Closed heating system has no connection with the atmosphere, which partially increases the pressure.

This is due to protection from environmental conditions and changes in the weather outside.

Filling a closed heating system with coolant has its own characteristics.

Odnoklassniki

Features of filling a closed heating system

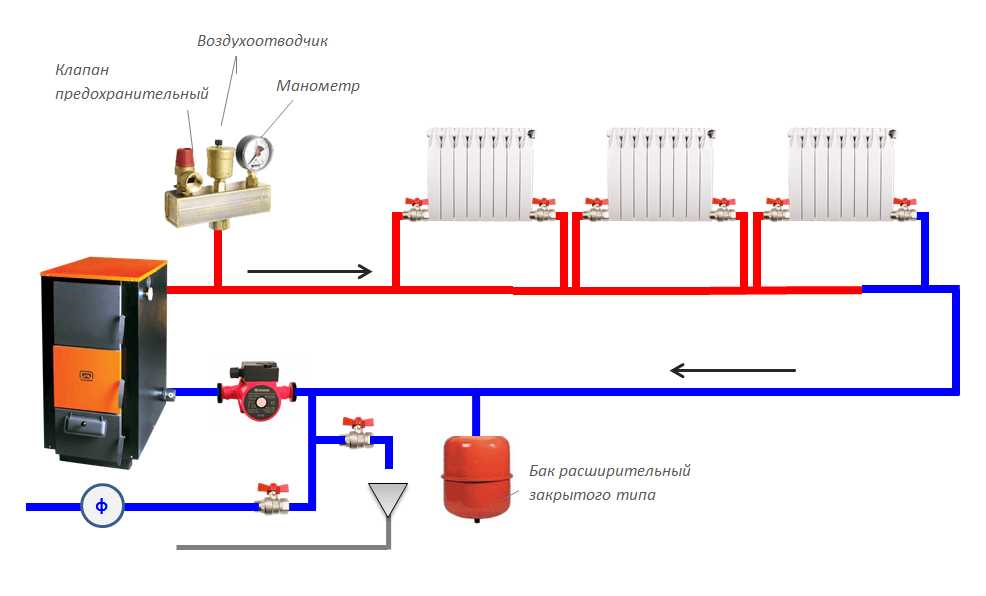

To complete the work you need pump and expansion tank. It is recommended to do this together... Task the first - fill the circuit with water while the second controls the air release.

If you have to do everything in alone, it is enough to turn on a weak head. The gas relief valve should be located in the upper part of the pipeline, away from the boiler.

Before starting, a container is placed under the place where the liquid flows out to collect it.

The tap to remove water is set down below... Not far from it, near the boiler, a supply pipe is mounted. For filling, a hose is used, which is placed in a water supply system or connected to a pump. A successful process is facilitated high head. The system will fill when liquid emerges from the vent valve. Then the air is released and the pressure is checked. Repeat the procedure if necessary.

In a two-circuit system the process is easier. For the bay use make-up system, if there is. It will automatically balance, remove gas and select the preset pressure. If it is absent, you will need to connect the water supply to the boiler with a hose and fill it through the latter. In this case, you will have to manually clean the circuit from air.

If the boiler gas, you will have to remove face cover... There is a booster pump. The device is turned on by heating the coolant.

The liquid is mixed with the gas that needs to be removed: for this, the valve inside the device is slightly opened with a screwdriver. When water appears from it, the valve is plugged.

The procedure is repeated 3-5 times with an interval of 2-3 minutes. If the boiler has stopped boiling, a pressure check is carried out.

Having finished filling the closed system, they proceed to inspect the integrity of the pipes. After it, debugging and hydraulic tests are done.

Types of coolants

There are several types, mainly liquidsbut also meet gaseous... More often than others they use the following two substances.

Water

It is the standard filler for the pipeline. It tolerates heat well and does not cause chemical reactionsexcept for the oxidation of metals. During operation, the contour partially fills scumformed as the liquid cools.

