials. The main stages look like this:

- Installation of brackets to the load-bearing wall;

- Thermal insulating layer device;

- Installation of a windproof membrane;

- Installation of guides;

- Installation of cladding.

The cladding is selected by the customer prior to choosing the ventilation façade subsystem.

Nuances of warming the facade of a wooden house in winter

Thermal insulation of wooden buildings requires special attention. Due to the fact that wood is a natural material, it is subject to the influence of natural phenomena and weather conditions. A selection of facade insulation materials in winter is carried out based on their protective properties. There are certain limitations in carrying out work in the cold season.

- Polyfoam as insulation on the outside should immediately be covered with protective materials, because with severe freezing and excessive moisture, it loses its properties and may simply collapse.

- Carrying out the "wet" process in winter is possible only with the "conservation" of the facade. Construction loess is installed over the entire area of the wall, onto which the film is stretched. It turns out a kind of greenhouse, inside which the building is located. Thus, a positive temperature is maintained for the insulation even in cold weather.

- When laying insulation, the natural drying and shrinkage of a wooden house over time is taken into account. If the building is new, then thermal insulation is carried out only after three years. The old house can be insulated at any time.

For a wooden house, a material is usually chosen that has permeability and will be able to remove moisture and steam from the walls. These are mineral wool, expanded polystyrene, ecowool (wet spraying). All these heaters practically do not absorb moisture, let in vapors and retain heat.

In addition to insulation, it is necessary to prepare:

- wooden bars for arranging the lathing;

- waterproofing film for covering a wooden wall;

- windproof membrane for covering thermal insulation;

- construction stapler and tape for nailing the film;

- self-tapping screws;

- screws with fungi;

- metal mesh;

- finishing.

Insulation of the facade of a wooden house outside in winter is carried out in several stages.

- Prepare walls for insulation. They should be smooth, clean and treated with antifungal agents. After processing, the walls should dry well.

- To prevent moisture that forms on the insulation from penetrating into the wood, the walls are covered with a waterproofing film. It is spread over the entire surface and fixed with a stapler with metal staples. Each edge should go over the previous one by 15-20 cm and be fixed with tape.

- The next stage is the construction of the lathing. To lay the insulation in one layer, you will need 50 × 50 mm bars. They are attached to the wall vertically with self-tapping screws. The distance between the bars is 4–5 cm less than the width of the insulating sheets.

- Between the bars, the insulation is placed end-to-end to each other and fastened with the help of "fungi".

- On top of the thermal insulation, a windproof membrane is fixed to the crate. The edges are overlapped and nailed down with a stapler.

- To protect the insulation from rodents, you can fix a metal mesh over the membrane.

- Vinyl siding is mainly used as a finishing layer.First, strips with a cross section of 30 × 50 mm are screwed onto the frame with self-tapping screws. Fasteners are fixed to them with screws, and then the siding is snapped onto them.

Insulation of the facade of a wooden house

Styrofoam, previously covered with decorative plaster, can also be used as an external front finish.

Usually, the internal thermal insulation of a wooden house is not done, but if there is such a desire, then expanded clay granules, mineral wool or sheet materials are used.

- Before installing the thermal insulation, the inner walls are treated with agents that prevent combustion and decay processes.

- A lathing made of wooden beams is mounted on the load-bearing walls. It must match the height of the indoor space.

- After installing the frame, the insulation is laid. It is cut to the height of the wall, the width should be slightly wider than the distance between the wooden blocks.

- The thermal insulation is fixed between the bars and the wall with anchors. As a cladding, a wooden lining will look harmonious.

For additional insulation, you can insulate the basement space of the house. This is most often used by expanded clay, in addition, this work can be done on your own, without the involvement of paid specialists.

The choice of winter insulation

Polyfoam, expanded clay, glass wool - similar heaters are used somewhere else. But you can forget about them in our article. Construction technologies have long stepped over these materials and produced new ones. Each of the materials has its own pronounced advantages and disadvantages that determine their popularity. We will give an example of two types of materials with which we actively work.

1. Mineral wool. Leader of materials for thermal insulation of all types of buildings and structures. Its structure, vapor permeability, fire safety won her this title. The mineral wool façade breathes and prevents condensation and mold growth. Minvata is suitable for all types of buildings and for all types of technologies.

2. Expanded polystyrene. A competitor to mineral wool in all industries. The slabs of the material are light, with a low coefficient of thermal conductivity, but they have significant disadvantages. Among them are fire hazard, poor tolerance to UV radiation, vapor permeability.

Insulation of the facade with expanded polystyrene or foam tiles

Consists of the following steps:

1. Preparatory work - sealing cracks in the walls, leveling the surface, cleaning from dirt and old coatings.

2. Installation of tiles - carried out using special adhesives, and now mainly with polyurethane foam adhesives.

3. Reinforcement of walls and finishing work - applying adhesive to the tiles, then laying a plastic reinforcing mesh, then again applying a layer of glue and finally finishing the walls (plaster, artificial stone, etc.).

From the point of view of weather conditions, the most critical is the application of the adhesive. Polyurethane adhesives and facade adhesives allow operation at temperatures from –5 to +35 degrees Celsius.