The device and principle of operation of the induction heater

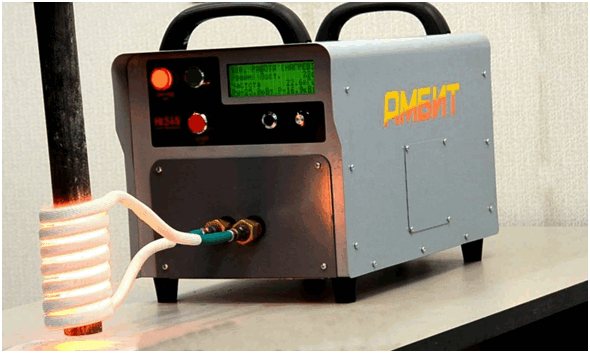

Simplified induction heater consists of three components:

- alternator (1);

- inductor (2);

- core (3).

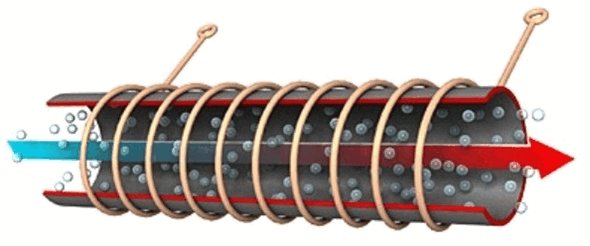

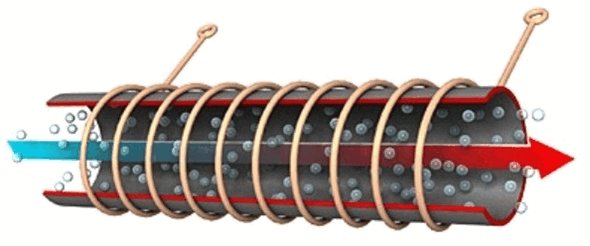

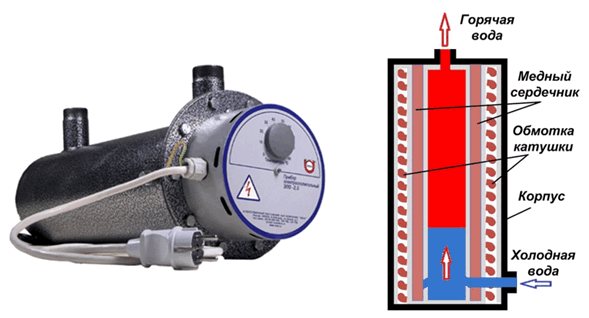

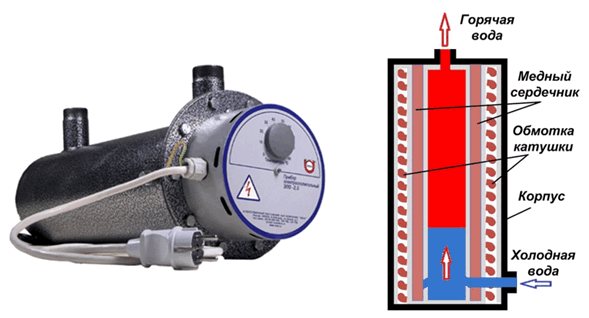

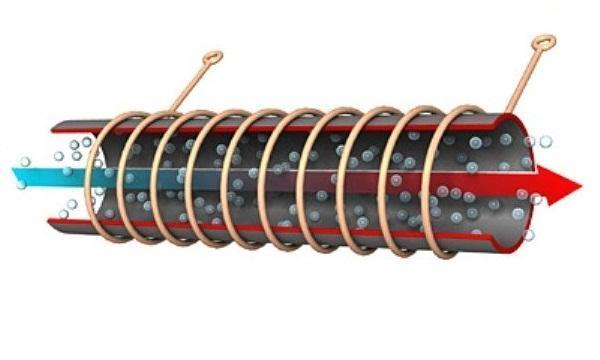

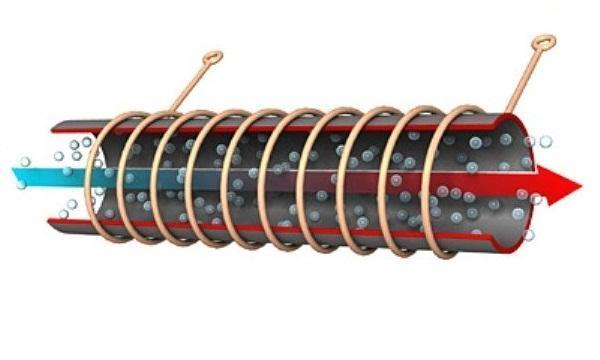

A conductive (metal, graphite) rod is placed in a coil consisting of a certain number of turns of a conductor of a given cross-sectional area without direct contact with it, after which a voltage is applied to the contacts of the coil from the alternator. An electromagnetic field is formed around the turns of the coil, under the influence of which Foucault eddy currents arise in the rod, heating the core. Thus, there is no heat transfer to the core, heat is generated by it independently under the influence of currents floating in it, and can be transferred using a coolant. The temperature of the rod does not rise simultaneously throughout the mass, but from the surface layers to the center, depending on the thermal conductivity of the core material. At the same time, increasing the frequency of the alternating current decreases the depth of inductive heating, but increases its intensity. Particularly noteworthy is the fact that the coil around the core remains practically cold during operation.

This process looks like this:

Areas of use

In industry, induction heaters are used for the following complex processes:

- ultrapure metal melting (produced in channel - contactless induction furnaces);

- bending of large diameter steel pipes;

- surface hardening of steel products (construction fittings, parts of transmission mechanisms of machine tools, etc.);

