When arranging flue gas ducts, many details must be taken into account. Including, and solve the issue of high-quality insulation. Its absence can lead to premature destruction of the chimney.

In this article, you will learn how and how to insulate an iron chimney pipe in a garage, bathhouse, private house or any other room. We will consider all the important aspects of solving this problem.

Why is the gas duct deteriorating?

The lack of insulation negatively affects the condition of the chimneys. To avoid premature failure of the smoke exhaust system, it is imperative to resolve this issue.

The main causes of breakdowns are associated with:

- Exposure to aggressive substances. When the fuel burns out, there is a large volume of elements that negatively affect the metal. First of all, these include acids. During the downtime of the chimney, aggressive substances settle on the walls of the chimney. This leads to the destruction of metal structures.

- Humidity. High humidity is present in the flue. Although water vapor escapes along with the smoke, a fairly large volume of condensate still remains on the walls of the structures.

Thermal insulation of the gas duct can prevent the occurrence of negative chemical processes that lead to the destruction of the system. If you do not take action, the condensate containing acids will damage the walls of the structure over time. The most dangerous period is the thawing period of the flue after winter.

https://youtu.be/kwVI1o6778Y

What causes the chimney to deteriorate

The made thermal insulation of the chimney does not always guarantee its long service life; it will fully meet all your expectations. Quite often, when making insulation with your own hands, pipes can soon begin to collapse, lose their tightness, and deform. There are certain reasons for this, with the most common of which you can familiarize yourself with below:

- Even basalt insulation for a chimney, in the event of an incorrect location of the pipe itself, violations of the laying process, may become unusable. In this case. Increased dampness occurs in the system. Excessive humidity is caused by the deposition of warm air masses on the inner surface of the system, which in turn form condensate, which leads to destruction;

- Not knowing how to insulate the chimney, it is important to remember that in the process of using a heating unit operating on solid fuel, various sulfuric, carbonic, nitric acids act on the surface, materials, which can also cause destruction. This is especially true if you use a fireplace or stove irregularly, with long downtime.

The metal chimney system can be installed even in a wooden house

Correct conclusion and fastening of the pipe when passing through the brick wall of the house

We suggest that you familiarize yourself with: Do-it-yourself brush for cleaning the chimney pipe

The importance of insulation

The creation of high-quality insulation of furnace or other round flue pipes is an important preventive process. Of course, this procedure will not 100% protect the structure from the negative effects of rain and other atmospheric precipitation. However, insulation of metal gas ducts can significantly extend the service life of all systems.

This operation must be carried out in order to:

- Eliminate the possibility of condensate entering the walls of pipe products, which contains hazardous chemical elements.The presence of an insulating layer will ensure their complete volatilization along with the rest of the smoke.

- Reduce the likelihood of temperature changes in the system.

- Create an energy saving effect. Arrangement of insulation reduces the rate of energy losses. The presence of this layer reduces the fuel consumption of boilers or furnaces.

- Increasing the durability of the gas duct. Insulating steel pipes helps to strengthen the structure of the flue system. The frame becomes more resistant to wind loads.

It is important to choose the right material for insulation. Only in this case can the system's resistance to low temperatures be significantly increased. Also, with its help, you can eliminate the negative impact on the roof in the form of corrugated board or slate. These preventive measures will extend the life of the chimney.

Insulation of a metal chimney in a stove or fireplace

The process of insulating metal chimney pipes in a private house begins with the selection of the necessary heat-retaining material. The main characteristics that the insulation must meet:

- Resistance to high temperature impact and drops. The material must be both frost-resistant and non-combustible, withstanding up to -35 degrees on the outside (for example, on a frosty night outside) and up to 300 degrees on the inside.

- Relative lightness. As in the case of carbon deposits, the applied insulation should not overload the pipe structure and worsen its stability. Also, you should not allow its weight to strongly "press" on the roof or other roof material.

We suggest that you familiarize yourself with How best to insulate a bath from the outside or from the inside

Mineral wool - a common insulation for chimney pipes

It is equally important to select the material (including its composition, shape and dimensions) in such a way that it matches the design and type of the chimney itself, otherwise it will be fraught with difficulties in its installation (application).

Having specified the quality characteristics of heat-retaining materials we need, we will consider a number of them that can most often be found on sale via the Internet in construction markets or in hypermarkets:

- Construction plaster. A relatively cheap material that allows you to reduce heat loss by about 25-30%. The disadvantages include the weighting of the structure from additional retaining elements.

