Stages of work

The first option is preferable in a wooden house, since wood tends to expand or decrease in size, "breathe". If the base material is the same as the coating, their joint oscillatory motion will not cause multidirectional stresses, leading to deformations, the appearance of defects on the surface.

In brick and concrete houses, before fastening the lining, a crate is mounted, which, moreover, can serve as a frame for laying thermal insulation. It is convenient to place corrugated hoses for electrical wiring, heating pipes in the space between the coating and the wall.

The second is the correct measurement of the room and the calculation of materials. This will help you avoid unnecessary waste or wasted time on additional trips to buy missing components. Determine the number of lining, based on the area of the walls, excluding openings. The length of the ceiling and floor plinths is equal to the perimeter of the room. To decorate the corners, you will need curly strips. Materials are purchased with a margin of 10-15% for marriage or other defects.

Before starting work, it is unpacked, allowed to "get used to" the new conditions, treated with antiseptics and fire retardants, if there is no factory preparation.

Before installing the lathing or directly attaching the lining to the wall, prepare the surface - clean, level, seal the cracks, cover with antiseptic compounds. This will protect the structure from the appearance of mold and mildew.

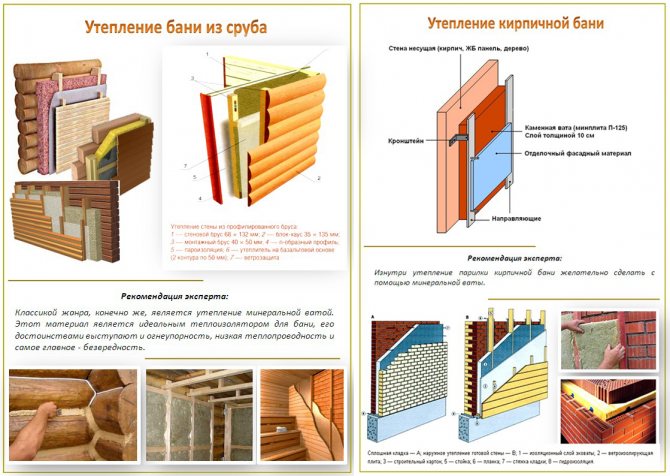

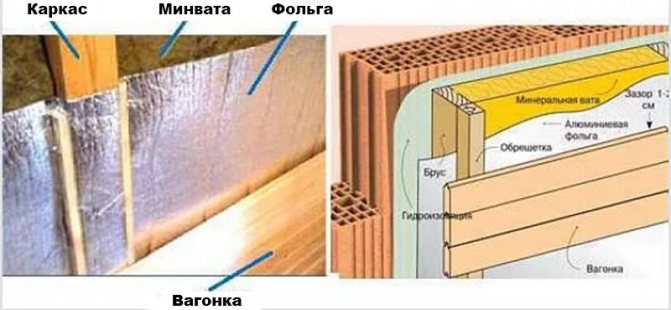

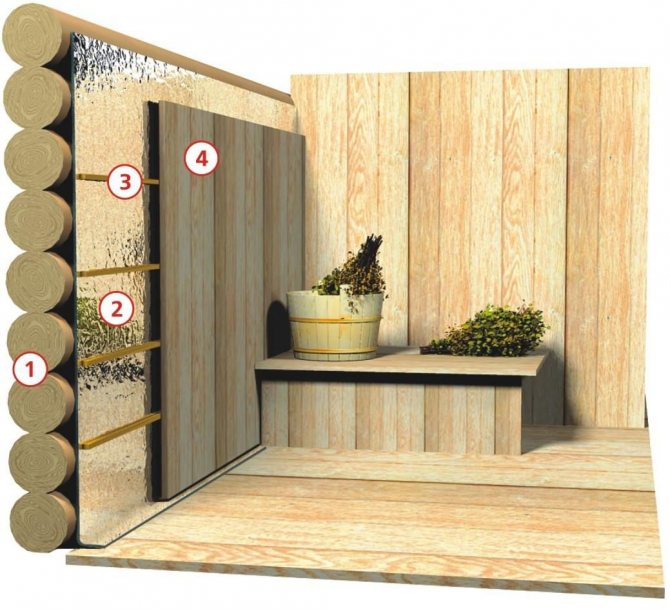

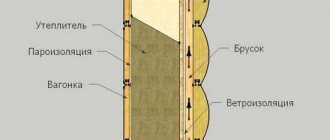

The third step is to install the lathing. Most often it is made from wooden bars with a section of 20x30, 40x50 or more. The thickness of the element depends on whether the insulation will be laid under the lining. A ventilation gap is left between the thermal insulation layer and the coating, which prevents the accumulation of condensation.

