Building a brick house is quite popular throughout the Russian Federation, because brick walls have many advantages. They are reliable, fire resistant and can last for years. But there are also disadvantages, for example, they do not retain heat efficiently enough. The problem can be easily eliminated if additional external insulation of the brick walls of the house is carried out with special materials. Almost every owner thinks about how to insulate a brick house from the outside.

In the process of building a brick house, you have to spend a lot, which is why very often the question arises of how to carry out work on the house insulation with your own hands. Everything is quite simple and if you thoroughly approach the issue, study all the nuances and choose the right material, insulate the house from silicate bricks, it will work without the involvement of hired specialists. The answer to the question of how to insulate a brick house from the outside is known to any seller in a hardware store.

There are a lot of insulation technologies, for a start we will consider a type of insulation for siding.

The choice of material for insulating a brick house outside for siding

The question, what is the best way to insulate a brick house from the outside, is very common in specialized forums. It is worthwhile to thoroughly study all the information provided, and choose what suits you. The main division of insulation for walls occurs according to the principle of installation, there are those that require additional finishing, and which do not need it. There are simply a huge number of varieties of materials for insulation and sound insulation, many of them are similar in characteristics, and differ only in price and manufacturer.

- Mineral insulation (Minvata). It is very often used, due to the fact that the price for it is quite low, and the characteristics are suitable. For example, its thermal conductivity is 0.04 W / (m * K). In addition, it is quite environmentally friendly and even an inexperienced person can mount it. Minvata is capable of burning, so it has a low level of fire safety, which can be considered a minus, and during installation it will be necessary to additionally carry out work related to the moisture insulation of the walls, tk. the material absorbs condensation well.

- Expanded polystyrene (styrofoam). Thermal conductivity 0.036 W / (m * K). Lightweight, practical, with high moisture resistance. Just like mineral wool, it is environmentally friendly. The disadvantages of insulating a brick house outside with expanded polystyrene are toxic emissions during combustion, fragility, vapor resistance.

- Extruded polystyrene foam (penoplex), a warm brother of ordinary polystyrene. But it is produced using a different, fundamentally new technology. Thanks to this, it has improved characteristics of heat and sound insulation, as well as steam and water permeability. House insulation with penoplex is very popular.

- It is possible to insulate a brick house from the outside using modern methods, using foaming technology. Mounting polyurethane foam. The product is new, but has already conquered most of the market. Perfectly insulates and protects against moisture ingress. Minus, the application is carried out using special equipment.

insulation of a brick house from the outside by spraying polyurethane foam

External insulation

We will find out what types of thermal insulation materials are used in order to insulate brick walls from the outside.

