Here you will find out:

- Disadvantages of other devices

- Infrared heaters - principle of operation

- Advantages and disadvantages

- Varieties of infrared industrial heaters

- Scope of application

- Popular models of IR heaters

Heating industrial and industrial premises is a problem - not every heating device will be able to efficiently heat large volumes, including those with high ceilings. The way out of the situation is industrial infrared heaters, which are optimal for use in large rooms. Let's see what these heaters are, how they work and what are their advantages.

Disadvantages of other devices

Heating in industrial buildings is often based on classic radiators and bulky registers made of large-diameter pipes. But if the room has a large area, then heating it will be somewhat difficult - high ceilings and too large a distance between the walls affect. Let's see in what other ways we can heat industrial premises:

The use of diesel heat guns requires a lot of space, and the high noise level and the need for ventilation make this method rather inconvenient in many rooms.

- Using gas heat guns is an excellent way out of the situation, allowing you to pump heat into large rooms. The downside is that these devices require a source of liquefied gas;

- With the help of diesel heat guns - these devices are often used for industrial premises, but they require good ventilation, which is necessary to remove combustion products;

- Using convectors is not the best option, it is only suitable for small workshops. The thing is that the height of the ceilings in this case should not exceed 3-3.5 meters. A different type of heater should be used in taller buildings.

Therefore, the best industrial space heater is an infrared device that works by means of infrared radiation.

Another disadvantage of the cannons is the increased noise level - they buzz perceptibly. Also, they are not environmentally friendly.

What are industrial infrared heaters?

Infrared heaters for heating workshops and warehouses use gas, electricity or other fuel to obtain an initial energy source with its further transformation into infrared radiation. The device has a simple and reliable design:

- metal case with heat-resistant coating;

- sealed container with a heating element;

- aluminum reflector.

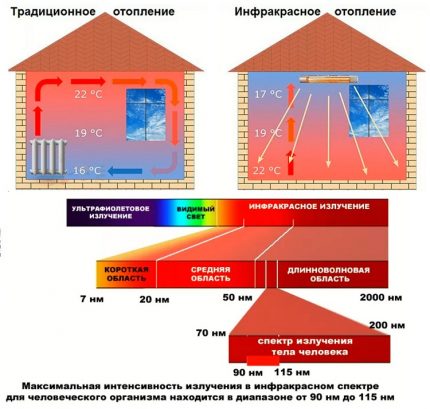

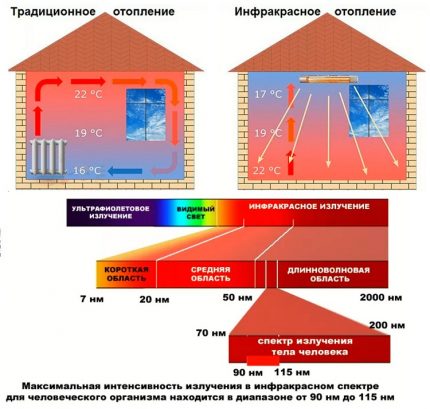

Heating the working areas of production with infrared heaters is cheaper than standard heating using a radiator system. The warmth in the room is felt immediately after turning on the equipment. Infrared radiation affects the surface of objects, heating them. The remaining heat is transferred to the air by natural air exchange. The method of operation of the heater is somewhat reminiscent of heating the earth and the effect of a natural heat carrier - the Sun. In winter, under the direct rays of the sun, a person is hot outside, even with frost. This is due to exposure to ultraviolet radiation. A similar method is based on IR heating systems.

Infrared heaters - principle of operation

Our natural luminary called the Sun does not warm the air at all, as it might seem at first glance - it warms up for completely different reasons. It delivers infrared radiation to the Earth's surface. This radiation, reaching the surface of the planet, landscape elements and artificial buildings, is absorbed by them and turns into heat.... In principle, we can call infrared rays thermal, although this is a bit different.

We go further - objects located on the surface of the planet (including the surface of the earth with landscape elements) begin to give off heat. It is this heat that heats the air and the objects around us, buildings and much more. With an increase in altitude, air cooling is observed, since it simply has nowhere to take heat from. Therefore, at the heights where the planes fly, a terrible cold reigns, reaching marks of -50-60 degrees and even lower.

