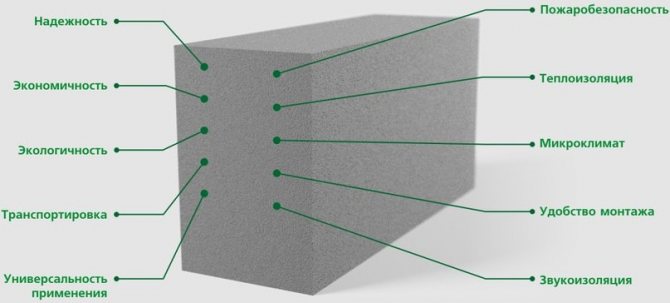

Foam concrete - building blocks of a light shade, which consist of gas silicate and foam concrete. This building material is applicable for both low-rise buildings and high-rise structures. The structure of such raw materials is characterized by high adhesion to any cladding, good thermal insulation and the ability to suppress noise, but many building owners still prefer to perform additional insulation of foam concrete. Installation work with any of the types of heat insulators is quite simple and can be done independently.

High-quality heat and sound insulation

Foam block as a base

Foam block is a building material that consists of cement mortar, sand, water and special substances involved in the formation of a stable foam.

The material has high performance in heat and sound insulation, is resistant to moisture penetration, fire resistant and is not able to freeze.

It is not used as a material for the capital construction of a load-bearing wall, but an internal partition or non-load-bearing structures can be made of it.

Expanded polystyrene and its characteristics

Expanded polystyrene is a white substance that consists of individual elastic granules, firmly soldered into one whole. It is obtained by foaming polystyrene, the structure of the foam block is 90 percent air. In the current construction, this heat insulator claims to be one of the leading places in popularity - it is used to insulate brick, wooden and aerated concrete buildings.

Polyfoam is one of the best options

Expanded polystyrene has the following characteristics:

- a high degree of thermal insulation due to a low coefficient of thermal conductivity;

- small mass with large dimensions - it allows you to transport it without problems and refuse to use special assembly and loading equipment;

- hydrophobic - does not allow water to pass through and does not retain;

- moisture resistance - insulating properties do not disappear even after prolonged stay in a humid environment;

- environmental friendliness - expanded polystyrene is harmless to the environment and human health. This property is taken into account when choosing it for the production of food packaging;

- good workability - polystyrene foam can be cut with a sharp knife, it is easy to make holes in it and it is convenient to glue it;

- frost resistance - does not lose its properties at low temperatures;

- durability;

- non-flammability;

- affordable price is a factor that significantly affects the cost of thermal insulation.

Expanded polystyrene is sold in the form of plates of various thicknesses and sizes. The thickness of the insulating layer depends on the required degree of insulation, climatic conditions in the region and other similar factors. The number of slabs is calculated based on the total area of the walls that need to be insulated.

It is quite easy to work with these plates, since they have a strict geometry, and if necessary, they are easy to cut.

Warming reasons

Insulation of external walls only with foam concrete is quite popular, since the blocks are lightweight, durable and have good durability. In addition, in some cases, additional insulation of the foam block itself can be performed.

There are a number of reasons for this:

- protection against moisture, which has a very bad effect on the durability of the wall;

- when freezing, there is a risk of complete destruction of the building material;

- prevention of condensation on the main wall and, as a result, the formation of fungus, mold.

Also, experts advise to insulate buildings from foam concrete exclusively from the outside.

Insulation options for the facade and walls outside

Lightweight materials with a low level of thermal conductivity, non-combustible are suitable for insulating the walls of a house from foam blocks. You need to insulate the facade of the house from the outside. This will help preserve the useful area of the building, as well as protect it from the formation of fungus and excess moisture. When the thermal insulation is outside, all condensation cannot penetrate the inside of the building.