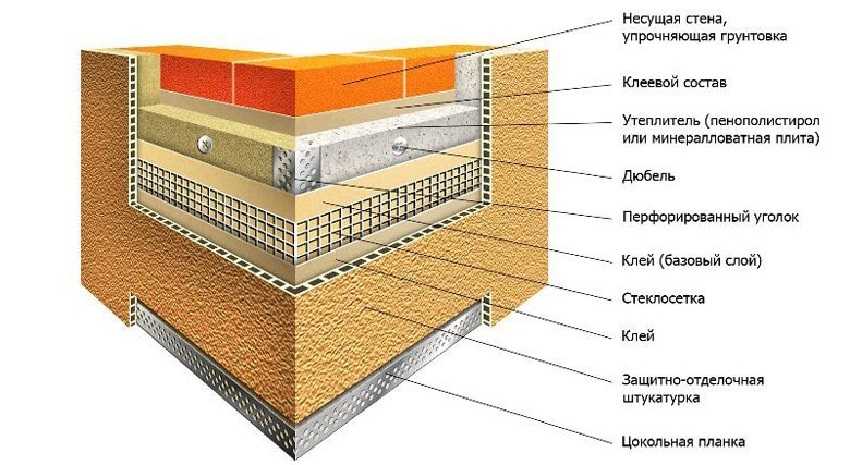

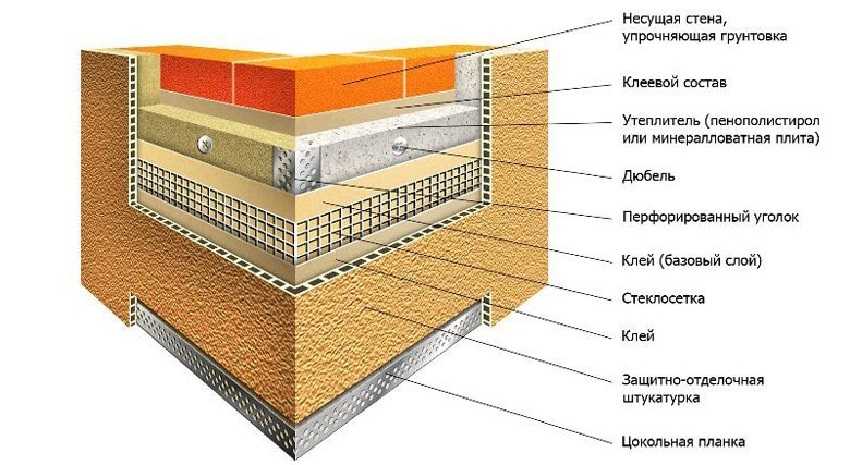

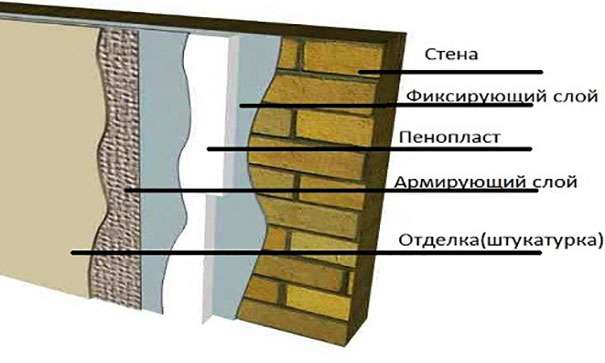

Wet facade

In this case, the walls are insulated with polystyrene, cotton wool, and other material, and then from the outside they are finished with plaster.The top covering must always be laid on the crate. There will also be more to learn about how the wet facade installation technology is carried out.

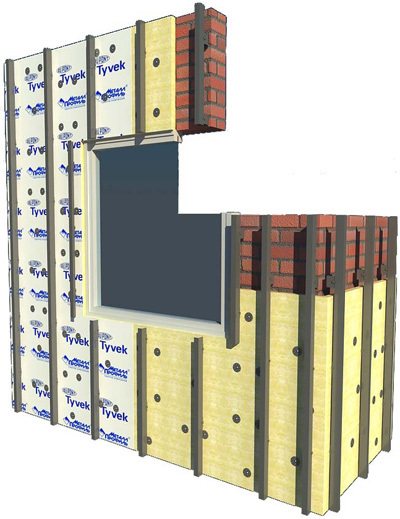

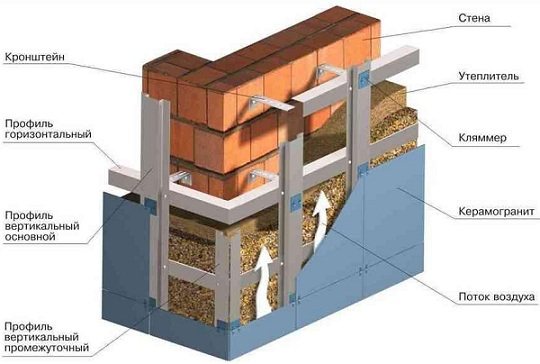

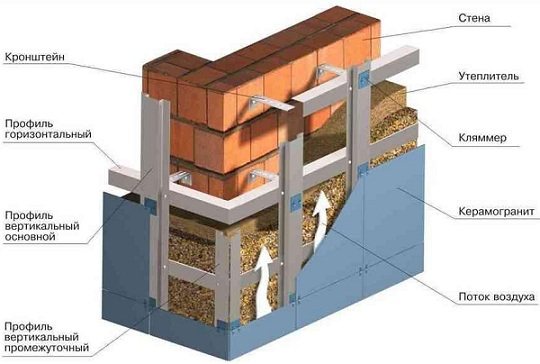

Ventilated facade

With this option for warming the walls of a brick house, the material is laid between the elements of the outer sheathing. Siding, facing brick or clapboard are used as the final finish. But how a ventilated facade for a house made of aerated concrete occurs, you can see in the article at the link.

Ventilated facade for brick wall

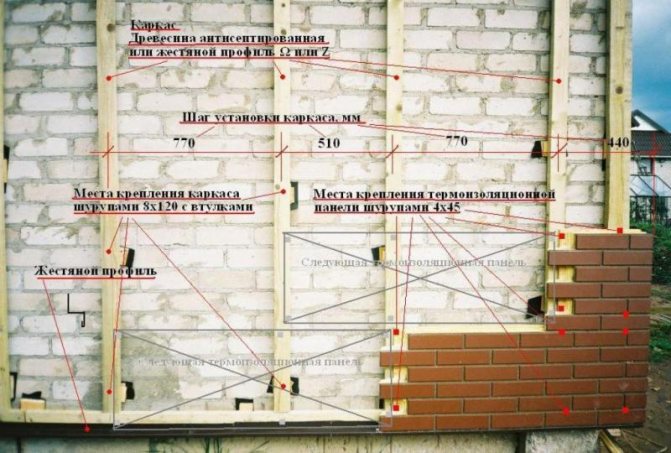

Thermal panels

This type of insulating material makes it possible to reliably protect brick walls from the cold, and from the negative effects of the atmosphere. Thermal panels, in addition, are also very decorative: they can be made in the form of natural masonry, porcelain stoneware or neat clinker tiles. But what the facade thermal panels look like with Russian-made clinker tiles, and how to properly install such panels, you can find out in this article.

