The movement of air flows in the smoke exhaust ducts is subject to the laws of physics, however, with the help of some devices, you can adjust the thrust force. One of these devices is a gate damper - a mandatory attribute of a home or sauna stove.

Let's find out what types of valves there are and whether it is possible to build a gate for the chimney with your own hands if there is no factory analogue at hand.

Functions, purpose and characteristics

A gate is a partition that is located inside the chimney. It repeats the shape and area of its cross-section and, when closed, almost completely overlaps it. Changing the position of the gate allows you to increase or decrease the opening of the chimney pipe, increasing or weakening the air flow. With the help of the damper, you can stop air movement after lighting the stove.

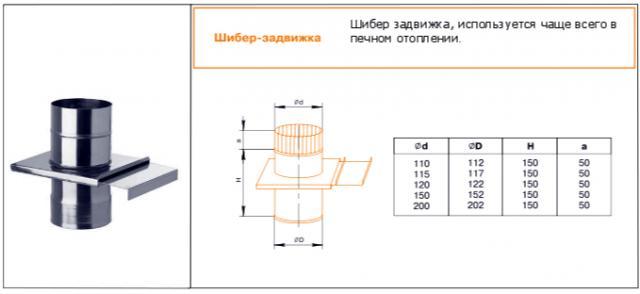

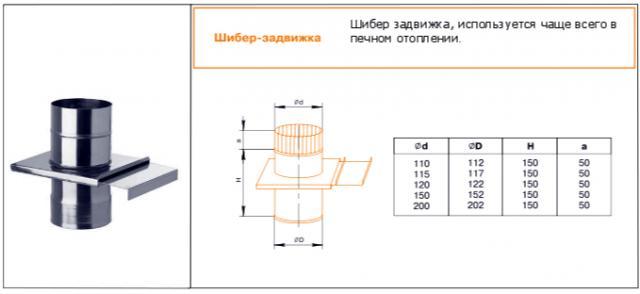

The slide gate is a thin metal plate that is manually adjusted using a special knob. The latter is located outside the chimney pipe so that the user can manually adjust the position of the plate.

Depending on the design and type of the damper, it is installed using a special metal frame, or inserted into the pipe and fixed with an axial rod.

The chimney damper performs the following functions:

- increases traction in difficult weather conditions;

- increases the intensity of combustion in the furnace by increasing the flow of oxygen;

- reduces traction when there is a strong hum in the chimney during strong winds;

- saves fuel by reducing combustion intensity;

- prevents heat leakage after the heater has warmed up.

Shiber: what is it?

A gate is a simple in terms of design features, but a very important device, which is a damper for a chimney. Such a damper closes a certain section of the chimney in order to ensure fire safety.

The damper controls the air flow and flame strength during fuel combustion. When the fuel has burned out, and the stove or some other heating device is hot, the damper is closed so that the heat remains in the room, and does not escape through the chimney.

Advice! When the heater heats up, the flap must be open. As soon as the combustion process in the fuel compartment is completed, it must be pushed in so that the heat remains in the room, and does not go out through the chimney.

The device, which has become the subject of our conversation, must necessarily be installed on all heating devices, not counting those in which the traction force is regulated by special automation (meaning the use of a deflector and a weight stabilizer).

Features of the installation of slide dampers

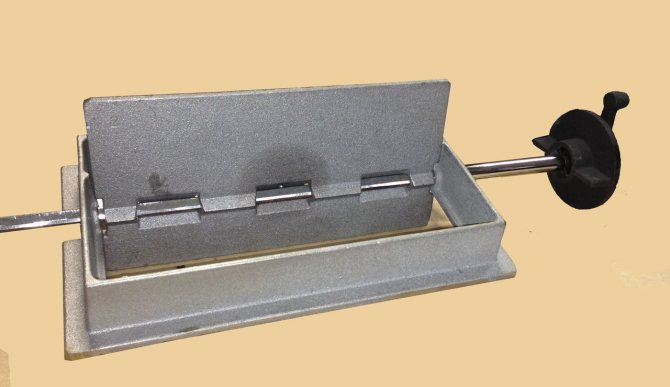

Structurally, the gate is a locking device with an adjustable gate valve. It is thanks to the displacement of the valve that the movement of gases in the chimney is regulated. It can be installed in round, square and rectangular chimneys. It is a metal plate that moves inside the smoke channel in a certain way.

