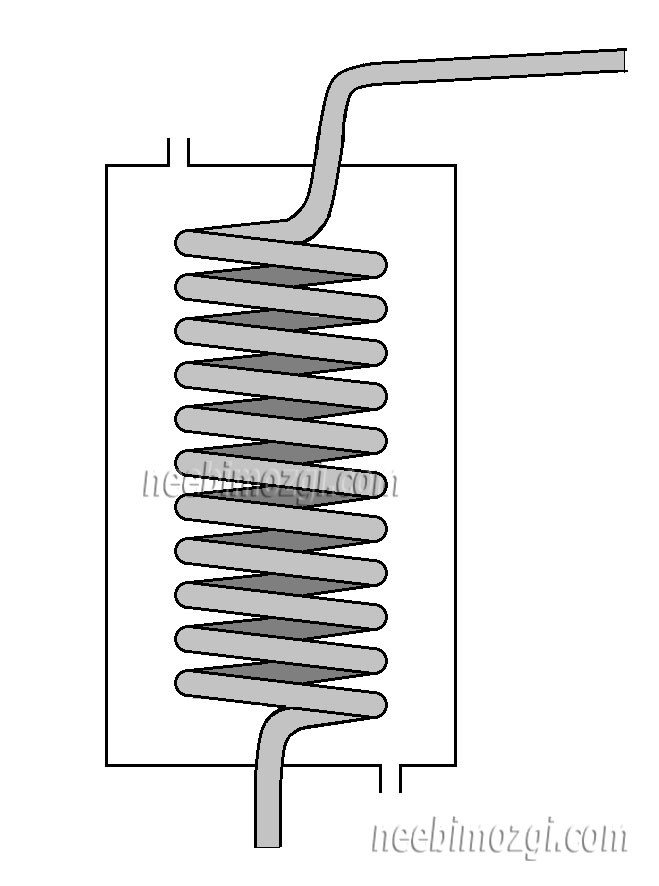

What is a coil for?

A good and suitable coil for the moonshine is more important than the tank itself. The output of the drink, its quality and productivity depend on the spiral tube inside. If for the cube itself, in which the mash or other alcohol-containing solution is heated, it is possible to adapt a pressure cooker, a flask, a juice cooker, then it is very difficult to find a ready-made alternative to a coil.

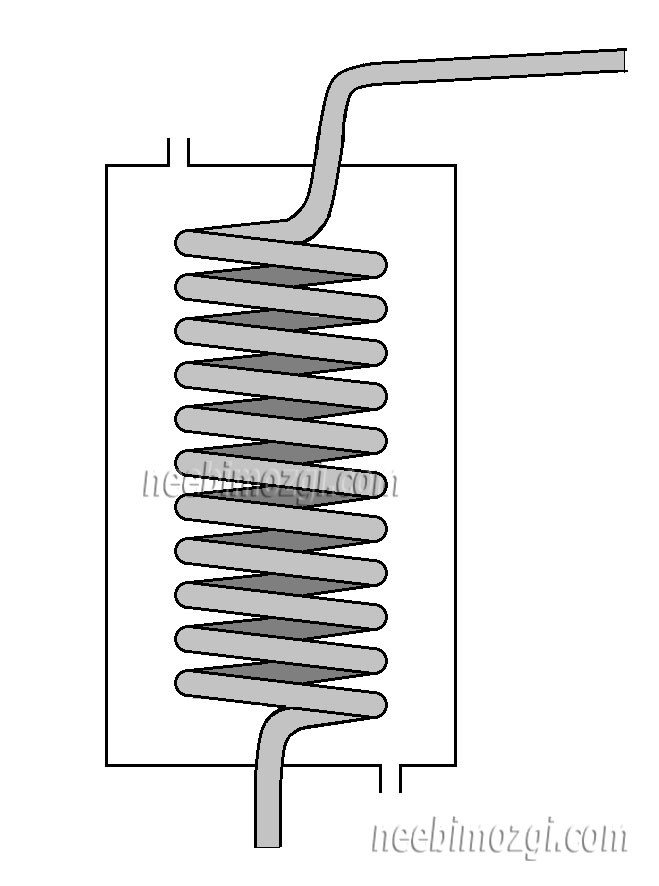

The main task of the coil is to cool the alcohol vapors and condense them inside the tube. The correct name for this part is coil cooler.

Serpentine Doctor Degree

How this part of the device works:

- Braga or other liquid inside the cube heats up.

- Alcohol vapors enter the tube.