Thermal panels for brick wall

Expanded polystyrene

This is one of the cheapest and most comfortable types of material to work with. According to scientists, the use of expanded polystyrene plates as a heater for a brick house can reduce heating costs by 4 times. Agree, a good argument in favor of this material. In addition to ordinary polystyrene foam, its extruded type, which is more durable, is often used. You may also be interested in information about how a log house is insulated from the outside with expanded polystyrene.

Expanded polystyrene

Extruded polystyrene foam

In fact, extruded material is a multitude of tiny cells filled with gas, while ordinary polystyrene foam is filled with air. The material does not lose its valuable qualities under the influence of temperature extremes, it is durable and reliable. In addition, it is easy to install and can be easily cut into pieces of the required size.

Extruded polystyrene foam

Due to the fact that the material is completely inorganic, it is not afraid of rotting and decomposition, even under the tangible influence of moisture. The disadvantages include the high level of flammability of the material. You may also find it useful to learn how to insulate a concrete floor with expanded polystyrene.

Polyurethane foam

This material has excellent strength characteristics. It is absolutely not afraid of moisture, does not rot, fungus and mold do not form on it

Two types of insulation that do not require additional finishing

- Another method of insulating a brick wall from the outside, using a thermal panel for a brick, is a fairly new technology. The main advantage is that there is no need to hide such panels under the siding. They have a beautiful appearance.

Thermal panels for brick

- insulation for a brick house using warm plaster, an innovative look. In our country, it is gaining more and more popularity due to its simplicity and low cost.

Insulation for a brick house using warm plaster

Types of thermal insulation materials used

Warm plaster. This type of heat insulator appeared relatively recently and is now widespread in the southern regions, where even in winter temperatures do not drop below zero.

It is not recommended to use such warm plaster for insulation outside the wall of a brick house in central Russia. It is much more profitable to insulate a brick house with mineral wool.

Expanded clay it is used mainly as in-wall insulation. It is possible to use this heat insulator for external wall insulation, but in this case it is necessary to make special plasterboard structures, inside which the material is poured.

Mineral wool. A popular heat insulator that is used for work with private houses.It must be said that due to the high moisture absorption, it is difficult to use mineral wool for outdoor work. This material is mainly used for internal insulation. When using mineral wool outside the house, it is necessary to use a special crate, which is closed with waterproofing membranes that protect the insulation from moisture. This is the only way you can extend the life of the insulation and provide excellent performance in protecting the walls of the house from the cold. It is not difficult to insulate a brick house with mineral wool.

Cork heaters are widely used in the west, but in the domestic market due to

the complexity of working with them and their high cost, this material has not received proper distribution. Among the disadvantages of cork, one can also single out a high degree of flammability, which also limits the popularity of this material.

Styrofoam. An inexpensive and effective insulation for walls that does not absorb moisture and has zero vapor permeability. It must be said that modern versions of polystyrene are durable and resistant to fire.

Extruded polystyrene foam. It is a kind of foam that has improved durability. Insulation is excellent for performing internal and external thermal insulation work with a brick house.

