How to choose a boiler?

The owners usually select a heating unit for a private house for the benefit of using any energy carrier from those that are available. This approach is correct, and it must be followed when choosing a boiler for underfloor heating (TP). That is, when choosing a suitable heater, the following factors must be taken into account:

- what energy carrier is the most profitable;

- what heat power is required;

- how electricity is supplied in the region of residence, are there frequent blackouts;

- comfort during operation, including ease of maintenance;

- how easily the future heat source fits into the underfloor heating circuits.

In the context of this article, the last point is of particular interest. The fact is that no manufacturer produces special boilers for underfloor heating. In some models of gas heat generators, you can find only the function of working with water heated floors and nothing more.

The main difference between a radiator heating system and floor heating circuits is the temperature of the coolant. For supply to radiators, water is heated to a maximum of 85 ° С, while in pipes of water floors it should not exceed 55 ° С.

The optimum temperature schedule for underfloor heating is 35–45 ° C in the supply and 25–35 ° C in the return pipe. If a warm floor and radiators supplied with heated water from one boiler participate in the heating of the house, then this does not affect the choice of the heat generator. Another issue is when batteries are not provided, and the boiler plant should only serve a low-temperature floor heating system.

Not every heat source is capable of maintaining a coolant temperature of 30-40 ° C. The issue is solved using various methods of piping the heating unit. The complexity of joining depends on the type of boiler used for a warm water floor:

- gas wall or floor;

- electric;

- solid fuel;

- automatic pellet or coal.

How compatible these boilers are with underfloor heating and how to connect them correctly, we will consider separately for each of the varieties.

Characteristics of gas models

Modern modifications of gas boilers should be equipped with electronic controls that regulate temperature parameters, ensuring the safety of the system.

In order for the automation and the circular pump for a warm water floor to work in the event of a main power outage, it is advisable to stock up on a local source. Car batteries will provide several hours of operation. In situations where there is a risk of frequent power outages for several days, you will have to purchase a diesel generator.

Compared to the electric model, the gas boiler is a model of efficiency. Particularly efficient is its condensation type, which receives integrated heat from fuel combustion (sensible energy) and from steam condensation (latent thermal energy).

The principle of operation of the boiler is based on the circulation of the coolant through the exchanger, during which it heats up from the flue gases resulting from the combustion of fuel. During the transfer of thermal energy, the gases are cooled, and at a certain temperature, condensation forms, causing the appearance of additional heat. This feature significantly increases the efficiency of heating equipment.

Gas boilers function flawlessly under conditions of uninterrupted gas supply, without requiring special procedures for routine maintenance.In structures where an electronic mechanism is provided for the ignition of the boiler, the functioning of the burner is regulated in accordance with the specified temperature indicators with the removal of all harmful combustion products by means of forced ventilation. Piezo ignition boilers, working automatically, also stop the gas supply if the flame is extinguished, but combustion is restored manually.

Related article: Curtain and tulle for the hallway, corridor, arch: ideal solutions

Underfloor heating from a gas boiler

If your home is gasified, then it would be logical to choose a heat source that runs on natural gas. You just need to choose the right power and compare the selected model with the operating conditions. With frequent power outages, it is easier to install a floor-standing non-volatile heater with an open combustion chamber than to buy and operate gasoline or diesel generators.

In the Russian Federation and Belarus, the use of natural gas for home heating is one of the most profitable options in terms of paying for energy. In Ukraine, the situation is different, where the price of gas is so high that solid fuels - firewood, coal and pellets - take the first place in terms of profit.