- Mineral wool. Such insulation is the least susceptible to thermal effects and is resistant to toxic smoke fumes generated during operation. Cotton is used to cover both indoor pipe elements and those that go outside. The filler of the coating differs in fiber, fiber length and viscosity (thickness). On sale you can find cotton wool with 4 types of filler: fiberglass, stone chips, basalt and slag. The advantages include its high temperature resistance and environmental friendliness.

- Cylindrical "sandwich" heat insulator. Its undoubted advantage is ease of installation, since it is sold already in "finished form" for various diameters of the outlet pipe. The design includes cylindrical stainless steel rolled metal, in which a light mineral wool filler is laid, for example, basalt, with a longitudinal hole in the center for the pipe diameter.

- Extruded polystyrene foam or EPS. A durable waterproof material that is used for external thermal insulation of stone and brick chimneys. It is sold in the form of plates, subdivided into classes, depending on heat resistance (or flammability). The coefficient is considered from 1 to 4, where the first two are the most heat-resistant and can withstand gas temperatures up to 500 degrees at the exit from the pipe.

- Stainless steel casing.Just like the "sandwich" cylinder, a stainless steel casing is put on the outer elements of the pipe, filling the space between it and the pipe with mineral fiber or asbestos, closing the top with cement mortar from moisture and combustible particles flying out along with the smoke.

- Wood. In order to save money, the material of the "cylinder", or rather, in this case, the outer box, can serve as a tree. It is made of panels knocked together at right angles so that 15-17 cm remain between them and the pipe. This space is then laid and sealed with a suitable heat insulator.

The cylindrical "sandwich" heat insulator is easy to use

When organizing chimneys for gas heating boilers, sandwich-type pipes have recently been used quite often. This is not only convenient, but also quite effective, because condensate does not accumulate inside the chimney, and heat loss is significantly reduced.

When passing through the boiler pipe, heated gases lose their temperature, giving off part of their own heat to the walls of the structure. But at the same time, the gas must be discharged outside.

The quality of draft largely depends on the temperature of the walls of the chimney. With insufficient draft, there is a possibility of smoke in the room and even poisoning with waste combustion products.

The efficiency of the removal of combustion products, in other words, the quality of traction, depends on the speed of overcoming the moment of condensation formation. This indicator is largely determined by the material from which the chimney is made.

In the insulated chimney, the moment of condensation formation is reduced and the quality of draft improves

If a stainless or galvanized steel pipe is used as a chimney, then the period of condensation formation lasts for 2-3 minutes, but a standard brick chimney needs much more time - about half an hour.

At the moment the condensate appears and until it disappears, water is actively mixed with the combustion products, as a result of the reaction, an acid solution appears. It is this acid that has a negative effect on the pipe, causing its destruction.

If an asbestos pipe or brickwork is used as a chimney, then the residual condensate can be absorbed into their walls. In the absence of high-quality insulation, the accumulated moisture will freeze and destroy the chimney.

If you qualitatively insulate the chimney from a gas boiler, then you can identify a considerable number of advantages. The main ones are:

- Reducing the influence of atmospheric precipitation;

- Reducing heat loss during the heating season;

- Improving traction quality;

- Presentable appearance of the chimney;

- Reducing the volume of condensate that forms on the outside of the chimney.

Taking into account the above advantages, it is obvious that insulating the pipe of a gas boiler is simply necessary. For work, various heaters can be used, each of which differs not only in physical characteristics, but also in the features of the work.

Which material should you choose?

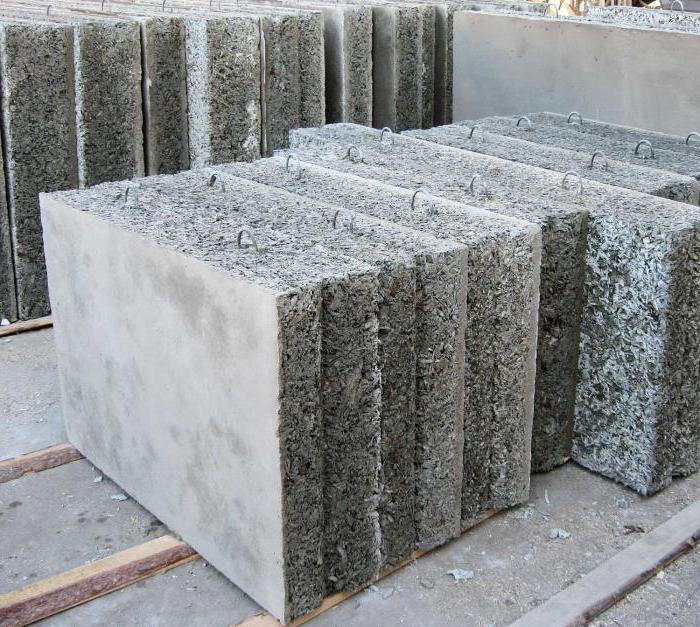

In order to insulate the steel pipe of the gas duct, it is necessary to take into account that the temperature of its heating can reach three hundred or more degrees. To do this, you need to use a material that is completely devoid of flammability. For this purpose, as a rule, mineral wool, slag concrete slabs or other analogs are used. In addition, the insulation process can be carried out by using a plastering solution.

It is important that the weight of the insulation material is comparable to the supporting capacity of the roof. Since items that are too heavy can damage it.

Most experts prefer mineral wool.It is lightweight and therefore ideal for this task.

You can also purchase special cylindrical heaters. They provide an adequate level of protection for the chimney. Since their construction has a protective foil layer. The sizes of the products under consideration are different. Therefore, you can easily choose an option for a pipe of the required diameter.

Thermal insulation options

Before starting work, you need to decide on the insulation material. You can use almost any, you just have to take into account that the chimney heats up to high temperatures, which means that the insulation must be heat-resistant and non-combustible.

- Mineral, basalt or glass wool. Most commonly used material. Sold in mats or in rolls. The material is non-flammable, has good thermal insulation properties, and often has an additional waterproofing layer in the form of a thick film. It should be borne in mind that when wet, cotton wool loses most of its thermal insulation properties and gradually collapses. In the open air, the structure should be protected by a casing made of metal or other material.

Basalt wool is sold in rolls or in the form of mats and may have a waterproofing film on the outer surface - Loose insulation. This is broken brick, expanded clay, sand and other materials. In this case, you also cannot do without a casing. It is built around the chimney, the free space is filled with insulation. Keeps warm well, cheap.

Expanded clay is poured into a casing, which is built around the chimney - Metallic foil. Shields heat and cold, reducing temperature differences. It is used as an additional layer with fibrous insulation.

- Ready-made cylindrical insulation with a foil screen. It has a different diameter, which greatly facilitates the solution of the problem of thermal insulation. The insulation is put on the pipe and fixed with clamps or construction tape.

Cylindrical insulation is matched to the diameter of the chimney pipe - Slag concrete slabs. Most often they are used for thermal insulation of brick pipes. Plates are attached to the walls of the structure, after which they are covered with plaster mortar.

Slag concrete slabs are used to insulate brick chimneys - Plaster mortar. Prepared from special heat-resistant mixtures. For greater efficiency, the solution is applied in three layers, each next thicker than the previous one. For effective insulation, the thickness of the plaster must be at least 4 cm. It is applied to a reinforcing mesh that serves as a frame.

It is not recommended to use polystyrene for thermal insulation of chimneys because of its flammability.

The choice of insulation method depends largely on the material of the chimney. It is also necessary to take into account the strength of the structure on which the structure will be installed. Heavy insulation can push the ceiling over time and cause it to deform.

Video: professional advice on choosing fiber insulation

https://youtu.be/WMqJuB_BwTs

How to insulate a gas duct with your own hands?

To insulate a steel pipe, it is necessary that the installation of the chimney is carried out correctly. The design must comply with existing technological standards.

The following requirements are imposed on gas ducts:

- A sufficient level of thrust occurs only for pipes with a length of five or more meters.

- The distance between the chimney structure and the roof must be at least 25 cm.

- If the roof is made of combustible materials such as ondulin, roofing felt or slate, the pipes must be equipped with a spark arrestor. Its design consists of a mesh plate that surrounds the gas duct from above. To prevent debris from getting into the spark arrester, it is closed with a special cap.

To equip the flue, be sure to observe the indicator of the fire distance between the ceiling of the room and the stove ceiling. For stainless steel structures, a distance of 1.5 meters is required.

To complete the winding of metal chimney pipes, a system diagnostic stage is required. If there are no faults, then you can start solving the problem. Use only non-combustible insulation.

Insulation of chimneys made of steel

For steel chimneys, other materials and other installation technology are used. If you want to make a chimney according to all the canons of modern fashion, then stainless steel pipes are the best choice. This material has several advantages.

It heats up very quickly, is multifunctional and does not corrode.

An excellent solution is the installation of prefabricated sandwich-type chimneys. This design is easy and quick to install, which saves on specialist services. The minimum service life of a sandwich chimney is 10 years. Such chimneys are usually equipped with mineral wool as insulation, which is located between two stainless steel pipes. The cost of sandwich systems is quite high, this is justified by the simplicity of their assembly and the quality of the materials used. In this case, the thermal insulation of the chimney will be very good.

The stainless steel chimney can be insulated with your own hands. However, the savings in this case becomes questionable, because pipes made of "stainless steel" must be selected in accordance with GOST, and according to their thickness, choose a heater. If you add to this factor the time spent, the services of auxiliary workers and welders, you will hardly be able to save money. That being said, the quality is likely to be worse. Materials and tools are used in a similar way to insulation using asbestos cement.

Chimney and chimney wrapping

To equip decorative stoves that do not serve as a source of heat, metal pipes are often used. Isolating them is easy. For this purpose, it will be sufficient to use a plaster mortar.

The required mixture is prepared according to a specific technology. First, water is poured into a special container. Then add the previously prepared dry mixture. Next, you need to mix these ingredients until a homogeneous mass is obtained.

With this solution, you need to isolate the surface of the structure by using a spatula.

It is distributed evenly over the entire length of the canal. Next, you need to create a fiberglass reinforcement mesh. Only in this way can the protective layer last a long time.

Next, plaster is applied to the reinforcing frame. Then the operation is repeated. Thus, the pipe receives reliable protection. Alternatively, you can use mineral wool. It is fixed with masking tape.

The main thing is that moisture does not get on the surface of the insulation. Otherwise, the material will lose its protective properties.

Materials and features of insulation

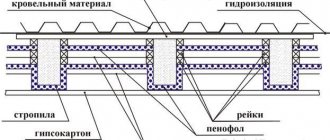

For home craftsmen who have made the decision to insulate the chimney with their own hands, the approach to implementing this idea depends on what the chimney is made of. But in any case, it is necessary to ensure the sealing of the outlet of the smoke channel through the roof. The following types of thermal insulation for chimney pipes cope best with this task:

- mineral wool;

- kaolin (asbestos) slabs;

- roll filters.

For waterproofing, mullite silica slabs are used. The advantages of this material include its ability to withstand significant temperature changes, flexibility, strength, and the fact that it is not flammable.

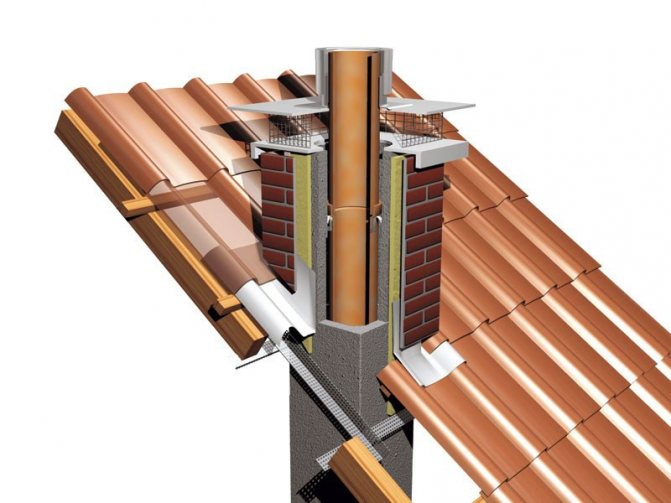

Insulation of the flue made of stainless steel. In order to prevent the roofing material from igniting due to the high temperature of the furnace gases, the passage of the pipe through the roof requires the use of additional safety measures. Contact of the roof elements with the chimney is prohibited. The passage of the pipe through the roof is hidden with a metal collar, and the free space is filled with insulation for the chimney pipe made of non-combustible material.

Steel chimneys are most often insulated with fibrous materials such as mineral wool shells

Glass wool, basalt wool or expanded clay are used for thermal insulation of a stainless steel chimney. If the design of the flue gas exhaust system has a circular cross-section, a metal pipe is additionally used for thermal insulation.

In general, the procedure for insulating a stainless steel chimney looks very simple:

- a metal pipe is installed on the chimney. Its diameter should be 8-10 centimeters larger than the same parameter of the inner channel;

- a previously prepared insulation for chimney pipes is placed in the space between these elements.

Insulation of a brick chimney. The centuries-old practice of creating brick chimneys has developed a traditional approach to their insulation. It consists in plastering with lime. The volume of the solution made for this purpose should be enough to create a layer applied to each wall with a thickness of at least 30 millimeters. But there are also new technologies for thermal insulation of the chimney with your own hands. For example, the use of special thermal insulation boards performs this function even more efficiently. They can be fixed with wire or with the same solution.

Good to know! In any case, the thermal insulation of the outer walls of the pipe leads to an increase in their density, which, in turn, increases the level of protection of the structure from destruction.

You can insulate a brick chimney by plastering the outer surface.

If the thermal insulation is performed correctly at the installation stage, the service life of the chimney will be increased. In addition, a chimney that is correctly insulated even with your own hands will reduce the level of costs necessary for carrying out its current repair.

Perform the warming procedure in the following order:

- prepare pieces of insulating material. Do this after measuring each wall of the flue duct;

- fix the previously prepared sections with mortar on the chimney wall;

- make cladding from asbestos-cement slabs or brickwork;

- additionally plaster the brickwork.

Insulation of an asbestos-cement smoke channel. And in this case, each wall of the pipe must be covered from the outside with a layer of thermal insulation. To seal the chimney outlet through the roof, slag wool or other non-combustible material is used. Insulation is placed in the gap between the outer surface of the asbestos-cement pipe and the protective stainless steel casing.

For thermal insulation, carry out the following sequence of measures:

- Assemble the protective cover from separate parts. The height of each component should not be more than one to one and a half meters;

- put the casing on the chimney at the location of the chimney outlet through the attic floor;

- insulate the free space with insulating material (it can even be loose, such as expanded clay and etc.);

- waterproof the outside of the chimney.

For some types of chimneys, insulation with bulk materials is used, which is placed between the inner and outer pipes.

Gas boiler flue insulation

Different technologies are used to equip the protective layer of chimneys. The best way to insulate a gas boiler is to use a sandwich pipe. They are considered to be the most effective. The design of these products consists of an outer and an inner pipe, between which a heater is located. These products are fireproof.They can even be used to insulate pipes from wood and other combustible materials.

To create a chimney sandwich:

- holes are created in the ceilings and the roof itself, which should be 250 mm larger than the structure itself;

- the thickness of the basalt wool insulation must be at least five centimeters;

- the fixing of the protective layer is carried out using a wire;

- a larger tubular product is put on the resulting structure;

- the casing of the upper metal layer must be iron.

Next, you need to put insulated pipes on the nozzle of the furnace or boiler through the hole in the ceiling or roof. After finishing the installation, you need to fill the metal sheet around the riser with a special non-combustible material. To solve this problem, you can use asbestos, clay or expanded clay.

Watch the video:

How to insulate an iron chimney pipe

To insulate a metal pipe on the street, use basalt insulation and metal clamps - roll insulation must be wrapped around the pipe and secured with clamps every 30-40 cm. A tool that comes in handy for insulation:

- Hammer, pliers, screwdriver, clamp, and other locksmith tools;

- Tape measure, metal ruler or square, building level, pencil or marker;

- A cutter or scissors to cut the chimney insulation to size;

- Riveting device and rivets used to connect the casing. Instead of rivets, short press washers can be used;

- Screwdriver or electric drill, drills Ø 3-4 mm for rivets;

- If the chimney is plastered, you will need: a spatula and a bucket for mortar;

- For sealing cracks and joints - a construction gun and bitumen mastic.

Why chimney insulation is needed?

First, we will try to answer the main question - why do we need non-combustible thermal insulation for chimneys?

- This question will be easier to answer if you measure the temperatures of gases leaving the furnace. The high temperature causes not only deformation of the decorative wall decoration. The main purpose of such a layer of insulating materials is to protect the home from fires.

- Another job of the insulating layer is to prevent the formation of a layer of soot on the pipes. The rapid cooling of the smoke causes a layer of condensate to be released from the temperature difference. This becomes the reason for the increased settling of soot on the walls, a decrease in draft and an unscheduled cleaning of the chimney.