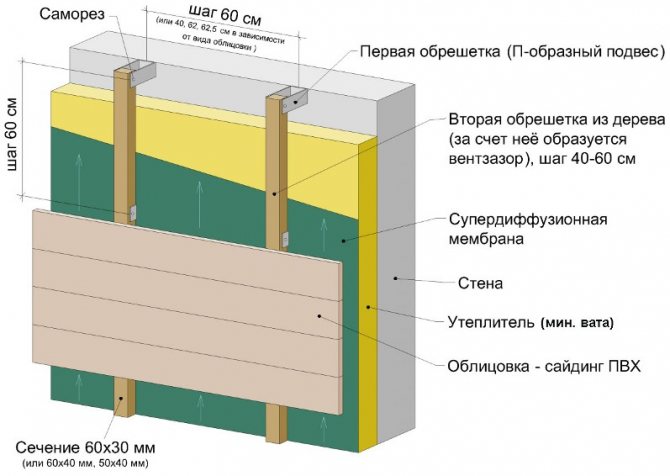

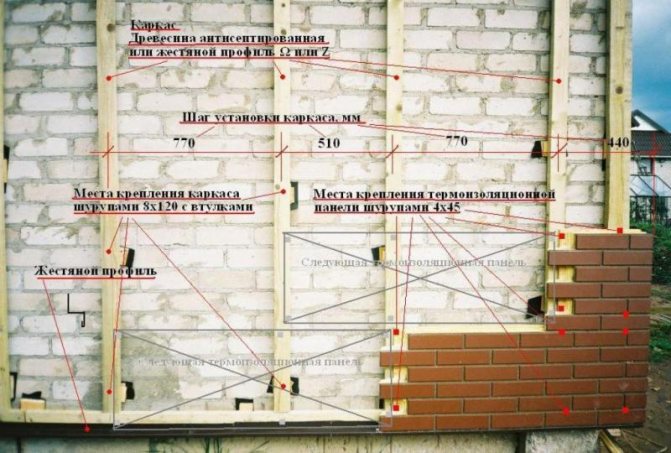

Installation scheme for siding

Surely not everyone knows how to properly insulate a brick house from the outside, or rather how exactly to mount the insulation. Installation, a group of heaters for siding, is fundamentally similar for all types of materials in this group. Before insulating a brick wall from the outside, it is necessary to expose the frame for the subsequent installation of siding. To do this, you will need to have:

- A hammer drill with an 8 mm drill, or an impact drill with a drill of the same diameter.

- Screwdriver.

- Construction level.

- Building corner.

- Roulette, hammer.

As a material for the manufacture of the frame, you can use a metal profile 60 * 27mm., Or wooden bars with a section of 50 * 50 mm.

Work should begin with cleaning the wall from anything that would interfere with the installation of the frame. Dismantle ebbs and slopes from windows. Then you can start installing the extreme bars. If the wall to be insulated is flat enough, then the frame can be made of wood, and the bars can be fastened with a dowel - nails, through and through. For exterior walls with irregularities, it is better to use a metal profile.

The extreme bars are installed, using a building level, strictly vertically. After that, between them, for convenience, a lace is pulled, it is convenient to control the installation of the remaining bars along it. All installed bars should be at a distance of 60 cm from each other in the same plane.

Insulation, cut into pieces of the required length and fit between the bars. It should be fixed using dowels - nails for insulating materials, having previously drilled holes for them in the wall.

If additional vapor barrier is necessary, it is mounted before installing the bars, directly on the wall, and only then proceed to the installation of the frame bars. If a metal profile is used as a frame, the whole scheme looks about the same, only instead of bars, profiles are installed using special suspensions.

Insulation with polyurethane foam

The process of insulating the brick walls of the house from the outside, using polyurethane foam, is slightly different in the order of work. You should start by cleaning the wall and removing anything that will interfere with the correct installation of the frame. The next stage is marking and installation of hangers on the wall for mounting profiles. After mounting the suspensions, they start applying the polyurethane foam.The last step after applying the foam is the installation of the profiles. As in the case of the bars, the extreme profiles are first installed, and then the lace is pulled and the rest are mounted with it. The profiles must be in the same plane.

Important: Before applying the foam, the hangers should be bent in such a way that they are ready for the installation of profiles in them, if this is not done, then after applying the foam, this will not work.

Siding installation

After installing the frame and insulation, the next stage is the installation of siding. The installation scheme depends on the type of siding panels, but general points are worth noting.

- Installation is carried out starting from the bottom of the house.

- Installation of the first panel is carried out strictly horizontally using a level.

- Each next panel is mounted in the previous one.

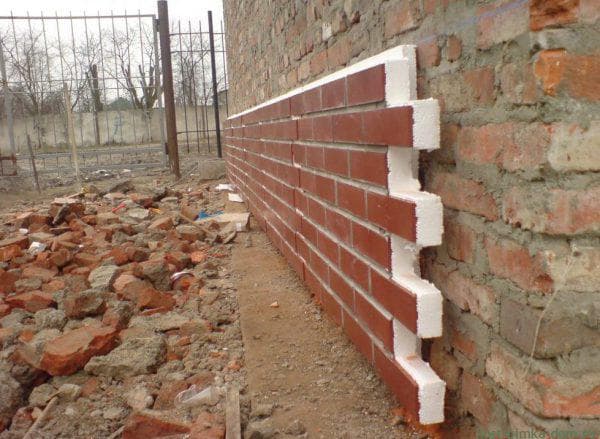

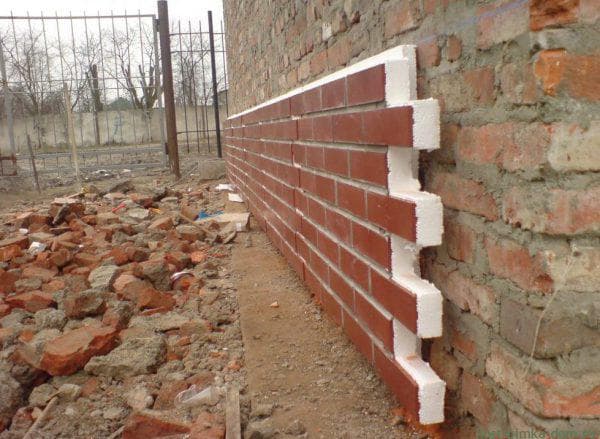

Finishing the facade of a brick house can be carried out using other technologies. For example, mount plates of mineral insulation (mineral wool) and then plaster and paint the surface. Or insulate the walls from the outside with foam and brick it.

