It's all about vapor permeability

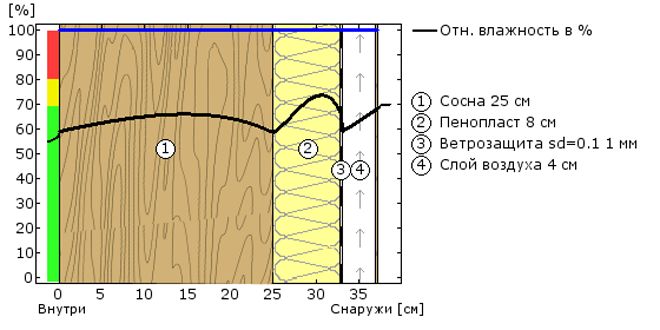

So that the wood of the walls does not rot after insulation, it is required that the "dew point" - the point where water vapor turns into water, does not fall on the surface or body of a wooden wall. If this happens, the tree will rot. That is, after making a calculation using a calculator, the walls of a house in the Moscow region have the following structure:

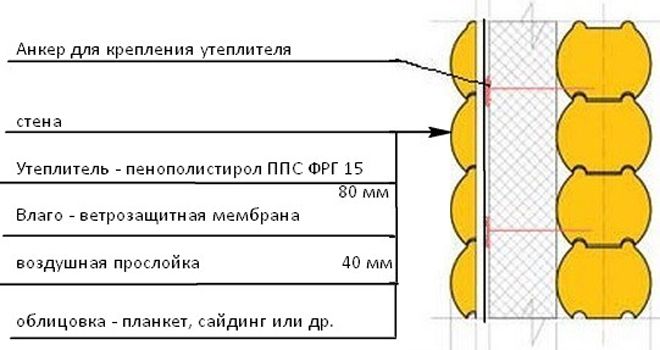

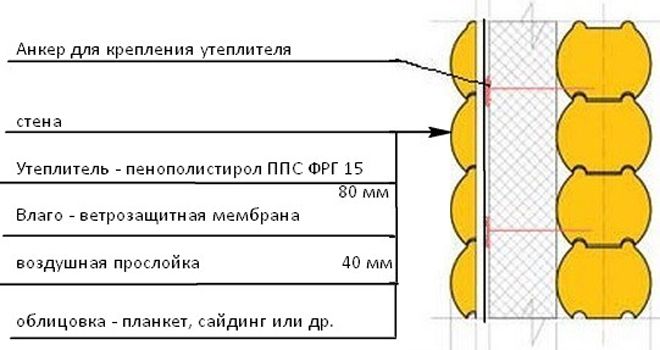

- A beam of pine or spruce wood, across the grain - 250 mm.

- Insulation - polystyrene concrete slab PPS FG15–80 mm.

- Moisture-windproof membrane - 0.1 mm.

- The air gap is 40 mm.

- Facing with planks (like a ventilation facade).

We get that the wall meets all the heat engineering requirements, and it does not have the conditions for the formation of condensation. No condensation - no rotting, which means that insulation with expanded polystyrene followed by finishing with a plank or clapboard, walls of such a structure is possible.