- heat treatment of small parts of complex configuration;

In everyday life, induction heating devices are also widely used. Areas of their application:

- household autonomous heating systems (for summer cottages, apartments, private houses);

- induction hobs and kitchen tiles;

- small-volume crucible furnaces for household metal smelting;

- jewelry craft.

Since the main topic of the article is an induction heater, we will dwell in detail on a heating boiler, which is based on the idea of inductive heating of a coolant.

Induction heater - heating boiler

Since then, as homeowners began to install autonomous heating systems in their homes, the issue of the efficiency of heating boilers for them remains one of the most important. According to this indicator, at least among devices that generate heat from electricity, induction heating boilers are in the lead. At the same time, their power, which is not comparable with the identical parameter of such a device as a baseboard heater, makes it possible to use the units as the main method of heating in large rooms.

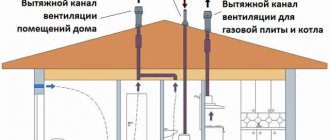

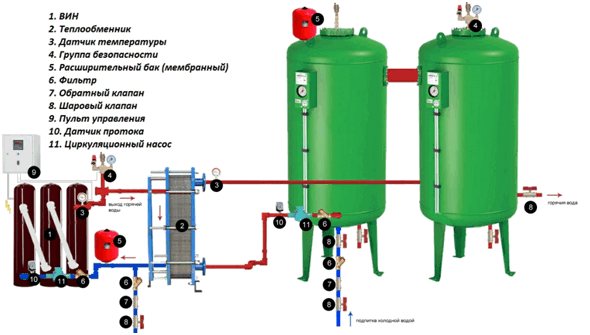

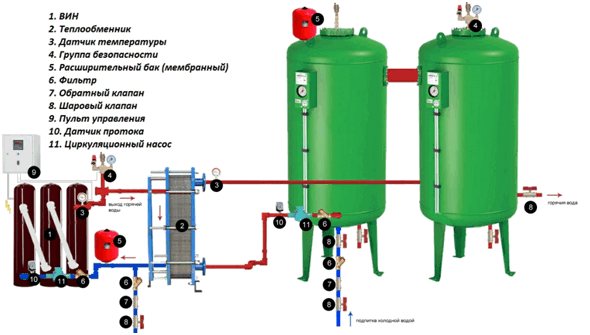

Induction heating boilers consist of two circuits - primary (electromagnetic) and secondary (heat exchange piping). The first circuit, consisting of a voltage converter and a heat generator with an induction-type heater, creates an electromagnetic field, eddy currents and generates heat. The second circuit, which includes a heat exchanger with a piping system, transfers this heat through the circulation of the coolant to the radiators of the heating system. Pure water or with additives is used as a heat carrier.

