How to install a thermostat for a warm floor and other issues

Underfloor heating is not new in a modern home for a long time, but for an ordinary ordinary user, this equipment still raises a lot of questions about installation, maintenance and repair. One of the main elements of an electric heating system is a thermostat, which is paired with a temperature sensor. The sensor takes readings of changes in the environment and transmits them to the regulator, which in turn makes adjustments to the operation of the warm floor. It is these two elements of the heat supply system in the house that we will try to consider from the point of view of an ordinary user.

Where to install the thermostat when installing a warm floor?

When choosing a place to install the thermostat, the following considerations should be followed. The thermostat must be installed on the wall in a convenient and accessible place. It is also important to take into account the fact that when arranging furniture, you can block access to the device with a large sofa, wardrobe or other interior item. It is unacceptable.

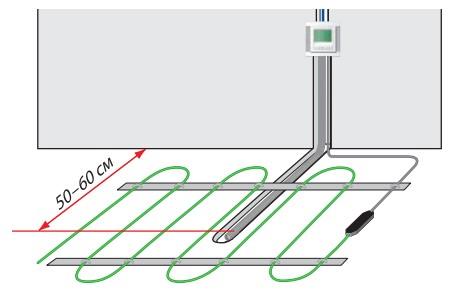

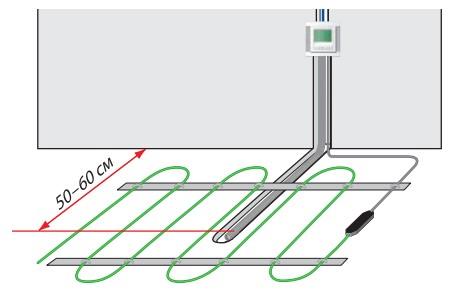

The temperature sensor is located in the screed inside the corrugated pipe. Uncured cement or tile adhesive should not come into contact with the sensor. If necessary, the user or the repairman should be able to replace the equipment that has failed the thermal sensor.

A thermostat designed to regulate the operation of a heated floor in rooms with high humidity (sauna, bath, pool, bathroom) should be located outside the room.

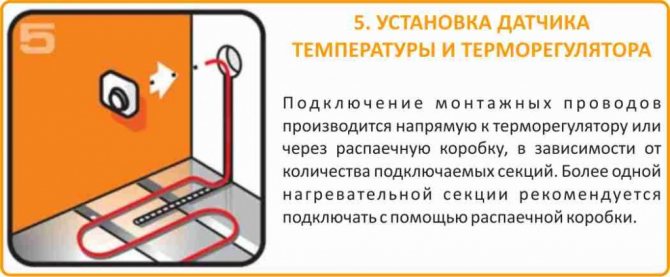

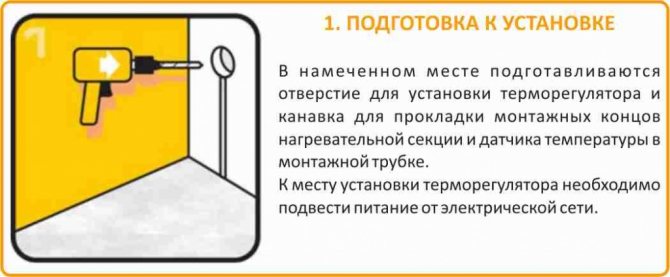

The diagram below offers basic recommendations and dimensions for installing the thermostat and sensor.

Why doesn't the floor heating thermostat turn on?

A popular question from the “why” series is that the floor heating thermostat does not turn on / does not work. To find out the reasons for such an incident, it is necessary to check whether power is supplied to the regulator terminals. To do this, having previously disconnected the machines in the switchboard, dismantle the filling of the thermostat from the mounting box. Turn on the power again and use a tester to check the presence of voltage at the supply terminals. If there is no voltage, then the fault should be looked for in the wiring, and not in the underfloor heating system. If during the check it turned out that the phase cable is connected to the zero terminal of the regulator, then it is necessary to perform a phase change, i.e. just swap the wires. If power is present, the wires are correctly phase-separated, but the display of the thermostat does not light up, then the device itself is out of order. To restore system operation, the thermostat must be replaced.

