If you often encounter problems with hot water supply, then you can take advantage of the excellent possibility of overfitting the hot water system. To do this, you should purchase a gas water heater. However, not every house has the opportunity to install such equipment, because the column functions by removing combustion products through the chimney.

In this case, the turbocharged model, which does not have a chimney and is also known as a non-exhaust column, is able to help out. If you decide to purchase such a device, it is recommended that you first familiarize yourself with the pros and cons of such equipment. This recommendation is due to the fact that some consumers refuse to purchase smokeless gas water heaters for several reasons, among them the complexity of installation should be especially highlighted.

The main advantages of smokeless gas columns

Chimney gas water heaters are good for a variety of reasons. First, they can be installed without complementing a chimney in the traditional sense. Secondly, such equipment has a fairly high efficiency. This is due to the forced air injection. Thirdly, the unit has a closed combustion chamber, which excludes an increase in the temperature in the room, which is especially important when operating the equipment in the summer.

However, smokeless gas water heaters are chosen not only for the above reasons. They are also good in that they do not burn out oxygen in the house with their work, since they take air for functioning from the street. In addition, the casing of such devices is almost completely closed, which significantly reduces the risk of combustion products getting inside.

Selection of pipes for exhaust, depending on the column

The development of water heating gas technology involves the introduction of a closed combustion chamber into the device. To ensure the removal of combustion products from it, coaxial chimneys are used. Using such equipment it is necessary:

Disassembled coaxial chimney is used to remove combustion products

- install pipes only in an upright position;

- use non-combustible materials;

- do without changing the cross-sections of the air outlet;

- to seal the seams with special heat-resistant agents;

- use no more than 3 bends of the ventilation pipe;

- ensure the integrity of all ventilation elements.

The extractor hood of the gas column with forced function is equipped with a special fan. It starts its work when the ignition is turned on and forcibly pushes the combustion products out of the ventilation. A low draft hood in a private house is perfectly compatible with such a device. The advantage of a column with a forced exhaust system is the complete absence of combustion products in the room, in the kitchen or in the boiler room.

The main cons

Before you purchase the equipment described in the article, you need to familiarize yourself with its main disadvantages, among them you should highlight:

- volatility;

- noisiness;

- high cost;

- the need to obtain approval;

- the formation of condensation inside the discharge pipe.

If you liked the chimney gas water heaters, then before purchasing one of the models, you need to familiarize yourself with the disadvantages of such equipment. For example, many consumers are repelled by energy dependence, because the fan of the structure is powered by electricity. If it is turned off, then the operation of the turbocharged column will be impossible.

You may also be put off by the fact that the fan of the equipment is quite noisy.Such devices cost more than traditional models. On average, the cost of a turbocharged unit is approximately 17,000 rubles. In order to carry out the installation of such a column, it will be necessary to agree with the organizations that are responsible for the supply of natural gas. You cannot do without the permission of neighbors who live on the floor above. The installation of the column provides for the need to lead the pipe to the facade of the building, which may be prohibited by the architectural control service.

Positive reviews

Chimney-free gas water heaters have many advantages; among the additional ones, you should definitely highlight the possibility of installation in any room. The latter can be located in a new house or in a suburban building, as well as in a country house where there are no specially equipped chimneys. Such equipment can also be located in a room located in a building built according to a project that does not provide for the presence of gas appliances.

If we compare it with a traditional-type gas water heater, then turbocharged devices do not dry the air inside the premises. The efficiency of the water heater is increased due to the forced removal of exhaust air. If we are talking about a standard gas column, then in it the combustion products go into a common pipe by gravity. The combustion chamber of the device is completely insulated, so no foreign odors can appear in the room.

How to properly install the hood for a gas column

Installing a gas water heater helps to solve the still common problem of lack or irregular hot water supply to apartments. And for owners of private houses, this is the most convenient method of obtaining it, along with the use of double-circuit gas boilers.

When installing a gas water heater, you should be aware that neglect of the requirements for such work is fraught not only with claims from the controlling organizations, but can also cause accidents. The geyser can work without a hood, but tell me, where will the combustion products go?

The article will tell you why you need a hood for a gas water heater in an apartment, what are the features of calculating its parameters and tips for performing work.

Negative reviews

Non-chimney gas water heaters, reviews of which should be read before purchasing such equipment, according to consumers, also differ in the presence of some disadvantages. Among the disadvantages, buyers note a more complex installation compared to conventional water heaters. So, a hole has to be drilled in the wall, and then it must be carefully repaired, leaving a special nozzle outside.

According to consumers, the noise will be heard not only inside the premises, but also outside the building. This feature cannot be called a plus. According to the owners of the described equipment, the increased noise during the operation of the gas device may not please the neighbors. After all, they will smell of exhaust gases, in addition, they will hear noise.