Gate dampers can be of two types:

- Retractable. Moves back and forth in the same plane.

- Swivel. Regulates air access by turning around its axis.

In addition, the gate valves can be manual and equipped with an electric actuator. The cost of the latter is an order of magnitude higher and they are not used in chimneys.

To install the throttle valve, it is necessary to make markings on the pipe in order to drill holes according to the welded valve structure.

To do this, you need to measure the pipe with a measuring tape and make marks for future holes. After making sure that the marks are symmetrical, drill holes for the future rotary handle with a drill.

The throttle gate is installed as follows:

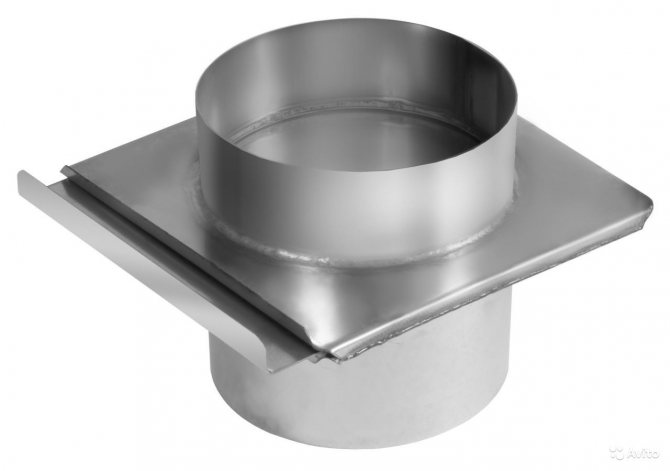

- A steel damper circle with a welded tube is inserted into the chimney pipe.

- A metal rod is threaded through the drilled holes in the pipe through a small tube, the end of which is fixed with a bolt and nut.

- The end of the rod is folded up using the rotary handle pliers.

Next, you can install the resulting structure in the chimney pipe. For this, the first piece of pipe is put on the nozzle of the furnace heating furnace, on which a structure with a slide damper is installed on top. The next piece of metal pipe is put on the gate. All joints are sealed with liquid silicone sealant.

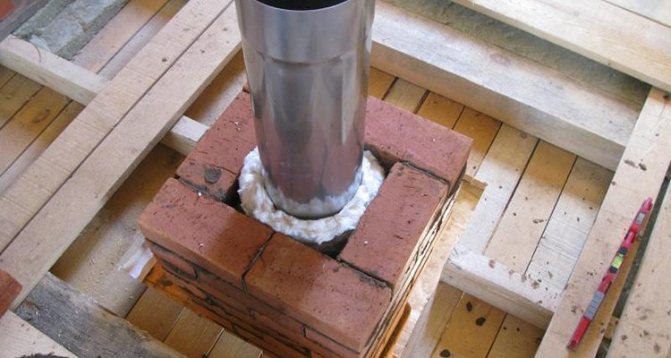

The installation of a retractable gate in a brick chimney occurs during the masonry process. To do this, after 6-8 rows of bricks, a layer of cement masonry mortar is applied, on which the wire frame is installed with the open side to the performer. The latch must be inserted into the frame and brought into a closed state.

From above, the frame is covered with mortar and the brick continues to be laid out according to the standard scheme.

- Horizontal retractable gate. The plate inside the gate extends, due to which the chimney cross-sectional area is adjusted. Typically, this type of valve is used for installation in brick chimneys. Often, small holes are made on the surface of the plate so that even in the closed position of the gate, it does not 100% block the smoke channel. This complies with fire safety regulations. The advantage of this type of device is the ease of installation.