Do-it-yourself insulation of brick walls of a house outside - modern technologies

Insulation of brick walls from the outside during masonry

Today, modern building materials provide an opportunity to choose the most effective technology for insulating the walls of a brick house. And what is very important, they suggest maximum compliance with both your requests and ideas, about the style and comfort of a residential building, and financial possibilities. Today, we can confidently say about the two most popular technologies for insulating brick walls of a residential building:

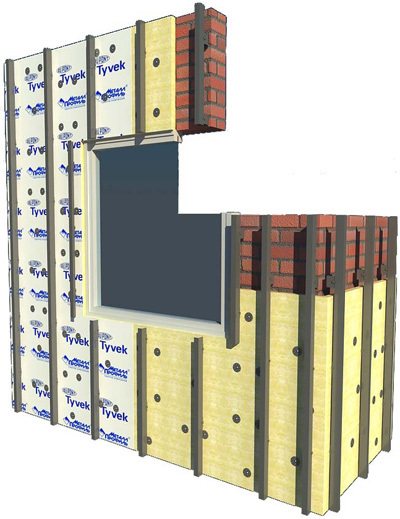

- Sandwich technology. Thermal insulation of brick walls is laid at the stage of construction. As soon as the brick walls are laid, a wooden or metal frame is installed on them. Further, a thermal insulation is laid in it. After that, decorative finishing is attached - siding, block house and other building materials for facade decoration. Such actions can be carried out only on a sufficiently strong foundation of the building;

- "Wet facade". Another, no less modern, technology for external wall insulation. This is when the heat insulation is attached using special adhesives. After, it is covered with a special reinforced mesh. Further, it is closed with decorative trim. To insulate a brick building with your own hands, in a similar way, you can use stone wool, polystyrene or expanded polystyrene. As a finish, as a rule, decorative plaster, siding, etc. are used.

Thermal insulation of a brick building outside with mineral wool and foam - the pros and cons

For thermal insulation of a brick building from the outside and from the inside, two types of insulators are mainly used: foam plastic and stone (mineral) wool.

The most important benefits of stone wool:

- Excellent sound insulation;

- high vapor permeability;

- incombustibility;

- long period of operation;

- it is equally effective both for insulation from the outside (under siding, etc.), and for thermal insulation of walls from the inside. For interior decoration, it is considered the best option.

The main advantages of thermal insulation of brick buildings with foam:

- Good thermal insulation characteristics;

- low water absorption;

- relatively low cost;

- resistance to the emergence of fungi and the development of bacteria;

- do-it-yourself installation availability.

The process of insulating a brick house from the outside with foam

Preparation and purchase of the necessary tools and building materials:

- Sharp knife;

- hammer;

- impact drill (puncher);

- spatulas for styrofoam putty;

- assembly glue (regular tile glue will also work);

- fastening material;

- putty;

- reinforced mesh;

- building material, for priming the surface of the walls;

- polyurethane foam.

We thoroughly clean, level and prime the brick walls.

Wall priming

We dilute the glue and lubricate the foam sheets with a spatula.

Applying glue to styrofoam

We apply and press the insulation well against the wall. At 5-6 points, using dowel-nails, we fix the sheets.

Fixing with dowel-nails

After 2-3 days, when the insulators are completely fixed, we seal the cracks with polyurethane foam.

We fill the seams with polyurethane foam

Putty - align the joints.

Putty seams

With the help of special glue, we reinforce the foam sheets with a special mesh. It is allowed to glue the mesh, with a slight overlap.

Fastening the reinforcing mesh

Further, as soon as the thermal insulation has dried out, we carry out decorative, finishing of the facade of the building. Typically used: vinyl siding, block house, plaster, etc.

Brick wall insulation

Thermal insulation with expanded polystyrene of a brick building

You've probably heard that polystyrene and expanded polystyrene are one and the same thermo-material. However, this is a serious misconception. Yes, indeed, polystyrene and polystyrene foam are made from the same raw materials, but the production process is very different.