Chimney requirements

The standards set the following requirements for the installation of air ducts for gas water heaters:

- the diameter of the exhaust pipes must exceed the size of the outlet pipe;

- for the choice of material, the maximum operating temperature is assumed to be + 200 ° С;

- laying chimney ducts inside residential premises is prohibited;

- the maximum permissible number of pipe turns is up to three;

- the minimum length of a section without joints is more than 3 m (in new buildings, at least 6 m);

- the length of the branch at the outlet of the device must be at least 0.5 m;

- distance to walls made of non-combustible material - more than 50 mm, non-flammable - 250 mm or 100 mm, if insulation was installed;

- pipe slope from 0.01 to the side of the heating device (at least 30 ° per linear meter);

- only one chimney can be connected to the appliance;

- the minimum distance between the equipment is chosen at least 0.75 m.

The main reasons that the "Oasis" column does not light up

Sometimes consumers ask themselves why the Oasis gas water heater does not turn on. Several factors can be the cause of this malfunction. First of all, it is necessary to check if the pipes are connected correctly. The water heater has a special design that will not work if the connection of the outlet and inlet pipes has been made incorrectly.

The most common and frequent reason for the failure of the gas column from work is the lack of traction. If there is a blockage with foreign objects or dust, the burner will simply go out. The protection system will work, which will cut off the fuel supply. If the column nevertheless ignites, but after a while it goes out, then the reason for this may be a sensitive protective relay. When the windows are closed, the relay overheats, its protection is triggered. In this case, it is necessary to open the window or windows. This measure is temporary, because the relay in this case must be replaced.

The main advantages of the column Grandini JSQ24-С

The gas chimney Grandini JSQ24 C is an equipment that is made in the best Italian traditions. The device is capable of heating water in the shortest possible time, providing the consumer with the required amount. The structure has a modern design and compact dimensions.

Installation is quite simple. The water supply will be provided in a volume of 8 liters per minute. This parameter is minimal. When the temperature drops, it can be increased to 12 liters per minute. The power of the equipment is 24 kW. The column works in automatic mode, and the ignition is carried out from batteries.

The main advantages of the column brand "Neva" 4505

Non-chimney gas water heaters "Neva" are among the most popular on the market. Among others, the model that was mentioned above should be highlighted. It is an equipment for instantaneous heating of water. The device can use liquefied or natural gas in operation. It is noteworthy that the unit can be connected to bottled gas.

As practice shows, 6 liters of water per minute can be obtained using this gas column. At the same time, harmful substances are thrown into the room 1.5 times less compared to a household gas stove. Among other things, this model is equipped with oxygen sensors and timers, which are responsible for turning off the equipment if the level of combustion waste exceeds the norm. The power of the equipment is 9 kW. You will have to pay 4500 rubles for it.

Why the column cannot be turned on together with the hood

When you turn on the equipment for heating water combustion products are removed into the ventilation duct by natural draft.

IMPORTANT! If you turn on the hood simultaneously with the column, then the natural movement of waste substances will be disrupted! They will begin to move in the opposite direction, filling the living space with harmful elements.

The thought about the possible removal of all harmful components into the cooker hood is wrong.

! Because non-combustible particles will constantly fill the space, and subsequently settle on furniture surfaces. Exactly

such facts of the simultaneous inclusion of the hood and the column often became the cause of accidents of carbon monoxide poisoning.

It is impossible to neglect the Rules for connecting gas appliances... This can lead to tragic consequences. Proper connection and observance of the sequence of turning on the equipment will preserve the health of you and your loved ones.

Pluses of the geyser "Vector" JSD 11 N

This gas water heater without a chimney "Vector" costs 4900 rubles. Electric ignition is provided by batteries. Productivity is slightly lower compared to other devices and amounts to 5 liters of water per minute. The body is compact in size.

The minimum water pressure is 0.2 atmospheres.Among the additional advantages, one can single out the presence of a copper heat exchanger, which is treated with an anti-corrosion coating during the production process. There is a gas control and overheating protection in the system. Protection also works when there is no sufficient draft in the chimney.

Installing a column hood

Installation of hoods must be subject to certain conditions. So, the regulatory documents for safe operation stipulate:

- The height of the straight section above the column is at least 500 mm (in some cases, at least 250 mm);

- The length of the connecting requirements is no more than 3 meters in new buildings and no more than 6 in the rest;

- The number of pipe bends - no more than three with a bend radius not less than the pipe diameter. Bends with a smaller radius are not allowed at all.

- The presence of a bias towards the column is not less than 0.01.