In addition to these two circuits, the heating system includes automation, which is responsible for the operation of individual units of the unit.

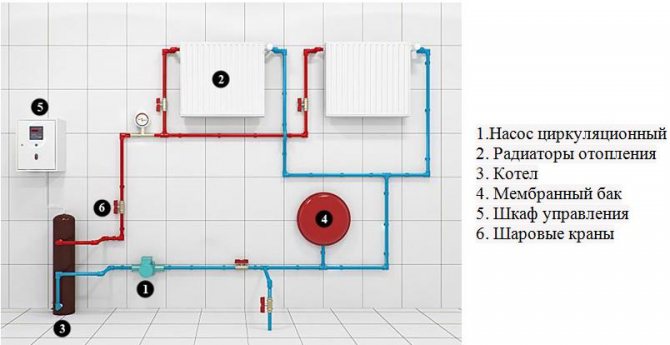

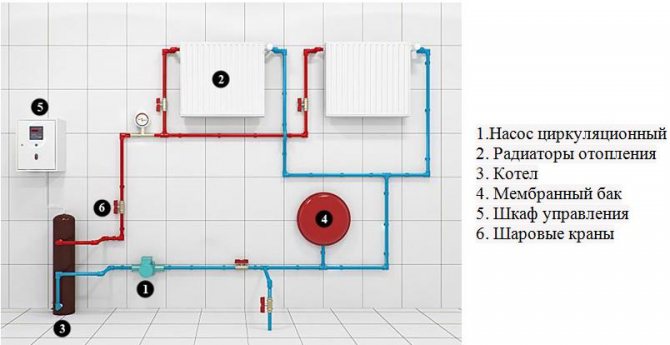

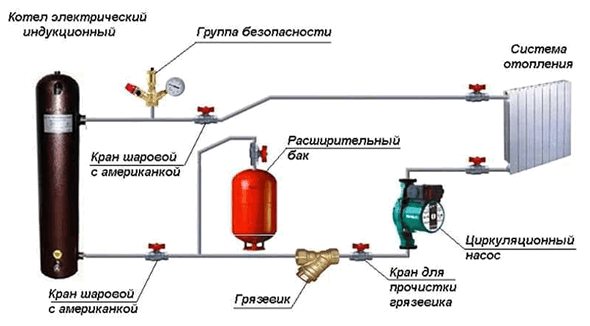

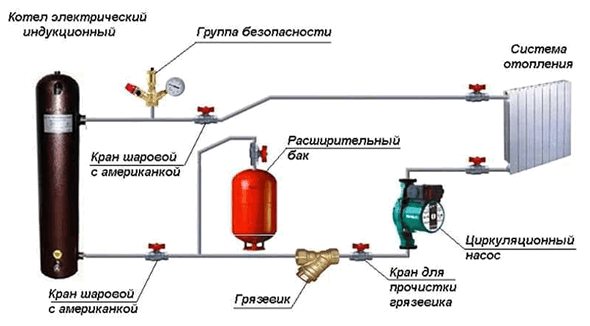

Modern induction heating boilers are installed only in a closed-type heat exchange circuit, which has a membrane-type expansion tank and a forced circulation pump in its design. The use of a circulation pump is a forced measure and is due to the small volume of the coolant at a high intensity of heating of the heat exchanger. The possibility of natural circulation in such a system is excluded - without a pump, water will boil before it starts moving through the pipes.

Important! The induction boiler must always be grounded. In addition, when installing the heating system, the heating medium distribution circuit must be installed from plastic pipes for safety reasons, or the heating unit must be isolated from the steel circuit by inserting polypropylene fittings.

Induction heating boilers are classified in the same way as other electric heating units - in terms of power, design, parameters of consumed electricity. But these devices also have a classification according to the constructive solution of the electrical part.