The frame pitch is 40-60 cm, the direction is perpendicular to the finishing boards. Insulating roll or slab material should fit tightly into the space between the bars. For residential premises, it is usually mineral wool; outside, foamed polystyrene foam or other polymers are often used. They are not afraid of moisture.

The geometry is controlled by a bubble or laser level. Dowels or construction nails are used as fasteners for the lathing.

Wooden lining, treated with paintwork

Lining made of PVC, MDF does not require preliminary preparation. Wood must be treated with protective equipment or coated with a layer of paintwork, except for the case of its use in the interior of baths and saunas

How to make a crate for a lining

You can attach lining without lathing to the ceiling or wall in three cases:

- If the surface is flat.

- If there is no need to install heat and sound insulation material.

- If there is no need to use the space between the cladding and the wall for other purposes. For example, to hide the lines of communication - the Internet, telephone, etc.

In addition, the free space will be a ventilation shaft, which will reduce the risk of mold and wood deformation.

The material of the lathing can be a wooden beam, a galvanized iron profile. A combined option is possible.

The use of wide boards or strips of chipboard is justified only in the case of the "herringbone" facing, when the lining is connected at an angle.

- First of all, holes are drilled in wooden blocks at a distance of 0.5 - 0.7 m.

- If it is planned to cover external surfaces or rooms with a high level of humidity, then the bars must first be treated with moisture-proof compounds.

- Then they are mounted strictly horizontally or vertically (depending on the direction of the lining). Slats are mounted to reinforced concrete slabs using a perforator. If it is impossible to use hardware (screws of different lengths are recommended), liquid nails are used.

- The accuracy of setting the elements of the crate is checked by the level. To ensure a tight fit, wooden or plastic wedges are inserted on an uneven wall. A wide range of the latter is presented by hardware stores.

- In the crate of surfaces of rooms with a high level of humidity, it is recommended to install remote counter-strips. This is necessary to increase the distance between the facing material and the ceiling (wall) to improve ventilation.

The distance between the strips is 0.6 - 1 m. The short strips are joined end-to-end.

Fastening the lining

Fastening

Fastening the lining with nails - option A

Before starting to fasten the lining, it is necessary to check the evenness of the lathing structure with a building level. After that, installation begins from the corner. The first board is set as evenly as possible. In this case, a small gap may appear against the wall. It can then be closed with a plastic corner. A small amount of deviation will increase significantly by the end of the work.

- The connection of strips of plastic, as well as wooden "Euro-lining", "American" is carried out "groove in groove".

- Regular panels without grooves are fastened with staples of a construction stapler, self-tapping screws, furniture studs.

The cladding with hidden fastening looks as neat as possible - the fasteners are placed in the groove. Moreover, they should not interfere with the installation of the next board.

For this purpose, a screw hole is drilled from the side of the spike on the wood panel. At the end of the work, the protruding parts of the dowels are cut off, then the surface is sanded.

Installation with cleats

In addition, a thin lightweight lining can be fastened with metal galvanized brackets - clamps:

- First, the top of the first board is fixed with a self-tapping screw. His hat is subsequently closed with a dowel.

- Then the boards are joined with the already installed clamps. The clamps are attached to the wall with self-tapping screws or nails.

- The last board is fixed with self-tapping screws closed with a dowel.

Fastening the lining with nails - option B

You can install the lining in a faster way - by driving nails in the center, but it will look less neat. Thin boards can also be split in this way.

The choice of lining material is determined according to the operating conditions in which the lined surface will be located. Wooden, plastic panels can be used for interior and exterior cladding. MDF only in indoor heated rooms.