Correct chimney installation

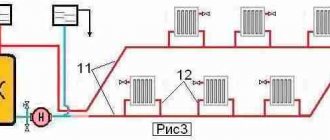

The gas water heater is connected to one chimney only at a certain distance from the previous connection. It is believed that each additional meter of the hood located horizontally reduces the productivity by 5-10%.

Using gas columns with forced draft

This device is designed to quickly heat water using the energy of the combustion gas. In such models, it is often possible to use both natural and liquefied gas, it is only necessary to install jets of a suitable diameter.

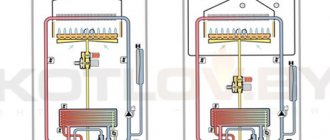

Column with forced draft differs from conventional chimney - in the technology of removing gas and smoke (combustion products). Gas and smoke are removed by means of a cooler through a thin chimney (about 5 cm in diameter), which goes out into a regular hole in the wall. A small chimney of this chimney is used to discharge combustion products into the street thanks to the fan. Unlike columns with a closed combustion chamber, models with forced exhaust do not have coaxial chimneys, since their combustion chamber is open - atmospheric. Therefore, combustion air is taken from the room. Another very important distinguishing feature of this column is that the ignition and fan are powered from the 220V mains.

Of the advantages of a forced draft gas water heater, the following features can be emphasized:

- there is no need for a chimney (this suggests that such columns can be installed in houses that were not designed for conventional gas water heaters);

- forced draft - increasing the efficiency of the column;

- isolated combustion - no unpleasant odors, gas pollution and dustiness of the room.

There are several nuances worth knowing:

- the installation of this column is more complicated;

- the column creates additional noise due to the operation of the cooler;

- it is worth considering the layout of the house before buying a speaker, in order to avoid unpleasant surprises.

Purpose of the hood for the column and its types

The hood may not particularly affect the operation of the column, but its presence must be performed in accordance with all SNIP standards. It is enough to have a small draft, which is available in the ventilation shaft, and the processed products will leave the combustion chamber. They are self-disposed of in the required direction. The gas water heater and the hood are safe in operation, provided that all the rules of use and the serviceability of the parts of these devices are observed. A correctly installed hood is a reliable means against the penetration of large volumes of gas and its combustion products into the room where it is installed.

Choosing the necessary ventilation for the column, you need to know the diameter of the pipe. There is a system of standards. For gas water heaters, the diameter is 11 and 13 cm. Anything less is a low power removal agent. Such a pipe can withstand no more than 19 kW of energy.And with a larger diameter, the use of high-power gas water heaters, with several points of water intake, is suitable.

For the best operation of the water heating equipment, it is necessary to apply such a system, which will provide the best draft. Sometimes, with some building features of a house or apartment, exhaust systems are installed using a knee at 90 degrees. This method is allowed by SNIP, but it can reduce the draft of harmful gases from the combustion chamber. A forced draft gas water heater is an ideal option for boiler household equipment.

According to the material of manufacture, pipes are used of several types. These include: enamelled steel, stainless steel and aluminum.

The use of corrugated pipes is especially popular.

They perform their functions well, are lightweight and less expensive than others. This consists of several layers of aluminum foil.

Corrugated pipe is very popular in use

Less commonly used types of pipes made of enamelled or stainless steel. In addition to the high price, some problems associated with condensation due to temperature differences can arise when using them. Sometimes the use of special heaters for pipes is simply necessary. That is why steel pipes are rarely used.

How to choose a gas water heater with forced draft

In order to choose the right forced draft water heater for yourself, you should pay attention to a number of factors, which we will talk about below.

One of the most important criteria for water heating geysers is power. The performance of the unit depends on the power. However, do not dwell on this indicator if you plan to use it for only one draw-off point. then a model for 20 kW - 10 l / min will suit you. For 2-3 water points, you need to buy a more powerful model - 24-26 kW, or 12 / 14l / min.

In turn, productivity is responsible for the amount of water heated over a period of time. The higher it is, the more water is heated (based on this indicator, basically, consumers choose their columns). It is also worth paying attention to that. that such columns are equipped with a horizontal chimney with an exit through the wall. The chimney is telescopic and extends by about 1 meter.

Summing up, it is worth saying that if you decide to become the owner of a forced draft gas water heater, then you need to take into account some features. This column needs to be connected to the mains, since the ignition of the burner and the operation of the fan directly depend on the supply of electric current.

It is worth taking into account the reviews that the device can be a source of noise, because the silence and the operation of the electric motor are mutually exclusive concepts. However, in the end, by installing a column with forced draft, you can always be sure that your funds have become a wise investment, because saving time and money during operation is a very important argument when choosing a water heater.