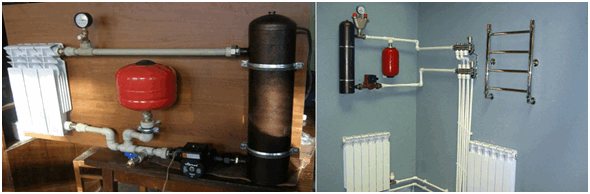

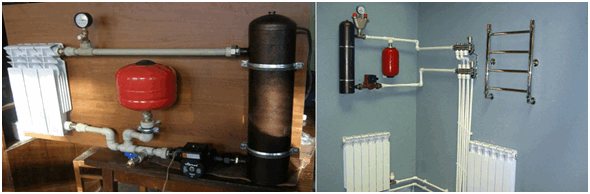

Installing an induction device

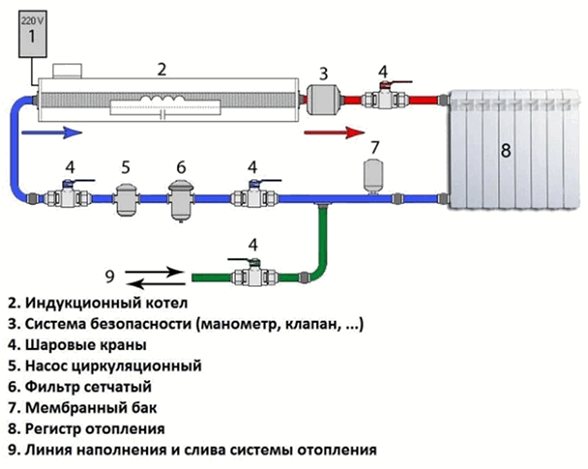

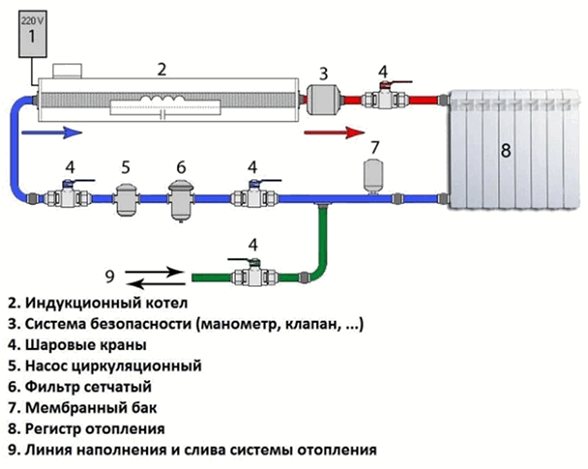

The system with an induction boiler is equipped with a circulation pump, an expansion tank, shut-off and adjustable equipment (ball valves, etc.). In private houses, as a rule, a typical connection scheme is used.

Installation of induction boilers is carried out in accordance with the instructions or technical data sheet. The device is located strictly vertically, the lower inlet branch pipe is connected to the return, the upper one - to the supply pipeline. Only metal or metal-plastic pipes are used.

If you decide to install an induction electric boiler with your own hands, do not forget about grounding. A safety group, a control cabinet are installed in the immediate vicinity, filters, a circulation pump and a flow sensor are installed at the inlet.

Induction boilers overview

On the Russian market, induction-type electric boilers are represented by CJSC NPK INERA (brand SAV), LLC Alternative Energy (brand VIN), NPK Miratron (brand Miratron).

Reviews of SAV induction heaters are equally positive and negative:

“The SAV boiler heats up the water in the heating system faster than the heating element, but it also cools down immediately - the low inertia affects. Savings are achieved by adjusting the productivity of the automatics: first it heats at maximum, and then to maintain the temperature of the liquid it turns on at half the power. "

Sergei Boldovsky, Alexandrov.