Industrial heaters, which are based on sources of infrared radiation, work in a similar way. Here's how they work step by step:

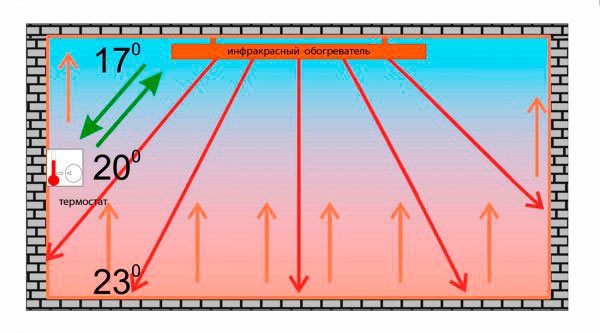

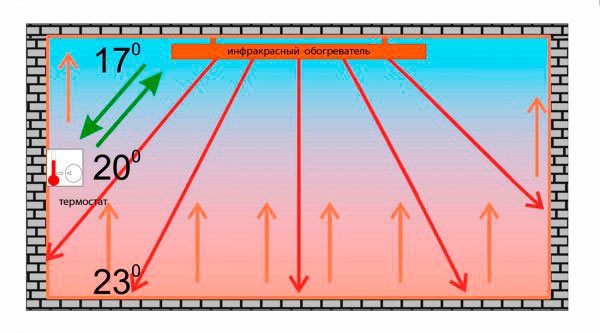

IR heaters concentrate heat in the floor area, which allows people to be in the most comfortable environment.

- Infrared emitters are connected to the mains and begin to generate infrared radiation (or generate it due to the combustion of natural or liquefied gas), and in very large quantities - you need to remember about the volume of industrial premises;

- Infrared rays penetrate the surrounding objects (ceilings, walls, floors, machines, furniture, etc.), as a result of which they begin to give off heat. In other words, they become noticeably warm;

- Heat is removed from heated objects into the air - as a result, the industrial premises become warm and comfortable.

While standard batteries heat the air near the walls, industrial heaters based on IR emitters actively heat almost all surfaces and objects. Even if the distance between the walls is 50 meters, the rooms will be heated practically throughout the entire volume.

Advantages and disadvantages

Industrial air heaters are ideal for large spaces. They warm them up throughout the entire volume and do not interfere with anyone, since in most cases they hang from the ceiling or are located on tripods (on stands). Infrared radiation spreads over fairly long distances, so it easily reaches surrounding objects, floors and even partially reflects towards ceilings. Let's see why infrared industrial heaters are so good. First of all, we note the fact that they are absolutely harmless to human health - provided they are correctly installed. Some experts point out that they are even useful. In any case, they do not harm at all and give a pleasant sensation of warmth - standing under them, you begin to feel how life-giving warmth penetrates literally into every cell of the skin and into its inner layers.

Absolutely silent operation is a very important advantage. It is one thing when it is noticeably loud in industrial premises (machines, pumps, various technological equipment are working). And it's another matter when the production is quiet - in this case, industrial heaters with fans will add a few extra decibels. Therefore, the noiselessness of infrared devices is a solid plus.

Other advantages:

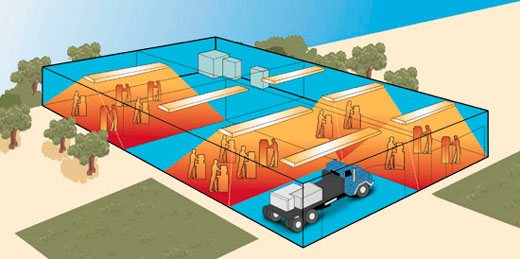

When using infrared heaters, it is not at all necessary to cover the entire area of the heated room with them. It will be enough to concentrate them directly on the jobs of people.

- High efficiency - heating industrial premises with infrared heaters allows you to deliver heat directly to consumers. They are located above equipment and workstations, creating a comfortable environment.Their high speed of work is also noted - if the room has not been completely frozen before, then it will warm up rather quickly;

- The ability to work in rooms with high ceilings - industrial infrared heaters heat from top to bottom. Suspended from the ceiling or by cables, they send infrared radiation down to the consumers;

- Maintenance free - industrial electric heaters don't require any attention. We hang them at the required height and use them;

- Economical - the use of industrial infrared heaters can reduce heating and energy costs by 10-15%;

- Even distribution of heat - only infrared devices can boast of this.