Buy a gas water heater with forced draft in a gas water heater store at a bargain price!

klimatvspb.ru

Exhaust gas boilers: device, features

Gas heating boilers with a power of up to 30 kW are usually located in a kitchen with an area of 15 sq. Requirements for a window - an area of 0.3 square meters, a ceiling height of more than 2.2 m. In this case, the presence of a window in the room is mandatory.

Higher power equipment requires a special boiler room. In any case, a high-quality exhaust hood for a gas boiler is the most important condition for its efficient and safe operation.

The main elements of a reliable exhaust hood for a gas boiler:

- pass-through box;

- pipeline branch;

- adapter for fixing the branch pipe of the through passage and the outlet pipe;

- crimping clamps with brackets for fastening to walls and ceilings;

- telescopic pipes;

- tee equipped with a condensate drain;

- special bends;

- cone tip.

Exhaust materials

The temperature of gas combustion products is within 400 ... 450 degrees. Therefore, hoods for gas boilers and modern dispensers are made of heat-resistant materials. Due to insufficient tightness and reliability brickwork, which was previously widely used for chimneys, is now used as an element of decorative design for metal pipes.

Ceramic exhaust pipes wrapped with insulation in a expanded clay box are used relatively rarely due to their high cost. The key advantage of ceramic trails is durability.

Mainly used pipes metal thickness of about 0.6 mm. Lightweight aluminum is easy to install and reduces the risk of condensation. Aluminum foil is also popular for hoods, easy to install, condensation-resistant corrugated pipes. Strong, reliable steel pipes are made of stainless steel or protected with an enamel heat-resistant coating.

A highly efficient solution is to use coaxial pipes. Through the internal line, flue gases are discharged outside, and air is sucked in between the pipes. Heating the air improves the efficiency and effectiveness of the equipment, and reduces gas consumption.

Without fail, a coaxial pipe is used to exhaust a gas boiler, a closed column.

Insulation requirements

Thermal insulation must be used to eliminate condensation. Often, hoods for gas water heaters are made from double-circuit chimneys with an internal stainless, external galvanized pipe and thermal insulation between them.

Heat-resistant materials are used as thermal insulation - usually mineral fibers. Galvanized pipes are used only for the outer coating of heat-insulated channels, since overheating of zinc over 419.5 degrees leads to its melting.

How to choose a hood for gas boilers and water heaters?

There are several types of pipes for installing a ventilation system when installing a gas column.

As a general rule, it is necessary to purchase pipes at least 11 mm in diameter. The intensity of the removal of combustion products during the operation of a gas boiler or a flow column directly depends on the diameter of the pipeline.

The best option would be to purchase pipes with a diameter of 13 mm. Wider chimneys are installed if several points of water intake are provided with more powerful gas equipment.

There are established requirements for the quality of materials for the extraction of the combustion products of the gas column. Effective, reliable and safe operation requires:

- Increased smoothness of the inner walls of the pipeline (equivalent roughness no more than 1 mm) so that not only gases, but also soot can freely leave the communications. Roughness higher than the permitted parameters creates favorable conditions for retaining ash and soot, which leads to a narrowing of the pipe lumen and insufficient intensity of gas removal.

- Resistance of pipes to high temperatures and aggressive attack of chemically active compounds of combustion products.

The final choice of material for pipes for the hood remains with the owner. It is influenced not only by considerations of practicality, but also by material possibilities at the moment.

Manufacturers offer pipes of different quality, price and service life:

- Aluminum. Lightweight, affordable pipes have one drawback - they quickly burn out when operated at high temperatures.

- The cooker hood made of galvanized steel is protected from corrosion, has a reasonable price, but when it is operated under high-temperature conditions, harmful substances can be released.

- Enamelled steel hoods are a good choice. These communications are highly resistant to temperature conditions, impeccable smoothness of the inner wall, but not cheap.

- The experts recognize the stainless steel hoods for the gas column as the best choice. They are characterized by a long service life, excellent smoothness, temperature and chemical resistance. There are different configurations, but the installation of a stainless steel hood is quite expensive.

The number of fittings (and therefore connections and potential air leaks) directly affects the tightness of the future hood. The density of the chimney must correspond to class B, and this is a minimum of air leakage from the outside. The last parameter to choose is the exhaust pipe configuration:

- conventional pipes with mounting on fittings,

- corrugated, flexible,

- coaxial.

Coaxial pipe is a complex structure where one pipe is inserted into another with sufficient clearance in diameter. The combustion products are removed through the inner pipe. Forced blowing of clean air from the outside into the room through the clearance between the outer and inner pipes.

Coaxial stainless steel hood has not only increased cost, but also a number of practical advantages:

- The isolation of the inner pipe + cold air supply prevents the pipe from heating up during operation. There is no need for additional thermal insulation and safety is increased.