- When they come into contact with the cold coil walls, they turn into condensation.

- Moonshine (or another drink, depending on the base) flows through a tube into prepared dishes.

You can buy a coil for a moonshine still, even together with an outer tube, now this is not a problem, but more often it is made independently. The reasons are different: desire to save money, non-standard size, do not like the material that the stores offer.

DIY stainless steel coil

Category: Crazy Hands | Published: 05-12-2015

Another handicraft (to order) from the "Crazy Hands" series. This time - spiral coil (heat exchanger) made of stainless steel... I wanted to make it according to this scheme (long live Paint

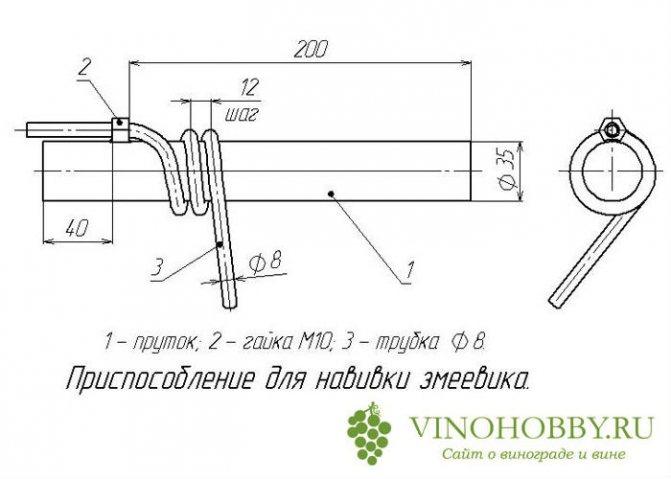

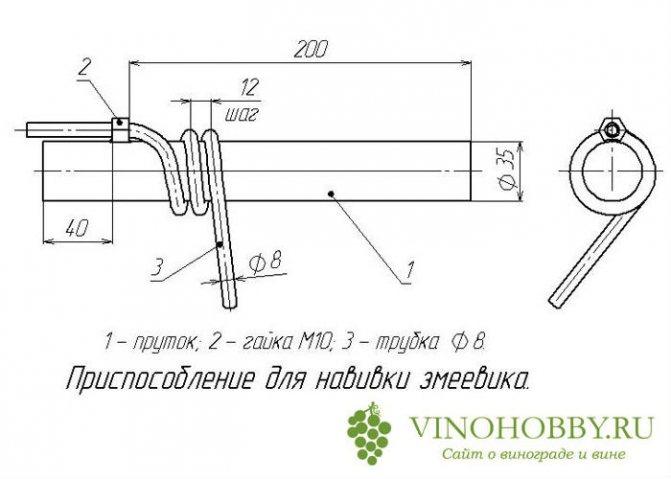

Before making, I looked on the Internet who and how does such things. I was interested in a video on YouTube, in which the author winds a spiral coil-heat exchanger on a two-inch pipe using a machine:

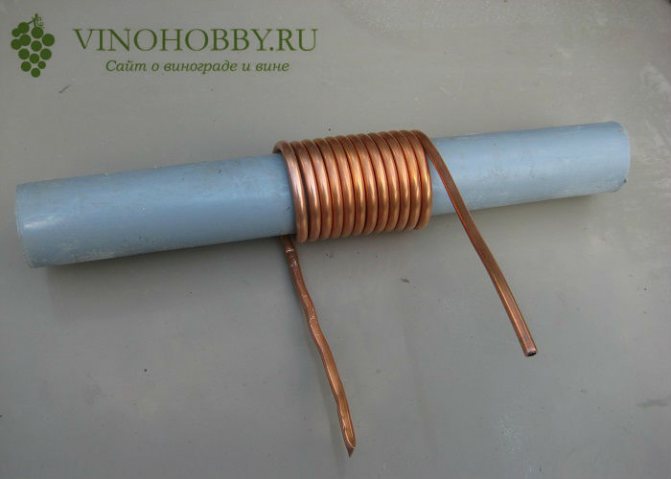

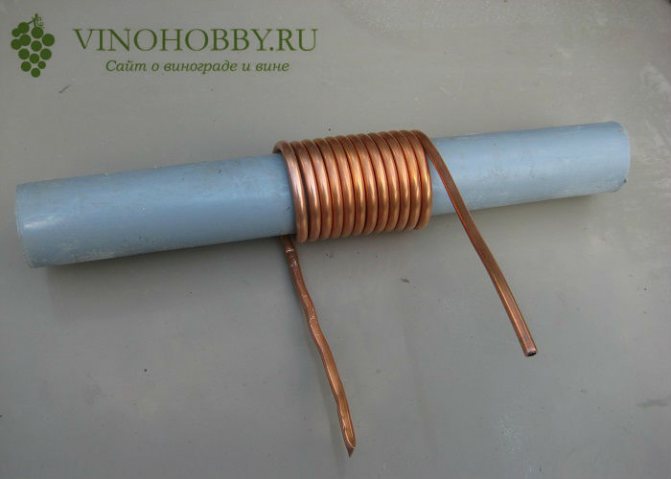

I don't have a machine, so I decided to wind the heat exchanger coil from the same tube as in the video, but manually. A stainless steel tube with an outer diameter of 10mm and a wall thickness of 1mm was found. Almost four meters long. I decided to reel in the same way as in the video above - on a two-inch pipe (was available).

Moonshine coil material

Steel is considered a durable and reliable material. It has many advantages: it does not oxidize, does not rust, it serves for a long time. The only negative is that it is difficult to find food steel, technical materials are more common. Coils are often made of aluminum. But this material cannot boast of high strength and durability, moreover, it reacts with alcohol.

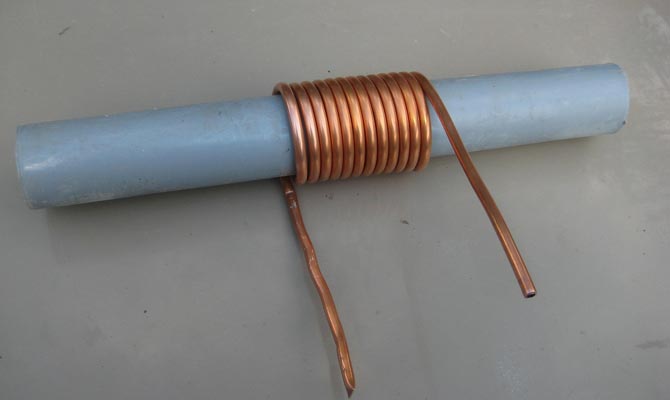

There was no steel and aluminum in the old days, so a copper coil was most often used for the moonshine still. And to this day it is the most demanded material. Brass is sometimes used. In this alloy, copper also occupies a large part.

Stainless steel coil

Aluminum tube coil for moonshine still

Copper coil for moonshine still

Sometimes for moonshine stills, coils from gas columns are used. They are also made of copper, but this is not the best option.

Alternative for stainless steel owners - Panchenkov's nozzle

Owners of column-type moonshine stills can equip their unit with Panchenkov's copper nozzle, which will purify alcohol vapors from sulfur and give alcohol a pleasant taste. This is quite a worthy alternative to buying a full-fledged copper coil with a reflux condenser and a refrigerator (it costs about 10 thousand rubles).

Of course, you will not be able to completely repeat the production technology of the famous cognac houses, but at least something can be done to improve the taste even in ordinary home conditions.It is Panchenkov's grid that will come in handy here.

Panchenkov's nozzle made of copper

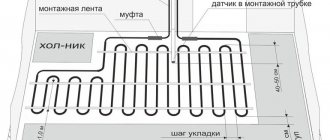

Coil size for moonshine still

Why does the coil spiral? This is done only in order to increase the cooling area of alcohol vapors. However, the length cannot be increased indefinitely. First, the curls should not touch each other. Secondly, in a large coil, the resistance is higher, therefore, the driving speed decreases, the process is delayed. Hardly anyone wants to squeeze a glass of distillate per hour.

The optimal tube length for the moonshine coil is from 1.5 to 2 meters. It will be much shorter when curved. Cross section from 8 to 1.2 mm. The optimum material thickness is around 1 cm.

Serpentine: Sample Drawing

Glass coil

Glass is the least used material for the moonshine coil, although it provides absolute purity of alcohol after distillation. It is only necessary to bend the glass in a special glass-blowing workshop, otherwise local stress points will appear in the curved tube, which will lead to spontaneous destruction of the coil, even without mechanical or temperature effects. In addition, glass has a significant drawback when connecting the coil with other elements of the apparatus: it cannot be threaded or a tight tightening clamp installed on it.