Why doesn't the floor heating thermostat turn off?

Another common problem in the operation of underfloor heating is that the thermostat does not turn off and, accordingly, the system works around the clock. In this case, the thermostat does not turn off, because it does not go to the set heating mode. Most likely - the thermostat itself is faulty, in order to finally make sure of its breakdown, set the maximum heating temperature. If in this case the device does not turn off, then it is definitely faulty and requires replacement.

Why is the warm floor heating with the regulator turned off?

In fact, there may be several reasons for this behavior of the heating system.

The first reason - this is the inertia of the warm floor.It does not cool down instantly, it takes some time, about 1 hour, so it seems that after turning off the warm floors continue to warm.

The second reason - the heating system is somehow connected directly, bypassing the thermostat. In this situation, it is necessary to put in order the electrical wiring and everything will work as it should.

Why does the underfloor heating thermostat click?

Clicks of the thermostat are a sign of turning on / off the warm floor. If the thermostat “clicks” frequently, it means that during the heating installation you installed the temperature sensor too close to the heating elements. The floor does not have time to heat up, and the sensor already reacts to temperature changes. It is necessary to change the mounting point of the sensor. Loud clicks of the thermostat are typical for a situation when the conductive contacts are loosely tightened in the corresponding terminals.

See more

Share on social networks:

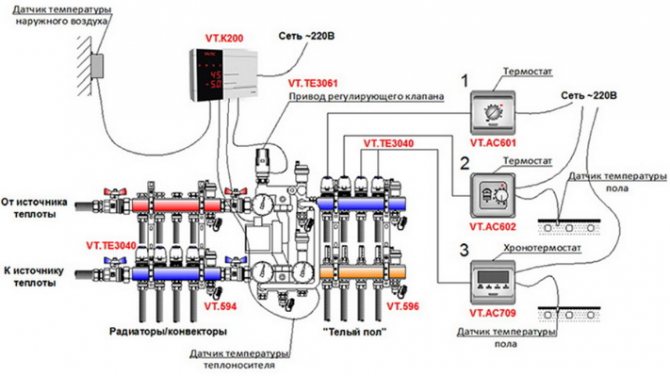

Thermostats are widely used both in underfloor heating control systems and in air conditioning and ventilation control systems, as well as in anti-icing and snow melting systems. Regulators are used in underfloor heating systems both for comfortable (additional) floor heating in rooms with other heating sources, and for main heating, when a warm floor is used as the main and only source of heating.

Thermoregulators overview

Maintaining a constant floor temperature

Easy programming of floor temperature

For open wiring

In this article, we will talk about the regulators that are used for underfloor heating. Comparison of thermostats for anti-icing and snow melting systems in another article.