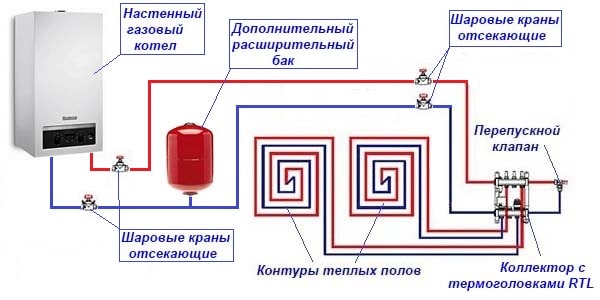

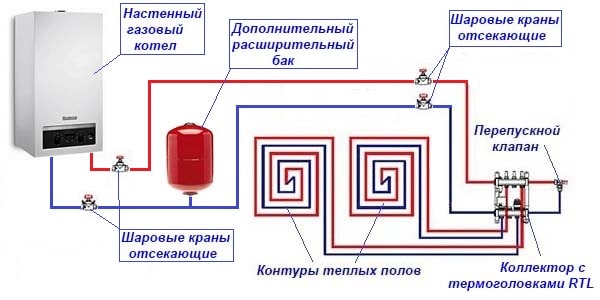

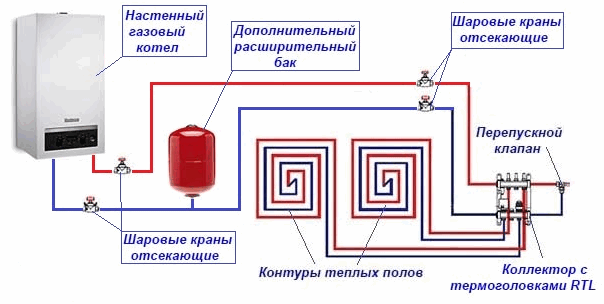

When everything is in order with the supply of electricity, it is easiest to install and connect a wall-mounted gas boiler for a warm floor. It is good because it has its own circulation pump, expansion tank, safety valve and strainer. In this case, the connection diagram of the underfloor heating is very simple: the heater is connected to the distribution manifold with pipes directly, but taking into account such nuances:

- At the inlet and outlet of the heat generator, there must be cut-off ball valves.

- The capacity of the built-in expansion tank (usually no more than 10 liters) should be sufficient for servicing the heating system. Calculate the volume of water in the pipes and compare with the capacity of the tank. If the latter is less than 1/10 of the total amount of heat carrier, then put an additional expansion vessel on the return pipe in front of the boiler inlet.

- If the construction of the wall-mounted heating unit does not provide for a built-in expansion tank, place it separately on the return pipe, as described above.

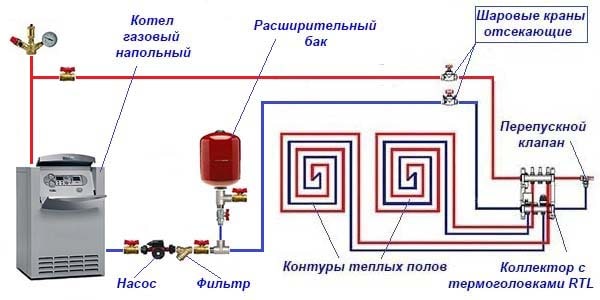

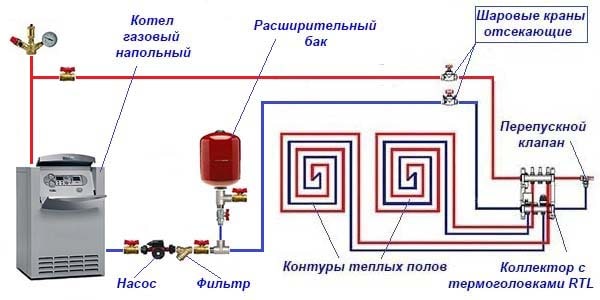

The diagram below shows how to connect a warm floor to a wall-mounted gas boiler. As you can see, there is no circulation pump in the system, since the boiler unit is involved. The distribution manifold without a mixing unit is equipped with RTL-type thermal heads, for more details about this type of connection for water circuits, see this article.

Since the expansion tank is integrated in the wall heater, an additional tank can be installed if necessary. For example, a large amount of water in the heating system

Floor-standing gas heat generators, with rare exceptions, are not equipped with pumps and expansion tanks. Therefore, its connection is carried out in a similar way, but with missing elements in the harness:

In closed systems, which include underfloor heating, a safety group and a pump must be installed. These elements are absent in floor-mounted boilers.