During installation work, you must remember about switches and sockets - make a marking with a marker. Holes for them are cut with a jigsaw or a hacksaw.

Fixing panels with glue is not considered a very reliable method and is used in extreme cases. In addition, it requires preliminary surface preparation - cleaning, leveling, processing with special compounds to increase adhesion.

Floor insulation

In order to insulate the floor in the sauna, it is made double, as in an ordinary wooden house, a subfloor made of low-grade boards is nailed on the lower side of the log, and insulation mats are laid on it.

If the room is already ready, and the floor needs to be insulated without opening or overhauling it, the bars are nailed onto the finished floor with a certain step, and insulation is laid between them. Another layer of boards is laid on top. They should be smoothly planed, especially if there is no intention of using another covering over the plank layer.It is not bad if the floor level in the sauna can be set higher than in the adjacent rooms.

Wall cladding with clapboard on the crate

Different materials can be used for surface finishing. They are selected based on their characteristics, properties and, of course, cost.

One of the most common options for cladding surfaces is clapboard. However, to use it, you need to understand how to fix the lining to the wall.

In this article, we will take a closer look at the installation methods, the advantages and disadvantages of each option.

Installation of the lining on the walls is best done using a lathing - a frame made of wood. To do this, all the bars of the lathing, both in the horizontal and in the vertical plane, must be aligned exactly.

Even minor mistakes can, over time, lead to depressions and bumps that will be visible on the walls.

After the installation of the lathing is completed, the lining is attached. Below you can see the scheme of the lathing for surface finishing.

Keep in mind that if the lining is used for facing surfaces in the bath, the material must be pre-treated with antiseptics.

The installation of the lining will not depend on the fastening method. For walls and ceilings, the work will be the same. There are two ways to place boards:

- Vertical. With this method of placement, work begins from one of the nodes. The first board is fastened with the groove outward. The next bar is inserted into the previous one. Upon completion of fastening the board, using a level, the evenness of its placement is checked.

- Horizontal. With this placement, the spike of the board is directed upward, allowing water to slide down the finish. Such an installation begins from the ceiling.

Do not fasten the lining close to the ceiling and floor, leave gaps

After all the boards are installed, a small section of the board is inserted into the groove of the finish panel, which is nailed down with a hammer. This trick will allow you to tightly connect all the planks and prevent gaps or holes.

When installing the lining near the floor and ceiling, you need to leave a small hole of about 2 cm. This will protect against sudden temperature changes and provide additional ventilation. If this is not done, the boards may swell after a certain period of time. After finishing the finish, the slots are covered with a plinth.

Regardless of the fastening method chosen, the first and last planks are fastened with nails with a small head.

The rest of the panels can be attached in the following ways:

- with screws, self-tapping screws or nails,

- clamps. This is the name of the clamps, which have a design with a special holder holding the board spike,

- construction stapler.

You can choose any mounting method. But keep in mind that the board is first nailed to the middle beam of the sheathing and only then along the edges. Then the evenness of the placement is checked using a level, after which the board is attached to the rest of the lathing bars.

Fastening with nails

This method is one of the simplest and cheapest, but it is not able to provide a long service life of the structure. Driving in a nail can damage the panel, which will significantly reduce the strength of the fastener. To avoid this, you can use a doboinik or pre-make holes in the desired section of the panel.

For one board of standard sizes, you will need about 6-7 nails. Such fastening will affect the appearance of the finish, so cracks and other defects will remain at the place of driving. But in some situations, this method of fastening is the only possible solution.

For such work, galvanized nails with a length of about 6 mm are used. They are carefully driven into the groove of the board and hammered into place.The hats are hammered inside with a doboiner, this will allow the installation of the next bar without problems.

Fasteners with self-tapping screws

This method is used for buildings where the appearance of the walls does not really matter. You can often find the use of this method for decorating baths.

But high humidity and a sharp change in temperature can lead to drying out of the fasteners, which will further worsen the appearance. This can be prevented by treating the finish with special antiseptics.

For prevention, it is better to process the boards every three months.

Self-tapping screws are sufficiently high-quality fasteners, therefore, if a high service life of the finish is required, their use can be considered the optimal solution.