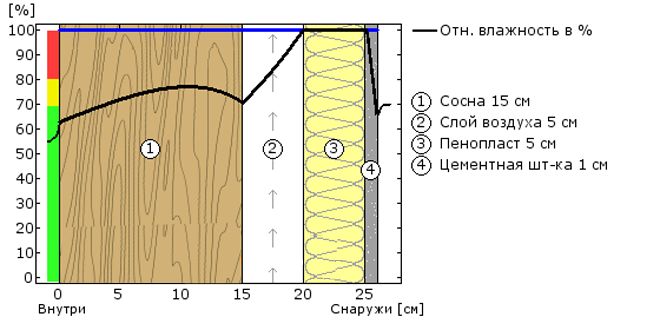

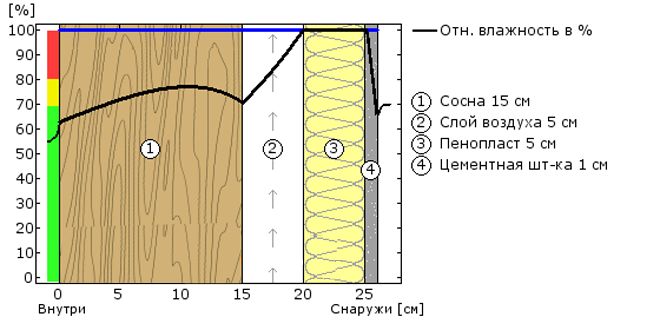

The second option: we have a house in the Moscow region made of logs Ø 250 mm, insulated according to the plaster system:

- Pine or spruce log, working thickness - 150 mm.

- Air closed layer (due to rounding of the log) —50 mm.

- Insulation - polystyrene concrete PPS F 20-50 mm.

- Finishing layer - mineral plaster - 8 mm.

In this case, there is 100% moisture inside the structure and wall decay is inevitable. This can be prevented only by increasing the thickness of the insulation.

As can be seen from these calculation examples, external insulation of a wooden house with expanded polystyrene is possible, however, it requires a balanced approach, and the thickness of thermal insulation of 50 mm for a log frame Ø 250 mm with a working thickness of 150 mm is clearly not enough if you want your house to stand more 5-8 years old. A person who claims the opposite is a myth-maker.

In terms of functionality, foam insulation works better when subsequently cladding with a ventilated façade rather than with plastering systems. This is due to the fact that the layers of materials, as they approach the outside air, should have greater vapor permeability.

The vapor permeability of moisture - windproof membranes is higher than the adhesive and finishing layers of plaster materials, and the air gap and cladding give 100% water vapor release.

Reviews about insulation with expanded polystyrene

“I myself insulated the ceiling with penoplex. It's how it happens - the warm air flow rises upward, and due to the fact that there is a layer of insulation there, it does not cool down. Therefore, heat is significantly saved. And you don't need to hire anyone for repair work, he did it himself. Personally, everything suits me. The house is warm and very pleasant to be. "

Victor Smolensk

“A year ago I first insulated the floor and then the ceiling in the house. I didn't touch the outer walls yet - I decided to see how it would hold up. There is an effect - in winter, the thermometer rose to 25, instead of the usual 20, with the same gas consumption. Therefore, I am satisfied. The floor, of course, has become a little higher, by some 5-6 cm, but now it's not cold to walk on it without slippers. So my review is only positive. "

Dmitry Belgorod

“You know what amazes - the amount of advertising, moreover negative. Apparently, manufacturers of more expensive materials are afraid of competition. So they are trying to prove that their material is better. For a long time I doubted whether to insulate the ceiling in the whole house with penoplex. At first I thought to do it out of drywall, even sheathed the ceiling in one room. But drywall, firstly, is more expensive, and secondly - all these metal frames, again, the ceiling goes down. Therefore, I bought penoplex and insulated it with it. Class, honestly! Quick and easy. I repaired the seams, putty on top, painted - everything is ready. Both warm and good in the house. Fungus on the walls and does not smell.Therefore, I am very pleased. "

Gennady Omsk

Foam insulation outside

So how to insulate a wooden house with foam plastic in order to live a long and comfortable life in it?

It is necessary to follow fairly simple rules without trying to save money on the necessary:

- Before carrying out the work, make a heat engineering calculation to make sure that the thickness of the insulation is sufficient and that the dew point is not in the wooden wall.

- Carefully prepare the wall - clean it of dust, dirt, rot, moss, treat it with a fire retardant and fungicide, check and repair all joints and grooves.

- Carry out work at minimum air humidity, in good weather; in case of possible precipitation, cover the wall with polyethylene.

- Observe the technology for performing insulation in accordance with the recommendations of the material manufacturer.

Insulation work does not require special skills and is available to any homeowner. All that is required is the ability to use a building level, a stapler and a drill.