There are also some disadvantages:

- If the location of industrial infrared heaters is incorrect, people may have headaches - be sure to observe the correct installation height of the equipment;

- Electric models are quite voracious - but there is no getting around it. Gas infrared heaters for industrial premises are becoming an alternative to them;

- Risk of burns - the emitting plates of infrared industrial heaters are heated to a high temperature, so accidental contact (for example, when placed on a wall) can cause burns.

Some of the disadvantages are quite serious.

Gas infrared industrial heaters still need periodic maintenance - they need to be cleaned and checked for leaks. In addition, gas equipment is more dangerous than electrical equipment.

Features of industrial infrared heaters operating on gas

Many manufacturers understand that the cost of their products is getting higher due to the cost of heating the workshops during the cold season. For enterprises, in the face of rising prices for centralized services and energy resources, the issue of saving is becoming more and more priority. In addition, in workshops built in Soviet times, heating systems in many cases have worked out their time or have a significant percentage of wear and tear.

It is too hard to survive in the market for those who do not seek to master new technologies and do not think about how to reduce the costs that affect the final price of manufactured products without deteriorating their quality.

Infrared gas emitters are the best match for the tasks of independent heat supply of enterprises. IR heaters have significant advantages over other types of heating equipment. They are:

- quickly warm up the required local zones. Heat begins to appear in less than 30 seconds;

- have the ability to control the direction of infrared rays (for this, it is enough to remotely turn the emitters, directing them to the desired area);

- first heat objects and people under the influence of infrared radiation;

- do not create convective flows, therefore they do not raise dust, which is important for production processes;

- are not afraid of drafts. Since infrared waves are not absorbed by air, they do not follow it when the air masses move;

- do not burn oxygen and do not reduce its level in the room;

- do not emit harsh and harmful odors during work;

- do not dry out the air and do not affect the optimal humidity conditions in the room;

- safe for health, do not cause migraines and other unpleasant sensations;

- they are quickly mounted and do not require heating systems with radiators.

Industrial IR emitters are larger than their household counterparts, but they are lost in the volume of the workshop. Gas infrared devices are intended for installation on floors, ceilings or roof structures, as well as on walls. They operate silently on a mixture of gas and air.Such heaters are simple to maintain, and in operation they are economical and durable.

Industrial infrared emitters are more economical than conventional gas heaters, which, in turn, allow you to spend much less money on fuel compared to other types of equipment.

The traditional method of heating large production areas leads to significant heat loss. In order to establish the optimum temperature in the room, the heaters must warm up the entire volume of the air inside. Here it should be borne in mind that, according to the laws of physics, a warm air mass will continuously rise upward, therefore, in order to achieve the required temperature in the work area of people, more heat resources will have to be spent on heating a workshop with high ceilings.

Industrial infrared heaters work on a completely different principle. They do not heat wasted ambient air, but directly warm a person, equipment, furniture and other items located in the lower area of the room, where infrared waves are directed. Heated surfaces retain heat better than air, gradually releasing it to the surrounding space. The average room temperature, in this case, can be reduced by several degrees without losing a comfortable stay in it.

Application area

Infrared heaters have been used in Europe for a long time. Western manufacturers understand what fuel economy is and why it is required. Fast heating, a comfortable temperature in the working area, no need to increase capacity for heating workshops or warehouses, as well as the use of thermostats, gives excellent results - up to 50-80% of fuel energy savings. In most cases, emitters in industrial conditions pay off in 2-3 years.

Industrial infrared emitters are used in rooms with a ceiling height of more than three meters:

Ceiling mounted

- in production workshops and warehouses;

- in exhibition pavilions;

- in swimming pools and gyms;

- in offices (limited) and entertainment centers;

- trading floors, etc.

It is not allowed to use industrial gas heaters in residential premises.

IR emitters are energy-saving heating technologies for industrial enterprises. Their use becomes a rational solution for any owner of a manufacturing company. The transition to autonomous heating helps to respond in a timely manner to changes in the temperature regime inside the building, depending on weather conditions.