To implement such fasteners in the boards, you will need to pre-make holes. Their diameter should be equal to half of the thickness of the fasteners.

Self-tapping screws are screwed into the board with a screwdriver. They should go as deep as possible. To hide the location of the fastener, you can use a wooden dowel or sand the surface.

Fastening with a stapler

We recommend practicing before work, otherwise a mistake may lead to a deviation in the placement of the panel or another defect.

The staples must be inserted at a 45 ° angle. If the insertion procedure was performed correctly, the subsequent procedure for installing the bar will proceed without complications.

Fasteners with clamps

Clamps allow for hidden fasteners in almost any finish.

At the same time, the fixation will be strong and guarantee a long service life.

Mounting the lining with the help of such devices will allow you to achieve the following advantages:

- With the right choice of the size of the fasteners, it is possible to carry out the installation concealed and guarantee its strength.

- Clamps are made of high-carbon steel, which allows them to withstand high levels of moisture and sharp temperature changes for a long time. This allows you to use this method of fastening in bath rooms.

For the installation of standard profile euro lining, clamps are purchased with a tongue height of about 4 mm, and for fixing a block house - 6 mm. To finish 1 m2 of surface, you will need about 20 clamps.

With this method of fixing, the plate is put on the spike of the first panel and attached to the crate with nails or self-tapping screws.

There are three holes for fixing, but only two can be used. It is better not to install the lining on one nail, as it can be torn out.

Screwing in self-tapping screws is best done with a screwdriver. This will greatly speed up and facilitate the process.

Therefore, mainly with horizontal placement, the boards begin to be fixed from the top of the wall. The first panel is installed with the groove downwards directly under the ceiling. The next element is fastened with the first ridge into the groove of the previous one.

According to this scheme, the installation of all boards is carried out. The final plank is cut to the width and inserted using a pry bar or nailer. A small hole near the floor is hidden with a plinth.

As you can see, fastening the lining can be done in different ways. The choice depends only on your personal preferences and knowledge. The work is easy enough, so professional help is most likely not required.

Wall cladding with clapboard on the crateOne of the popular options for cladding surfaces is clapboard. However, to use it, you need to understand how to fix the lining to the wall.

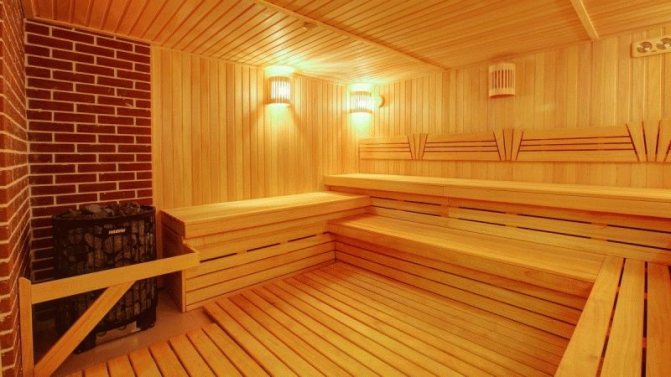

Modern lining is a beautiful finishing material that is very popular. The lining is successfully used as part of interior solutions for living rooms, for decorating building facades and even for cladding the walls of saunas and baths.Therefore, many are interested in how to fix the lining correctly, so that this process is easy, takes a minimum of time, and allows you to achieve several goals at once.

It should be noted right away that the lining on the wall can perform not only a decorative function. If you mount the finish appropriately, it can solve a number of side problems at once:

- When located on the outer part of the wall, you can bring the dew point beyond the surface level and get rid of problems such as dampness, freezing, and avoid mold and mildew.

- If you fix the lining on the frame, this will make it possible to mount insulation materials inside and thus better save heat.

- By mounting the lining directly on the wall, you can simultaneously save space and provide vapor barrier, provided that modern protective films are used.

Thus, having properly finished the walls with wooden clapboard, they can not only be made beautiful, but also ensure the performance of various additional tasks. There are several general recommendations on how to fix the lining.

Everyone can choose the method that is most convenient in terms of qualifications, speed of work, as well as financial investments in finishing.