- The oxygen content in the room is replenished, which "takes" the gas water heater during operation.

An alternative to the expensive steel coaxial chimney is the cheap dual-channel plastic piping. However, its service life is much shorter.

Note! Most modern gas water heaters and boilers have a closed fuel combustion system. For them, the installation of a coaxial hood is mandatory.

Corrugated stainless steel pipes can be called ideal for installing a household gas hood: they are easy to assemble, have a minimum number of connections, have high corrosion resistance, and are easy to hide in cabinets. These are the most expensive and most durable chimney pipes for gas equipment.

Norms and rules for combining gas water heaters and kitchen hoods

Equipment designed for water heating works without forced removal of combustion products. They are removed from the combustion zone by natural draft, which must be checked annually by utility workers. This procedure is known to speaker owners.

IMPORTANT! To neglect such verification is to endanger life.

Based on the requirements for the installation of gas water heaters, a separate ventilation duct is installed for them, which cannot be combined with a kitchen... This is due to the fact that combustion products can enter the living room. In the absence of such a chimney, the installation of a column in the room is prohibited by the "Rules for the use of gas at home".

REFERENCE! In Soviet times, houses were designed with a special channel for gas water heaters!

That is why it is very difficult and even almost impossible to obtain official permission to install such equipment in houses equipped with centralized hot water supply.

To avoid the ingress of combustion products into the living space, the Rules provide for the installation of a kitchen hood and its connection to one ventilation duct. And the water heater - to another. The combination of these pipelines is strictly prohibited!

Even if you technically think over and calculate the possibility of moving exhaust gases strictly towards the air duct of the ventilation hood, then it is impossible to calculate the probability of further movement of air masses along the channel... In this way, there is a likelihood of harmful substances getting to neighbors.

IMPORTANT! You can not connect either the column to the hood, or the hood to the column. This must be understood not because the Rules require it, but in connection with the danger of such a connection for life.

If a combined connection of the hood and the column is detected, they report the violation to the appropriate utilities!

Traction Test Rules

In accordance with the instructions for use of gas heaters, it is necessary to check the draft of the ventilation pipe before each start. In fact, speaker users forget about this requirement on the very first day after connecting the equipment. And this issue is very important when removing combustion products. Your cravings should be checked at least every few days.

IMPORTANT! If there is a gas heater in the apartment, it is not recommended to close the windows tightly, even in winter. Open vents will provide the air flow necessary to create a normal air exchange!

Code of practice for the installation of a gas hood

The hood for a gas water heater is equated in technical requirements and standards to chimneys, since it is a transport line for removing combustion products.

Based on this, the same requirements are imposed on it as for chimneys:

- the design temperature for the choice of material is 200 degrees;

- the diameter of the exhaust pipe must be larger than the outlet of the gas column;

- the vertical tube at the exit from the equipment must be at least 50 cm long (halving is allowed in some cases);

- during installation, do not make more than 3 turns of the pipeline;

- the withdrawal of the hood through the living rooms is prohibited;

- sections of a solid pipe in new buildings at least 6 m, in old ones - at least 3 m;

- the gap between the pipe and the walls of the room depends on the material of the walls: fireproof - at least 5 cm; hardly flammable, combustible - 25 cm or 10 cm (subject to additional insulation).

The installation of the pipeline for the exhaust of the gas column is carried out with a slope towards the gas equipment of at least 0.01. The walls of the room are pre-insulated. All sections of the chimney passing through cold rooms must also be additionally insulated.

Note! A separate hood is required for each unit of gas equipment. A common hood is allowed for 2 gas combustion devices of medium and low power, which are located on the same floor. Their insertion into the common chimney is carried out at different levels.

If there is no chimney in the room where the gas water heater is installed, then a main or removable pipe is mounted. Temporary connection of gas equipment to the stove chimney is allowed if it has the required performance.

At the same time, it is forbidden to install equipment with forced evacuation of combustion products in rooms with stove heating, if there is no forced air flow from the outside. Here the exit is a coaxial pipeline.

Features of the hood for the geyser

For many apartments and houses, the only way to heat tap water is a gas water heater. In terms of its characteristics, this device is not inferior to other heating elements. The use of a gas water heater in an apartment requires the necessary safety measures. These include the presence of a ventilation system. This important element is designed to remove combustion products from the device itself.

The extractor hood removes the combustion products from the gas boiler

Features of the installation of the external and internal parts of the chimney

For the installation of the inner part of the flue gas exhaust vent, a weak point is the device for the transition of the pipeline through the ceiling and roof covering. Poor installation leads to leakage, overheating of floors, to the ingress of carbon monoxide and other combustion products into living quarters.

Before starting the assembly of the hood, marking is carried out.

