The scope of application of polyurethane foam boards (PPU boards) is construction. Plates are used as a heat-insulating material in construction, as well as in the decoration of buildings and premises. In addition, polyurethane foam boards are actively used for the insulation of automobile refrigerators.

The use of rigid thermal insulation in the form of PPU slabs with high-quality insulation of walls, roofs, facades, foundations, refrigerators and houses can significantly reduce the thickness of the insulating layer, therefore, increase the usable area. This quality is especially valuable where there is a lack of free space or where every centimeter of area is valued especially highly. In other words, it is advisable to use polyurethane foam insulation boards where other insulating materials with a significantly greater thickness cannot be used.

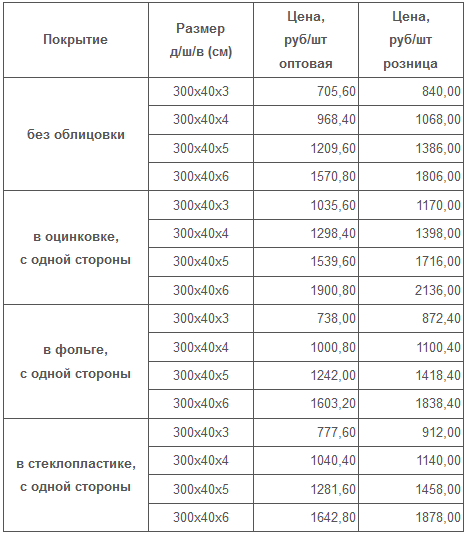

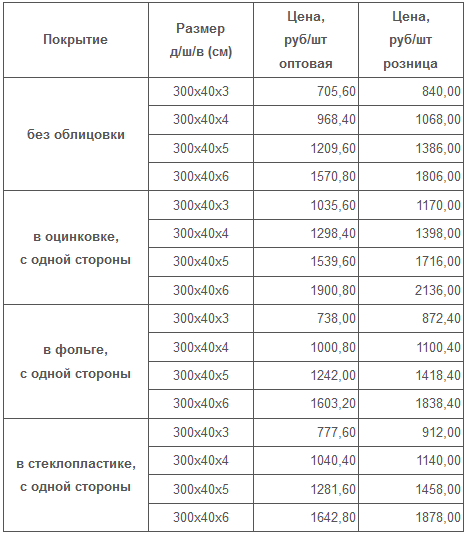

The cost of polyurethane foam (PPU) boards

The standard dimensions of the slabs are 300 * 40 cm, but other parameters are also possible. The ends of the material can be made in a quarter so that their joining is of the highest quality and reliability.

We are ready to provide discounts on PPU boards depending on the purchased volume.

As a thermotherapy, including a decorative function, we suggest that you consider decorative boards with imitation of wood texture. Facade decorative panels with imitation of wood can be used indoors and outdoors.

You can familiarize yourself with the prices for facade decorative thermal panels with wood imitation in the price list, with their outward appearance in the product catalog in the "Decorative boards" section.

The popularity of rigid polyurethane foam, which is the basis of polyurethane foam insulation boards, is due to its unique hydro-, sound- and heat-insulating qualities, as well as resistance to decay processes, fungus formation, aging and aggressive external climatic conditions. In addition, the advantages of PPU boards include simple material processing. These products are easy to saw, drill and cut. Another undoubted advantage is the ability to dismantle the PU foam boards and reuse them at another facility.

The standard dimensions of polyurethane foam insulation boards produced by the manufacturing enterprise are 40 cm in width, 300 cm in length and 25-100 mm in thickness.

It is possible to manufacture polyurethane foam boards with an additional coating of fiberglass or foil, as well as painted thermal insulation boards. Additional surface treatment of the insulating material makes it UV resistant.

Applications of polyurethane foam

Polyurethane foam is produced by two main methods:

- spraying with the help of special polyurethane foam equipment on the surface directly on the object;

- pouring on equipment for the production of polyurethane foam in the production of molded products in the workshop.

Polyurethane products have a wide range of applications: automotive, furniture and design industry, building renovation, waterproofing and thermal insulation of building envelopes, insulation of refrigeration equipment, insulated vans and much more.

More about the production methods of polyurethane foam:

- PPU spraying technology

- Polyurethane foam filling technology

|

|

| Thermal insulation | Furniture decor |

|

|

| Architectural decor | Furniture manufacturing |

Scopes of polyurethane foam:

- Construction of pre-fabricated industrial and civil facilities (sandwich structures);

- Construction and overhaul of residential buildings, individual houses, cottages (insulation of external walls, foundations, internal insulation of the roof, window openings, doors, etc.);

- Industrial and civil construction (external heat and waterproofing of roofs with rigid sprayed polyurethane foam);

- Pipeline transport (thermal insulation of fuel and oil pipelines, highly efficient insulation of low-temperature pipelines at chemical facilities under a pre-assembled casing);

- Heating networks of settlements (thermal insulation of hot water supply pipelines by pouring polyurethane foam during new laying or during major repairs);

- Refrigeration equipment (heat and cold insulation of household and commercial refrigerators and freezers, warehouses for food and agricultural products);

- Transport refrigeration equipment (thermal insulation of refrigerated trucks, railway refrigerated cars of the "thermos" type);

- Radio and electrical engineering (imparting vibration resistance to various electrical devices, hydraulic protection of contact connections);

- Automotive industry (molded parts of the interior of a car based on elastic, semi-rigid, integral, thermoformed polyurethane foams);

- Furniture industry (production of upholstered furniture (foam rubber), cabinet and decorative elements made of hard polyurethane, varnishes, glue, coatings, etc.);

- Light industry (production of synthetic leather and products, duplicated fabrics, etc.);

- Car building and aircraft building (molded elastic products with increased fire resistance, noise and heat insulation based on special grades of raw materials);

- Mechanical engineering (products made of thermoplastic polyurethanes, as well as special grades of PU and polyurethane foam).

Much of the above can be obtained with the help of modern polyurethane foam equipment from NST: installations for spraying polyurethane foam and equipment for pouring polyurethane foam.

We are ready to transfer the technology to you, install and set up equipment for the production of polyurethane foam, help you select the necessary raw materials: components for pouring and components for spraying polyurethane foam, equip with knowledge and skills, in a word, do everything so that you can set up your own production.

|

| FOAM series equipment certificate for polyurethane foam |

Physical and mechanical properties of rigid polyurethane foams:

| Parameter name | Value |

| Apparent density, kg / m3 | 30-100 |

| Breaking stress in compression, mPa | 0,15-1,2 |

| Breaking stress on bending, mPa | 0,2-1,3 |

| Thermal conductivity coefficient, W / m ° С | 0,020-0,035 |

| Water absorption in 7 days,% vol. | no more than 3.0 |

PPU products and chemical compounds:

| Name | Reaction |

| Sea water, soapy foam | Racks |

| Benzene, toluene, xylene, gasoline, kerosene | Racks |

| Vegetable oils and animal fats | Racks |

| Concentrated KOH solution | Racks |

| Methylene chloride, carbon tetrachloride | Swells |

| Alcohol, acetone, styrene, ethyl acetate | Swells |

| Concentrated hydrochloric acid | Swells |

| Concentrated sulfuric, nitric acids | Dissolves |

Advantages of polyurethane foam as insulation

Polyurethane foam is considered one of the best insulation materials due to a set of high installation and performance properties. The structure of polyurethane foam is cellular, gas-filled up to 90%. It provides the insulation with a low weight, eliminating excessive stress on the thermally insulated object.

The solidified polymer has a thermal conductivity of 0.020-0.035 W / (m · K), which is better than the indicator of mineral wool and gas glass. Unlike expanded polystyrene, such products are resistant to all chemical environments, moisture, and external factors. Polymerization prevents the corrosion process, therefore the pipeline system insulated with polyurethane foam does not rust. Moreover, its moisture absorption is extremely low.

From the point of view of fire safety, this polymer has no equal. The material is non-flammable, self-extinguishing, does not spread smoke.According to environmental standards, it is completely harmless. Insulation serves for at least 30 years.

Due to the high adhesive strength, there is no need to use fasteners or adhesives - the polyurethane foam sprayed with the help of special equipment adheres securely to the surface. At the same time, you can thermally insulate a surface of any geometric shape, slope and size.

Polyurethane foams also provide high acoustic insulation, therefore, they can simultaneously be used as sound protection.

The customer can independently choose a system of liquid components, on which the density of the finished polyurethane foam insulation layer depends.

Foamed polyurethane is used for thermal insulation of industrial and civil objects made of reinforced concrete products, bricks, foam and gas blocks, wood, metal and other materials. Due to the seamless application of the composition, there are no so-called cold bridges through which heat escapes from the room.

Application of polyurethane foam boards

- Roof insulation.

- Wall insulation (applied before finishing cladding).

- Thermal insulation of internal and external enclosing structural elements.

- Insulation of basements and foundations.

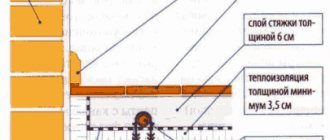

- Insulation of the floor and interfloor floors.

- Construction of ventilation ducts.

Specifications

The plates obtained from liquid polyurethane have good technical characteristics for insulation:

- thermal conductivity coefficient - 0.028-0.030 W / (m × ° K);

- density - 40-160 kg / m3;

- vapor permeability - 0.02-0.05 mg / (m * h * Pa);

- compressive strength to fracture - 200 kPa or more;

- ultimate bending strength at fracture - not less than 300 kPa;

- water absorption at full immersion in water for 24 hours - 1-1.5%.

These characteristics require comments, especially the thermal conductivity coefficient.

The thing is that some of the manufacturers on their websites post fantastically low thermal conductivity values - 0.017-0.025 W / (m × ° K). Where such figures come from is not explained. However, if you go headlong into the specialized literature, it turns out that only in laboratory conditions it is possible to obtain a material with a thermal conductivity of 0.022 W / (m × ° K).

And this is subject to all parameters, from the recipe to the temperature regime. And another very important point that passes by the attention - the density of the prototypes was 28-30 kg / m3. PPU slabs have an average density of 50-70 kg / m3. And even from school physics lessons it is known that denser bodies conduct heat better.

But that's not all. Record low values of the thermal conductivity coefficient are achieved only when using freon r141b for foaming. But it is banned for use on an industrial scale, and its production is generally prohibited in Europe. Other types of foaming agents give higher thermal conductivity values.

Therefore, in European countries, insulation with a coefficient of 0.028 W / (m × ° K) is considered to be of the highest quality. With regard to Russia, the value of the thermal conductivity of PPU boards 0.028-0.032 W / (m × ° K) is real and this is the best thermal insulation properties among all types of heaters presented in the trade.

Features of polyurethane foam (PUR and PIR) thermal insulation

In recent years, interest in the construction of energy efficient houses has increased among domestic developers. Affected by the constant rise in energy prices and the desire to reduce heating costs. One of the basic foundations of such construction is the choice of the best way to insulate the foundation, walls and roof.

The modern construction market offers many insulation materials. Along with the well-known species, new types have appeared. This is polyurethane foam (PUR and PIR) thermal insulation. Therefore, within the framework of this article, with the help of specialists from the National Association of PU Foam Panel Manufacturers (NAPPAN), we will answer the following questions:

- What is PUR and PIR insulation.

- What is a sandwich panel with PIR and PUR - insulation.

- Where can you use sandwich panels and PIR - thermal insulation.

Differences between PUR and PIR thermal insulation

Before talking about the technical features of PUR and PIR thermal insulation, you need to understand what requirements professional builders are guided by when erecting energy-efficient cottages and commercial buildings. Key parameters include: speed, quality of work performed, optimization of all technological processes, high thermal performance of the structure, environmental friendliness and durability.

It follows from this that a material is needed to insulate a house, which, along with a high heat-insulating ability, strength and ease of use, has a long service life (durability). Those. retains its thermal insulation properties during the entire period of operation of the building. Based on these requirements, the key parameter that affects the characteristics of any insulation is the material from which it is made. Let's consider the properties of PUR and PIR thermal insulation.

Alexey Gorokhov Executive Director of the Association "NAPPAN"

Polyurethane foam (PUR) and polyisocyanurate (PIR) are two related classes of closed cell polymers. The cells are filled with a foaming agent (gas) with a low degree of thermal conductivity (0.022 W / m * K). This is lower than the thermal conductivity of air (0.025 W / m * K).

Because the system of closed spherical cells in the material is closed, then it does not release gas, therefore, and also due to the use of vapor-waterproof facings, the insulation does not lose its high heat-insulating properties over time.

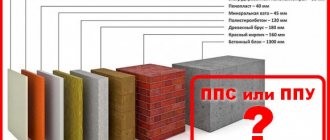

For clarity, let's compare the coefficient of thermal conductivity of polyurethane foam with other thermal insulation materials.

Alexey Gorokhov

Some manufacturers, due to the use of various technological features, achieve even lower thermal conductivity values than 0.022 W / m * K.

Due to the peculiarities of production, as well as the use of vapor-tight facings (most often - foil), this indicator of thermal conductivity remains throughout the entire period of operation of the insulation. Therefore, to ensure the same characteristics of thermal protection of the building requires a thinner layer of PIR insulation than other heaters.

This feature is of great importance when insulating a room from the inside (we do not increase the thickness of the insulation, which means we save the usable area of the room). In the case of thermal insulation of the floor (the distance to the ceiling is limited) or balcony (a small area of the room, so there is no way to build up a layer of insulation). In addition, thanks to the use of a thinner material, we save money on delivery and material consumption of the buildings being erected. Because on the walls, in order to achieve the normalized value of the thermal resistance of the enclosing structure (depending on the region of construction), a layer of insulation of lower weight and thickness is mounted.

It should be noted that since the production of synthetic fibers from polyol and isocyanate products by the German chemist-technologist Otto Bayer in 1937, polyurethane foam has long and firmly taken its place in our life. Polyurethanes are used in medical, civil, aerospace and defense industries. Therefore, we can say that extensive practical experience has been accumulated, confirming the ability of the material to maintain low thermal conductivity for a long period of time (40 years or more).

Burmistrov Roman Expert of the "NAPPAN" Association. Representative of the manufacturer of PIR thermal insulation boards

Polyurethanes are widely used in the production of car interiors, office furniture, mattresses and upholstered furniture, pillows, shoes, adhesives and sealants, floor coverings.

It should also be noted that the main feature of the insulation based on polyisocyanurate (PIR), — is an thermosetting polymer... Those. when the polymer is exposed to fire, a porous carbon matrix is formed (carbonization and coking of the outer surface of the insulation occurs), which prevents the combustion of the inner layers of the polymer and, accordingly, the spread of fire.

The main difference between PUR and PIR is that PIR is a more fire-resistant version of PUR.

This provides high fire-technical performance of both the material itself (flammability group G1) and the structures where it is used. In the case of using heaters in structures, indicators K0 - K1 are achieved according to the class of constructive fire hazard, in the case of using sandwich panels - K1. Those. according to its indicators, the material occupies an average niche between mineral wool (NG, K0) and expanded polystyrene (G3-G4, K0-K3). These indicators are especially relevant in the construction of roofs.

Burmistrov Roman

Unlike the option of using polystyrene, when installing roofing systems of any area using PIR plates, a fire protection device is not required.

Interesting fact: PIR is also used for thermal insulation of tanks for launch vehicles, in armored vehicles, because in the event of incendiary shells hitting the machine, the material is instantly coked, which prevents the spread of the flame.

Also, the material has high strength characteristics. This is especially important in the case of using PIR for insulating flat roofs, because the rigidity of the base is a key parameter for maintaining the performance of waterproofing roofing material.

Burmistrov Roman

The durability of a waterproofing carpet is 80% determined by the rigidity of its base.

The use of improperly selected thermal insulation materials, which during operation lose their performance characteristics (including rigidity), leads to an inevitable reduction in the service life of the entire roofing system.

Alexey Gorokhov

In Europe there is a special term walkability, which means the ability of thermal insulation to withstand periodically occurring alternating loads. According to this indicator, PIR is significantly ahead of mineral wool insulation, which ensures an increase in the service life of the roof.

It should also be noted the moisture resistance of PUR and PIR thermal insulation and the ability to maintain their geometric dimensions and uniformity. These are important parameters because when the insulation is oversaturated with water, the coefficient of thermal conductivity of the material increases, which ultimately leads to a decrease in the thermal resistance of the enclosing structure. And if the insulation shrinks over time (loses its rigidity and bearing capacity), as is often the case with fibrous materials, and slides down, then the upper part of the enclosing structures in the case of sandwich panels will remain without insulation at all.

In addition, fully cured polyisocyanurate is a chemically stable and inert material that practically does not lose its mechanical and thermophysical properties over time. The material does not rot, moisture resistant, does not decompose, is not affected by rodents, is chemically stable and safe for the environment.

Sandwich panel with PIR and PUR - insulation

Sandwich panels with PIR and PUR insulation are a three-layer composite building material, each layer of which has a specific function.

Fausto Baldino Expert of the "NAPPAN" Association. Representative of the manufacturer of PIR and PUR sandwich panels

Between the two layers of the sandwich panel, there is a layer of insulation, which can be polyurethane foam (PUR) or polyisocyanurate foam (PIR).

Profiled or flat steel sheets can be used as insulation cladding, i.e. a sandwich panel is at the same time a heat-insulating and structural material that conserves heat and serves as an external and internal cladding that does not require finishing.

Because sandwich panels are manufactured under industrial conditions, they have clearly defined geometric dimensions, which speeds up the process of building a building. The panels themselves are relatively lightweight. This reduces the load on the foundation, reduces transport costs and simplifies all technological operations. If necessary, the building made of sandwich panels can be dismantled and transported to another location. Also, there is no debris on the construction site.

Fausto Baldino

During installation, sandwich panels are connected to a metal, reinforced concrete or wooden frame, open or hidden fastening system.

Sandwich panels can be used as enclosing and self-supporting structures in the construction of buildings and structures by frame-panel method, or as facing material in the reconstruction of facades. Also, sandwich panels can serve as sound and heat insulating partitions in commercial and industrial buildings.

Alexey Gorokhov

Unlike other heat-insulating materials, PIR was initially used only in sandwich panels and only then began to be used as a heat-insulating material in the form of a slab.

It is necessary to focus on the peculiarities of the production of sandwich panels and PIR insulation. The technological process requires that polyurethane foam is sprayed between two linings, and since there is no gluing (polyurethane has increased adhesion to facings), a strong connection is obtained. In the case of sandwich panels, a metal sheet is used as cladding, and in the case of PIR panels, there are many options. By combining different options for the substrate (using fiberglass, foil, etc.), we get a material with different properties and areas of application.

For example, there is a lining with a flame retardant coating (graphite) that expands when exposed to flame. Or - fiberglass (for insulation of external walls according to the "wet facade" system), as well as a special coating for fusing the waterproofing with a fire method.

Another important nuance is the presence of a thorn-groove locking connection.

Fausto Baldino

Thorn-groove locks, labyrinth and groove joints of sandwich panels ensure the creation of a continuous surface, increase the bearing capacity and resistance to loads. This greatly speeds up and simplifies the process of assembling structures.

Alexey Gorokhov

When constructing an energy efficient building, it is important to provide a closed thermal insulation loop and remove all cold bridges. When connecting "thorn-groove" in the case of using polyurethane foam insulation (PUR, PIR), the panels are connected "by foam".

For example, for thermal insulation of pitched roofs, the castle joint, coupled with high strength characteristics, allows you to perform thermal insulation of the roof over the sheathing, which allows you to completely get rid of cold bridges (wood has a sufficiently high thermal conductivity).

Summarizing

Features of the material determine the scope of its application. Sandwich panels and PIR thermal insulation have zero moisture absorption, are durable and durable, and allow you to quickly erect energy-efficient buildings. If the main area of application of sandwich panels is commercial and industrial construction, then in the case of thermal insulation boards based on PIR (they are also called panels in soft cladding), this is the construction of roofs (both flat and pitched). Also, the plates are used for insulation of external and internal enclosing structures, floors, walls in saunas, balconies. In addition, sinceproduction of sandwich panels and PIR thermal insulation is possible only in high-tech and expensive production, the likelihood of product counterfeiting is excluded.

The material was prepared with the participation of specialists from the Association "NAPPAN".

In the FORUMHOUSE topic, you can take part in the discussion of PIR - thermal insulation. We also recommend watching a video about building an energy efficient house according to passive house building standards.