The easiest way to fix a wooden paneling on a wall is to nail it down. It is very simple and even a beginner can handle such work. The process is as simple as possible:

- the wooden lining is cut into strips of the appropriate length,

- placing the elements neatly, they are simply nailed right through the front side,

- the heads of the nails are flush with the surface of the lining.

So you can mount a wooden lining on almost any wall. Both on the frame and directly on the surface, which is very convenient in wooden houses. If you work with self-tapping screws, using the Novosel kits, you can arrange a concrete wall in this way.

The method, despite its simplicity and speed, has a lot of disadvantages:

- The nail heads or screw heads will be visible. Therefore, the neat appearance of the finish is disturbed.

- In rooms with excessive humidity, metal caps can rust. This causes unsightly streaks as well as discoloration of the lining around the attachment point.

Therefore, the method of fastening with nails or self-tapping screws through the surface is very rarely used.

The second simple method of fastening with nails or screws through the face can provide a neat appearance, but has a limited range of applications. The work looks like this:

- drilling is done in the lining,

- fastening nails are hammered into the hole or self-tapping screws are twisted,

- the tongue is hammered, which masks the anchorage point,

- the excess tongue is cut off and the surface is sanded.

Thus, the excellent appearance of the wood surface is maintained. However, the method has limitations:

- When cutting the tongue and sanding the surface, damage is formed, so the appearance of the lining with paintwork will be spoiled.

- The best results are obtained if you need to fix the lining either without finishing or treated with impregnations. It is easy to make the fasteners completely invisible.

Fasteners for lining

The profile strips can be positioned vertically, horizontally or obliquely. In dry rooms, the direction of the board is chosen arbitrarily, in accordance only with the design idea or your preferences.

In places where humidity is high or water may flow into the gaps between the planks, the boards are installed either vertically or horizontally so that the spike is directed upwards.

Fastening the lining is carried out using fasteners, the following methods are distinguished:

- Nails;

- Self-tapping screws;

- Claymers;

- With staples.

Nails

The fixation must be reliable, and the material must be firmly held on the frame. It is desirable that the fasteners are invisible and not corroded in a humid environment.These requirements are met by finishing nails, the head of which has a cylindrical shape, and its diameter is slightly larger than the rod. The surface of the hardware is plated with zinc, brass, copper or bronze, they are not afraid of exposure to water.

The length of the dowels is 20-50 mm, the section is 1.2-1.8 mm. The diameter of the cap is 1.6-3.4 mm. The nail easily enters the wood without splitting it. Doboinik it is sunk into the thickness of the material.

Specialized equipment for hammering nails - pneumatic gun. It allows you to quickly, efficiently, without spending much physical effort, to mount the lining on a vertical surface and ceiling.

The length of the nail should be 2.5-3 times the thickness of the profile board. Most often, hardware is used from 50 to 60 mm. They are hammered with a hammer using a doboiner having a tapered end, or with home-made devices from a bolt or center punch. You can nail the strip through the middle of the element, obliquely from the longitudinal tongue or from the side of the groove into the protruding lower shelf.

Kleimers

Cleamers - staples made of spring steel or galvanized iron with a tongue for the board and 3-4 holes for nails, screws or staples. The element is inserted into the foot and attached to the frame with hardware. From the front of the surface of the finish, the connection is completely invisible.

Kleimers are selected taking into account the thickness of the lining, the larger it is, the more powerful the fasteners should be. The amount of foot lift varies from 2 to 5 mm in 0.5 mm increments. The number of the hardware is chosen in accordance with the size of the spike of the wooden profile, otherwise the mount does not hold the part tightly or it will have to be pushed in with hammer blows.

Kleimers are not designed to withstand the load, therefore, hangers, ceiling lamps, shelves, cabinets cannot be fixed to the coating. Before fixing the lining, determine the places for hanging the equipment. If it is heavy enough, additional embedded parts are mounted on the wall.

Self-tapping screws

Self-tapping screws - hardened steel rods with threads and a head for a screw-in tool. For fastening the lining, yellow and white hardware with a protective anti-corrosion coating is used. The thread pitch is increased in comparison with metal fasteners, since the wood has a layered loose structure.

The most commonly used self-tapping screws are 20-45 mm long and 2.2-3.5 mm in diameter. They are screwed in with a screwdriver, screwdriver, holes are pre-drilled in solid wood. You can fasten the lining through the through method, then use products with a countersunk head. After installation, the grooves are filled with a dowel, leveled and putty.

Kleimers are attached to the crate with thin small screws, nails or staples. Recommended sizes of pins are 10-12 mm.

Compared to nails, self-tapping screws have a higher fastening strength, are less susceptible to being pulled out, and can be removed if necessary. They are more convenient when using cleats, as the fasteners can be damaged by hammer blows.

Experienced craftsmen advise how to properly fix the lining: use nails and screws in inconspicuous places, and put a kleimer in plain sight.

The fastening of the lining with staples is performed with a construction mechanical, pneumatic or electric stapler. Fasteners are introduced into the wood with little or no physical effort, so a large amount of work can be done in a short time. The advantage of this method is the absence of irreversible damage in the material. The most popular sizes are 4-14 mm - the length of the legs and 11.4 mm - the width of the staple.

Hardware is produced both untreated against corrosion, and galvanized or copper-plated, for use in conditions with high humidity. In pneumatic and electric models of staplers, the impact force is regulated, which is important when working with such soft materials as wood.

The staples are driven into the groove at an angle. Clips can be fastened in the same way, the dimensions of the hardware must correspond to the distance between the holes in the plate.

How to insulate a steam room in a bath: step by step instructions

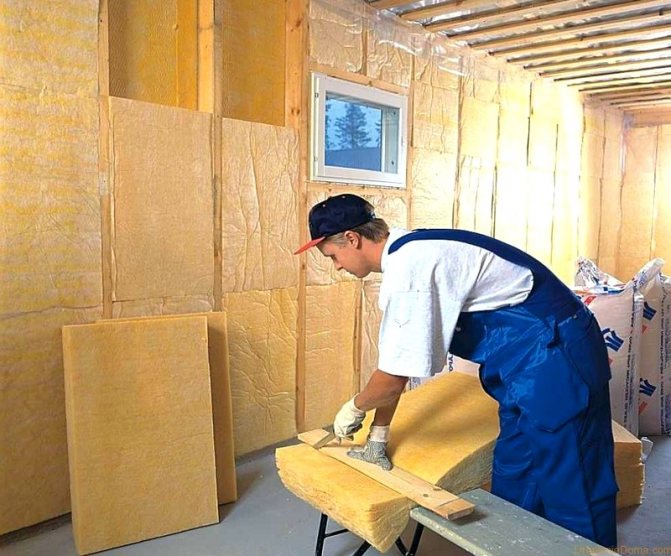

The process of warming a steam room in a bath from the inside can be divided into 3 stages:

- wall treatment;

- floor treatment;

- processing of the ceiling.

In general, they do not differ from each other, but they are carried out sequentially, starting from the floor of the steam room, and ending, of course, with the ceiling covering.

It is not necessary to insulate some part of the steam room in the bath, but its entirety - from floor to ceiling, along with the walls

Instructions for laying floor insulation in a steam room look like this:

- If there is already a floor in the steam room in the bath, it is dismantled. Then, a monolithic concrete base is poured on the cleared and cleaned land plot. Its area is equal to the area of the entire bath, or at least the washing and steam rooms of its parts. Under the dressing room and the rest room, the monolith does not need to be poured.

- The screed takes 2-3 days to completely harden.

- Then roll waterproofing is put on the concrete. It is necessary so that moisture from the ground does not "make its way" to the insulation coating. They are able to seep even through micropores in concrete that appear over time.

- Insulation is placed on the waterproofing. Fix it with self-tapping screws.

- Joints and attachment points with self-tapping screws are treated with metallized tape for strength.

If the floor in the steam room is already built, but not insulated, you need to disassemble it and properly sheathe it

- Above - again waterproofing so that moisture does not get on the insulation from the steam room itself.

- Sheathing is attached to the waterproofing in the steam room.

- Next, this "layer cake" is again poured with concrete. Thickness is about 3-4 millimeters.

- The casing is treated with an anti-fungal coating and left to dry for about 2-3 days (the more, the better: it is good if the bath will not be used for about a week).