“The CAB 5 boiler, according to the assurances of the sellers, operates from the socket. In fact, to operate above +60 ° C, he needs a three-phase power line and an RCD. After a failure or decrease in voltage in the network, the automation is turned off, you have to start it manually. When contacting the manufacturer, they offered to replace it. The same problem with the boiler you received. "

According to reviews, the VIN vortex induction heater to a certain extent corresponds to the declared characteristics.

“I installed VIN-7 2 years ago. No complaints, it functions normally. I did not notice the savings as such, but scale does not form. In general, apart from the price, it is no different from ordinary boilers. "

Alexander Sokin, Rostov-on-Don.

According to buyers, the noiselessness of induction boilers is a conditional value.

“I connected the underfloor heating system to the Miraton 6 boiler. He warmed up very quickly, but the hum is constant, unpleasant. The controller malfunctions, the set temperature level does not support. "

Selection recommendations

1. When choosing a boiler, emphasis should be placed on the correct technical calculation of the heat loss at home. This is the first and main parameter.

2. The second criterion is the number of phases. Single-phase can be connected directly to the outlet, three-phase - only a separate power line. Grounding is carried out in any case.

3. Consideration should also be given to how the induction boiler will be used. If it is required to maintain a reduced stable temperature, a low-power 2.5-6 kW device is sufficient.

4. Some manufacturers offer to purchase separately a mode programmer, a GSM remote control unit and others. With their help, the operation of the boiler is optimized, and the cost increases accordingly.

We offer you to watch an introductory video review of induction electric boilers:

Varieties of induction boilers

There are the following types of induction-type heating boilers, designated both by the principle of operation and by the manufacturer's brand:

- SAV is a type and at the same time a trademark of new generation boilers with a capacity of 2.5 to 100 kW, manufactured in Russia since 2007;

- VIN - the abbreviation is not only an abbreviation for the name of the type of induction devices (vortex induction heaters), but also the patented name of the boilers produced by Izhevsk.

Induction heaters SAV

Operation of SAV units does not require the use of an inverter; a current of 50 Hz is supplied to the inductor. The electromagnetic field induced by the primary winding causes the formation of vortex flows in the secondary winding, the role of which in boilers of this type is played by a section of a closed circuit of pipes with a coolant. This section of the pipe - the secondary winding is intensely heated under the influence of Foucault currents and transfers heat to the coolant, which is forcedly circulated in the heating system using a circulation pump.

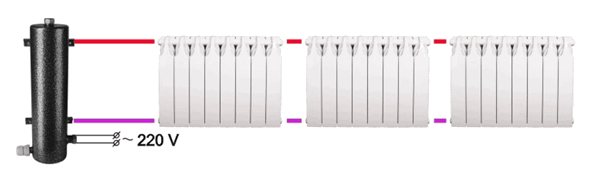

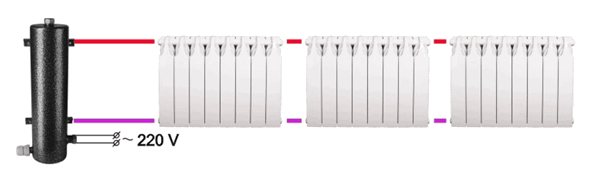

The arrangement of the heating system is carried out using radiators or in a labyrinth way, reminiscent of plinth heating, in order to increase the total area of the outer surface (heat transfer) of pipes - the heating circuit, at least, should not be minimal in length.

SAV boilers are produced under voltage of 220V and 380V. They use water (in pure form or with anti-freeze additives) as a coolant, as well as antifreeze. It takes about 5-20 minutes for the unit to reach full operating capacity (depending on the volume of the coolant), the efficiency of the heaters of such devices is at least 98%. For efficient heating of premises up to 30 sq. M. an induction device with a capacity of 2.5 kW is sufficient, the purchase of which, complete with automation and control systems, will cost approximately 30 thousand rubles.

VIN heating units

Boilers of this type are more advanced in terms of operation and design, which, of course, affects their cost. For the operation of VIN devices, an inverter is required - a device for increasing the frequency of the incoming current. The high frequency current causes the formation of a high intensity electromagnetic field, which, in turn, causes the emergence of more powerful eddy currents in the secondary winding. In addition, the heat exchanger and the boiler body are made of ferromagnetic alloys with their own magnetic field. The result of all these processes is a high intensity of heating of the heat exchanger and, of course, the heat carrier.