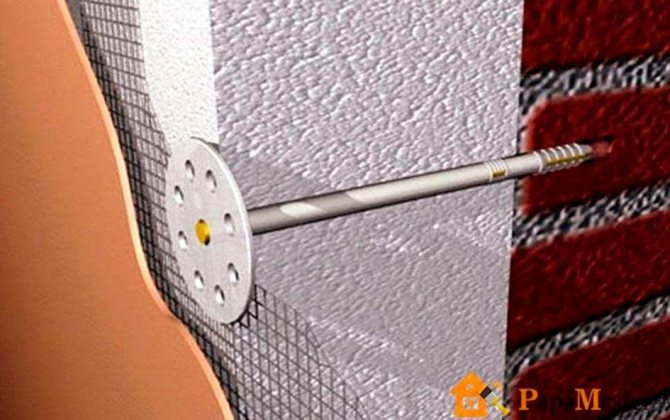

Insulating with lathing is the easiest option. They are attached to the wall on the edge of boards 40 mm thick, with a width equal to the thickness of the insulation, along the entire height of the facade. The distance between them is equal to the width and length of the foam board minus 5 mm. The slabs are installed in a spur, without gaps. If necessary, the seams are filled with scraps of insulation or polyurethane foam. Plates are fixed with anchors, at least 5 pcs. on the stove.

Moisture - the windproof membrane is mounted from the bottom up with gaps of 10-15 cm between the canvases using wooden blocks 40x40 to the lathing boards with special nails.

Finishing cladding is carried out, attaching it to the bars.

Where do doubts come from?

There is an opinion that polystyrene is not very suitable for insulating wooden houses from the outside. Some people doubt and study this issue before insulating a wooden house with polystyrene foam.

This is due, in particular, to such material characteristics as vapor conductivity. Hence, it is concluded that such insulation will not be able to prevent moisture, and, consequently, decay of the walls. At the same time, in fact, the foam plastic has a steam conductivity commensurate with the steam conductivity of pine wood itself, so it is logical that the fears are groundless. The main thing is to observe the technology of insulation, then the house will be warm and the walls are not moistened. The only thing that is not recommended is to choose polystyrene for external insulation of baths, saunas and similar rooms. It is better to dwell on other material here. If you have a house, then use it for health!

Opinions and reviews of various builders and house owners about whether it is possible to insulate a wooden house from the outside sometimes differ significantly, that's what experts say about the pros and cons of foam insulation for wooden houses.

- Traditional inexpensive material;

- Easy process;

- Saving;

- High thermal insulation properties

- Protection not only from cold, but also from heat and noise.

- Worse than some heaters, it releases moisture to the outside, which can lead to condensation;

- It is necessary to observe the technology and think over ventilation;

- Difficulty air exchange, but a tree is chosen for building a house precisely so that the house "breathes";

- Combustible material (however, when processing with a fire retardant, this minus can be leveled).

- May begin to crumble over time.

As you can see, styrofoam has its pros and cons. However, like other materials. Consider carefully the choice of insulation, enlist the advice of professionals. And then you don't have to worry about the result! If you have already decided to insulate the house with polystyrene, because of its inexpensiveness and ease of installation, then mount it on the ventilated facade system, and then there will be no problems.

The concept of polystyrene heat insulators

Polyfoam, like expanded polystyrene, is made from the same material, but using different technologies, therefore they have a number of differences.

The foam is formed as follows - styrene granules are heated for a long time with steam, it expands and takes the form of a plate. With prolonged heat exposure, the material hardens, becomes solid, and pores form on the surface, due to which the foam breaks down into individual granules over time.

Expanded polystyrene or, as they say, extruded polystyrene foam. Its manufacturing technology is slightly different - styrene granules are initially filled with a certain gas, then all this mass is heated so that it begins to expand. After that, it is squeezed out with an extruder into a special shape, this is necessary in order to obtain a more homogeneous structure of the material and strengthen the bonds between molecules. When the material fills the entire workpiece (block), it is pressed - this increases the quality characteristics of expanded polystyrene. After the material hardens, a block of penoplex is obtained, which is sold in stores.