DIY moonshine coil

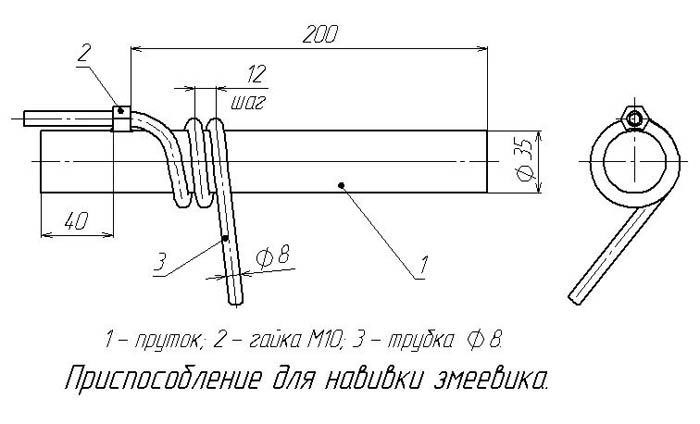

Consider a copper option. In addition to the tube, you will need construction sand or regular table salt. They are necessary to keep the hole inside and shape, to prevent kinking, flattening. If the tube is damaged and bent, it will be difficult for vapors to move, congestion will form, and the device may explode. Additionally, you will need a template pipe of a larger diameter, onto which a copper spiral will be wound. Diameter in the region of 3.5-4 cm.

Making a coil for a moonshine still

How to make a coil for a moonshine still

- Fill the hole with copper or any other pipe with sand (salt), put plugs on the ends, you can simply wrap it with tape, insulating tape, stick pegs inside or insert sticks.

- Gently spirally wind the prepared pipe with sand onto the template, observing a distance of 10-12 mm between the curls.

- Remove the resulting coil from the template, remove the plugs from the pipe ends, pour out the filler.

- Attach the coil to a tap with running water, rinse the inside to remove any remaining sand or salt.

Instead of salt and sand, the tube can be filled with water and frozen. This is convenient in winter, when the structure can be taken outside. The advantage of this method is that the coil does not have to be washed.

It is not difficult to make a coil for a moonshine still with your own hands, but it is important to install it correctly. Basically, it is placed vertically so that the dripping condensate does not disturb the incoming steam from moving. It is also important not to forget about sealing the joints. If done correctly, the capacity of the coil of the above dimensions will be from 2.5 to 4 liters of distillate per hour.

Small digression.

As for me, winding on a two-inch sleeve is ideal for a DIYer. Let me explain why. It was planned to cool the coil using running water. This means that a cylindrical casing will be needed, inside which there will be a coil. For better heat transfer, the casing must be selected in such a way that between the turns of the spiral and the wall of the casing there is room for water flow (and not just in the center of the spiral winding).

Because with such a coil winding - the outer diameter of the coil turns will come out in the region of 80-85mm (the base pipe for winding = 60mm, the thickness of two turns = 2 * 10mm = 20mm, plus a few millimeters will be added due to a slight reverse expansion of the turns), then hands immediately combed to use a ready-made plumbing pipe 110mm as a heat exchanger casing.

Now for the preparation for winding. 1) While the stainless steel tube is still intact and even, it must be cleaned from the inside. Yes Yes. Despite the fact that the outside of the tube is clean and smooth, inside it can be much worse.What are we doing? We take a thick steel wire (I had a diameter of 3 mm) and long enough (at least - a little more than half the length of the stainless tube, then you will have to clean it on both sides). At the end of the wire, we tightly wrap a wet cloth (more precisely, a ribbon), and so that it does not break off, we grab the cloth with a thin copper wire. We dip this impromptu "kvach" into fine sifted sand (more on it later) and either push the wire with the kvach at the end through the tube, or drag it (depending on the thickness and length of the wire) after the wire. We take out the kvach - we look at it, we are horrified and repeat the operation until our OTK accepts the inner purity of the tube.

Important! The tube must be cleaned before winding. After winding, this will not be possible.

Important!! Kvach is securely fastened, because if it breaks off the wire, you can get a new quest called “Ma-a-a-a-l-a-dets! Now get this crap out of the pipe. " Use strong wire.

Important!!! It is NOT NECESSARY to wet or rinse the stainless steel tube with water from the inside! Because further according to the plan, filling the tube with sand.

2) Sand. The sand needs to be dry and sifted. It is needed for packing the coil tube. As in the video with the machine - we cut chopiks out of a tree, tightly hammer one chopik into the tube and, using a funnel, add sand in portions to a vertical tube, together with tapping on the tube from the bottom up. After the tube is tightly packed with sifted sand, the second chopik is clogged. The tube is ready to be wound.