Polyfoam is made by the "dry" method, for reliable "adhesion" - the granules are processed with steam. Expanded polystyrene is produced by extrusion. This is when the granules melt to form a homogeneous substance. In terms of strength, density and sound permeability, expanded polystyrene is several times superior to polystyrene. In addition, it is more convenient to install thermal insulation under the finishing, finishing building materials of the facade. In general, the process of installation work is practically similar to fixing foam. Do-it-yourself installation of expanded polystyrene is performed as follows:

- Brick walls are cleaned of dirt and cement mortar residues. Cracks are putty and the surface is primed.

- Install the start profile. Fasteners are carried out using dowel-nails. Using the building level, we strictly check the profile for horizontalness.

- We fix polystyrene foam. This is done with anchors, construction glue or special pastes. Apply the adhesive in the middle and along the perimeter of the slab. After that, the product is carefully pressed against the wall. Additionally, we fix the thermal insulator with dowel-nails.

- Joint seams - we seal. It is better to use polyurethane foam for such events.

- On top of the thermal sheets, we mount a reinforcing mesh. We use only acid and alkali resistant mesh material. For the reliability of the entire building structure, we attach a galvanized corner in the corners. The mesh is attached to construction glue. On top of it, thickly spread, another layer of glue.

- First we apply a primer, and after that we apply a plaster. To increase the aesthetic characteristics of a brick structure, the plaster is given some kind of texture. It is also not forbidden to use it for decorative finishing of the facade: siding, block house, etc.

Clinker panel installation diagram

Insulation of the facade of a brick house using a clinker thermal panel has a fundamental difference from the installation of mineral wool and other similar types of insulation. It consists in the fact that the installation of the frame and, accordingly, siding is not required. The pattern of clinker panels can be different, there are panels for brick, natural stone, etc.

Before installation, as in the case of conventional insulation, the wall must be cleaned of dust, dirt and anything that might interfere with installation. The clinker panel is installed from the bottom up. The process from the outside resembles the assembly of a puzzle. First, the corners and the base are collected, then the inside of the wall is gradually filled. Fastening takes place using dowel nails for insulating materials, as well as a small amount of mounting foam, which is applied under the insulation and then glues it to it.

Insulation thickness for brick walls

External insulation of the facade of a brick house depends on 3 important factors:

- From the shape of the brick (solid or hollow brick). Thermal conductivity of products is in the range of 0.4 - 0.9 W / (m * K). It affects the required thermal protection performance.

- From the type of building material. Brick can be ordinary, stove, silicate, etc.). Different types have different insulation needs. The lowest thermal conductivity is possessed by double silicate brick, therefore, for such structures, the thermal insulation layer will be minimal.

- Bricklaying method (solid or with an air pocket). The thickness of the floors and the operational features of the walls depend on this indicator. If the walls were erected with continuous masonry, the insulation must be laid both on the outside and on the inside of the wall. If we are dealing with a well method, it is necessary to insulate the walls only from the inside.

Warm plaster

Abroad, for a long time, this type of insulation of the outer walls of a brick house is considered one of the best and is used almost everywhere. In Russia, the advantages of warm plaster have not yet been properly appreciated, although many builders are already using it in practice.

Warm plaster, has a composition almost the same as ordinary plaster, only instead of sand, bubbles of foam plastic, or perlite or vermiculite are added to it.

Polyfoam is a good insulation, even anyone unfamiliar with construction technologies knows this. The use of plaster with the addition of polystyrene will allow you to insulate the house without high costs, and in a short time. Plastering does not require special preparation of the walls. Simply moisten with water and the mixture can be applied. Thermal insulation using warm plaster is quite effective because no joints, cracks or other defects remain on the wall through which heat can escape. Another indisputable advantage is the complete incombustibility of the plaster and the absence of the need to replace the slopes on the windows, which also allows you to save on finishing.

In addition to the article, watch the video:

Multilayer thermal insulation system

- If you prefer this option for your home, it is important to properly prepare the surface of the walls for work. The facade must be cleaned of dirt. If defects are found in the plaster, they must be eliminated.

- Insulating material is installed. If you are using Styrofoam, a special adhesive is required to secure the boards. It must be applied evenly to the surface of the insulating board. When the composition is set, the foam can be fixed to the wall. For this, umbrella dowels are used. The seams are sealed with the same mixture on which the foam was installed.

- After that, the reinforcement is installed. This operation is carried out using a plaster plastic mesh, on top of which a layer of plaster is applied. After it dries, the finishing plaster is applied. When the surface is ready, it can be painted with a special facade paint.