Which foam to choose

It has been proven that the density does not significantly affect the thermal conductivity indicators, therefore, preference should be given to a material with a low density, for example, PSB-S-15.

This material has the following characteristics:

- It weighs a little.

- Compressive strength is equal to 10% and 0.05 MPa at deformation. This means that the insulation will be resistant to kinks.

- Thermal conductivity is not higher than 0.042 W / mK, it is not much higher than that of other materials, the density of which is higher.

- Affordable price.

This material will be an acceptable option to insulate the house from the outside with foam.

Reviews on vapor permeability and service life

"Penoplex" for floors is so popular among the modern consumer also because of its low vapor permeability. This indicates that the material is highly resistant to evaporation. If you use a layer with a thickness of 2 centimeters, then the vapor permeability will be equal to 1 layer of roofing material. All buyers who have been using the described thermal insulation for more than one year note that with repeated freezing and thawing, the characteristics of the material remain unchanged. The manufacturer guarantees the service life of the insulation for 50 years or more. The deadline will depend on proper styling, performance and external factors.

When to insulate

It is optimal that the insulation of a wooden house outside is carried out in the summer, it is dry and warm outside. If it's hot outside the windows, then even better. Thus, there is no doubt that the walls will be dry enough. When the walls are deeply dry, moisture will not come as steam during further use of the house.

There are many videos on how to properly organize the process. Any thematic forum will also help. The technology is easy to figure out on your own. When preparing the walls, they are cleaned of dirt, old paint. It is necessary to analyze whether the seal between the logs is in good condition. If not, such places should be filled with polyurethane foam.

To protect ourselves from fungus, we treat the walls with an antiseptic or a special primer against fungi. Take care of the drainage on the windows, their edges need to be taken 4 centimeters from the wall. Puff up the junction of the ebb and the wall below with foam, then put something heavy on the ebb, for example, a few bricks, and leave it for several hours.

Polyfoam is produced in the form of sheets (plates). Fastening the foam to the wall can be done on the crate, or the sheets can be fixed with a special adhesive, while nailing with special dowels.

Penoplex

In order not to get confused, you should remember that this is just a brand (subspecies) of extruded polystyrene foam.

Characteristics of materials:

- External differences.Polyfoam - consists of small white lumps. Expanded polystyrene is a very hard material with a uniform structure, which is somewhat reminiscent of a sponge.

- In terms of thermal insulation, penoplex is somewhat better than polystyrene.

- In terms of air permeability, on the contrary, foam is superior to expanded polystyrene.

- Moisture resistance - expanded polystyrene and polystyrene almost do not allow moisture to pass through. Even after sudden changes in temperature, nothing will happen to them.

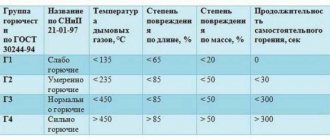

- Flammability. Since both materials are the result of foaming of a combustible substance, it burns by itself. But there are different flammability classes. By this concept is meant the reduction of the flammability of styrene. This coefficient can be lowered in two ways - by treating the finished slab with special mixtures, or by filling the granules with carbon dioxide when creating the material.

- Strength. It is this parameter that is most different for polystyrene and foam. The first is almost four times stronger than the second. Depending on the thickness, polystyrene can withstand pressure from 0.2 to 0.6 MPa.

There are a lot of negative reviews that penoplex does not allow moisture to pass through - this is not the case. The vapor permeability coefficient for different types of material can range from 0.005 to 0.008 mg / m • h • Pa.

On the crate

Fastening to a wooden wall on a crate: first, nail the boards vertically along the wall at a distance of the width of the foam sheet from each other. The distance still needs to be made a little wider than the sheet, you can estimate like this: the thickness of the strip between the sheets is minus 0.5 cm. And add this distance to the width of the foam sheet.

It is not difficult to fix the crate on the house made of beams. With round logs you will have to tinker more, definitely some logs will need to be hanged.

The boards should be of the same thickness as the ventilation gap between the insulation and the walls of the house. To insulate wooden houses from logs, you can immediately attach slats to the logs, and then nail a vapor barrier to them with a stapler. In general, the result should be a structure with boards and slats (or with slats on logs), with a vapor barrier. How often do you nail the strips? Start from the width of the insulation sheet and reduce this value by 5 mm.

How to deal with slopes

Thermal insulation of house slopes is also important for comprehensive insulation. In some situations, it is even worth starting with the windows, and only then insulating the walls. When choosing insulation for windows, do not forget that there will still be a layer of finishing on it, and all this thickness should not interfere with the operation of the window. Where the insulation of the slopes is connected to the insulation of the wall, you just need to cut the first one.

When everything is ready, the walls and slopes are insulated, you can choose: whether to cover the wall with clapboard, more modern siding, or just plaster the house.

Both the lining and siding require the installation of more battens, which are nailed to the ends of the battens of the sheathing directly onto the membrane. The siding strips or lining themselves are attached to these mounting rails.

To plaster the walls, a composition of glue should be applied to the insulation, a reinforcing mesh should be laid in it, and then the whole structure should be allowed to dry. We level and clean the surface, apply the finishing.

Now you know how to insulate a house with expanded polystyrene. Remember that there is an optimal solution for each case, and you will definitely have your own opinion and your answer to the question of whether it is possible to insulate a wooden house with foam outside. Considering that thousands of homeowners in our country have insulated and will insulate them with foam, it can be concluded that this method has the right to life. Do not forget to install good ventilation and do not freeze anymore in your wooden house in winter!

The question "How to correctly insulate a wooden house?" - the undisputed weekly leader of the "Construction and Repair" section.Log and log houses, built several decades ago, have already aged and begin to let in the cold during the winter months.

Errors when insulating a wooden house

therefore it is very important to exclude possible oversights, which regularly occur with unqualified thermal insulation of wooden log cabins with modern materials. Let's take a look at the most common ones.

Mistake # 1. Thermal insulation of a log house without inspection of the state of wood

As a rule, already "old" log cabins are insulated. On the one hand, it is technologically convenient: the log house has finally settled down and the dimensions of the structure remain unchanged. However, the past years could not but leave traces on biologically living material - wood.

For the most part, already old log cabins are insulated

Therefore, before the planned insulation, which implies that there will be no access to the logs for many years, it is necessary carefully examine all crowns and discard defective fragments... If a bug eating wood has wound up in the logs, I will make a cautious assumption that it is no longer advisable to insulate the house. A cardinal medicine for such a case, except for a weekly forty-degree frost, has not yet been invented. Read more about this issue in the articles:

- How to save a wooden house from a woodworm beetle: expert advice

- How to protect wooden buildings: choosing the best antiseptic

Good wood should soak with fire-fighting and antiseptic composition and dry thoroughly... It is a mistake to carry out insulation on raw wood.

Mistake # 2. Lack of attention to caulking

Traditional caulking is performed, strictly speaking, not to insulate the log house, but to prevent blowing it, which ultimately affects the preservation of heat in the house.

Linen-batting material is used for caulking

Deciding to insulate log facades, pay attention to the condition of caulking on all crowns... This operation should not be dismissed. Perhaps it is thanks to 2-3 defects of this natural insulator that it is cold in your house in winter.

At the beginning of 2020, a reader contacted the editorial office of www.7dach.ru with a request to help with insulation in a modern way. Word by word, it turned out that the cunning birds had long been pulling caulk fibers from its log house onto their nests.

Loosely twisted, with protruding fibers or loosely clogged tourniquet will be pulled apart by birds

It seems that after the clarification of this fact, the craving for total warming of our dear reader has somewhat weakened.

Mistake number 3. Insulation of a log house on the wrong side

From which side to insulate the log house? This is truly a conceptual issue that needs to be resolved for yourself once and for all. In addition, it will be useful to share the acquired knowledge with friends and neighbors.

If the house is cut down from thick logs, then this is the rare case when it can be additionally not insulated

Without plunging into the basics of building heat engineering and without delving into the meaning of the obscure phrase "dew point" (which underlies the choice of the location of the insulation), take on faith the craft postulate: insulation of structures is carried out from the outside. Such an installation improves the operation of both the wall bearing material (tree crowns) and the insulation itself. Otherwise, both the insulation and the wood of the logs will get wet from the humid vapors that are inevitably found in the atmosphere of human habitation. Of course, we do not strive for this at all. You can read more about the features of the insulation of the outer walls of a wooden house in the section of the same name of the article Warming a country house inside and out.

Features of expanded polystyrene

- Relatively low weight - this parameter reduces the cost of installing insulation. In addition, it is much easier to work with light material, especially when it comes to work at height.

- Simple processing, here the absence of special protection means is implied. Like glasses when cutting metal. Also, materials made from styrene are odorless, non-irritating, and dust-free.

- Polystyrene foam, resistant to biological effects, is not absorbed by animals, and also due to its very dense structure, fungus does not start in it. Many are indignant that mice eat penoplex - this is not true, but just another marketing ploy of competitors. Expanded polystyrene has a chemical composition, therefore it is not of interest to rodents.

- Processing with chemical materials is acceptable - cement, glue, saline, putty, primer and so on.

- Even extruded polystyrene foam can be cut and installed without the use of special tools. An ordinary construction knife will do.

- They will withstand a high load when exposed to the entire area of the material.

- Demonstrate high performance in energy saving.

- Suitable for insulation, both from the inside of the house and from the outside.

Now that you have a general idea of the material, you need to figure out where and how it is used. Reviews of penoplex agree on one thing - people are happy with the ease of installation of the material and durability. After all, expanded polystyrene can last up to 50 years.

Applications

Considering all the above properties of the material, it becomes clear what its advantages are. Therefore, polystyrene, like expanded polystyrene, is mainly used as insulation. In this case, polystyrene is often used indoors, and expanded polystyrene - outside.

More precisely, the materials can be used in the following cases:

- To protect the foundation from the outside, it is more correct to use extruded polystyrene foam;

- To make thermal insulation in the basement, you can use both polystyrene and polystyrene;

- Floors - the most dense material is needed, that is, penoplex;

- Ceiling and ceiling slabs - both materials are suitable for their insulation;

- It is better to insulate the walls from the outside with expanded polystyrene, and from the inside - with foam.

- Both materials are also suitable for thermal insulation of loggias, but in this case, expanded polystyrene is preferable so that the room remains dry in any weather.

High-quality penoplex

How to insulate walls with expanded polystyrene:

- Any repair work should begin with surface preparation, this case is no exception. It does not matter from which wall the insulation will be made, it must first be prepared. This means - to clear of wallpaper, paint, tiles, plastic and other finishing materials. Check how well the putty holds when it comes to internal insulation, or level the wall outside the house.

- When the outer layer is reliable, you can proceed with the installation of expanded polystyrene. The insulation is fixed very simply - a special glue (both a dry mixture, which is diluted with water, and foam glue) is applied to the panel along the perimeter, and then the block is glued to the wall. To keep it more secure, fix it with dowels from above. At the rate of one sheet - 5 dowels.

- Next, the insulation is covered with a thick layer of glass mesh glue (reinforcing mesh). A mesh is laid on the uncured layer and rolled with a roller until it disappears. Another layer of glue is applied on top. After the surface has dried, finishing work can be carried out - plastering, painting.

It is quite easy and simple to make insulation in this way, you don't even have to hire workers. Many people have made their own wall insulation.

Review of expanded polystyrene

“Many people say that expanded polystyrene is fire hazardous. Nonsense! He burned it himself, because he doubted whether to insulate or not to insulate. As a result, I insulated the facade of the house, it turned out well, warm. There are no difficulties, and the top of the expanded polystyrene is reliably covered with plaster. "

Vladimir, Kaluga