Important! Sand is needed to protect the tube from crushing the walls during the winding process. Poor / Uneven Sand Packing - Most likely will result in improper deformation (collapse of the walls) of the tube during winding.

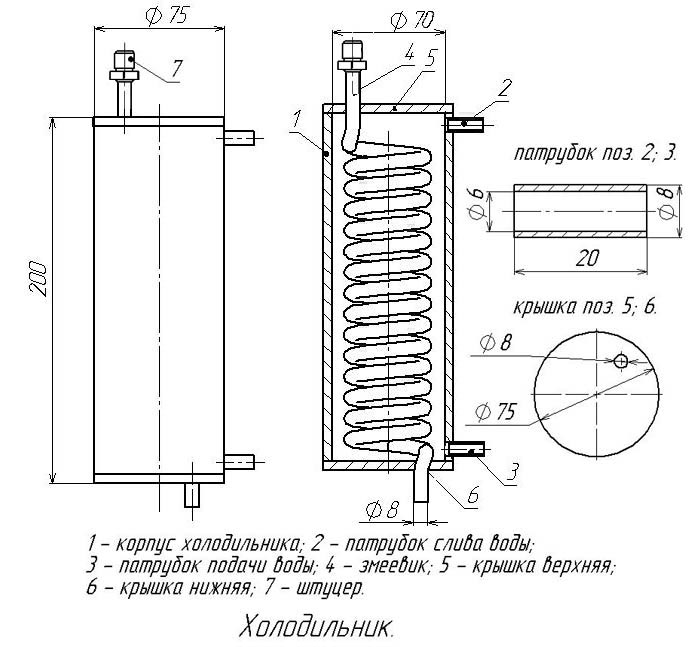

How to make a cooler with your own hands?

When a decision has been made of what to make the coil from, you can proceed to the next stage. The work on the manufacture of a moonshine refrigerator begins with the selection of a suitable tank for the condenser. The length and diameter of the coil tube winding will depend on the dimensions, inner diameter. The easiest way to make a refrigerator body is from a piece of sewer plastic pipe. Recommended diameter? 75-80 mm.

Coil tube parameters: length? 1.5-2 m; internal section? 8-12 mm; Wall thickness ? 0.9-1.1 mm. To ensure the most efficient cooling of alcohol vapors, the volume of the condenser in the refrigerator should be no more than 20% of the total volume of the tank.

Stages of the technological process:

- To prevent the metal from flattening during the winding process, the tube is filled with bulk material. Calcined sifted sand, baking soda will do.

- The ends of the tube are sealed or wooden pegs are inserted into them.

- Carefully wind the tube onto any solid cylindrical object with a suitable diameter. The distance between adjacent turns should be the same, about 10-15 mm.

- After winding, the ends of the coil are unsoldered (the chops are pulled out), the filler is poured, the tube is thoroughly washed.

- In the case of the future refrigerator, two holes are planned and drilled for the water inlet / outlet fittings. Install, firmly fix, seal the pipes? hoses through which water will flow into and out of the tank.

- The coil is placed inside the cooler body. The reservoir is closed with plugs from the ends. Places of all joints are sealed with a compound, superglue, or in another way.

The sealant dries out within 24 hours, after which the home-made refrigerator can be included in the scheme of the moonshine still and proceed to distillation.

Coil manufacturing instructions

The main stages of making a coil are as follows:

- Take a tube made of copper or stainless steel with a diameter of 10-12 mm. Length from 1.2 to 1.5 meters. Wall thickness 0.8-1.0 mm. Less than 0.8 is easily damaged during manufacture.More than 1 mm is very difficult to bend and their thermal conductivity also deteriorates.

Copper tubes are sold in shops annealed and not annealed. A tube that is not annealed cannot be bent, therefore it does not suit us.

That's all. This is where I end. Perhaps I will finalize the design of the refrigerator, there are some ideas. Subscribe to updates and I will keep you updated on all the changes. If you have any questions, ask in the comments. Also wondering which refrigerator do you use? Did you make it yourself or buy it?

Goodbye to everyone. Dorofeev Pavel.

The moonshine still is often used today for the production of homemade alcohol. The design is based on a distillation cube, into which the mash is poured, as well as a coil that allows you to condense alcohol vapor to obtain alcohol. You can make a coil yourself, even if you take into account its standard spiral shape. The main task of such a device is to separate heavy and light fractions, as well as harmful impurities.