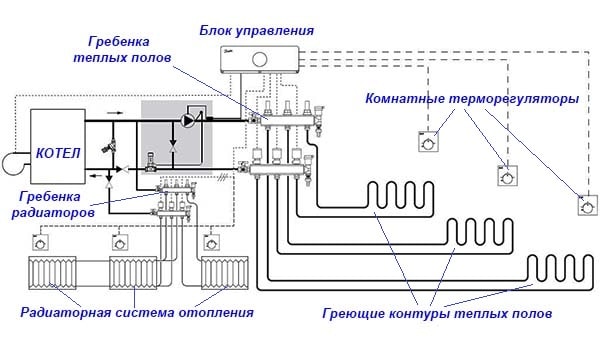

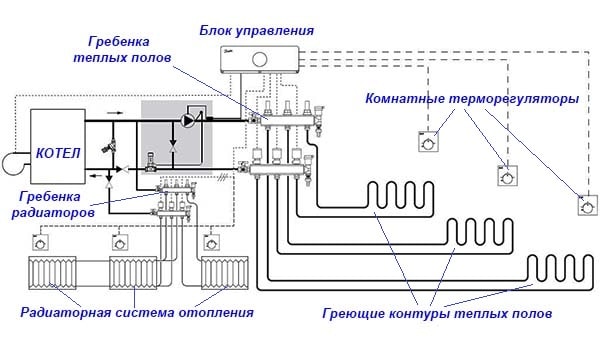

When it is necessary to install a traditional scheme, where the warm floor and radiators receive heat from one boiler, the connection is made as follows:

Note. The diagram shows a piping method using servo drives operating in conjunction with room thermostats. The heater can be connected without automation in the same way.

Connection to the heating system

It is difficult to overestimate the comfort of warm floors that create a uniform thermal background throughout the entire volume.They acquire particular relevance in autonomous residential buildings, they are used even in apartments where it is possible to equip local heating equipment, since connecting a water heated floor to a heating system coming from a central boiler room is prohibited for several reasons:

- low quality of the heat carrier;

- exposure of pipes to significant hydraulic resistance;

- the risk of damage to system elements from water hammer.

Using your own heating system presupposes the presence of a mixing unit that lowers the temperature of the coolant, since when the house is heated, the liquid heats up to 75 ÷ 90 ° C, and for the floor ≤ 50 ° C is allowed.

Related article: Paint bathroom doors

Collector - connecting the warm floor to the heating system

The sequence of work includes several stages:

- Simultaneously with the sensor, the circulation pump is securely fixed to the inlet pipe.

- The mixing valve (preferably a three-way valve) is connected to the warm pipe of the heating system.

- The outlet of the check valve installed on the outlet pipe is connected to the heating return pipe with a branch leading to the mixing valve.

Features of the operation of underfloor heating without radiators

To begin with, practitioners do not recommend using underfloor heating without the support of a radiator system, and here's why:

- To provide the room with a sufficient amount of heat, it will be necessary to raise the temperature of the floor surface to 30 ° C and higher, which is already uncomfortable for those living in the house.

- Batteries equipped with thermostatic valves react faster to changes in room temperature than heated floors. The latter are more inert due to the massiveness and heat capacity of the screed.

- Any water boilers, except for electric ones, cannot work efficiently in the minimum combustion mode, when it is necessary to maintain a low temperature of the coolant. Imagine that the efficiency of gas and solid fuel units at the same time drops by 5-20%, and think how much fuel you will burn in vain.

If the gas heat generator is switched to normal operation, setting the water heating temperature to at least 60 ° C, then the burner will often ignite and turn off (the so-called clock will appear), since the underfloor heating system does not require a large amount of heat. This mode is unsuitable for the heater, it can quickly fail.

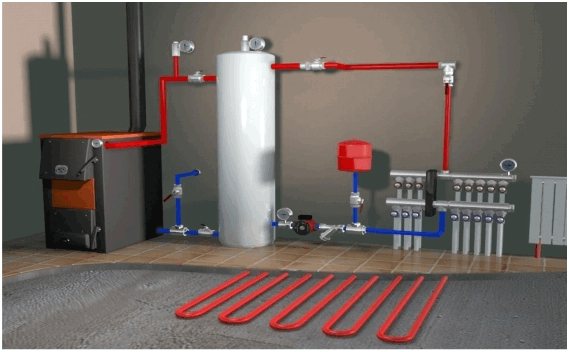

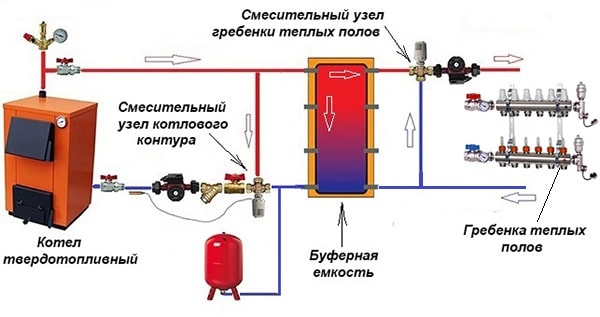

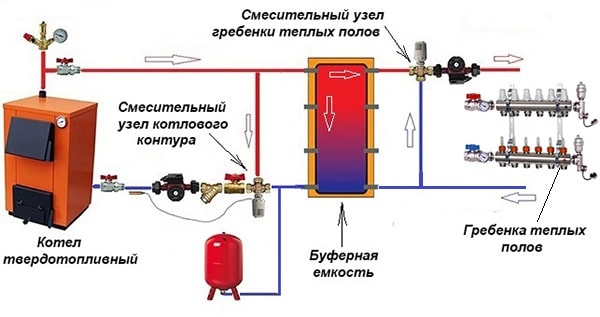

For normal joint operation of gas and other boilers with underfloor heating, but without radiators, there is an optimal way out - installing a buffer tank. Even a small tank will avoid the “clockwork” of a natural gas fired unit.

We will consider an example of installing a buffer tank together with a solid fuel boiler, which cannot do without it when supplying heat to underfloor heating.

Components for the "warm water floor" system

The main structural elements of such a system are:

- gas boiler;

- delivery pump;

- shut-off valves and connecting fittings;

- the main pipeline for distributing the coolant in living quarters;

- floor mini-pipeline for laying on the surface of the subfloor;

- collector;

- system of automation and adjustment of operating modes.

Gas boiler

For a private house with a large area, where it is planned to increase the comfort of the temperature regime in a large number of rooms, the best choice would be a floor-standing double-circuit gas boiler in an autonomous design. Such units have high power, are able to simultaneously solve several problems at once - heating living quarters and providing hot water supply.

On a note: for floor-standing gas heating equipment, it is necessary to equip an appropriate room with a chimney and ventilation. The room allocated for the boiler room (boiler power up to 30 kW) must have an area of at least 4 square meters, and the minimum volume - 8 cubic meters. If a single-circuit gas boiler is used for the underfloor heating, then for the DHW system, you will have to additionally install an indirect heating boiler, which can be placed in the same room.

For an apartment where every square meter of area is expensive, you can use a wall-mounted gas boiler, which, with the correct selection of power, will also ensure the efficient operation of a water heated floor. Due to its dimensions, it is easier to find a place for placing such equipment; wall-mounted gas boilers can be installed even in the kitchen or in the bathroom. Typically, the power of wall-mounted gas boilers varies in the range of 7-30 kW.

Wall-mounted autonomous gas appliances in most cases have a closed combustion chamber, therefore, for effective and safe operation, it is enough to equip a coaxial chimney with access to the street or to the central chimney shaft.

An important point when purchasing equipment is to determine the optimal power of a gas boiler, which will have to ensure the operation of the "water underfloor heating" system, therefore, when choosing a model of a gas boiler, it is necessary to rely on data from thermal calculations.

For reference: for heating 1 sq. m of living space, the costs of approximately 100 W of electricity are required, provided that the room is well insulated, ceilings no more than 3 m high and there is no excessive number of windows.

Most of the premises of a private house have external walls in their design, heat losses through which may require an increase of up to 150 W in heat consumption for heating 1 square meter. living space. Therefore, when buying a gas boiler, even having a heat calculation indicating the required power of the unit, it is better to purchase a device that exceeds the calculated value of this characteristic by 15-20%.

In most cases, the power of double-circuit boilers is designed for hot water supply with one or two points of water intake. Therefore, with an increase in the number of hot water intake points, an increase in the boiler power will be required.

In this regard, a water-heated floor has an advantage - it loads the gas boiler in a gentle mode. The principle of operation of the underfloor heating system in this situation requires the boiler to heat the coolant with minimal energy consumption. Most of the boiler's power is released to heat the hot water supply system.

Pipes for water underfloor heating

For laying a warm water floor, copper, polypropylene, metal-plastic or PEX pipes are used.

Pipes made of copper (high coefficient of thermal conductivity, durability) are an ideal material for the installation of water-heated floors, therefore their price is high and availability is limited.

Polypropylene pipes are also not widely used, but for another reason - their flexibility is insufficient, and the minimum bending radius of the pipe should be equal to its 8 diameters, which removes the turns from each other.

Pipes made of metal-plastic are deservedly popular - the inner aluminum coating provides them with good thermal conductivity, and polymer shells protect them from damage. With such characteristics, an affordable price is a good incentive to choose in their favor.

Solid fuel unit connection

Have you chosen to heat your home with wood using underfloor heating without connecting radiators? Get ready for a significant investment in the piping of a solid fuel boiler, since in this situation you cannot do without a buffer tank. The reason is that wood-fired heaters need to dump heat somewhere, otherwise the water jacket of the unit may boil.

Moreover, a solid fuel heat generator is not able to heat the coolant only up to 40 ° C, its minimum operating temperature is 55 ° C. If it is lower, condensation forms in the combustion chamber, which adversely affects the metal walls. Even in a non-corrosive cast iron boiler, condensation builds up a layer of deposits that impedes efficient combustion.

In order for a solid fuel boiler to function with maximum efficiency, and you burn firewood with the greatest benefit, you need to maintain the temperature of the coolant at 80-90 ° C, which is absolutely incompatible with warm floors. This means that a buffer tank is needed - a heat accumulator.

During the maximum burning of firewood, excess heat will accumulate in the heat accumulator, and the floor heating system will gradually select the required amount using the mixing unit, as shown in the diagram:

Cut-off valves for the heat accumulator are conventionally not shown in the diagram.

According to the proposed scheme, you can connect any solid fuel or gas boiler, this is the best of the existing options, although not the cheapest. It is recommended to connect pellet and coal automated heat generators in the same way. Calculation and selection of the volume of the used heat accumulator is a separate topic discussed here.

Installation of the "water heat-insulated floor" system

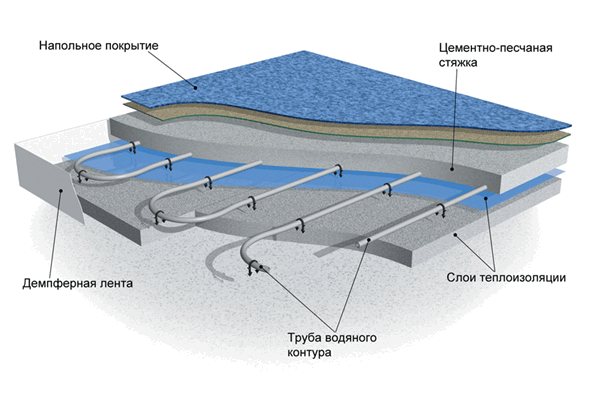

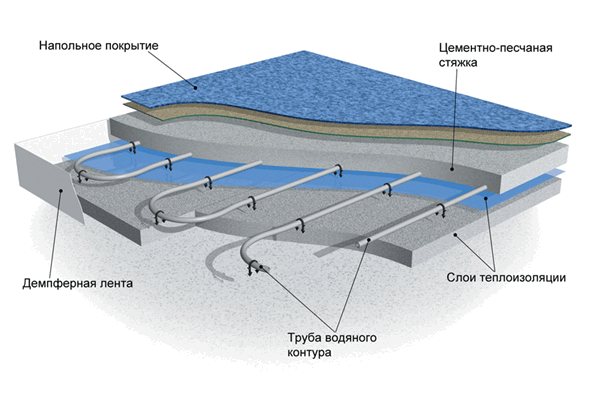

The installation of a water-heated floor system begins with the preparation of the base, which includes several operations, which we will now briefly consider. Failure to comply with the requirements for the subfloor, on which the underfloor heating is mounted, is fraught with at least a decrease in the efficiency of its work, as a maximum - depressurization with subsequent expensive overhaul.

Preparation of the base

The base must be suitably prepared before laying the pipeline. The surface of the base must be firm, clean and level. Height differences are allowed in the range of plus or minus 10 mm per meter of linear length. If the floor surface does not meet the requirements, has a large curvature and obvious flaws, a leveling screed is installed, followed by waterproofing of the base in case of depressurization of the system.

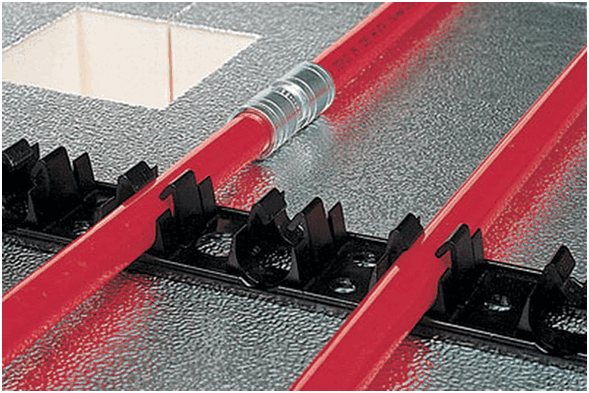

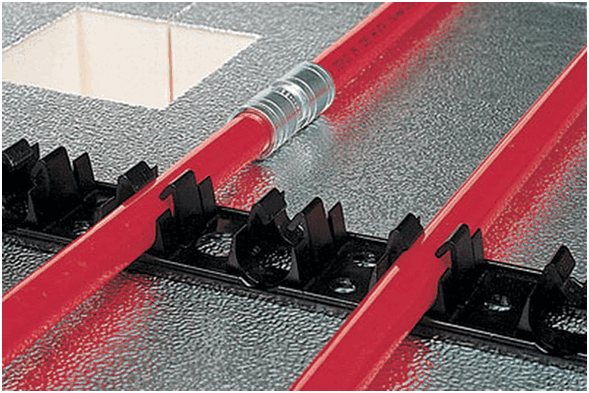

Before laying the pipeline, the sub-floor is also insulated. For these purposes, plates of extruded polystyrene foam or basalt fiber with a thickness of 30-50 mm are used.

With a sufficient budget, the use of foil-shielded plates and equipped with special protrusions for convenient pipe laying is justified. Such measures are resorted to to reduce heat losses through the floor in the premises of the first floor - a warm floor together with a gas boiler of any capacity will work with increased load simultaneously with floor heating to heat a basement room or someone else's apartment on the floor below.

Important! Before pouring the laid pipes of the underfloor heating system with cement mortar, it is necessary to glue a strip of damper tape 5 mm thick and a width equal to the thickness of the layer of the mortar to be poured around the perimeter of the room on the walls. The tape will compensate for thermal expansion of the screed and reduce its pressure on vertical structures.

Installation

Systems of water-heated floors are divided into 2 types in terms of design and, accordingly, the method of installation:

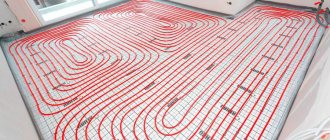

In the first case, we are talking about pouring concrete laid on the prepared base of the contour of the system of water heated floors. This operation is preceded by the division of the base into sections and the laying of the reinforcement mesh.

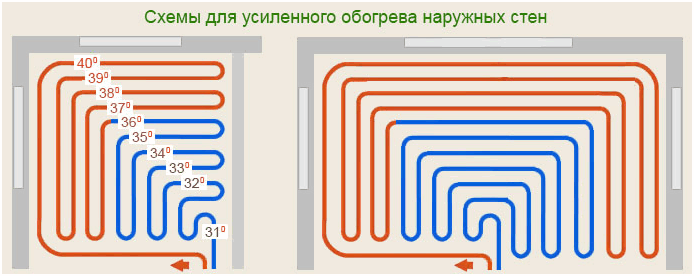

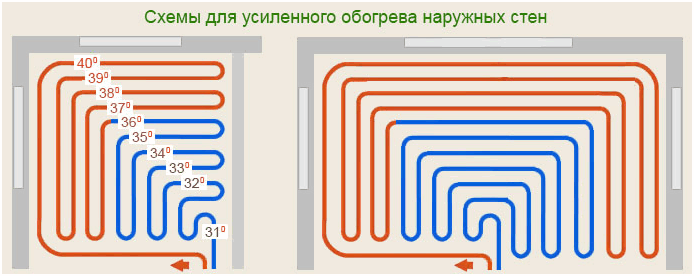

The following types of laying of heating pipes are used:

- snake;

- double snake;

- spiral;

- offset spiral;

- combined method.

The diagram shows how the heating circuit is laid in a room with increased heat loss - two or more outer walls.

Important! After the installation of the underfloor heating system is completed, it is pressurized under a pressure of 5 Bar within 24 hours.

The concrete screed acts as an additional element participating in the heat distribution process. Taking into account the poor performance of concrete in tension, it is laid at a pressure in the heat supply system of 3 Bar, reducing the tensile load upon further supply of water to the system to the value of the working pressure.

For the screed solution, cement of a grade not lower than M-300 is used, and its thickness should be 30-50 mm, while the layer of solution above the heat pipes should not be more than 2 cm.

When installing a system of water-heated floors, technological limitation should be taken into account - the finished floor covering must have a high coefficient of thermal conductivity in order to transfer heat to the air of the room with minimal losses. That is, laying linoleum, laminate, parquet, plank flooring on top of a warm floor is impractical due to the high thermal insulation properties of these materials. And laying on top of a tile system, especially with a high density - porcelain stoneware, natural stone, broom is not only justified, but also advisable because of the constantly cold surface of such a finish.

The laying method of laying is used in rooms where the use of a screed is undesirable due to low ceilings, or the production of concrete works is fraught with moisture leakage into the lower or adjacent rooms. The limitation may be seasonal or due to the design features of the building. The main advantage of floor systems is their high speed of installation. Warm water floors of the laying type of laying according to the materials of the system device is divided into:

All these types of flooring systems are less labor intensive and there is no significant contamination of the housing during the installation process.

Polystyrene underfloor heating

This system is a set of heat-insulating cover made of extruded polystyrene foam (expanded polystyrene), heat pipes and heat-distributing aluminum plates.

Polystyrene plates are laid on the supporting base, on top of which heat pipes are mounted on aluminum plates with special grooves.

On top of the aluminum plates, the floor is finished with a material with a high coefficient of thermal conductivity (for example, ceramic tiles with 2-component epoxy adhesive).

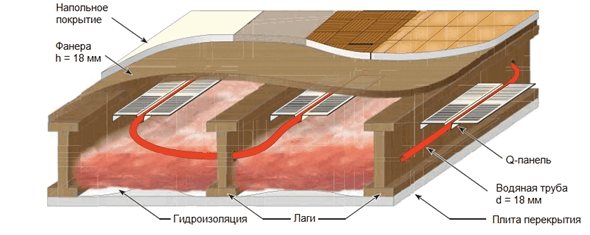

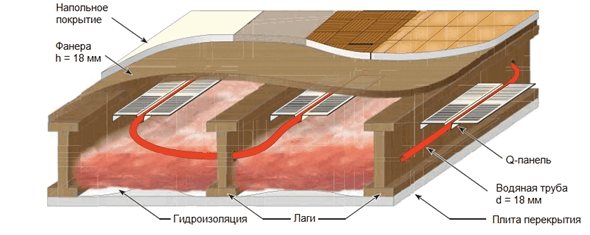

Underfloor heating systems

These devices are mounted on existing wooden floors or timber joists.

The modular version uses plates (modules) with channels and grooves for heat-distributing plates and pipes.

In the slatted subspecies of underfloor heating, the installation of modules is carried out between the logs available on the hard rough floor, or the logs are installed for this in advance. These structures play the role of stiffening ribs of the warm water floor being arranged and its subsequent finishing, the list of structural elements does not differ from the modular look.

After the end of the laying of underfloor heating floors, the system is also pressurized and commissioning (tightness check, tightening of connections).

The layered method of installing the underfloor heating system is universal and applicable in almost all buildings and structures. However, its advantages are reflected in the cost, which is quite high.

Floor heating with electric boiler

Any type of electric heat generator is perfect for working with underfloor heating water circuits:

- Heating elements;

- electrode;

- induction.

A household electric boiler for underfloor heating is the simplest and most convenient option. Regardless of the type and design, these heaters are able to maintain any temperature in the heating network without loss of efficiency. Therefore, they do not need buffer tanks and complex wiring diagrams.To connect the electric heating unit to the heating circuit manifold, you can use the diagrams given above for gas boilers.

As a rule, heating elements electric boilers are manufactured in wall-mounted version and are equipped with their own pumps and expansion tanks. Simpler models, as well as induction and electrode heat generators, are connected by analogy with floor-standing gas boilers. The missing working elements are added to the circuit, only an electrical control cabinet is installed in addition.