Holes for the pipe are cut in the roof and ceiling slab with a sufficient margin of distance for high-quality thermal insulation.

The assembly of the structure starts from the boiler. In the process of work, it is necessary to monitor the rigidity and stability of communications, for which, after 2-3 meters of a one-piece pipe, fasteners + additional fasteners are installed in the places where the fittings are installed. Sagging of the pipeline must be avoided in long sections.

The outer outlet of the hood for the gas water heater is carried out through the wall. This version of the chimney installation is simple and reliable. The outlet through the wall is more convenient in terms of work, the accessibility of the outlet for repair and maintenance. It is leak-proof due to its configuration.

The hole in the wall is cut 25 cm larger than the diameter of the pipe to be brought out. The distance between the wall and the hood is clogged with thermal insulation. Insulation of the outer part of the chimney is also carried out, the joints of the pipe itself are additionally coated with a heat-resistant sealant.

Note! A coaxial pipeline is preferable for exhausting a gas column, regardless of how the pipe is brought out.

At the end of the work, a test run of the gas equipment is carried out, the tightness of the hood and the traction force in the chimney are checked.

Protective umbrellas or deflectors are not installed on the gas hood. They provoke freezing of the head, blockage by foreign objects, which impede the free removal of hazardous combustion products.

infotruby.ru

| Gas columns BOSCH more BOSCH gas water heaters with forced smoke removal are used in the absence of a chimney. The gases are removed using a coaxial pipe and a built-in fan. Electronic temperature control, automatic maintenance of the set water temperature. The gas column is equipped with a heat exchanger made of high-quality copper, the atomospheric burner is made of stainless steel and can be adjusted to both natural and liquefied gas. |

Geysers with forced smoke exhaust ARISTON, are used in the absence of a chimney. The gases are removed using a coaxial pipe and a built-in fan. Economical gas consumption, low noise level, convenient control, two-stage overheating protection, maintaining a constant temperature of heated water.

Gas water heaters with forced smoke exhaust Oasis are used in the absence of a chimney. The gases are removed using a coaxial pipe and a built-in fan. LCD display to indicate water temperature.

prof-gaz78.ru

What is needed to ventilate the gas column

An important condition that provides an exhaust hood for a gas water heater in an apartment is a sufficient flow of air. Usually, the operation of such equipment begins with the obligatory opening of the window.

A good solution is to install inflow valves above the battery to warm the supplied air in winter.

More often, exhaust pipes with diameters of 110 or 130 millimeters are used for gas columns. The basic rule is that the pipe must correspond to the exact dimensions of the connecting devices.

The exhaust connection must not block the only entrance to the exhaust shaft in the room. Each connected device must have its own entrance to the smoke exhaust shaft.

The number of turns on the track should be the smallest and should not exceed three units. Each turn results in a ten percent increase in track resistance. Ideally, you should install a straight pipe with an outlet a meter above the roof elevation, but this option for an exhaust for a gas water heater in a private house can only be implemented at the construction stage.

When installing a pair of speakers on one exhaust route, the inlets should be 0.75 meters apart in height. Usually, a natural draft is used, but there is also a forced draft for the gas column. Such products are equipped with fans that are connected at the moment the ignition is activated. The main advantage of the forced system is the guaranteed exclusion of the ingress of combustion products into the premises.

BOSCH

Model: Bosch Therm 4000 S WT 13 AM 1E

Geysers with forced draft of this model, all have a closed type of combustion, which is designed to supply apartments and private houses with hot water without any problems. Experts advise installing such a model if there is no chimney in the house. A geyser of this type comes with the function of the necessary smoke removal, that is, there is already a fan in the system that removes the processed gas. All gases escape thanks to the coaxial chimney. For operation, a connection to 220 V is required. It can work even at a low pressure of 0.3 bar.

Advantages and advantages:

- you can control the temperature of water heating, starting from one degree;

- even if the water in the set changes, its temperature will be automatically maintained;

- the gas water heater has a heat exchanger, which is made of high-quality copper;

- the atmospheric burner is made of stainless steel, and can easily operate on both natural gas and liquefied gas;

- has an ionization sensor in the system that monitors the flame;

- safety sensor that protects against overheating;

- a display that shows both the temperature and errors, if any;

- warranty for any boilers of this company - two years;

- the kit contains all the parts to fix the device;

- production Portugal.

Minuses:

-It is necessary to frequently clean.

Rating: 4, 5 out of 5.

Model: Bosch Therm 6000 S WT 24 AME

The column operates on a closed combustion system. Designed to supply hot water to any type of premises, be it an apartment, a house or a small business. Also, manufacturers advise installing this model if there is no chimney in the room.