Vertical lining

With this layout of the boards, the crate is installed horizontally. The bars are pretreated with impregnations against decay and pests. The locations of the guides are marked on the wall in increments of 40-60 cm. The dowel or self-tapping screw is deepened into the wall by at least 50 mm. If necessary, the hole is reamed.

Before fixing the lining, determine the most visible angle. The first profile is nailed. Alternately insert the board with a spike into the groove of the previous element, fix it with fasteners to the crate. Verticality is controlled by the building level.

The hardware is driven into the bottom shelf of the groove at an angle, the caps are recessed so that the crest of the next lining can freely enter the recess. The last board is trimmed to the size of the remaining piece and nailed down.

Horizontal lining

The lathing is mounted vertically from the corners, observing a step of 40-60 cm. To fix the insulation, horizontal bridges are additionally nailed through 1.2 m or an additional frame is arranged so that the plates do not slide down. Before fixing the lining, lay a vapor barrier, heat insulator and waterproofing.

The installation of the lamellas starts from the top element, since the last bottom bar is usually trimmed. At the level of the ceiling, a whole lining looks better visually, and a board that is non-standard in width near the floor will be covered with a plinth.

When fastening the lining horizontally, the spike is directed upward. Gently tapping with a rubber-tipped mallet or hammer on the trimming of a wooden profile, set each subsequent board in place and fix it from below with fasteners. The first and last element, as well as short pieces less than 10 cm long, are nailed or fastened with self-tapping screws.

If the wall is sheathed from the bottom up, the board is fixed to the crate from the bottom side, and a self-tapping screw is screwed into the spike at the top with a head flush with the surface.

Ceiling insulation

The next step in the thermal insulation of a sauna is to insulate its ceiling.The technology of the thermal insulation device on the ceiling is also somewhat different from the thermal insulation of the bathhouse ceiling.

The ceiling in a sauna is usually insulated from the inside. If a material is used for thermal insulation of the ceiling, where one of the surfaces is equipped with a foil coating, then it is installed with foil inside the room. Attention should also be paid to the need for ventilation of the ceiling covering, as well as for the tightness of the joints between the layers of the material.

If a material such as mineral wool is chosen as a heat insulator, without any additional options, then foil should be used.

In general, the installation procedure is as follows: first, a grooved board is nailed, then there is a layer of vapor barrier, insulation (mineral wool, basalt wool), waterproofing. It is possible to use expanded clay as a heater, then it should be poured over the ceiling, if there is a technical possibility for this. The layer of thermal insulation material on the ceiling should be at least 20% larger than on the floor or walls.

If all the work is carried out correctly, and the sauna is qualitatively insulated in all directions, then it will be much more pleasant to bask in such a sauna, it will retain the heat much longer, and the service life will also significantly increase.

Frequent mistakes

To avoid mistakes, it is important to know how to properly fix the lining:

- Choose well-dried material;

- Prime and paint before installation so that there are no areas that are difficult to access for finishing;

- Leave a gap between the board and the adjoining wall to compensate for shrinkage or expansion;

- Secure the first, last and extreme elements firmly - with nails or self-tapping screws;

- For interior decoration, insert the spike into the groove tightly so that no cracks form when the tree dries out;

- When cladding from the outside in the tongue-and-groove joint, gaps are left to compensate for the moisture expansion of the wood;

- Select nails, screws and clamps according to the size of the lining;

- Cleamers are not intended for fixing the board in unheated rooms and outdoors;

- Do not work in frost or rain;

Do not neglect the treatment with antiseptics, fire retardants, protective paint compounds.

Sauna insulation recommendations

Insulation of the steam room from the inside, in order to save money, can be done according to a simpler scheme. It is cheaper to choose materials, limit yourself only to steam or waterproofing. If you follow the technology, you will solve many problems:

- increase the service life of the stove and sauna;

- shorten the heating interval of the sauna to a minimum;

- achieve a more comfortable microclimate;

- to minimize heat loss;

- reduce energy and fuel costs.

Do-it-yourself work is much more appreciated than ordered. The time spent in such a sauna will give you maximum pleasure.