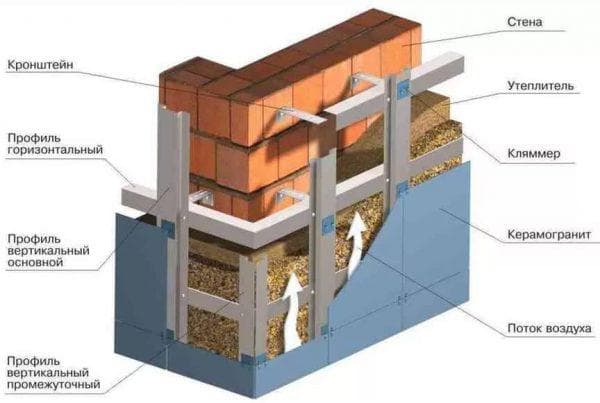

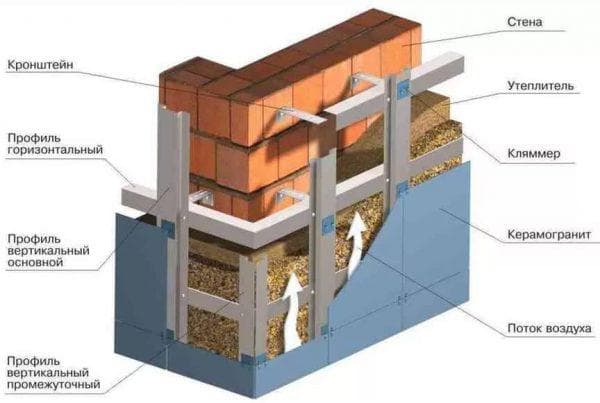

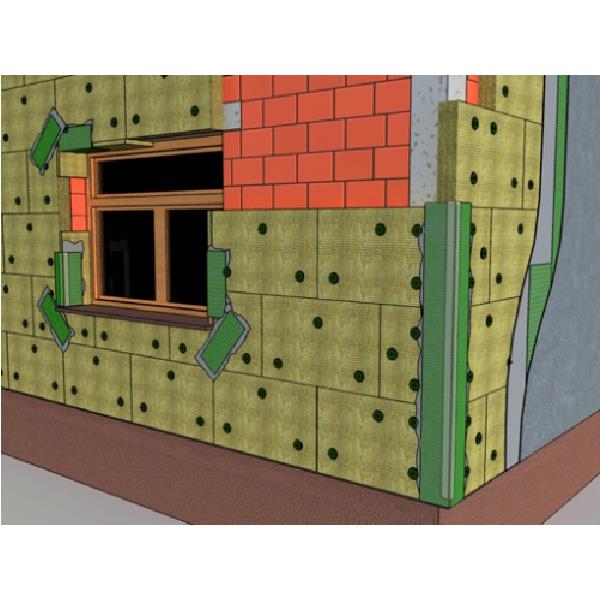

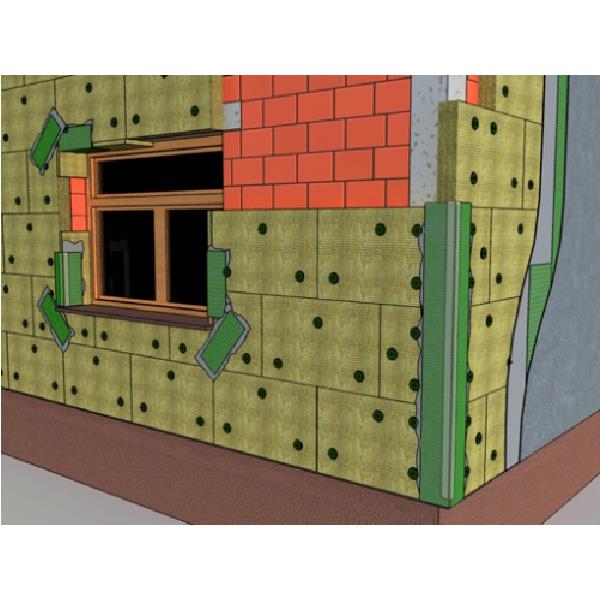

Ventilated facades

Before you start insulating a brick house from the outside, you need to decide on the device of ventilated facades. They include several layers. Typically, the following layers are used:

- Outer layer represented by a cladded screen.

- Lathing.

- Ventilation gap.

- Heat insulator.

The following stages of ventilated facades are distinguished:

- First you need to properly prepare the surface for work. Clean the facade from dirt and eliminate possible defects.

- Then it is necessary to install load-bearing surfaces, which are constructed from a metal profile. The frame can also be made of wooden blocks, but its service life will be significantly lower.It is important to leave equal gaps between the elements of the system so that the insulation for the outer walls of a brick house is located "in tightness" with some tension.

- At the next stage, the heat insulator is laid. To fix it, use dowels and special adhesives.

- It is important to create a hydro-barrier. This will protect the insulation from wind and moisture.

- At the final stage, finishing is made, which can be tile, siding or other materials.