Important! When using this substance, it is sufficient to carry out annual cleaning the system from solid formations.

Antifreeze

Anti-freeze is used in systems that periodically turn off, especially in the cold season. It is also useful in northern areas. When cooling down, the pipes will not burst, which happens with water. For the infusion of antifreeze, it is recommended to create a system with contour of small diameter, and install radiators panel... This helps to save on fluid consumption.

Photo 1. Antifreeze model EKO-30 based on propylene glycol with carboxylate additives, weight - 10 kg,.

In addition, it is much more difficult to fill: the antifreeze cannot be filled directly with a hose or through the tank (in a closed system).

Bay perform in one of two ways:

- From below with a pump. It creates pressure, thanks to which the antifreeze begins to circulate. This will require a special mechanism capable of acting on liquids other than water.

- Through a non-return valve. It is connected to the container, placing it as high as possible. This helps to relieve pressure. After completing the filling, the residues are drained.

Types of antifreeze liquids

Antifreeze in the heating system of a private country house can be made on the basis of one of two types of liquids:

- ethylene glycol;

- propylene glycol.

Ethylene glycol antifreeze can be described as toxic, but at the same time cheap, while propylene glycol antifreeze is not harmful to human health, but is expensive.

Antifreeze for the heating system

Sellers focus on selling the second type of coolant based on its non-toxicity. There are even rumors that a small amount of harmful liquid can enter the drinking water through the hot water supply system and poison the residents if a leak occurs.

Do not worry, because a properly installed heating system will never let antifreeze into the water. While leaks are so small that they cannot be so dangerous. In addition, manufacturers paint antifreeze based on ethylene glycol in red, and on the basis of propylene glycol - in green, so if a leak suddenly occurs, it can be easily noticed.

If you are completely confident in the high-quality assembly of the heating system and do not have a lot of money to spend on expensive liquid, then do not be afraid and fill in ethylene glycol anti-freeze, carefully following the process and without departing from the instructions. If you want to insure yourself once again and not worry, then just pay the required amount and buy propylene glycol-based antifreeze.

Antifreeze can often be purchased as a concentrate. It must be diluted strictly, as the instructions say. Do not make the "anti-freeze" very concentrated, as this can cause deposits in the heat exchanger. It is better to change antifreeze every five years.

Detailed information about propylene glycol coolant can be found here.

Preparatory work

They are performed regardless of the state of the equipment.

Hydraulic test

Both old and new pipes must be flushed and tested:

- With water harness cleaned from technological debris, scale. With the addition of chemicals it is possible to remove scale and rust.

If the operating rules are followed (do not drain the coolant in the summer), this procedure is carried out with a break of two years.

- Testing performed with air at high pressure. For crimping the working indicator multiply by 1.25 (value varies depending on material and volume of water). The pressure during the entire operation may drop no more than 1%.

Checking for problems

During hydraulic tests, the system is inspected for the presence cracks and cracks, leaks. After that, you need to check the performance of the equipment: pump, expansion tank, boiler and others.

Overlapping reinforcement

After completing the inspection, you need to tighten everything valvesleading to the drain of liquid from the radiators, as well as block air valves.

Varieties of coolants

The most budgetary option for a thermal carrier is water, but the use of this liquid is not always justified. This fluid should be used in pipelines that are not corroded. Before filling the heating system, it is advisable to distill the water, which will prevent the formation of scale in the pipes. In addition, the specified liquid freezes when exposed to negative temperatures, which will ultimately lead to pipe rupture.

Injection of anti-freeze fluids improves the heating performance of the home The price of antifreeze for the heating system of a country house depends on many characteristics. The following requirements are imposed on any type of coolant:

- a certain degree of viscosity with sudden changes in temperature;

- inertness of the liquid in relation to the surface of the pipes;

- the coolant must be safe for human health, not destroy the walls of the pipelines;

- the cost of the liquid should pay off within a certain period of time.

How to fill the system correctly

Exist two fundamentally different ways bay of water.

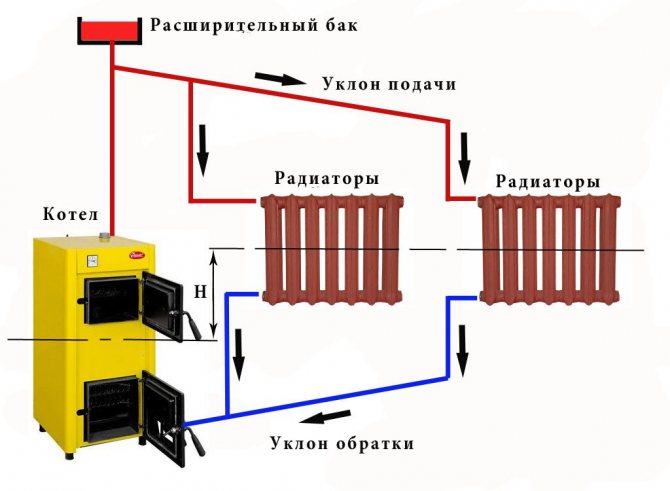

From above

Done with circulation pump... It is advisable to use electric, especially in systems with a drop heights from 10 meters.

If there is only a manual device, filling can be done from the top point using a nipple that is connected to the air valve.

Liquid flows by gravity... The drain valve must be open at the bottom. It is closed as soon as water appears. This helps to create a static pressure equal to the height of the circuit divided by at 10 atm.

Next, you need to increase the amount of liquid to the working value. TO fitting connect the hose with a ball valve. On the other hand, an adapter is attached to it to a pump with a pressure gauge. The hose is filled with water with the valve on the pipe closed. Then it is forwarded to the circuit, creating an air flow from the pump. Procedure repeat 3-5 times... This must be done carefully so that gas does not enter the pipeline. Otherwise, you will have to clean the system.

From below

For the procedure, you will need a container with a volume not less than 200 liters (more, depending on the system). A pump is placed in it, the required pressure is created.

The latter is calculated from the head height: value in meters divided by 10 and get the number in atmospheres.

The barrel is pre-filled with water. The level must be higher branch pipeto avoid air ingress. As the pumping progresses, the liquid is topped up.

When filling with antifreeze, use a small container so as not to contaminate the hose and pump housing. Its amount must be replenished more often, periodically stopping the process.

Filling is performed when open air ducts... The last are the cranes of Mayevsky, placed on the batteries. Objects are installed under them to collect liquid. When it flows, the valves are closed.

Pressure control is carried out according to pressure gauge... If the indicator exceeds static (it is taken equal to the length of the head in the circuit, divided by 10), water continues to be poured into the system until the required value is obtained.

After finishing the process, the pump is turned off. The air valves are then unsealed. This is necessary to remove gas from the system. The pressure in this case will drop, so you will need to top up the fluid.

Attention! Finally, the piping should be inspected for cracks and leaks.

How to pour antifreeze into an open system

This is where you should buy safe propylene glycol. It's all about the open expansion tank, communicating with the atmosphere. Since it is located within the house (usually in the attic), small amounts of fumes can enter the living quarters. In general, pouring antifreeze into an open system is impractical. It is better to remake it closed, from where it will not evaporate.

The diluted concentrate is poured through an expansion tank or make-up valve using a pump. In this case, all Mayevsky air taps installed on the radiators must be open. As the filling progresses, the taps close, after which the coolant level is brought to about 1/3 of the expansion tank.

Advice. Before pumping antifreeze into the heating system of a house with your own hands, you need to make sure that all shut-off and control valves are open.

After starting and warming up the boiler, you need to re-bleed the air through the batteries. If the level of the heated coolant in the expansion tank has dropped, then the antifreeze is added to about half.