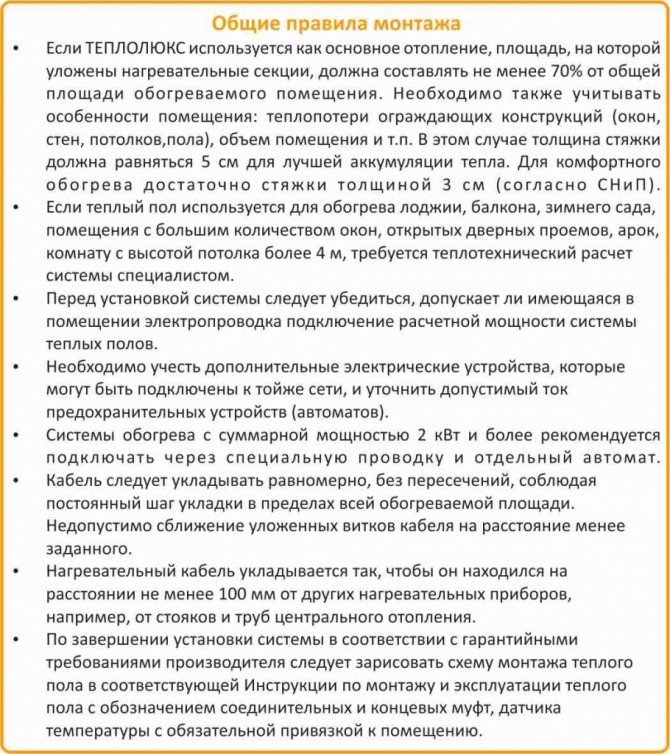

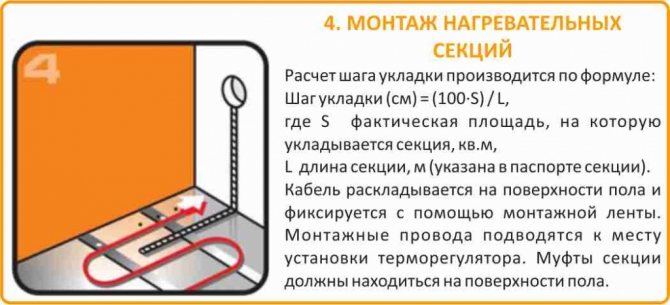

How to install underfloor heating

Every owner wants his home to be comfortable and cozy. Modern underfloor heating helps to achieve comfort and warmth. But it is not at all necessary to involve craftsmen in installing the floors. You can do this yourself if you know some of the subtleties and nuances.

There are several designs for underfloor heating. Let's consider the main ones.

Electric floors can be composed of a heating cable, special heating elements and a film. The peculiarity of this type of floor is that, in addition to the entire room, it also heats the floor covering

When choosing a coating, you need to pay attention to some nuances. Certain materials are capable of releasing very harmful substances

Some systems are not suitable for certain coatings. For example, such a floor is not laid under linoleum, which has double insulation.

A water-based warm floor can be covered with any floor covering you like. Except for high-rise buildings. This type of flooring can disrupt the public heating system. But if you really want to install it, then you need to take the permission of the public service. Underfloor heating in a private house - reliability, durability and economy.

There are several options for laying a warm floor under the laminate. As a general rule, uneven temperature distribution can cause distortion and cracking of the coating. The heating temperature for the laminate should be no higher than 30 degrees and have a power of about 110W / m2.

Parquet is much more sensitive to heat. It cannot withstand more than 24 degrees. But experts generally do not recommend laying this covering on a warm floor. It is also not recommended to install under coatings with low thermal conductivity - wood and cork.

The most suitable material is ceramic tiles, stone and porcelain stoneware. Any kind of underfloor heating is suitable for them, since they perfectly conduct heat.

It is dangerous to cover a warm floor with cheap linoleum. It is capable of releasing very harmful phenolic-aldehyde compounds.

Any floor heating has its drawbacks.Sometimes you simply cannot do without floor insulation, for example, in your house and on the lower floors of high-rise buildings. It is undesirable to install the floor in the bedrooms - headaches may appear.

The warm floor installed in the bathroom has its own specifics. On the one hand, the feeling of inconvenience disappears when stepping on the ice floor.

On the other hand, a room with high humidity and great care is needed during installation:

- Good copper wiring must be used;

- Then grounding is installed;

- An automatic shutdown device is connected.

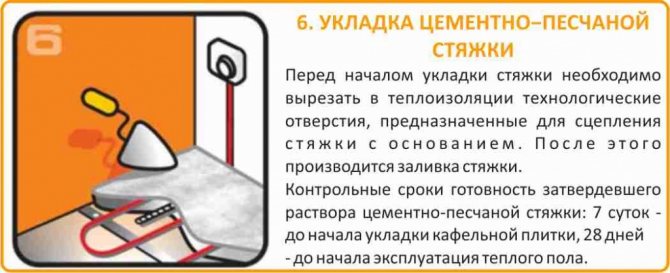

There are also some requirements for the concrete screed itself. Air pockets should not form near the floor, because of this, insulation breakdown and breakdown of the entire system may occur.

Advice from a specialist: household appliances should not be placed on a warm floor and furniture that does not have legs may overheat.

If you cannot use the services of professionals, you can do it yourself. Thermal film is best suited for self-styling.

First you need to position the film, retreating about 70 cm around the entire perimeter. You cannot install skirting boards and furniture on thermal foil. All strips of thermal film must be mounted in parallel, secured with special clamps. The cable connection points must be insulated with electrical tape.

Any covering can be laid on it without the presence of a cement screed. Household linoleum does not spread without a screed, since it is very easily damaged. If you plan to lay a carpet on a warm floor, then you need to put sheets of MDF or plywood under it so that the base becomes rigid.

If the installation of water-heated floors is required, some additional skills will be needed. First you need to remove old flooring, dust and debris.

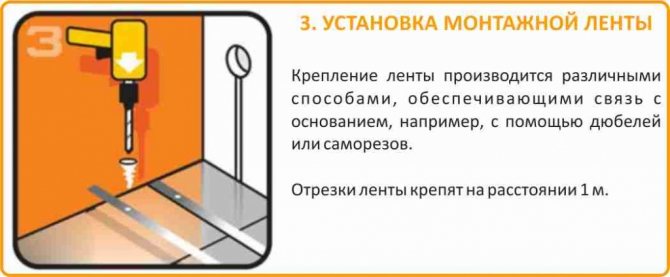

1. In order for the screed to turn out to be of high quality, it is necessary to install beacons using a level. Then concrete is poured and leveled.

2. A heat-insulating layer is laid.

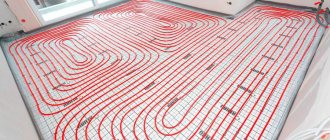

3. The pipeline is being laid.

4. The entire system is carefully poured with concrete.

5. Then the selected floor covering is laid.

The time it takes for the concrete to dry is about 4 weeks. If it is necessary to speed up the drying of the floor, it is allowed to temporarily turn on the water heating with a maximum temperature of 30 degrees.

Following these instructions, you can qualitatively install any heated floor. The main thing for this is desire.

Overview of Devi thermostats for underfloor heating

Thermostats that control underfloor heating operate basically according to the same principle: activation and deactivation of the heating cable by a temperature sensor.

The algorithm for triggering the underfloor heating for all controllers is as follows: the sensor, sensing the temperature drop on the floor, changes its resistance, and when the floor temperature drops below the set value, the thermostat closes the contacts of the enabling relay and starts supplying 220V power to the underfloor heating heating cable, and this heating the cable, accordingly, heats up, and with it the floor structure heats up.

The floor temperature sensor under the influence of heating begins to change its resistance in the opposite direction, and when it reaches the temperature set in the regulator (i.e. when the floor heats up to the one you defined in the temperature regulator), it gives a command to turn off the relay. The warm floor begins to cool down.

The cycle is repeated an infinite number of times. The only difference between programmable regulators: they control the time of day and day of the week, and if you and your household are not at home or you are sleeping, and the regulator knows about this through the settings you have set, then the heated floor will not turn on. In addition, some controllers have a built-in air temperature sensor.

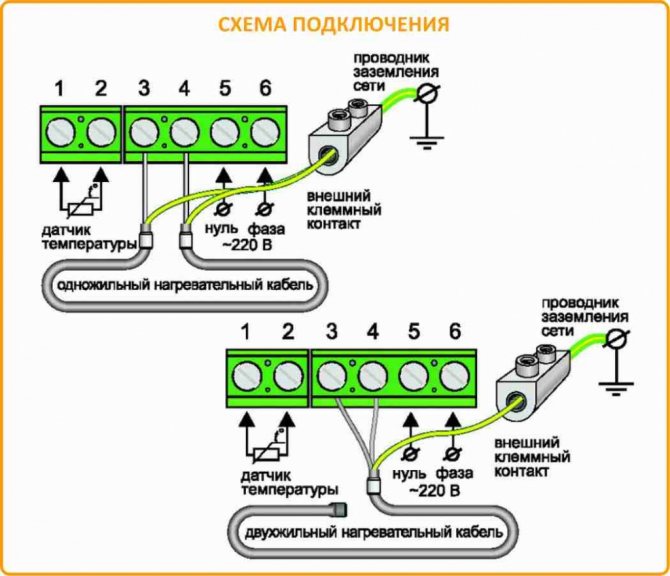

Electric floor heating connection diagram

From an electrical point of view, the "heart" of a warm floor is not a heating element, but a thermostat, and the joy of a warm floor is based precisely on the operation of the thermostat. The great thing is that most thermostats have the same wiring diagram.

This property is due to the fact that they have a common filling. Differences, identical in electrical parameters of thermostats, are only in the design of the case and design elements. Therefore, despite the difference in price, thermostats perform approximately the same functions.

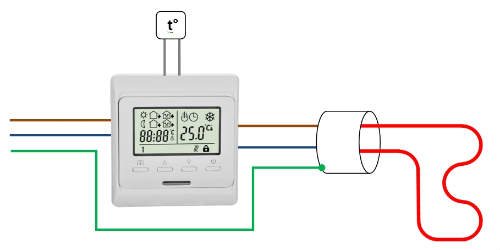

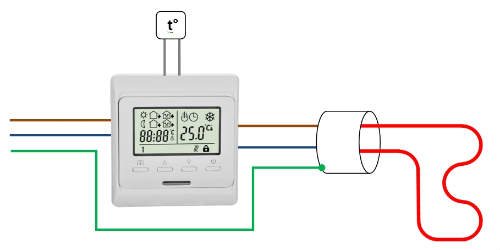

As can be seen from the diagram, on the one hand, two 220 V AC mains voltage wires fit to the impromptu "input" to the thermostat. On the other hand, a heating cable is connected to the "output". A temperature sensor is present as a feedback system that should determine when the heating element is turned on. Sometimes the thermostat can be equipped with a built-in sensor that measures the air temperature. In our case, as in most schemes with a warm floor, an external temperature sensor is used as the main one. An external sensor is either a semiconductor sensor or a thermocouple, which change its resistance depending on the temperature.

The grounding contacts are usually not connected to the thermostat. If the heating cable provides a separate screen, then it must be connected to the PE wire coming from the machine or RCD, separately in the junction box. If possible, it is better to provide a spacious junction box, because, unlike a conventional outlet, you have to lay not 2-3 wires, but at least six. Typically, mounting boxes with a diameter of at least 68 mm are used.

Connecting a warm floor to a thermostat

At the stage of connecting the electric underfloor heating, its installation has already been carried out and the ends of interest from the heating cable and thermocouple are led to the installation box. We unpack our thermostat, figure out how to attach the case to the junction box, and see which contacts our wires should be connected to.

The GreenBox heating cable is a two-core cable with a protective shield. The shield is already connected to the PE and is not shown in the photographs.

Mains wires are connected to contacts 1-2 with strict observance of polarity: contact 1 - phase (L), contact 2 - neutral (N). Then there is a heating element: contact 3 - neutral (N) and contact 4 - "phase" (L1). A temperature sensor is connected to contacts 7-8, here the manufacturer does not provide for the polarity. Usually, all contacts are signed directly on the case and there shouldn't be any problems.

In the design of our thermostat, it is very unusual for the case to be fastened to the mounting box. First, a black metal frame with protruding hooks is attached to the mounting box, and then using an elastic wire in the shape of a square, the thermostat itself is fixed by the hooks on the black frame. The photograph illustrates this mounting method, but most thermostats have more familiar ways of attaching to a back box. A decorative frame with snaps is put on top, covering the fastening elements.

As you can see, there is nothing wrong with connecting an electric floor heating, everything is very simple. All this is more reminiscent of a constructor, with which anyone can afford to "play", the main thing is that any games are safe. In relation to the warm floor, the guarantee of safe use is only careful observance of the installation instructions, from the first to the last stage.

Maintaining a constant floor temperature

Mechanical controls for internal wiring (for concealed installation in apartments, when the wiring is hidden in the wall under plaster).The models differ in the number and nature of floor temperature sensors.

All mechanical thermostats work according to approximately the same principle: maintaining a constant warm temperature on the floor. The underfloor heating is switched on and off using a button, and the floor temperature is regulated by a wheel.

Temperature sensor at the thermostat:

- located in the floor (this is a remote sensor),

- a temperature sensor in the controller is built into the housing and reacts to changes in the air temperature (not the floor),

- has two temperature sensors - a remote floor sensor and built-in air sensors, respectively, the regulator operates from a combination of these two temperature sensors.

An additional function for thermostats is the control of a temperature sensor, a green green LED at the moment when the underfloor heating is not being carried out signals that everything is in order.

More details

Electric underfloor heating

It is problematic to mount a water-heated floor in an apartment. It will not be advisable to run a pipe from centralized heating, since the loss of heating temperature by the coolant will be significant. The neighbors will simply have cold batteries. District heating is not designed to be connected to such systems.

In this case, the ideal solution would be to install an electric heating cable. Connecting a warm floor to a thermostat will allow you to control the heating temperature. In this case, the owners of the house can choose the most suitable type of system. «>

Today, such types of heating wires are on sale as a cable (poured into a screed), a mat (mounted immediately under the tile adhesive), infrared film (installed under a laminate, linoleum without glue). There are also self-regulating wires, which are most often mounted on pipes. However, it will be very expensive today to create a full-fledged heating of a house with their participation, therefore, the presented heating elements are not used for such purposes.

Easy programming of floor temperature

A programmable regulator is a more complex regulator model to control compared to mechanical thermostats.

Setting up a programmable regulator during operation is usually intuitive, but at first you may need instructions to learn all the possibilities of the regulator and how to properly control them. However, this nuance more than compensates for the economical consumption of electricity, because the heated floor will work only at certain hours of certain days of the week.

To set the operating time of the underfloor heating, the thermostat has built-in programs, from which the user selects the most suitable one and sets the operating hours on his own. The following algorithms are possible from the built-in programs:

- maintaining the same temperature on the floor both day and night on any day of the week

- automatic lowering of the floor temperature day and night

- automatic lowering of the floor temperature only at night

- automatic lowering of the floor temperature during the day and at night on weekdays, on weekends only at night.

Each day of the week is divided into 4 time periods: morning, afternoon, evening and night. The start and end times of each part of the day are programmed independently.

In addition to time programming, the user can configure the parameters for selecting a temperature sensor:

- operation of underfloor heating according to the floor temperature sensor in rooms with existing heating

- operation of underfloor heating according to data from air and floor temperature sensors in rooms where underfloor heating is used as the main and only source of heating

- operation of underfloor heating without a floor sensor using one air sensor.

As additional options for the thermostat, you can name such useful functions as setting the maximum and minimum floor temperature,child protection with locking buttons using a hidden button (it must be pressed with a paper clip or a pin), frost protection in rooms that can cool down to outside temperature while maintaining a minimum air temperature of + 5 ° C, hard reset of the thermostat with a return to factory settings when incorrect programming, warning of a regulator malfunction (clock failure due to a power outage, overheating of the regulator, break and short circuit of the temperature sensor, overheating of the floor above the set temperature).

More details

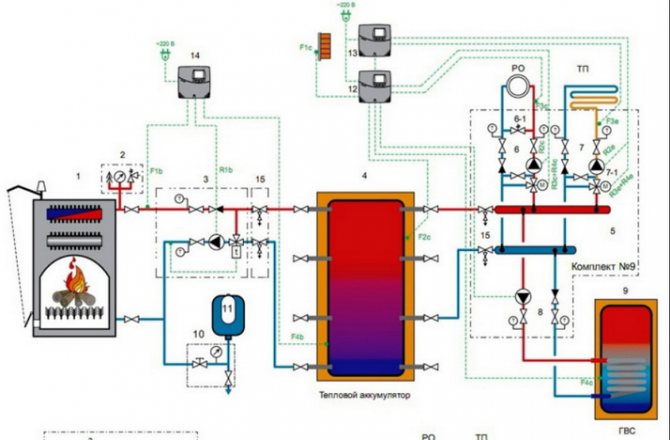

The nuances of filling the system with a coolant

Thermostat for a water underfloor heating

First of all, before starting the floor heating for the first time, it is necessary to organize the circulation of the liquid through the heating circuits and expel the air locks.

The way in which the coolant will be supplied depends on the characteristics of the device of a particular system. If you plan to use tap water, then a tap is specially installed for this, which opens its flow.

When it is necessary to fill in other liquids, then the tip with a stopcock is used, which is located in the manifold, in its supply part. Pressure testing equipment is connected to it, which is used, among other things, for filling the working environment into the system. Such devices are produced of a manual and automatic type.

You do not need to purchase a crimping machine, but rent it from a specialized store. But, when the heat carrier is water, for the underfloor heating system it has to be used annually before the start of the heating season in order to replace the working environment. Perhaps then it is better to purchase this device. There must be a special valve on the outlet manifold to start the equipment.

Before filling the underfloor heating system with a heat carrier, it is rinsed with running water. After the completion of the installation work, grease and other materials remain inside it, from which the elements of the heat supply structure were made. Often small chips and debris get into the pipes when they are laid.

For this reason, flushing is a must. To this end, the system is filled with water several times and then drained. Once the liquid is clear, the flush is complete.

In addition to the first start-up of a warm water floor, this procedure must be performed before each replacement of the coolant. When using soft or distilled water, this event is carried out annually.

If antifreeze is used, the manufacturer's instructions should be followed. Some of them indicate the need to replace the coolant every second - third season, and some once within 10-15 years. But it is imperative to flush the system before this.

For open wiring

Thermostats for open wiring are simple mechanical thermostats, in fact they are analogs of thermostats for hidden wiring - both are designed to maintain a constant floor temperature with switching on and off on command from the floor temperature sensor in the controller (floor and air).

The main difference between such thermostats is that they are designed for open wiring (for example, in a country house, where the wires are laid openly along the wall or in a cable channel).

In addition, it can be added that it is more convenient to use a regulator with a floor sensor for warm floors in city apartments, a regulator with a floor and air sensor is more convenient to install in country houses, where it can control not only the floor temperature, but also the air temperature in the room.

More details

More on the topic:

Preparation and commissioning

When setting up underfloor heating, a thermal head is used in the form of a conventional tap, which is installed for water supply and reverse flow.Such a system is not assessed unambiguously:

- firstly, saving finances for the installation of the circuit is a plus;

- secondly, complications in operation, that is, frequent use of the thermal head disables it, an early replacement is required.

We recommend: Is it possible to use underfloor heating as the main heating?

A convenient device is called a flow meter (or rotameter), which is installed near the collector at the circuit holes. Adjustment in this situation is the control of device readings (0.3 ... 0.5 liters).

The first start, done correctly, reveals weak points, malfunctions, possible malfunctions in the floor heating system.

Every year, with the onset of a cold snap, heating is started.

Thermal management of electric floors

The electric unit that warms the floor can be adjusted, and the operation of the heating device is debugged. This is done by turning the heating on and off, adjusting the temperature, and adjusting the repeatability of the process of turning the heating elements on and off.

Thermostats for electric underfloor heating

The electric adjustable floor is controlled by special panels. They differ in appearance, in the place of installation, in the means of attachment and in the number of connected sensors.

Thanks to the control panel, electricity is saved, it is possible to regulate the temperature regime without overheating.

The operating principle of the panels is special:

- electric underfloor heating is adjusted quite simply by an electronic-mechanical regulator with a meager set of functions. Manual wheel control like an iron. The wheel is connected to a constant temperature regulator. In this case, simplicity is the best solution both in terms of price and strength (rarely breaks, easily repaired);

- the digital control panel functions as an electronic mechanical regulator. The difference is that instead of a wheel, buttons or a sensor are arranged. The control unit is equipped with electric sensors that measure the overall temperature in the apartment and transmit these data to the thermostats;

- a modern part is the thermostat, which can be programmed. It contains several sensors for measuring temperature indicators. These sensors send information to the control device (controller). It is able to simultaneously maintain different temperatures in separate rooms;

- and the most modern regulators are controlled from the Internet. For example, leaving home, you can turn off the heating, and returning home, turn on the system from the phone. The floor will be warmed up by the time it arrives.

We recommend: How to assemble a Valtec underfloor heating manifold?

When choosing your option for a warm floor, it is recommended to take a closer look at the digital project. The advantages consist of ease of use, affordable prices.

In addition, the variety of design solutions contributes to the entry into the overall color of the apartment design. It is also important that the dimensions of the sensors and heating objects are combined.