A VIN-unit with a capacity of 3 kW is enough to heat a room with an area of 35-40 square meters. (depending on climatic conditions and the quality of thermal insulation of external building structures).

Due to their higher productivity, VIN-units can be used not only in heating systems for housing, but also for hot water supply. For this, additional storage tanks equipped with protective automation are cut into the coolant circuit, the capacity of which is calculated depending on the number of hot water intake points. These containers are provided with hot water by circulating it in a system with direct-flow heating by an induction heater.

Brand popularity

The inner part of the water heaters is made of bio-glass porcelain, which provides protection against corrosion and increases the service life of the device. All Edison water heaters have simple instructions, easy to install even in a small room. The brand quickly gained popularity not only due to its quality, but also due to its low price. According to reviews, Edison water heaters are available to absolutely everyone.

Did you know that ...

The brand regularly holds promotions, and Edison boilers are sold with discounts up to 30%.

What the buyer gets when choosing a water heater from the Edisson trademark:

- easy installation;

- one year warranty;

- minimum energy consumption for heating;

- temperature maintenance function;

- high level of protection against pressure drops and overheating;

- a complete set of parts, as well as the ability to easily purchase them separately.

The Edison water heater is capable of providing hot water at any time of the day all year round.

Evaluating Marketing Claims

Induction heating boilers are credited with many advantages, often without arguments. Let us list these characteristics and give an assessment of the degree to which the statements correspond to the fact:

Profitability

Statement

Electricity consumption by induction boilers is 20-30% less than other electric heaters.

Fact

All heating electrical appliances that do not perform mechanical work convert 100% of the energy of the electric current into heat, their efficiency is always below 100%, but differs in magnitude for different devices in different conditions. To generate 1 kW of thermal energy, it is necessary to spend more than 1 kW of electricity, but how much more depends on the parameters of the dissipation medium. Inside the boiler, of course, losses are also present - for example, for heating the coil, since any conductor material has resistance, but all these losses remain inside the room

Important! Old-style meters (bakelite) will record a lower (1.6 - 1.8 times) electricity consumption than modern electronic ones, since they are not designed to take into account the reactive power of induction boilers.

Perhaps this fact is due to the statement about the efficiency of induction boilers.

Durability

Statement

High reliability and long service life of the equipment - more than 25 years.

Fact

Indeed, the absence of moving parts excludes mechanical wear of induction boilers. But the heating system with a VIN unit includes a circulation pump, the resource of which is much more modest. In addition, the control and automation system includes mechanisms that also consist of many components subject to wear.

The core of an induction heater operates under conditions of constant cyclic heating and cooling, temperature deformations, which are also a negative factor. Therefore, to call the resource of induction boilers almost unlimited is an exaggeration. However, it is, in fact, several times higher than heating elements.

Consistency of characteristics over the entire service life

Statement

The absence of scale formation on the inner surface of the pipes ensures the constant efficiency of the heater and heat exchanger.

Fact

Scale is the deposition of salts in water (heat transfer fluid). The amount of these impurities in a limited volume of the coolant is also limited and small, therefore, the effect of scale on the efficiency of the heater is insignificant. And in an induction boiler, the secondary winding is under an almost constant vibration, and no scale formation occurs at all. So the statement is correct, only its significance is exaggerated.

Noiselessness

Statement

The operation of induction heating boilers is silent, which distinguishes them from other electric heaters.

Fact

The statement is true, but - all boilers on electricity do not make noise during operation, since acoustic waves do not enter the range of their oscillations. Only the circulation pump can make noise, but if you wish, you can choose a model of silent action.

Compactness

Statement

Induction boilers are compact, which is convenient when choosing a place for their installation.

Fact

This is really so, if you do not use a cascade of induction boilers and do not install intermediate tanks in the presence of several hot water intake points in the hot water supply system, since an induction heater is, by and large, a small piece of pipe with a winding.