Economic prerequisites for IR heaters

The Russian climate implies a long heating period. In almost all regions of the country, it lasts most of the year, so the cost of heating production areas occupies a significant part of the company's budget.

Even if the heating system is not worn out too much and is in good condition, this does not mean that the coolant comes from the boiler room equipped with the latest technologies. In most cases, the physical deterioration of heating units is at least 50% of the possible period of operation, and heating mains are even more - 60%. This leads to significant losses during heat transportation, for which consumers have to pay.

Square shape

Almost every enterprise suffers from insufficient or excessive heating capacity, which is not regulated in any way "locally". Heat is supplied by centralized services regardless of the needs of a particular workshop. This is where the need to install autonomous heating appears, one of the options for which is gas infrared heaters.

Gas emitters:

- will give the ability to regulate the thermal regime not only in the entire room, but also at a specific workplace;

- help to reduce the cost of production and make it competitive;

- reduce heat loss at times;

- will save you from the maintenance and repair of heating networks;

- will not occupy the usable area;

- protect from the inertia of centralized services.

The use of gas infrared emitters in industry will reduce costs for:

- installation of equipment;

- maintenance of special personnel for the maintenance of boiler rooms, chimneys, warm-water communications and radiators;

- maintaining standby mode to avoid pipe breakage during breaks in work in winter.

Infrared heaters are the most promising solution both for new buildings and for refurbishing existing workshops.

Varieties of infrared industrial heaters

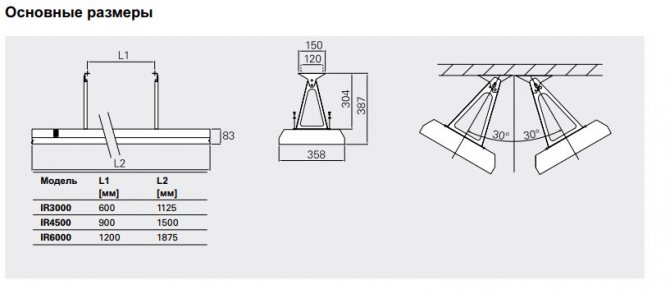

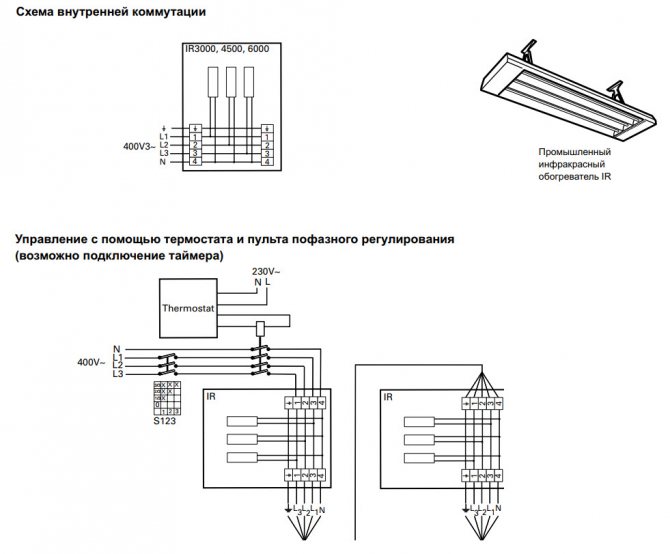

Let's take a look at what infrared industrial heaters are for industrial premises. To begin with, they are subdivided according to the type of fastener - there are wall, ceiling and floor. Wall mounted models are designed for small spaces. They are mounted on walls at a height of 2.5-3 meters and are most suitable for buildings of limited volume and small area.

For uniform heating, infrared heaters should be placed at an equal distance from each other.

Ceiling industrial air heaters are designed for large areas. They are distinguished by their high power, therefore they are mounted at high heights, on suspensions or cables. Such devices are quite popular and the most convenient - they have great power, do not interfere with anyone, the danger of getting burns is excluded.

Floor standing industrial infrared heater is the rarest type of heating equipment. A device of this type is a tripod or a single stand with emitters attached to them. Scope of destination - spot heating.

The next division of industrial infrared heaters is by the type of power supply. Industrial gas heaters run on liquefied or natural gas. They are equipped with miniature burners with automatic ignition. They heat metal or ceramic emitters, causing them to generate infrared radiation that is sent to rooms.

Gas industrial infrared heaters are divided into dark and light. In the dark, the combustion process is hidden; it takes place in a sealed pipe through which air is supplied. Infrared radiation is emitted using ribbed emitters. The combustion temperature in the system does not exceed +400 degrees.

Light infrared industrial heaters operate at higher temperatures - high-temperature burners are installed in them, giving a flame with a temperature of up to +1000 degrees. Compared to dark appliances, they are lighter, so they can be used in prefabricated buildings where various restrictions apply.

Scope of application

Industrial gas heaters and their electrical counterparts can be used in various premises. First of all, these are factories, factories, furniture shops, technological buildings and much more. They are also in demand in warehouses. An infrared warehouse heater will create excellent conditions for storing any goods, including food.

Industrial infrared heaters are also used in agriculture. Here they are needed to heat large greenhouses. For greater savings, gas models are used in greenhouses - they are economical and emit carbon dioxide consumed by plants and converted into oxygen through photosynthesis. And the infrared radiation itself has a beneficial effect on crops.

Popular models of IR heaters

If there is a need to buy infrared industrial heaters, pay attention to the following models:

Ballu BIH-T-6.0

This is an excellent device from a trusted manufacturer. Its power is 6 kW, which allows it to heat an area of up to 60 sq. m. and even a little more (depending on the ambient temperature).

MO-EL Hathor 793

Wall mounted shortwave infrared industrial heaters with three heating elements. Suitable for small spaces and open areas.

Neoclima UK-05

Gas appliance for small rooms. Endowed with a ceramic emitter.

The essence of infrared radiation

Infrared radiation is different from ordinary and familiar visible light. They are similar in the speed with which they propagate and traverse space. Both varieties are capable of refraction, reflection and bundling.

Unlike ordinary light radiation, which is electromagnetic waves, the IR flux has both wave and quantum properties. That is, it transmits both light and heat.

Both ordinary light and infrared radiation are streams of electromagnetic waves. The difference is that in the first case the visible component prevails, in the second - the visible component is combined with the thermal

The light supplied by infrared devices travels in waves. Electromagnetic light vibrations are in the spectrum segment from 760 nm (nanometers) to 540 microns (micrometers). The heat generated by IR emitters is a flux of quanta. Their energy ranges from 0.0125 to 1.25 eV (electron volts).

The heat and luminous flux emitted by infrared devices are interconnected. As the intensity of light increases, the quantum heat flux decreases. Depending on the temperature, infrared radiation may or may not be perceived by our eyes. Thermal radiation is not visually detected.

This specific infrared radiation is used in industry to accelerate the polymerization and curing processes. The thermal part of infrared radiation makes it possible to determine the presence and location of a person or an animal in a dimly lit and unlit night period.

Infrared heating devices emit light in combination with thermal energy used to create a comfortable microclimate on campsites, workshops, production halls, poultry farms, greenhouses and many other objects.

The non-standard operation of IR devices that emit light in combination with heat has become the basis for the development of night vision devices. It is used in flaw detection, in hidden signaling devices and in technical devices for photographing at night.

Both components of infrared radiation are almost not scattered in the processed space, they seem to be focused on objects in the zone of their influence. Heat penetrates into the body of the heated object, the depth of penetration depends on the properties, structure and material of the object. The depth varies from a tenth of a mm to several mm.

Infrared heaters are floor-mounted, wall-mounted, suspended from the ceiling. The devices are distinguished by flameless combustion, the preservation of oxygen in the surrounding space, they do not raise dust columns, unlike convectors

When used for industrial purposes, the wavelength from infrared emitters is selected based on the technical characteristics of the object or substance. IR rays freely pass through the air mass, therefore heating is performed without tangible losses. This circumstance is reasonably considered a weighty plus in production.

In addition to heating and lighting the area processed by the device, infrared emitters are used in solving the following tasks:

Image gallery

Photo from

Acceleration of polymerization processes

Acceleration of coating setting

Infrared equipment in medicine

Infrared lamps in the greenhouse industry