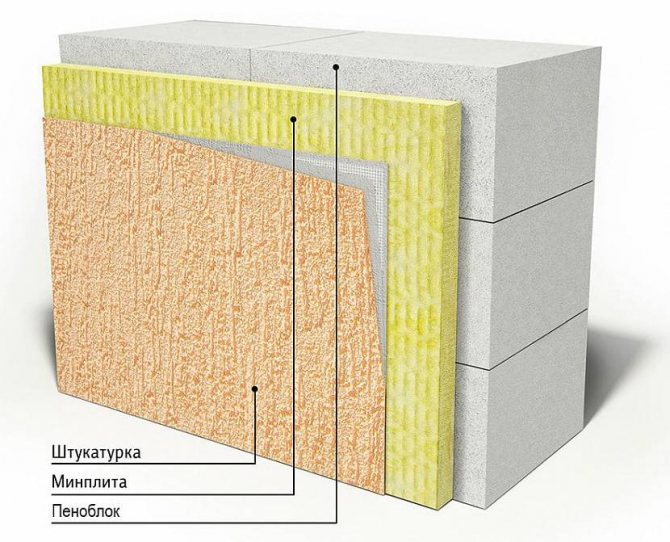

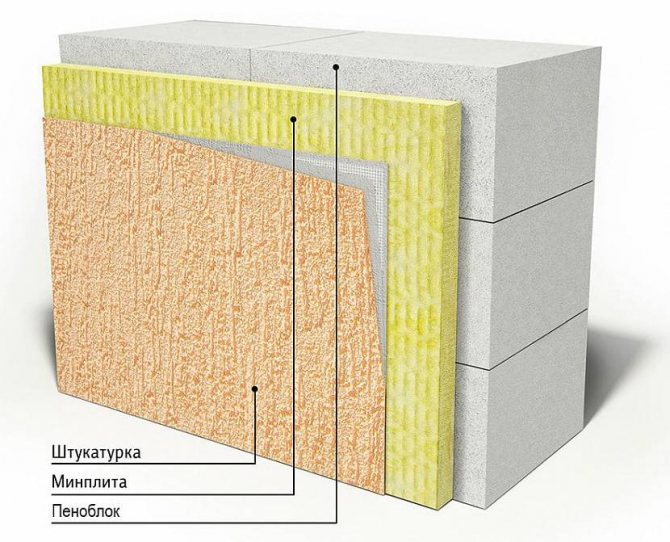

Wall insulation is of the following types:

- thermal insulation of a single-layer structure, for example, a flat wall made of foam blocks or bricks;

- thermal insulation of a multi-layer wall, here the insulation is located between the building blocks;

- thermal insulation of a wall that is covered with plaster or siding.

In order for the insulation to serve longer than ten years, it is worth insulating the structure with two types of materials. To insulate the walls of a house from foam blocks, you can use penoplex, mineral wool, polystyrene foam, polyurethane foam.

Penoplex

Penoplex or extruded polystyrene foam is used to insulate building structures. Penoplex has a low coefficient of thermal conductivity and vapor permeability, which indicates the ability to retain heat and remove moisture to the outside. Among the disadvantages of penoplex is a high class of flammability, that is, rapid ignition near a fire, which is accompanied by a pungent toxic odor. Also, penoplex is a thin and brittle material. May crack or break under mechanical stress. Has a low chemical resistance to acetone, resins, kerosene, gasoline, oil paints. Destroys on contact with them. The service life of extruded polystyrene foam is 10-20 years.

Minvata

Depending on the composition, mineral wool can have a different structure, but, as a rule, a mixture of slag, stone and glass particles is used for insulation. The flexible and soft texture of the material allows it to be used for thermal insulation of pipes and crevices. Minvata does not burn, you can insulate wooden structures and baths. It has low thermal conductivity and vapor permeability, but water absorption is 35% of the volume. This means that at high humidity, the material absorbs it and loses its ability to retain heat. Among the disadvantages of mineral wool is the presence of glass particles in the composition. They have a bad effect on human health, cause coughing and irritation of the mucous membranes. Therefore, in some countries the use of mineral wool is prohibited, for example, in Germany.

When installing mineral wool, you need to carefully glue the joints and seams, they are formed due to the softness of the material, they can be overlooked. Mineral wool service life is about 15 years.

Styrofoam

The foam has a low coefficient of thermal conductivity, water absorption is only 4%. In its properties, it is similar to expanded polystyrene, it is also highly flammable and emits toxic substances. It is destroyed due to the effects of resins, gasoline and acetone, but it is resistant to solutions of salts, bitumen and cement. The main disadvantage of polystyrene is its sensitivity to ultraviolet rays. Therefore, it must be covered with siding or plaster. The service life of foam when insulating a house from foam blocks is from 10 to 20 years.

Polyurethane foam

Closed-cell polyurethane foam (PPU) is suitable for insulating a house from foam blocks from the outside. Its low thermal conductivity coefficient and water absorption rate of 5% make it possible to insulate residential and industrial buildings, roofs, pipelines. Even a small layer of material is sufficient to provide seamless thermal insulation. Due to its good adhesion, the polyurethane foam is attached to vertical and horizontal surfaces. The flammability class of the material can be selected in accordance with requests: from G1 to G4.

Dowels and glue are not required for the installation of polyurethane foam.Equipment required - airless spraying unit. It will allow you to cover large areas in a few minutes. Depending on the operating conditions, polyurethane foam retains its thermal insulation properties for more than 30 years. When insulating a house from foam blocks, PPU is closed with siding, plaster or a curtain facade.

For more information about materials for insulation, read the link.

The relevance of insulation of houses from a foam block outside

Foam concrete was created for those buildings that are erected in one layer. It has good thermal insulation properties. However, in a continental temperate climate, winters are very cold and windy, so experts still recommend additional thermal insulation of foam concrete.

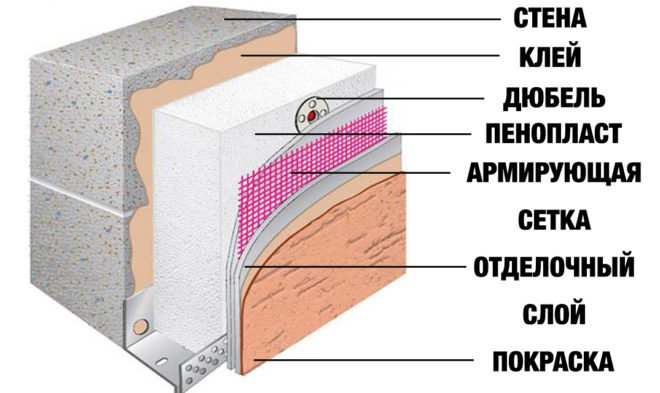

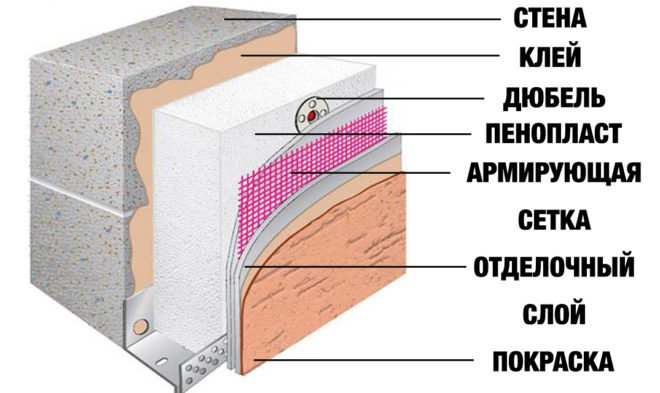

Scheme

Another important factor is that foam concrete can freeze during prolonged cold and even absorb moisture. To prevent this from happening, insulation is carried out exclusively from the outside of houses from a foam block, which has a number of advantages over the inside:

- saving space indoors;

- condensation does not accumulate inside, and also does not settle on the main wall;

- thermal insulation protects foam concrete from freezing and moisture penetration.

How to insulate a foam block with mineral wool outside

We have already written about the insulation of the facade with mineral wool for siding and plaster. And it is better to see once than hear a hundred times, so we will show a video of house insulation from a foam block with mineral wool with our own hands.

Foam blocks

are called blocks of foamed concrete, obtained by cold pouring a concrete solution into molds or by heating it in molds in an autoclave.

The result is cellular concrete

of various brands, significantly different in their properties. However, the common property of these building materials is thermal conductivity, which is 1.2–4.3 times lower than that of hollow ceramic bricks (depending on density).

According to this indicator, foam concrete blocks are close to wood, which makes them good heat insulators

... For this reason, houses built from such materials are often not insulated at all.

However, modern insulating materials are several times superior to cellular concrete in terms of thermal insulation properties. So, expanded polystyrene with a density of 33 kg / m³ with the same layer thickness conducts heat approximately 2.5 times worse

than foam concrete with a density of 300 kg / m³. This means that it makes sense to insulate buildings made of cellular concrete.

Important!

Foam concrete is a vapor-permeable building material. Its vapor permeability is 2–5 times higher than that of wood, therefore it must be protected from the penetration of vapors and drops. If this is not done, the water accumulated in the pores, when freezing, will destroy the blocks.

Outside, the foam concrete wall is plastered, closing the pores from moisture. Such a coating protects aerated concrete from destruction. There is another way of protection

- insulate the wall and only then finish it. In this case, the dew point will move from the porous wall into the thickness of the heat insulator. In this case, the foam concrete will not freeze and collapse.

Typically, the insulation is laid on the outside. However, this not always possible

therefore buildings are sometimes insulated from the inside. If you have to do this, read the article "". And here we will consider the insulation of a house from foam blocks from the outside.

In order for the thermal insulation to be effective and to serve for a long time, you need to choose the right insulation. For external thermal insulation

the following materials are most often used for walls made of foam concrete:

- Mineral wool

... Basalt wool and glass wool in slabs are suitable for outdoor work. This insulation allows steam to pass through and slightly absorbs moisture, reducing its thermal insulation properties. For this reason, mineral wool requires waterproofing. Glass wool and basalt wool do not burn and do not support combustion.These materials should be handled with gloves, protecting the respiratory system with a respirator, as they irritate the skin and respiratory tract. - Expanded polystyrene in slabs

... This insulation is available in the form of coarse-mesh and fine-mesh. It is advisable to choose penoplex, since it is stronger to break and does not crumble like foam. Both materials are impermeable to steam and very poor at absorbing water, so they do not need a vapor barrier. In terms of thermal insulation properties, expanded polystyrene is better than mineral wool by about 1.5 times. Another important advantage of expanded polystyrene is its low density. Due to this property, it practically does not create a load on the wall, which is very important for cellular concrete that does not have high strength.

Other heat insulators for aerated concrete used much less often

.

For fixing slabs

on the wall you will have to select fasteners. To fix the insulation on gas and foam blocks, choose dowels made of impact-resistant plastic or metal with a thermal head. In this case, the anchors (the expanding part with notches) of such dowels must be at least 100 mm long. Dowels with short anchors (50 mm) are only suitable for in-situ concrete or solid bricks.

For styling

on a wall made of aerated concrete, use basalt wool or glass wool of minimum density (50 kg / m³).

In this case, as a rule, one layer of slabs is sufficient. 50 mm thick

even for areas with a harsh climate, since the main thermal insulation is aerated concrete itself.

Styling

do in this order:

- The wall is cleaned of excess mortar and leveled

... If elements that cannot be removed are protruding from the wall, the material will fit around them. At the same time, slits are made in the slabs in the right place. - Mineral wool slabs are laid directly on the wall end-to-end

fixing them with dowels. It should be remembered that aerated concrete is a fragile material. The holes in the insulation and the blocks are drilled carefully and the dowels are driven in carefully so as not to crush the blocks. - If the insulation is laid in two layers

, the second layer of plates is placed in such a way that the outer plates cover the joints of the inner ones. With single-layer insulation, the joints of the plates are sealed with polyurethane foam. - Outside, mineral wool is covered with facing brick masonry

... Such a brick has a smooth surface, practically does not absorb water and is frost-resistant. Facing brick is placed on the foundation, and above the window and doorways - on reinforced concrete lintels, but in no case on aerated concrete. Aerated concrete does not withstand such a heavy cladding. - Openings are left in the lower part of the facing masonry

closed with plastic bars. The same barred openings are made in the upper part of the wall. These holes are needed for ventilation of the mineral wool. Steam penetrating through the foam concrete walls freely passes through the mineral wool and escapes through the upper vents.

Insulation types

If you still decided to insulate the walls of foam concrete, then the question certainly arose before you: "What kind of insulation to choose?" Considering the fact that today the market is overflowing with various types of insulators for insulating petroconcrete, they all differ in their characteristics and properties. The final choice can be made by examining all the main parameters of the proposed raw materials.

Foam application

Styrofoam

Polyfoam, also known as polyurethane foam, is a lightweight plate for thermal insulation of any walls. The advantages include not only low cost, but also resistance to moisture and sudden changes in temperature conditions.

The peculiarities of foam concrete insulation with foam include the mandatory performance of facing work, since the slabs are unstable to UV radiation.

Use of mineral wool

Minvata

Minvata is also quite popular for foam concrete insulation.

It has a number of advantages:

- long service life if all work has been done correctly;

- fire resistance;

- excellent heat preservation performance;

- additional sound insulation;

- does not absorb moisture.

Penoplex analogue to polystyrene

Penoplex

This insulation looks very much like foam, but the materials are produced in a completely different way. Another name for penoplex is extruded polystyrene foam. These are slabs that do not deform, are resistant to moisture and mold.

However, the vapor permeability coefficient of the material is slightly worse than that of ordinary foam, which increases the requirements for ventilation of a house made of foam concrete insulated with extruded polystyrene foam.

Thermal panels

Thermal panels

Thermal panel is a material consisting of a heat insulator layer (for example, expanded polystyrene, polyurethane foam, extruded polystyrene foam), a decorative outer layer (clinker, artificial stone, ceramics) and an adhesive base, which serves for gluing the decorative layer and the thermal insulating base.

The main advantage of such slabs is that there is no need for cladding work, since they already contain a decorative layer. In addition, there are other advantages of using thermal panels, and they are quite significant:

- installation at any time of the year;

- resistance to decay, the formation of all types of fungi and mold, as well as other microorganisms;

- special mounts that simplify installation work;

- the obligatory use of the lathing excludes the violation of the geometry of the facade;

- a variety of colors and textures allows you to embody the most daring design solutions into reality;

- high coefficients of heat and sound insulation;

- durability of the structure and resistance to ultraviolet radiation.

The only drawback is the high cost of thermal panels.

How to insulate a foam block house from the outside

What material to choose for thermal insulation? The ideal option for self-insulation of foam concrete is plate material: foam, expanded polystyrene or mineral wool mats. When using a vapor-permeable insulation (mineral wool), it should be protected with waterproofing. If the house is insulated with vapor-proof materials, then a ventilated gap must be installed, which will remove possible condensation from the wall surface.

Insulation of a foam block house with mineral wool

Mineral wool

- vapor permeable, environmentally friendly, non-flammable, prevents the spread of fire, may shrink if improperly laid. Material should be handled with personal protective equipment.

Expanded polystyrene, polystyrene

- vapor-tight, has a low heat transfer coefficient and water-repellent properties, does not shrink, does not freeze. When insulating a house with foam outside, it should be protected with a decorative layer from ultraviolet rays.

Another new material for warming the facades of country houses is thermal panels. The process of insulating a house with thermal panels is very simple and quick, the work is available to any non-professional builder.

What material is most preferable: possible harm to health

Fire hazard

When choosing an insulator for foam concrete insulation, the question of safety arises. It's not only about the release of harmful substances during operation, but also about fire safety.

All of the above-described thermal insulation materials will not harm human health if the installation work is performed correctly. All of them are produced using anti-flammable mixtures that prevent not only ignition, but also contribute to self-extinguishing in the event of ignition.

Considering the fact that synthetic resins from the phenolic group can be used in the production of mineral wool, it will not emit harmful substances due to its external location.

Choosing a suitable insulator for external insulation

Thinking about how to insulate a house from foam blocks from the outside, they usually give preference to light and affordable materials - polystyrene, mineral wool, penoplex. Each material provides a certain level of thermal insulation, protecting the structure and extending the life of the entire building.

Foam application

The most popular option for external insulation of foam block buildings. The material does not allow moisture to pass at all, is resistant to frost, and has a low cost. On top of the foam, it is imperative to carry out a finishing decorative finish, which will make the building aesthetically pleasing and protect the foam from the effects of ultraviolet rays that destroy the material.

The most popular types of foam:

- TechnoNIKOL Carbon Eco - sheets of 118x58 in size and 3 centimeters thick can be operated at temperatures ranging from -70 to +75 degrees. Low cost and excellent characteristics make the material popular.

- Knauf Term - good indicators of vapor permeability, the ability to withstand temperatures from -140 to +80 degrees, a low price. Supplied in sheet format 100x100 centimeters with a thickness of 5 centimeters.

- Ursa XPS - suitable for thermal insulation of foam block facades, it is produced in sheets of 125x60 centimeters with a thickness of 5 centimeters, it costs about the same as its counterparts.

How is external foam insulation performed:

- Thorough cleaning of the surface of the foam block from dirt, sand, debris, build-up mix.

- Application of a layer of primer, which will ensure the adhesion of foam concrete and assembly adhesive.

- Installation of the basement profile on the bottom of the wall - it will become the support of the insulation.

- Kneading glue using a special drill attachment (reminiscent of a mixer).

- Foam preparation - the sheets are processed with a needle roller to roughen them.

- Application of a layer of glue with a spatula on the surface of the foam.

- Installation of foam sheets on foam concrete from the bottom up, umbrella dowels are attached in the corners and edges.

Use of mineral wool

This insulation is inorganic and is a substance created by a large number of intertwined fibers made from sedimentary and rocks, metallurgical slags. A popular option, the main advantages of which are indicated by the following: high sound / thermal insulation, resistance to moisture, heat resistance, service life in the region of 35-40 years.

The most common type of mineral wool for outdoor insulation is produced by TechnoNIKOL, which supplies Technolight Extra basalt insulation material in packs of 8 slabs 120x60 centimeters in size and 5 centimeters thick. The assortment also includes sheets of greater thickness, the price of one pack starts at 555 rubles.

Penoplex: analogue of polystyrene

This thermal insulation material is similar to foam, but it is produced using a different technology. It uses high temperatures and pressures to create a durable and lightweight material. Its other name is extruded polystyrene foam. It is resistant to compression, completely environmentally friendly, is not afraid of moisture and mold, demonstrates excellent performance and a long service life.

The most popular penoplex options:

- Penoplex Facade - created specifically for thermal insulation of facades, the thickness can be different (3-10 centimeters), as well as the dimensions. The cost of one sheet is from 100 rubles.

- Penoplex Comfort - slabs with a size of 118.5x58.5 centimeters and a thickness of 3 centimeters (but maybe more), there can be 4/7/10/13 pieces in a package. A package of 13 sheets costs from 1400 rubles.

How to fix the foam blocks to the foam block:

- Leveling the wall surface, carefully sealing all cracks.

- Facade treatment with a primer.

- Knead the glue according to the instructions on the package.

- Gluing foam sheets, then fixing them with dowels.

- Installation of reinforced mesh for finishing.

Features of insulation technology with various materials

After you have decided on the material for the insulation of foam concrete, you can proceed to the preparatory activities. First of all, the amount of material required is determined, and the necessary tools are selected.

It is important to remember that due to the size of any sheets for wall insulation, you will need an assistant to facilitate the entire installation process.

How to insulate a house from foam blocks outside with foam

Before starting work on the insulation of foam concrete walls, they must be prepared. They must be free of old paint, debris, plaster. It is also recommended to patch up all cracks and holes.

The process of foam insulation itself is as follows:

- a deep-penetrating primer is applied to the wall to ensure maximum adhesion of the adhesive to the foam concrete;

- an initial plank is installed at the bottom of the building to support the starting foam strip;

- an adhesive solution is prepared according to the manufacturer's instructions;

- the surface of the foam is processed to create a roughness;

- a layer of glue is applied with a spatula to the plate;

- the insulation is fixed on the foam concrete, the rows should go from bottom to top;

- the foam is additionally reinforced with dowels with a wide head.

After the installation of the insulation is completed, decorative and facing activities are carried out.

Thermal insulation of foam concrete with mineral wool: stages of work

When insulating foam concrete with mineral wool, it is also necessary to pre-clean the walls. In this case, the surface should be as flat as possible.

Step by step, the whole process looks like this:

- a solution of antiseptic agents is applied to the foam concrete;

- steam and waterproofing membranes are attached;

- brackets for lathing are installed;

- vertical and horizontal guides are mounted;

- insulation is inserted and fastened with dowels.

When using mineral wool, plaster and further painting are most often used as cladding.

Installation of thermal panels

The most optimal option for installing thermal panels on foam concrete is a ventilated facade system. As soon as the structure is installed, they begin to install the panels. As a rule, they all contain special grooves for fastening, so work is done quickly and easily. All work should be started from the corner of the building, after installing the starting elements.

In this case, it is recommended to strengthen the film to protect it from moisture on the main wall.

Warming with foam

The work on the insulation of foam concrete with penoplex is completely identical to the work on the insulation of walls with foam. In this case, preparatory work is also carried out, an adhesive solution is prepared, the plates are fixed to the facade in a similar way, the fiberglass mesh is mounted, and decorative and facing work is performed.

Penoplex thermal insulation

When using foam for foam concrete, there is no need to use additional vapor barrier membranes, since the raw material already has high performance in this parameter. Also, due to the light weight of the plates, the work can be done independently, without the help of a partner.

Mineral wool insulation

Installation of the frame and thermal insulation

Ventilated facade layout

Somewhat more difficult to implement with your own hands is the insulation of the foam block from the outside with the help of mineral wool:

- On the cleaned walls (you can treat them with an antiseptic) we install brackets for attaching the lathing.

- We put heat-insulating gaskets between the wall and the base of the bracket.

- In the lower part, we install a basement profile, into which we insert the first row of heat-insulating materials.

- On top of the brackets with the help of disc dowels, we fix the mineral wool slabs. For reliable fixation, we deepen the dowels into the foam concrete by at least 40-50 mm.

Photo of fastening mineral wool to the foam block

- To provide additional thermal insulation, we put a windproof membrane on a layer of mineral wool heat insulator.

Note! In order for the design of a ventilated facade to retain its advantages, the membrane must be vapor-permeable! Of course, the price of such a membrane is higher than that of ordinary polyethylene, but it also releases moisture from the room much more efficiently.

Sheathing

The final stage of arranging the facade insulated with mineral wool is cladding.

The cladding technology is familiar to anyone who insulates a loggia with clapboard or plastic panels:

- On the brackets fixed on the wall, we attach the sheathing beams. Instead of bars, you can use metal profiles - they are more technological, but they conduct heat better.

- We fix siding or metal decorative panels to the crate with self-tapping screws. Separately we mount slopes on windows and doorways, plinths, ebbs, corner strips and other decorative elements.

Metal siding mount

When installing the cladding, it is very important that sufficient contact of the thermal insulation with the outside air is ensured, as this is necessary for the removal of condensation moisture.

Protecting the thermal insulator

Any insulation needs protection. And it's not just that materials behave differently when exposed to moisture or sunlight.

An open thermal insulator does not look attractive outwardly and in any case decorative cladding will be required.

Masonry

One of the most expensive, but at the same time durable, cladding methods. During the work, simultaneously with the laying of the insulation, the foundation is expanded. Its thickness is equal to the thickness of the insulation and plastering.

Masonry

Some construction organizations advise to carry out work on the insulation of foam concrete and brick laying at the same time in order to reduce the cost of gluing the insulator.

Wet facade

This method is often used for basalt wool and expanded polystyrene.

Wet facade

Its principle is as follows:

- the walls are cleaned, their plane is leveled;

- a deep-penetrating primer is applied;

- insulation elements are attached with glue;

- additionally, the plates are fixed with dowels;

- a layer of adhesive solution is applied on top;

- the reinforcing mesh is recessed;

- a thin layer of plaster is applied;

- paint is applied to the dried surface of the facade.

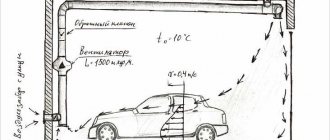

Ventilated facade

This method is ideal for insulating foam concrete walls. The bottom line is to install a special metal structure - a ventilated facade system. The peculiarity of such a hinged system is that there is a ventilation gap between the main wall and the insulation layer, in which air circulates freely, thereby preventing the appearance of condensation and contributing to better heat retention.

Curtain wall system

It should be remembered that when insulating foam concrete with mineral insulators, an additional installation of a windproof film is necessary, but for expanded polystyrene this is not a prerequisite.

Summing up, we can say the following: foam concrete is a building material, which still needs to be additionally insulated, despite good heat resistance indicators. In addition, it is better to carry out insulation from the outside of the building so as not to reduce the space from the inside of the room and not to expose the insulation to interaction with moisture and precipitation.

Choosing the best insulator is a matter of personal preference.As for the method of installation, in this case, the most suitable system will be a ventilated facade, which provides free air circulation inside the structure, which will avoid the deposition of condensate on the surface of the main wall.

How to insulate a foam block with foam from the outside

Stages of warming a foam block house with penoplex with your own hands:

1.The surface of the wall of the house is cleaned of dust, we knock down the influx of solution; 2. we process the facade with a primer, which ensures adhesion of the adhesive to the wall surface; 3. we attach the basement starting profile to the bottom of the wall - a support for materials that protects the insulation from rodents. 4. preparation of glue for penoplex, following the recommendations of the instructions, mix the solution thoroughly with a drill; 5. Spatula or float, apply glue to the plates and glue them to the facade from bottom to top and in a checkerboard pattern; 6. Each plate of insulation in the corners and in the center is fixed with an umbrella (dish-shaped) dowel; 7. on the cladded facade, we glue the reinforcing mesh: first we glue all the corners, and then all the walls; 8. Apply a plaster layer on the grid, after drying, apply plaster and paint the facade.

Insulation materials

The choice of insulation depends on the area of its application. As you know, housing can be insulated in two ways:

- Outside;

- From the inside.

Below we will consider heaters that are suitable for both cases.

Materials for external thermal insulation

The main requirement for thermal insulation materials for outdoor use is vapor permeability. If moisture that has accumulated inside the walls cannot escape, the walls will become damp.

In the photo of the minvat Ecover - a fireproof vapor-permeable insulation

Therefore, the following materials are usually used for aerated concrete walls:

- Minvatu... It is a fibrous insulation in the form of slabs (mats) made from molten rocks. Basalt mineral insulation is most often used, since it has the highest technical characteristics.

Thermal conductivity of basalt mineral wool is 0.055 to 0.11 W / m * K;

Ecowool - cellulose-based insulation

- Ecowool (cellulose wool)... It is a cellulose cotton wool with all kinds of chemical additives that increase the fire resistance and biostability of the insulation. Ecowool is applied to the surface wet using special equipment. Therefore, it will not work to insulate the walls on your own with its help.

The thermal conductivity of this material is 0.032-0.041 W / m * K.

I must say that, in principle, it is possible to use vapor-proof heat-insulating materials, such as polystyrene or penoplex. However, in this case, it is necessary to carefully vaporize the walls from the inside.

Materials for internal thermal insulation

Internal thermal insulation can only be used as a supplement to the external one or if it is not possible to insulate the house from the outside. For example, in a similar way, you can insulate a balcony or loggia. The fact is that after warming the house from the inside, the walls will no longer be heated, which will lead to a number of negative consequences.

As for the choice of heat-insulating materials, both vapor-permeable and non-vapor-permeable heaters can be used. The only thing, in the case of using vapor-tight insulation, the house will lose its ability to "breathe" and turn into a kind of thermos. Therefore, you will have to provide high-quality ventilation.

Foam plastic has low thermal conductivity and low weight

Varieties of foam concrete

Foam blocks are distinguished by density. So, the heat-insulating block has a lower density than that of the D400 brand, therefore it is used for laying heat-insulating communications in rooms for various purposes.

The structural and thermal insulation block has an intermediate density between the D500 and D900 grades. Used for the construction of structural elements of a building.

The structural unit has a density between D900 and D1200 grades. It acts as one of the most durable materials, which is clearly evidenced by its high cost. Bearing ceilings are often constructed from it, interior partitions are installed.

Types and characteristics of foam blocks (standard sizes and weight)

Foam concrete blocks, the sizes and prices of which fit into several classes, are subdivided depending on their density (the number of air cavities per unit volume) and purpose. The fewer the pores, the higher the density, thermal conductivity, strength and dimension of the brand.

- Construction blocks. D1000-D1200 grades are used for load-bearing structures. Such blocks take on the weight of the floors, the next floor and the roof. They have maximum strength and weight.

- Combined blocks (structural and thermal insulation). D600-D900 grades are suitable for load-bearing structures and effective thermal insulation in private construction.

- Heat insulating... Lightweight blocks with maximum thermal insulation, suitable for internal partitions. The grades used are D100-D500.

The standard size of a foam block for building a house has several options. For external load-bearing walls, a standard wall block with a size of 600x300x200 or 600x400x200 mm is most often used, for internal load-bearing walls - 300x200x600 mm, partitions are laid using blocks of 100x300x600 mm. The spread is associated with the peculiarities of the formation of different types of masonry. The weight of the blocks depends on the brand (it differs for blocks of the same size, but different brands).

Evgeny Filimonov

Ask a Question

It is important to understand that over time, under the influence of weather conditions, the weight of foam blocks will inevitably increase. This is taken into account when designing the foundation.

There are tables in which you can track the change in weight depending on humidity. The weight of the wall unit (with an initial weight of 10.8 to 43.2 kg) can vary from 11.7 to 47.5 kg (at a relative humidity of 75%).

Characteristics of a foam concrete house

When using foam concrete blocks for the construction of houses, it is envisaged to lay out single-layer walls. The idea of creating such materials, including the provision of thermal insulation of the home with little effort. They reliably retain heat in the house, but this is not the only argument in favor of choosing foam concrete for construction.

The advantages of this building material:

- The cost of a foam block is much less than a brick.

- The walls do not freeze through, due to which the life of the house is longer.

- No fungal infections or molds occur.

It must be admitted that the foam block still has a drawback, not too high strength of the building built from it. But this problem is solved with the help of reinforcement. The steel frame balances the load, which makes it possible not to worry about the integrity of the house. However, when working with a facade made of foam blocks, it is necessary to avoid excessive weighting of the structure. Important! Wall cladding with heavy materials, for example, stone, or the installation of a curtain or "wet" facade can lead to a violation of the integrity of the structure of the foam block.

Internal insulation technologies

There are two ways to insulate the walls from the inside, as well as from the outside:

- Wet method;

- For dry plastering;

Next, I will briefly talk about the nuances of both technologies.

Wet insulation

The principle of insulation by the wet method practically does not differ from external insulation using the technology of a wet facade. The only thing, after the insulation is reinforced with glue, the surface is covered not with decorative plaster, but with putty. Plastered walls can be covered with any finishing material, be it wallpaper, paint, tiles or even decorative stone.

From the inside, the house can be pasted over with styrofoam or styrofoam

For wet finishing, you can use any plate heat-insulating materials, such as mineral wool, polystyrene or polystyrene foam.

Insulation under dry plaster

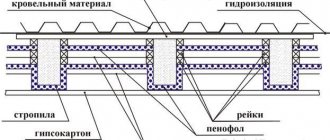

Dry plaster is called drywall, which is mounted on a frame. Thermal insulation by the frame method also resembles the thermal insulation of the facade - a frame is mounted on the walls, the space of which is filled with insulation.

The only thing is that outside between the drywall and the insulation, it is necessary to place a vapor barrier membrane or penofol so that the insulation does not get wet, especially for mineral wool. The fact is that its vapor permeability is much higher than the vapor permeability of foam concrete.

Pros of foam concrete blocks

The main advantage of foam blocks is that they do not contribute to the formation of condensation, which usually appears in the middle of the insulation.

These negative manifestations lead to significant heat loss and an increase in indoor humidity.

After which, ultimately, the plaster peels off and mold appears on the interior decoration.

The construction of external walls from foam blocks provides building owners with the technical opportunity to increase thermal efficiency without complications and violations of sanitary standards.