Security

Statement

The safety of the device is absolute.

Fact

There are no absolutely safe electric heaters. When operating induction devices, the possibility of a coolant leakage from the system is not excluded, and the electromagnetic field generator will continue to work, and the empty pipe system will heat up. To prevent the occurrence of such a situation, an automatic shutdown device is provided in the boiler design, but it can also fail.

Therefore, induction heaters, outperforming competitors in some safety criteria, are not completely safe.

Advantages and disadvantages

According to the assurances of the manufacturers, the use of induction heating boilers for heating a house is a continuous advantage with no disadvantages at all. Let's try to figure out where the truth is and where the marketing ploy is.

1. High efficiency. Efficiency up to 99% is typical for all types of electric boilers.

2. Maximum protection against limescale. Since there is no direct contact of the induction winding with the coolant (unlike the heating element), scale can only form inside the pipes. But closed systems are characterized by a consistently low amount of salts. That is, there are no prerequisites for the formation of deposits.

3. Saving resources up to 35%. Before you buy an induction-type boiler and install it, remember that its main task is to convert energy into heat. To generate 1 kW, according to the law of conservation of energy, it is also required to spend 1 kW of electricity. The only difference is in the heating rate - the induction unit operates faster by about 20-30%.

4. Complete absence of detachable connections in the structure, which excludes the likelihood of leakage. Not entirely true: the boiler includes 4-6 components connected to a block. The cost of the VIN induction heating system includes the boiler itself in a collapsible casing, a control cabinet, a safety group (sensors and relays) and condensers, pressure relief valves, a set of contacts for connecting external devices.

5. High degree of electrical and fire safety. This is true, but care must be taken that there is no leakage, and the amount of thermal carrier remains constant. Otherwise, the device will heat up very quickly and there is a risk of explosion.

6. It has no elements subject to mechanical wear, therefore the service life is more than 30 years. Firstly, the core is durable, but the lacquer insulation on the primary (toroidal) winding is subject to aging. Her service time is 7-10 years. The result of the destruction will be an inter-turn closure with the corresponding consequences. Secondly, induction boilers are a relatively new product that has not passed the test of time, the statement about 30 years of operation is hardly true.

7. Compatibility with other systems. You can connect underfloor heating, gas or wood boilers.

A clever meter that conserves electricity. Pays off in 2 months! Everyone needs to know this in order to save money!

8. They do not require a separate room and ventilation.

9. Do not need preventive maintenance. Boiler - in any case, equipment with many sensors, relays, terminals, which need to be periodically changed, tightened.Of course, compared to gas boilers, this is insignificant.

Thus, most of the positive qualities correspond to other types of electrical units. Now let's analyze the shortcomings identified over several years of operation.

1. Cost. The price of an induction boiler SAV 5 kW is 40,000 rubles. Whereas the heating element Protherm Skat 6 kW - 23,000.

2. Considerable weight with small dimensions. Since even the smallest unit weighs 20 kg or more, it is recommended to mount them on the floor or hang them on a load-bearing wall using strong brackets.

3. The electromagnetic field generates strong interference in the long-, medium-wave and VHF bands. Although manufacturers claim that they do not affect the human body, sanitary and medical officials say the opposite. It is not for nothing that SNiPs contain standards and rules for the location of devices with a high level of radiation.

4. To work in the heating system in a house with 2-3 floors, a powerful circulation pump is required.

Disadvantages of induction heaters

- High cost of devices.

- Considerable weight and compactness.

- The presence of a factor of influence of the electromagnetic field on the body and devices.

Let's consider the last point in more detail.

The electromagnetic field affects living organisms in much the same way as food in a microwave oven - heats them to a certain depth, and this can have consequences. The intensity of the impact of the field, including on a person, is determined by such an indicator as the energy flux density (PES), which grows with an increase in the frequency of the current supplied to the primary winding. When operating induction heaters, it is necessary to comply with the sanitary norm of the limit value of the PES, which is established in SanPiN 2.2.4 / 2.1.8.055-96, depends on the duration of the field exposure and is, for example, for an 8-hour exposure - 25 μW / sq.cm, one-hour - 200 μW / sq. cm.

In addition, radiation from the inductor adversely affects nearby electronics and radio equipment, interfering with operation.

Important! To protect yourself from the effects of the electromagnetic field, you can enclose the boiler with a fine-mesh (1x1, 2x2 mm) metal mesh (Faraday cage) that is not in contact with the boiler body and is grounded.

Choice

It is rather difficult to select a heating device. It is worth considering the facts, knowing which it becomes easier to choose a boiler. The cost of induction heaters is at a fairly high level. But this disadvantage is compensated by a long service life and economical operation. In addition, the power of induction boilers does not decrease over time, which distinguishes them from gas appliances. The power of the equipment is selected based on the calculation of 60 watts per 1 m2.

The indisputable ease of installation and operation speaks in favor of making the choice of an induction-type device. The boiler maintains the temperature level in all types of rooms, it can be pre-installed and controlled.

The electronic control system helps to control the device remotely, which increases the level of comfort of use.

Induction boiler connected to the heating circuit

Operating rules

The safe operation of induction heating boilers, like any other technical devices, is ensured by observing a number of rules regarding both their installation and use after installation:

- The boiler must be earthed.

- The distance from the device to the walls on the sides must be at least 30 cm, from the bottom point of the boiler to the floor - 80 cm, from the top point to the ceiling - 80 cm.

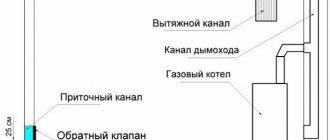

- Induction boilers are installed only in a closed circuit with a membrane expansion vessel.

- The system should include a block of safety devices (pressure gauge, air valve, overpressure relief valve, overheat automatic shutdown system).

Installation of an induction system

Vortex induction boilers are installed strictly vertically, only in a closed heating system with an expansion tank and central heating. To access the equipment, installation is carried out at a distance of at least 300 mm from the wall and 800 mm from the floor and ceiling. Particular attention is paid to mounting to the wall: they must withstand not only the large weight of the device itself, but also the volume of the coolant.

The boiler is connected with flanges and couplings to the heating system circuits: the supply pipe to the outlet pipe, the return pipe to the inlet. The heating system must include a safety block with a pressure gauge, air and safety valve.

The next step is connecting to the mains and grounding. The supply network and cable cross-section must correspond to the boiler output. After installation and piping of the boiler, commissioning is carried out.

We also recommend reading:

Review of renowned manufacturers

- Edison - induction-type heaters with a capacity of 4.7 to 500 kW, manufactured by Novosibirsk, for domestic and industrial needs;

- Miratron - products of the Russian manufacturer of induction heating equipment NPK Miratron for household use, characterized by an advanced design that allows using the equipment without damaging the interior of the room;

- Teco-House - induction heating boilers with a unique control system, produced by the Ukrainian company of the same name according to EU and Russian Federation standards.

Principle of operation

The functioning of an induction boiler is based on the use of the phenomenon of electromagnetic induction. When a large current is passed through the wire coil, an electromagnetic field propagates around it. When a core is found, which is made of a ferromagnetic material, vortex currents arise in it inside the coil, forcing metal particles to move at a high speed. The consumed electrical energy is converted into the energy of the electromagnetic field, and that, in turn, is converted into thermal energy.

The electromagnetic field heats up the core, which gives off thermal energy to the coolant, which is played by water, oil solution, ethylene glycol. The room is heated by locating a series of inductors inside the heating circuit.

The mechanism of operation of an induction heating boiler

The diagram shows the movement of the coolant inside the body of the inductor, when current is applied to which the cold medium is heated.

The rapid heating rate of the coolant causes convection flows in it. When heated, the coolant expands and rushes up. A drop is created, which is necessary for the functioning of a moderately long circuit. If it is required to increase the circulation rate, then a circulation pump should be used. The design using the phenomenon of electromagnetic induction is better than the others, since it saves up to 30% of electrical energy. This fact allows you to choose this particular boiler option.