This is because, in its configuration, such a model already comes with a system that takes all the processed gas using a specially installed fan. Absolutely all waste residues are removed from the system thanks to a coaxial chimney. The uniqueness of this model lies in the fact that it has a high-quality and strong water heater, which, in essence, is intended for commercial use. It can be combined into a large cascade of 12 pieces. Operation from the network.

Advantages and advantages:

- works at the lowest pressure of 0.3 bar;

- you can control the temperature from two degrees;

- if for some reason the water pressure and its flow change, the column tries to maintain the water temperature;

- a heat exchanger is available, which is made of copper of the highest standard;

- a valve that constantly monitors the ratio of gas and air in the system;

- the column can work perfectly on natural gas and reduced gas;

- mandatory presence of a flame tracking sensor;

- there are draft sensors, a closed case, and sensors that measure the temperature of both hot and cold water;

- LCD quality display to show temperature and operating errors;

- warranty - two years;

- production - Portugal.

Minuses:

- if there is no cold water, then there is no water in the house at all; -the need to periodically clean.

Rating: 5 out of 5.

Model: Bosch Therm 8000 S WT 27 AME

Geyser with forced draft of closed combustion type. Great for any type of building, especially if there is no chimney. The uniqueness of the entire line of these dispensers lies in the fact that they already have a compulsory function of removing the residues of the treated gas in the system. Everything happens with the help of a coaxial chimney. The high capacity condensing water heater is most suitable for commercial use, but is also great for home use (if the area is large).

The column can be connected in a large cascade of 12 pieces. A high percentage of efficiency lies in the use of condensation technologies that can reach an efficiency of one hundred percent, generating a higher percentage of heat. Operates at a minimum water pressure of 0.3 bar.

Advantages and advantages:

- you can control the temperature from two degrees;

- if for some reason the water pressure and its flow change, the column tries to maintain the water temperature;

- a heat exchanger is available, which is made of copper of the highest standard;

- a valve that constantly monitors the ratio of gas and air in the system;

- the column can work perfectly on natural gas and reduced gas;

- LCD - display, which displays both the temperature and errors, if any;

- warranty for any boilers of this company - two years;

- the kit contains all the parts to fix the device;

- production Portugal.

Minuses:

- big sizes; - periodic cleaning.

Rating: 4, 5 out of 5.

Advice: before you buy the device you need, you need to think carefully about what exactly you want to expect from it. To select a column, you need to start from: its power, safety, operating system, what type of ignition, what other additional functions are there and where does the entire product that is burned go.

comparison table

Gas-burners

To ensure the combustion process, oxygen and gas must be supplied to a special combustion chamber.

To increase the efficiency of the process, gas is uniformly supplied through a burner equipped with special nozzles and an electric ignition system.

By the method of air intake, there are:

- atmospheric burners with open combustion chambers;

- forced or pressurized, equipped with a closed-type combustion chamber.

Let's consider the principle of operation of each type:

- The functioning of atmospheric gas burners, according to the principle of operation, resembles the functioning of an ordinary gas stove. Gas is supplied through the burner, which is mixed with air from the room, after which the ignition and combustion process is carried out. Such burners have a simple design, but they show low productivity and, as a result of operation, the air in the room is very discharged.

- Fan or forced draft burners take the air necessary for work from the street by means of an exhaust hood. Such devices are characterized by increased stability when working even under low gas pressure conditions. Also, they do not need to equip a vertical chimney. All necessary work is done by a coaxial type chimney. The disadvantage of such units is the increased noise and high price.

ARISTON

Model: ARISTON MARCO POLO M2

This model works on the basis of an open combustion type and is best suited for use in apartments and private houses. This model of the column also has a forced gas removal system using a built-in fan that is located in the system. All residues are removed thanks to the coaxial chimney. For operation, it is necessary to be connected to the network, it works at a minimum pressure of a 0, 4 bar.

Advantages and disadvantages:

- can work both on natural gas, also without problems on liquefied gas;

- many features that protect the reliability and quality of the speaker;

- overheating protection two-level;

- practically zero noise level;

- reverse thrust protection;

- new LCD display that constantly shows temperature and code errors;

- control using buttons (modern);

- warranty period - two years;

- the set includes parts to which you can attach it.

The kit does not include coaxial pipe and LPG conversion kit, purchased separately. Country of origin Italy, China.

Minuses:

- the kit does not include the coaxial pipe itself, you will need to buy it yourself; -and a kit, thanks to which you can reconfigure the column for liquefied gas.

Rating: 4 out of 5.

Advice: it is necessary to remember that the time during which the column will heat a certain amount of water will depend on the power of the equipment. The higher this figure, the less you will have to wait as a result.The power is determined by the number of people who will use hot water. There are only 3 types of speaker power:

- 26-28 kW;

- 20-26kW;

- 17-20 kW.