Features of facade insulation with foam plastic for siding

If siding is used for exterior wall cladding, give preference to insulation materials such as EPS or foam. The latter material is the most popular because it has a lower cost.

If you plan to install insulation under siding for a brick house, use one of the following methods:

- Glue the styrofoam.

- Install it on the fasteners.

The use of foam for insulating brick walls for siding is the best solution. This is due to the high speed of work and their lower labor intensity.

Styrofoam sticking process

When installing with glue, the following sequence of actions is used:

- The walls are cleaned of dirt and, if necessary, leveled.

- Then a deep penetration primer is applied to them.

- A horizontal rail is installed at the bottom of the wall, which will be used as a support for the foam sheets during the gluing process.

- Then, vertical posts made of wooden bars or a metal profile are exposed. It is important that the step between them corresponds to the width of the insulation sheets.

- It is necessary to walk on the surface of the plates with a needle roller.

- A special adhesive is applied to the center and perimeter of the canvases. You can use dry mix, cans of polyurethane glue or special foam glue. Any of these compositions allows you to carry out high-quality wall insulation for siding.

- The first row of insulation boards is fixed with support directly on the horizontal rail.

- The second row of slabs is laid in relation to the first in a checkerboard pattern.

- When the glue is completely dry, the siding can be installed.

Video about polystyrene - outdoor insulation for a brick house

Note! It is better not to use a cement-sand composition for attaching foam plastic to external brick walls. It will not fully adhere to the heat insulator.

The process of installing foam with fasteners

If you plan to attach the insulation under the siding using fasteners, you need to buy dowels with wide caps. This is a more reliable method that will require much more labor. The following stages of work are carried out:

- The walls are cleaned of dirt and, if necessary, leveled. If there are no large differences in height, there is no need for alignment.

- A horizontal rail is installed at the bottom of the wall, which will act as a starting guide. Then beacons are stretched from stretched cords, which serve as a guide in the process of laying the slabs.

- Set up vertical racks of wooden bars or metal profiles. It is important that a step remains between them, corresponding to the width of the thermal insulation sheets.

- The foam sheets are fixed with five dowels. Four dowels are installed in the corners and one in the center.

- Then the siding is installed.

Materials for internal insulation

Thermal insulation of walls from the inside has many disadvantages, therefore, preference is given to external insulation of the house. The main one of these disadvantages is a decrease in the area and volume of the room as a result of insulation work.

However, there are pluses - the material and labor costs for internal insulation are much less, you do not need a specialist, you can do everything yourself.There are several options for achieving your home insulation goal, depending on the insulation material. For these purposes, the following can be used:

- plaster; polystyrene or polystyrene; liquid sprayed polyurethane foam; mineral fiber mats.

Each of these methods has its own characteristics.

Traditional plaster is the cheapest type of insulation, has good sound insulation, vapor permeability (the room breathes), low water permeability, incombustibility. However, it has such disadvantages as the duration of the working process associated with the technology of applying plaster (it dries for a long time), the maximum applied layer should not exceed 5 cm, a lot of weight, for this you will have to additionally strengthen the foundation. Nevertheless, this type of wall insulation is widespread, both for external and internal work.

Foamed polystyrene materials (polystyrene foam) are often used for internal insulation of a brick wall. Plates made of these materials have low thermal conductivity, they are excellent sound absorbers. Polystyrene is easy to install, inexpensive, it is not difficult to strengthen it with your own hands without the help of special tools.

Some nuances

So, you already know the properties of mineral wool and understand how to install it. Thus, the insulation of brick walls from the outside should not be a difficult process for you. Just keep in mind that the packaging of the adhesives should indicate that it is for mineral wool.

There are also different brands of mineral wool, which differ in rigidity, the presence or absence of additional layers. There are also lamellas with a special fiber structure, which provides additional strength.

See more on this topic on our website:

- Thermal insulation of a wooden house outside with mineral wool When building a wooden house, great attention is paid to the insulation of walls from the outside, which allows not only to create the most comfortable living conditions in the house, but also to significantly save ...

- Warming the walls of a wooden house with expanded polystyrene from the outside Recently, people began to give preference to wooden houses. The first thing that attracts this natural material is its ecological purity. On top of that, the wood is very good ...

- The best insulation for a brick house when insulating outside When constructing buildings of various types, a wide variety of materials are used. However, brick stands out in this regard. It is the most popular material. This fact is fully justified….

- Insulation of a frame house from the outside with environmentally friendly heaters Since the insulation of a frame house from the outside is a task of paramount importance in the construction process, it is recommended to approach the choice of a heat insulator with particular seriousness. In addition to such characteristics, ...

- Insulation and decorative finishing of a brick house In modern construction, walls are still built of bricks. Despite the many positive aspects, a brick house needs additional insulation. Insulation of the outer walls of a brick ...