Step-by-step instructions for installing and connecting an electric boiler to water heating are presented in a separate publication.

Boiler selection criteria

According to the method of installation, a gas boiler under a warm floor can be floor-standing or wall-mounted. The first type is optimal for frame structures, because does not create an increased load on the walls, it is dimensional and capable of fully serving large areas (a separate boiler room will be needed here). Wall-hung devices form the basis of heating systems in compact dwellings.

By the number of circuits, boilers are classified into:

- single-circuit - designed to perform heating tasks (the coolant will be heated for both radiators and underfloor heating);

- double-circuit - serve as a power source for hot water supply and heating. Many models have to alternate modes.

The heat exchanger - the main working unit of the unit - can be made of the following materials:

- cast iron. Resistant to corrosion, durable and reliable, requires control of the uniformity of heating, otherwise there is a high risk of cracking the container. A significant drawback is the fragility of the original substance;

- stainless steel. It does not have wide distribution due to its high cost, it exhibits a decent service life;

- copper. The most popular solution for wall-mounted boilers. Possesses such qualities as low dead weight, corrosion resistance. Low inertia facilitates flexible and fast temperature control.

The combustion chamber can be open or closed. In the first case, air for feeding the flame is supplied by natural draft through the channels provided in the design, such devices need a separate room - a boiler room - where free air access will be provided (this is the most affordable segment of equipment in terms of price). A turbocharged closed boiler is more convenient for arranging underfloor heating; it does not need to provide a separate area for it. Usually, combustion products are removed through a vertical chimney, if a horizontal method is planned, a fan is built into the system.

When choosing the best device, it is important to study the following characteristics of the range:

- equipment power;

- number of contours;

- combustion chamber design;

- maximum heating area;

- the amount of fuel consumed;

- the ability to heat and the intensity of water consumption (average values are kept at around 2.5-17 l / min, more productive variations are more expensive);

- Efficiency (it usually does not exceed 80-90%).

In order for the water heater to be able to fully service the warm floor, it is important to correctly calculate its power. On average, 1-1.5 kW is enough to heat 10 sq. m. It is optimal if the equipment is equipped with the ability to smoothly adjust the temperature regime.

Conclusions and recommendations

For the successful and long-term operation of the underfloor heating system, it is allowed to use any boiler from the existing ones. It is not the type of heating unit that plays a role, but its correct connection to the underfloor heating distribution manifold. Other selection criteria, such as power, functionality and type of energy carrier, are selected according to a standard algorithm.

Choosing a heat source and knowing what its docking with warm floors is fraught with, you will be able to select equipment and piping elements in advance. This will give you a future picture of the financial costs of installation, from where the payback of a particular heating system is calculated.

Think twice before implementing underfloor heating without a radiator. If you have high requirements for the interior design of rooms and you do not want to see heating devices under the windows, use a more modern solution - skirting convectors or air heaters built into the floor.

Gas boiler installation requirements

Room requirements:

- The boiler room requires a separate non-residential premises.

- The height of the ceilings in the room is not less than 2.2 m.

- The volume of the room is based on 7.5 m3 per boiler.

- Floor area for one boiler is 4 m2.

- Doorway from 80 cm wide.

- The size of the window is determined from the calculation: for every 10 m2 of area - a window of 0.3 m2.

- There must be a hole for air inlet (for 1 kW of boiler power - 8 cm2).

- The boiler must be installed at a distance of at least 0.1 m from the walls, which are plastered or the walls are finished with non-combustible materials.

- Installation of devices near fire-resistant walls is allowed if they are insulated with roofing steel, superimposed on an asbestos sheet with a thickness of at least 0.3 cm.

Communication requirements

- Electrical network characteristics: single-phase current, voltage 220 V, current 20 A. An individual circuit breaker (gas station) is installed. Grounding is provided.

- A shut-off unit is mounted on the gas main, for each boiler its own.

- Water supply and the ability to connect it to the heating and hot water supply (DHW) systems of the building.

- The sewerage system provides emergency drains from the water supply systems and the boiler.

- The parameters of communications (gas pressure in the gas main, water pressure, etc.) must comply with state standards.