The third power is the smallest of the entire list, this device is quite enough for use by one person who will constantly wash and wash dishes. If you need about 15 liters to pass through the column in one minute, then you need a second power column. Fifteen liters is the average percentage of water per minute from a family of four.

comparison table

Operating principle

A turbocharged instantaneous water heater operates on the same principle as a conventional gas water heater, only it has a more advanced device with a high level of automation. When the hot water tap is opened and a certain flow rate occurs in the DHW network, the device turns on the main burner and the fan, after closing the valve, it turns off.

But the principle of operation of a modulation burner in tandem with a supercharger is fundamentally different from combustion in an open chamber of traditional units. There, the air supply is not limited by anything, due to which the efficiency of fuel combustion suffers. In a turbocharged unit, the air consumption is clearly dosed depending on the burner demand, which leads to a higher heater efficiency - up to 92–94%.

After opening the hot water tap, the processes inside the gas column occur in the following order. The water unit opens the gas supply to the igniter and closes the sensor contacts. As a result, sparking occurs on the candle and the wick is ignited. After that, the fuel supply to the main burner opens, which is ignited by the igniter, which immediately goes out. The unit operates in the basic mode and heats the water until the tap closes or one of the emergency situations occurs:

- thrust sensor triggering;

- pressure drop in the water supply pipe;

- attenuation of the main burner;

- overheating sensor triggering;

- drop in gas pressure;

- power outage.

OASIS

Model: OASIS TURBO 20S

Suitable for any type of room, it works thanks to a closed combustion circuit. It is best to install such a model only in rooms where there is no chimney.

Advantages and advantages:

- works at the lowest pressure of 0.2 bar;

- you can control the temperature from two degrees;

- if for some reason the water pressure and its flow change, the column tries to maintain the water temperature;

- a heat exchanger is available, which is made of copper of the highest standard;

- a valve that constantly monitors the ratio of gas and air in the system;

- control using buttons (modern);

- warranty period - two years;

- the set includes parts to which you can attach it

The kit does not include coaxial pipe and LPG conversion kit, purchased separately. Country of origin China.

Minuses:

— there is no coaxial pipe, you will have to look for it yourself; — and no, reconfiguring to liquefied gas.

Rating: 4 out of 5.

Model: OASIS TURBO GLASS BG20

This model is perfect for any room, has a high efficiency. It works according to the closed combustion scheme and it is best to install the column if there is no chimney in the house.

Manufacturers have provided for the outlet of the treated gas and therefore, installed a special fan that takes all the gas. Then they are removed using a coaxial pipe. Powered by light and with a small water flow of 0.2 bar.

Advantages and disadvantages:

- can operate on two types of gas, the main thing is to install the transition system immediately upon installation;

- a new and interesting display that automatically displays the temperature and possible breakdowns in the system;

- shelf life - two years;

- a sensor that controls the heating system;

- overheating fuses;

- highest security measures.

Minuses:

- production and assembly takes place in China. - there is no transition system and waste pipes in the set, they must be purchased separately.

Rating: 4 out of 5.

Advantages and disadvantages

For apartments where chimney channels are not provided, for the preparation of water for the needs of hot water supply previously there was only one solution - an electric storage water heater. With the advent of pressurized flow heaters, residents of such apartments have an alternative. This is one of the main advantages of columns with a closed combustion chamber. And here are the rest:

- there is no need to organize the flow of combustion air into the house, the usual supply and exhaust ventilation required in accordance with the standards is sufficient;

- high efficiency of work, which means - profitability;

- gas water heaters without a chimney are fully automated and create additional comfort during operation;

- tandem fan - burner successfully smooth out the water temperature drops when opening several taps within the available power;

- getting into the room of various combustion products is practically excluded.

Like any other water heater, a closed-type chimney column has some disadvantages. One of them is the high cost of the product compared to conventional flow-through units. The reason is the presence of additional expensive elements and parts in the design. But look at the problem from a different angle in such a situation: the installation of the heater is planned during the construction phase of the house. And consider what will be cheaper: the device of a traditional chimney and the purchase of an ordinary column, or the installation of a coaxial pipe and the purchase of a turbocharged unit.

The heater, which uses a closed combustion chamber and fan, generates some noise during operation. In addition, the device is completely dependent on the availability of electricity, so it cannot be used in areas with frequent outages. Or you will need an alternative source of electricity, such as a gasoline or diesel generator.

Due to the complexity of the design, do-it-yourself maintenance and cleaning of the water heater is excluded. If you decide to install a turbocharged column, be prepared to contact the service department for troubleshooting. More information about the products can be found by watching the video: