Reliable fastening of the insulation is a mandatory step in creating thermal insulation for a room. Soft, loose and porous sheets or mats, which are easy to fix, are chosen as the insulating material. For small volumes, they are fixed on glue or simply placed between the bars. In the case of large-scale construction work, it is necessary to use special fasteners - dowels. They differ in the method of fastening, material of manufacture, length and diameter. Before starting work, it is necessary to choose the right holders for thermal insulation.

Types of retainers

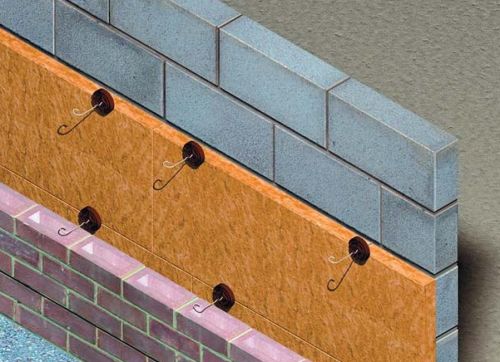

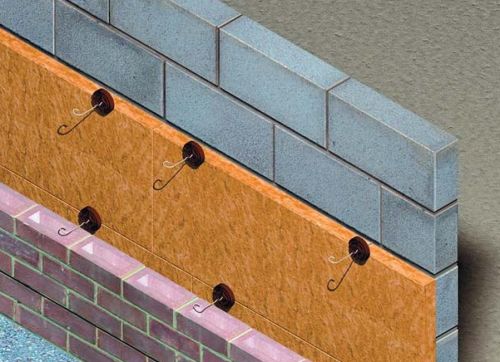

For the facade and roof, different types of dowels are used, differing in the size of the cap

Insulation is a heterogeneous multilayer material, often with a porous structure. The complexity of its fastening lies in the risk of violating the integrity of the structure, especially when using waterproofing and vapor barrier. For this reason, retainers are divided into two main groups:

- dowels for facade work and wall insulation;

- dowels for roof insulation.

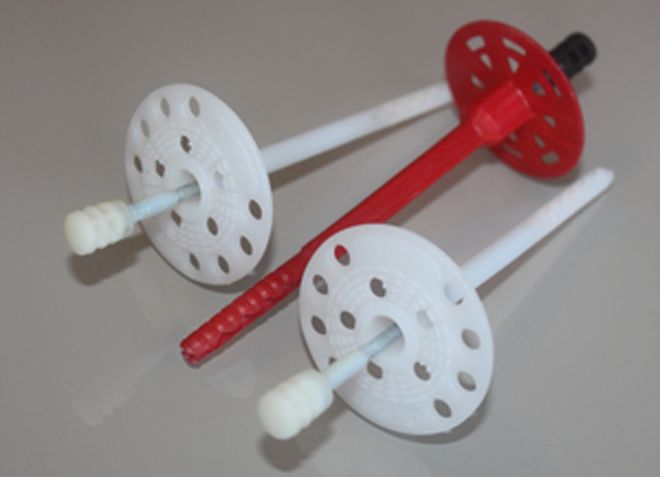

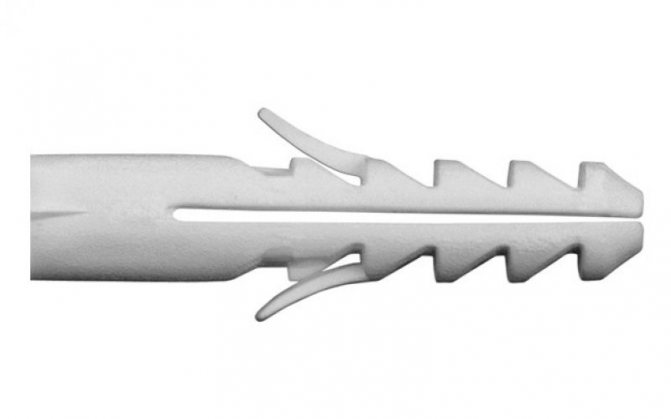

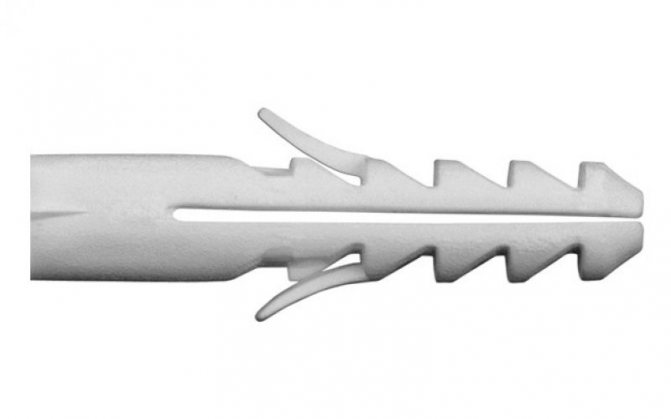

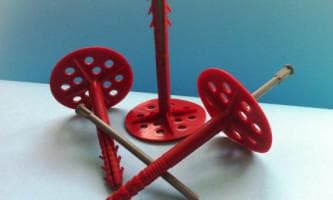

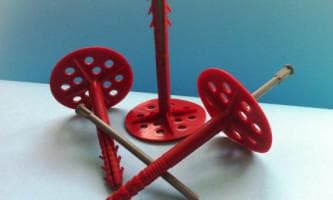

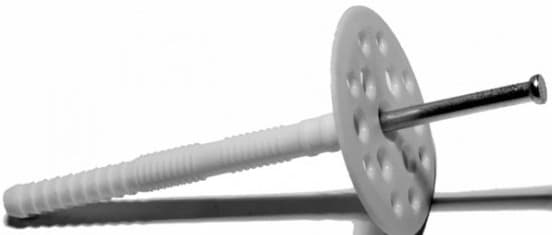

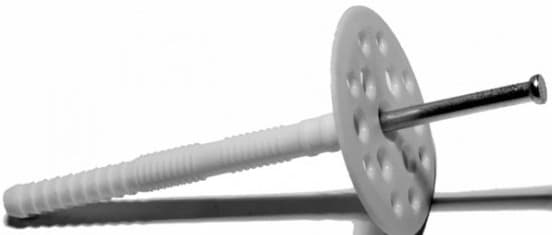

The first type of fasteners is an integral or collapsible structure in the form of a mushroom. The collapsible one consists of a sleeve with a spacer part, a head in the form of a pressure disk and a rod. The dowel for insulation differs from the usual only in the increased volume of the head. The disc diameter is 45-90 mm. Made from various types of plastic and metal.

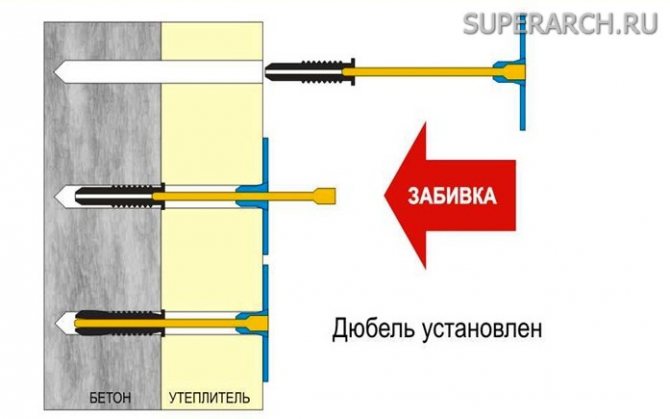

The second type of dowels is a hollow plastic rod with a wide clamping disc. It has a special way of installation - into the body of the heat insulator. The nail goes through and sinks into concrete or other dense material.

Dowels: mushrooms and plates

For fastening hard and soft insulation, the so-called mushroom dowels for thermal insulation, or, in other words, dish-shaped mushrooms. They are able to hold even loose and fragile insulation. With the help of a mushroom dowel, you can mount the material on almost all types of flat surfaces made of concrete, brick, foam concrete and aerated concrete, as well as building stone.

Disc dowels hardware are widespread due to the unique design of the outer cap - it is wide enough in size and has tapered holes that allow you to reliably fix the mineral insulation. The long wedge zone provides good load bearing performance. The disc of such a dowel has a rough surface and special technological holes. They provide a reliable clamping of the material to the base. In addition to this, the fixing of the insulation is facilitated by a spacer zone (60 mm), consisting of three sections, which, among other things, completely excludes pulling the dowel out of the hole.

The main component in the manufacture of the dowel is low-pressure polyethylene (HDPE), and the spacer nail, as a rule, is made of galvanized steel or glass-filled polyamide. Hardware not only contributes to heat retention, but also has excellent anti-corrosion properties. The disc dowel is firmly fixed in place by means of a spacer with a nail, screw or screw. Moreover, it expands in two or three directions, which makes it possible to effectively fix all known types of insulating materials, as well as to increase the fastening strength and bearing capacity of the dowel itself.In addition, the plastic material of the product avoids the formation of cold bridges and is characterized by resistance to aging, which, together with other quality characteristics, guarantees high reliability of the fastener for many years.

The disc dowel, in particular its head, is highly flexible, thereby compensating for thermal expansion and deformation of the material. This, in turn, makes it possible to reduce to zero damage to the insulation layer itself.

Criterias of choice

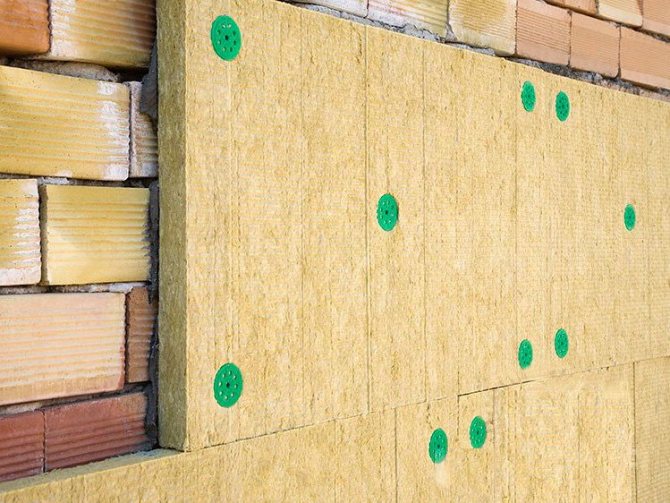

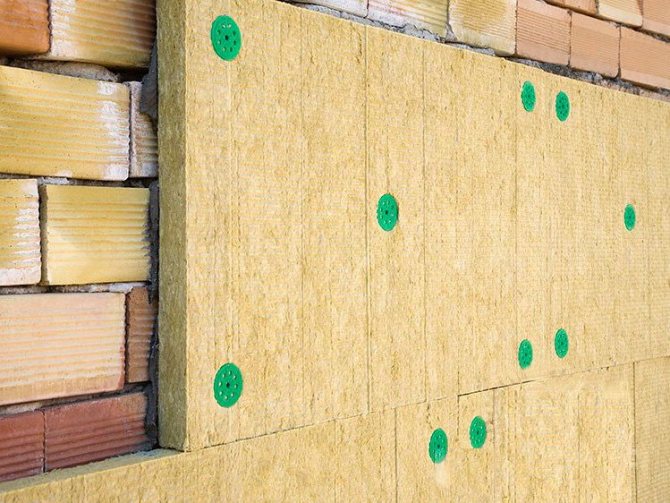

When choosing dowels for insulation, its density matters

The quality of fastening the material to the surface depends on the correct choice. When choosing dowels, you need to pay attention to several factors:

- Length. It depends on the thickness of the insulator and other layers, the deviation of the wall from the vertical, the minimum allowable deepening.

- Pull-out load.

The shape also depends on the material. Lightweight heat insulator does not withstand rigid attachment.

Calculation of the required number of dowels

To calculate the total number of necessary fasteners, you should first draw up a diagram of the location of the insulation on the wall. The skills of a draftsman are not needed here, a simple conventional drawing is enough, the main thing is to find out the number of sheets to be fixed, including small cut pieces, and estimate the points for optimal fastening of thermal insulation. The density of the insulation is also taken into account, that is, its weight.

Lightweight materials are fixed with four dowels per square meter, and heavier ones, for example, basalt wool, with six. The same amount of fasteners is used on the corner plates. With a high height of the insulated wall, the number of attachment points can increase to seven or nine. It should also be remembered about the possible increased wind load on the building.

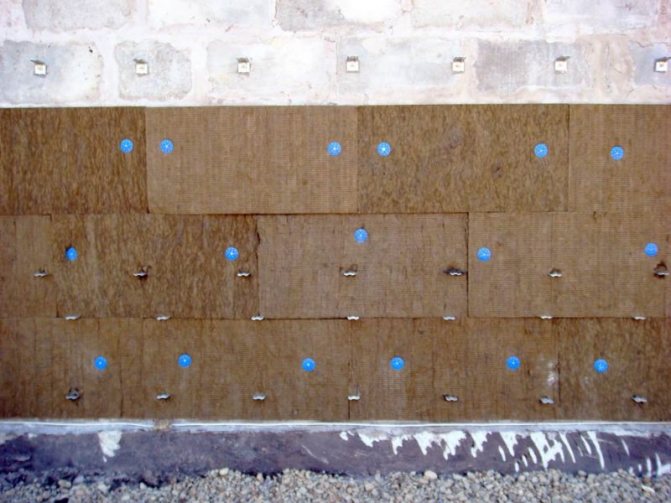

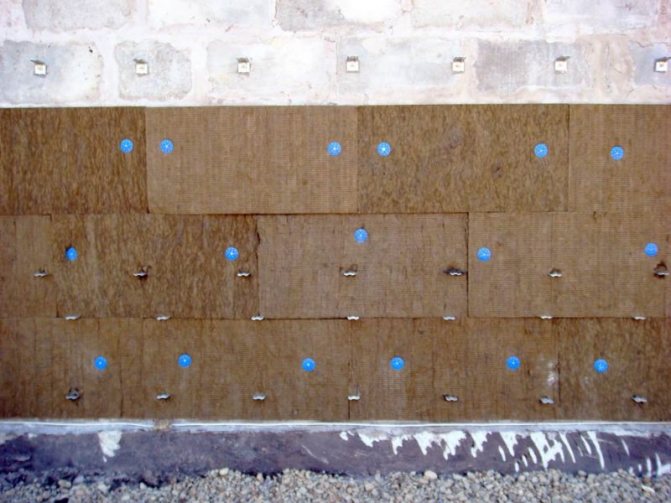

Fasteners are made at the joints of the insulation, so that the cap presses several sheets at once, and from one to three symmetrically in the center of each sheet.

Be sure to take a dozen dowels in stock in case of loss or breakdown. This will not bring you much financial damage, but it will save you from an unnecessary trip to the store because of a few pieces.

Varieties of dowels

Dowels can be classified according to several criteria - by design, material and design. The choice depends on the characteristics of the insulation itself.

Design

There are two main methods of fastening:

- Spreadless. The dowel does not need hardware. The fasteners are installed in a pre-drilled hole through the insulation.

- Spacer. A nail or screw is driven into or twisted into the body of the rod. A hole is pre-made under the rod, into which it must be placed.

Spacer

Spreadless

The first option is used for aerated concrete, and the second for dense materials (brick, concrete).

Manufacturing material

Glass fiber reinforced polyamide nail has the strength of metal

The dowel itself is made from different types of plastics. It is forbidden to use metal due to its high thermal conductivity. A screw or nail is made of plastic or metal.

The main types of plastics for dowels:

- Nylon or polyamide. It is a lightweight material with a high degree of strength. It can be used to mount to any surface. The maximum permissible load on the fasteners for the insulation is 120 kg. Working - 30 kg.

- Polypropylene. Differs in increased strength and hardness. The load reaches 150 kg.

- Glass fiber reinforced polyamide. It is a new material that has the same strength as metals. It has low thermal conductivity, which makes it a material of higher priority than metal parts.

The spacer rod can be made of the same plastic as the mushroom dowel for thermal insulation, or from metal.

Stainless steel is a more durable material than galvanized steel

The following materials are used from metals:

- Cink Steel. The thickness of the zinc layer must be at least 6 µm. It is used in normal conditions with normal humidity levels.

- Stainless steel. This is a more expensive fixative, but it does not corrode. The main area of use for steel holders is in places with high levels of humidity.

By design, there are:

- The nail and the dowel are made of the same type of plastic. It is not advised to use different types, since their coefficients of thermal expansion will differ. The thermal insulation dowel with a plastic nail is used in almost all climatic conditions.

- The dowel is made of plastic, the rod is made of metal. The fastening is improved, but the metal conducts heat. This leads to the formation of a cold bridge.

- Plastic dowel fungus for insulation and a metal rod with a thermal head. This design avoids the appearance of a cold bridge. The screw head is covered with a nylon cap and the nail is inside.

Each of the combinations of dowel-nails for thermal insulation has its positive and negative sides, as well as its own cost. The choice depends on the climatic characteristics of the room in which the insulation is carried out.

Views

Insulation materials are made in the form of slabs. They come from mineral wool or glass wool, as well as from foam. If it is necessary to fasten the last material, then its installation should be carried out before applying the plaster and reinforcing layer.

Butterfly dowel for drywall load and other characterizing data can be found in the article.

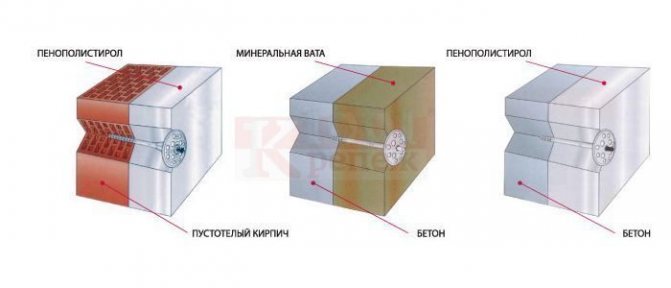

The dowels, with which it is attached, mount it to the supporting base. Depending on the variety of these surfaces, different types of dowels are used. The planes to which it is attached are subdivided into three types:

- full-bodied porous, such as aerated concrete and gas silicate blocks;

- hollow solid (alkaline brick or hollow concrete block);

- solid solid materials (concrete, ceramic and sand-lime bricks).

You can learn how to use a self-tapping screw for metal with a drill from this article.

Therefore, when choosing a material, you need to focus on them. Usually, plastic varieties are used, and products made of polypropylene or analogs made on the basis of nylon are used to fasten plastic insulation.

The dowel designed for thermal insulation is indispensable for installation due to its unusual design, consisting of three parts - a clamping component in the form of a cap, an internal strong core and an anchor element - a sleeve.

You can learn how to properly fasten the corrugated board to the roof with self-tapping screws from this article.

The connection of the cap, which is also called the fungus, with the core can have a straight joint or a transitional configuration. The core in the form of a nail can be plastic or metal. The first material is used for fastening light insulation, and the second for heavier bases, for example, basalt. When choosing it, you need to pay attention to its version with a thermal head, it is specially made to protect the fasteners from corrosion and cold.

Self-tapping screws for wood dimensions table weight and other characterizing data can be found in this article.

In the video - a dowel for thermal insulation with a plastic nail:

The dowel-nail is especially popular.... It is widely used for its galvanized coating, which resists corrosion and ensures the durability of fasteners. To achieve maximum strength, its version with a three-sided expansion is used.

Facade dowel often referred to as dish-shaped because of its hat, which resembles this flat dish.Its core has a thread, which ensures the perfect fastening of the insulation to the base. It can be used for the installation of ventilated thermal insulation systems.

Facade dowels are of three types:

- With nail and thermal head... This is the preferred type of dowel. It consists of a fungus and a nail with a tip of a resistant material that provides thermal insulation to each point of the fastener. The fungus is made in the form of a perforated disk, which provides a reliable grip and retention of the insulation sheet. This kind of dowels can be used in any climatic conditions.

You can learn about what self-tapping screws to fix drywall from this article.

- With a plastic nail... This type can be used to fasten the heat-insulating material to both solid and hollow base. Its construction consists of a spacer nail and a retaining disc element.

- With a metal nail... Such dowels are very similar in design to the previous type, but are used for heavier materials.

Dowel dowels for thermal insulation differ not only in design, but also in the method of fastening.

They are:

- with a core;

- with threads, which, if necessary, can be driven into the base.

The dowel nail butterfly for drywall is used in the following cases listed in the article.

The principle of fastening the insulation with dowels consists in the created friction, which arises as a result of the operation of the expansion mechanism of the dowel. Thanks to this design, the required holding force is created. Therefore, when choosing a dowel, you must first carefully consider the core used. Make sure it is able to withstand the required load. You can use not only a nail, but also other threaded hardware. However, it is worth making sure that they fit in length and diameter.

How to use nails for a pneumatic gun can be found in the article.

In the video - a dowel for fastening thermal insulation:

The advantage of dowels for insulation:

- reliability of fastening and good fixation of thermal insulation foxes;

- facade fungi do not destroy, rot or corrode;

- their design allows them to withstand large bearing loads;

- the insulation remains intact for a long time, due to the fact that the plastic discs of the dowels smooth out changes in the material when it expands or contracts;

- due to the expansion mechanism of the dowels, their adhesion to the wall is improved;

- such an attachment does not create additional cold checkpoints;

- durability and strength.

How to use construction nails GOST 4028 80 can be found here from this article.

Product dimensions

There are no GOST standards for plastic dowels, but they exist for polyamide products. The document states which brand of plastic can be used and in which macroclimatic conditions.

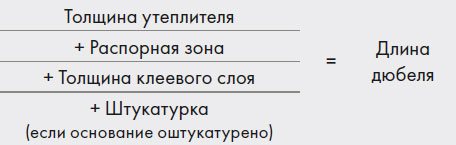

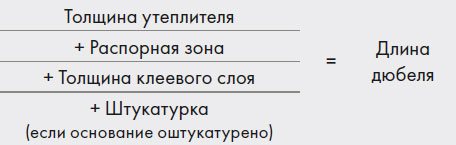

The formula for calculating the length of the dowel for different thicknesses of insulation

The insulation fasteners must be of sufficient length. This is due to the deepening through several layers of thermal insulation. The sizes of other parts vary within a small range:

- head diameter - from 45 mm to 90 mm;

- 2 rod diameters - 8 mm and 10 mm each;

- length from 40 mm to 400 mm.

The bearing capacity depends on the strength of the retainer and the material of the walls. The load can be from 0.3 kN to 23 kN.

The length can be calculated using the formula L = H + I + K + W. L - dowel length, H - insulation thickness, K - thickness of plaster or glue layer (if any), I - additive for fixing into concrete / brick / wood (50 mm), W - stock.

When using 50 mm foam, mounted on a 5 mm adhesive layer, a 110 mm dowel is required. In the case of a curved wall with a skew of 50 mm, the dimension will increase to 160 mm by the corresponding value. A dowel of 210 mm is required for a double layer of insulation.

Excessive length will not always be a positive factor. This must be taken into account when insulating thin walls in an apartment.

How to calculate the length of a fungus?

For the correct calculation of this parameter, you just need to add the following values:

- The thickness of the insulating material.

- Depth of the required mounting hole in the wall. This value is extremely important, since the reliability of the entire connection depends on it. For dense concrete or bricks, the minimum hole will be 50 mm, and with a looser and more porous base it can reach 100-120 mm.

- The thickness of the adhesive layer. Most often it is assumed that this is about 5 mm.

- Thickness of old plaster, if it has not been previously dismantled.

- You can also add 10 mm for the wall level error. With a greater curvature, an even, high-quality installation will be simply difficult.

It is worth choosing the size of the mushroom dowel close to the amount received with a tolerance in the big direction. For example, for attaching a standard foam sheet to a dense brick wall, fasteners with a length of 110-120mm are suitable.

Famous manufacturers

The leading manufacturers of insulation dowels are companies from Germany, Russia and Poland. The most famous firms include:

- Termoklip. The company supplies products to Russia and the CIS countries made of anti-rust coated carbon steel. Dowels are produced in several series, made of block polymer. Some models have a heat-insulating cover.

- Isomax. Produces disc dowels with a diameter of 10 mm. The nail is made of zinc coated carbon steel. It is possible to install a thermal head.

- Tech-Krep. The Russian manufacturer supplies plastic fasteners in different versions. They can have a plastic or metal nail, thermal cover. They have a complex chemical composition. The steel nail is galvanized.

All products have the necessary certificates and licenses for installation work.

Installation work

The number of dowels is calculated based on the presence or absence of additional fasteners, for example, glue

First of all, you need to calculate how many dowels you need, what length and diameter they should have. It depends on the insulation. Its weight is practically irrelevant, the thickness and degree of looseness are important.

The length of the fasteners for the insulation mushroom depends on several parameters. The thickness of the insulation sheet, adhesive layer, vapor barrier, waterproofing. It is also necessary to take into account the deviation from the vertical and the maximum possible deepening into the wall. All these criteria must be specified in the documentation and the size is selected according to them.

The diameter of the cap is determined by the degree of looseness of the thermal insulation. This criterion is approximate, the exact values are not indicated anywhere. If the insulation is light and loose in structure, the diameter should be large. In the case of styrofoam installation, you can choose dowels with a small head. For laying mineral wool, choose the largest hats.

The number of fasteners depends on the weight of the insulation boards and the possible load of the disc dowel itself for fastening the insulation. There should be at least 5 of them per plate - 4 are attached in the corners, 1 in the central point.

All these values are applicable if the interior of the house is insulated.

If the insulation is to be attached to the façade, the wind load must be taken into account. The number of bindings is increasing, there should be at least 6 of them, located in two parallel rows. If the building has a height of up to 20 meters, 1 sq.m. there are 7 dowels. At a height of more than 20 meters, the consumption of fasteners increases to 9 pieces.

Recommendations for choosing a dowel-fungus for insulation

- The insulation dowel with a plastic nail should be used when installing lightweight materials such as foam or mineral wool. For insulation with a high density, it is better to use a metal rod, but remember about cold bridges, use thermal heads.

- When buying, be sure to check the product for strength. If it cracked or deformed during bending, then you should not use it.

- Also, when buying, insert the rod all the way into the sleeve; for optimal reliability, the spacer part should at least double.

- The metal rod must have an anti-corrosion coating. Carefully check for traces of rust, if there is, then do not try to buy. If they started to rust already in the warehouse, imagine what will happen during further operation.

- When fixing is done on a porous base, for example, a brick or rather loose concrete, use a dowel for insulation with additional tendrils on the sleeve. This will increase the reliability of the installation.

- Always purchase a disc dowel complete with nails. Trying to save money and find nails separately can rarely be successful. Just waste your time.