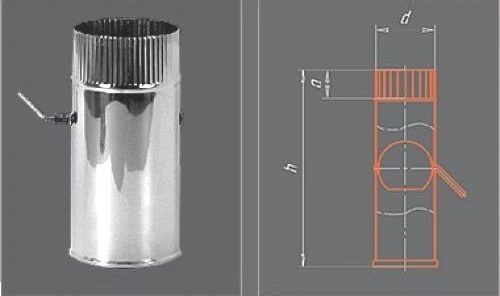

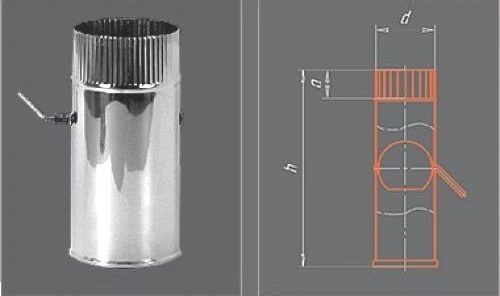

- Rotary gate. It is also called a “choke valve”, which is a metal plate attached to a rotating shaft. The axle, in turn, is mounted inside the chimney pipe. This device has a removable rotary disc, but with prolonged use it may become unusable. However, the scheme of the rotary mechanism allows you to repair and replace it yourself. The advantage of this type of device is its ease of use. This type of gate does not require constant monitoring by the owner of the house.

Due to the complexity of the design with your own hands, the rotary mechanism is less often used when laying a fireplace or stove.

The gate design is necessary for wood stoves and heating devices operating on any solid fuel.

Therefore, for a gas boiler, the most practical solution would be to install a rotary mechanism. The temperature of the outgoing gases is less low than when working with solid fuel, therefore, the operation of such a mechanism will be most convenient.

Valve on the insulated chimney

But it is better to refuse to install the rotary mechanism in the bath. The fact is that it will partially let steam through in a closed form. And when open, such a mechanism is difficult to clean.

Made of stainless steel, the slide mechanism will not completely cover the chimney, but at the same time will exclude the possibility of pulling out tongues of flame through the ash pan into the room.

There are three options for installing the gate.

- Installing a damper in a fireplace insert. For this, the gate is mounted at a distance of 1 meter from the heating device, which ensures simple operation.

- The "pipe-to-pipe" option involves combining the gate with other elements of the heating structure without the additional use of fasteners.

- Installation of a gate valve in a ventilation pipe. But this option is usually used to protect the fan motor from overheating during operation.

We suggest that you familiarize yourself with Cadastral registration of a bath

But even if the finished kit goes without this element, the gate can be easily made with your own hands, choosing the most optimal version of the mechanism for yourself.

Like any engineering solution, the gate has a number of advantages and disadvantages.

Pros:

- Possibility of traction control;

- Fuel economy;

- The dampers help to retain heat.

Minuses:

- Devices make it difficult to clean chimneys;

- If installed incorrectly, the gate can wedge and adversely affect the movement of gases;

- For correct adjustment, it is necessary to have a certain knowledge in the field of flue systems.

The retractable damper allows you to adjust the working section of the chimney, the rotary damper only opens or closes the pipe. Of course, some tricks are possible - such as fixing the hog in an intermediate position in different ways, but the factory equipment does not provide for this. In addition, the rotary gate complicates the mechanical cleaning of the pipe.

How to make a chimney gate with your own hands

It is better to make and install the gate yourself in the process of laying a fireplace or installing a metal chimney.

You can also make and install it if the steel chimney is already installed, but the damper was not provided in it. Depending on the diameter and cross-sectional shape of the chimney, the material of execution, it is possible to make a retractable and butterfly valve.

Note! For a brick chimney, a retractable rectangular damper on a special groove is better suited. For a metal pipe, you can choose any option.

Instruction for the manufacture of a retractable gate

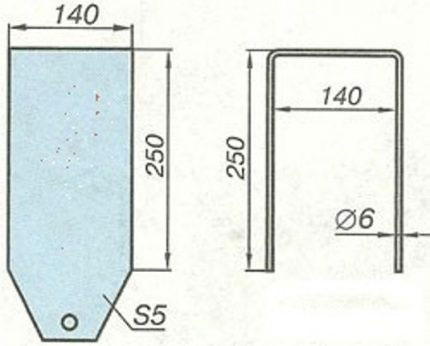

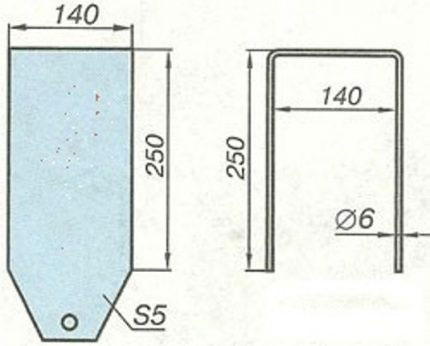

For the manufacture of a simple sliding damper, galvanized or stainless steel sheets with a thickness of 2-2.5 mm are required. Making guides around the chimney perimeter will require 6 mm thick wire.

We recommend that you familiarize yourself with: Ball valve made of stainless steel - selection criteria and installation methods

To complete the work you need equipment and tools:

- grinder or scissors for metal;

- grinding disc for angle grinders;

- drills and files for metal;

- marker for marking.

It is advisable to do all the work on a special lathe or benchtop machine. If the shape of the chimney is rectangular, you can make the simplest slide damper by simply cutting off a piece of sheet steel of the required size. It is recommended to weld the handle or drill a small hole for ease of gate adjustment.

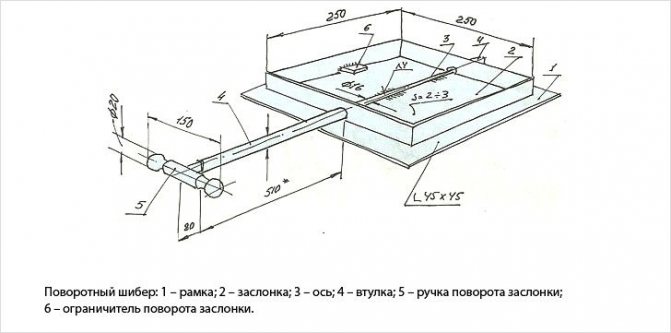

Before starting work, we measure the area and shape of the section of the chimney, with a marker we make marks on a sheet of cardboard in accordance with them. For the manufacture of the frame, we bend the wire in the shape of the letter P, in width and length that coincides with the section of the chimney. We cut out the flap according to the cardboard pattern with a grinder, we process the edges with a grinding disc.

Important! The width of the wire frame should be 2-3 mm larger than the gate plate so that the damper moves freely and does not get stuck during the thermal expansion of the metal.

Throttle gate manufacturing instructions

It will take more tools and time to make a butterfly valve. Most often, this type of gate is used for a metal chimney for modern fireplaces and metal freestanding stoves.

A set of tools for work:

- Bulgarian;

- drill;

- pliers;

- welding machine;

- compass;

- roulette;

- marker for marking.

To make a gate, you need sheet steel up to 3 mm thick, a stainless pipe with an inner diameter of 6 mm, fasteners (bolts, nuts) 8 mm, a metal bar.

- First measure the inside diameter of the flue pipe with a compass.

- According to him, draw a circle on sheet steel.

- Cut a circle with a grinder.

- Place the cut fragment in the pipe and check the tightness. If necessary, rework the shutter with a grinding disc.

- Put a metal tube with a diameter of 6 cm on the circle in the center and make marks on it, stepping back 3 mm from each side of the circle.

- Cut off the pipe with a grinder.

- In the obtained pipe section, drill the threads up to 6.8 mm on both sides.

- Drill holes for welding in the steel circle (one - in the center, two - 1 cm from the edge on opposite sides).

- Weld the threaded pipe to the steel circle.

We recommend that you familiarize yourself with: What you need to know to build a canopy from a professional pipe with your own hands

The gate valve is ready, it remains to install it in the chimney pipe.

The main types of gate valves

Being the main regulator of the draft inside the chimney, the damper regulates the combustion of the fuel. To reduce the thrust and reduce the intensity of the flame in the furnace, it is enough to cover the gate valve. To increase the thrust, on the contrary, it is necessary to open it.

In fact, a gate is a regular metal plate that allows you to adjust the thrust.

It can be installed both in single-wall boiler systems and in double-wall boiler systems.

If the fireplace with the stove is not used, then during this period the gate valve must be in the closed position.

As a rule, the valve is installed at the initial section of the chimney (on the first meter), since this particular section remains not insulated.

But on the section of a well-insulated chimney, on the contrary, it is not recommended to install a valve. Especially when it comes to double-circuit pipes. When the metal of the inner and outer pipe expands, the gate valve can jam.

So, the main tasks of the gate valve are:

- Chimney draft regulator function.

- Partial overlap of the chimney section.

- Regulator of the intensity of combustion of the flame in the furnace.

Today, there are two main ways to install a gate on a chimney:

- Installation in a fireplace insert. This installation option implies the location of the gate product in the immediate vicinity of the heating equipment. As a rule, in this case, the distance from the gate to the heater is 1 meter. This arrangement is very convenient for regulating the valve.

- Connection with other elements of the heating system. In this case, there is no need to use additional fixing elements, so this option is quite common. Such installation can also be called "pipe to pipe".

The above options for the use of valves for chimneys and ventilation systems are used everywhere. It is worth noting that today you can find a huge variety of stoves and fireplaces that differ from each other from a constructive point of view. Such a variety of heating devices also influenced the range of slide dampers.

- Installation of a gate valve in an insulated area. Thermal expansion can cause the damper to jam;

- Installing a cast iron part in a metal chimney (cast iron weighs a lot);

- Using too thin steel or stainless steel with a low nickel content for the manufacture of the valve. Such a product quickly deforms under the influence of hot gases and can burn out;

- Installation of a gate with an uneven surface;

- Installation of a valve without a hole for the release of carbon monoxide;

- Installation of handles that do not allow tracking the position of the valve (applies to rotary elements).

What it is?

The gate is an ordinary steel valve, which is installed in a pipe inside the room, and is located from the firebox (fireplace, stove) at a distance of up to 1 meter. The gate is a horizontal retractable system that changes the section of the chimney. In addition to conventional stove gates, such a gate valve is installed in the chimney systems of single-wall heating boilers.

Round gate damper on the left and rotary gate on the right

Damper with inspection window

A correctly calculated and installed damper allows you to use the heating system in the room efficiently and at full capacity. Experts do not recommend additionally insulating the pipe where the valve is located, since this place is subject to strong heating, and because of which the gate often jams. Such a device is not installed in places where the supply air supply is injected. The design is ideal for a stove or fireplace.

There is another type of damper - on the axis (swivel mechanism), located inside the pipe. But it can hardly be called a full-fledged gate, since it completely closes the pipe, moreover, it has a bad reputation due to its poor quality. This type of valve often burns off the welded seams. It depends on the manufacturer, the best purchase is a stainless steel rotary damper.

Diy chimney gate

There are masters who are able to make a retainer on the throttle with their own hands, thereby changing and fixing the position using a chain. Such a device can be used for gas heating, which will protect against accidental release of the flame from the oven.

Tips for choosing a gate valve

It must be remembered that the correct selection of such an element as a gate damper will affect in the future not only the draft indicator, but also the safety of the heating system, of which the chimney is a part. Installation of the gate is carried out on any model of fireplaces and stoves, except for the most modern ones, in which there is a deflector.

The main recommendations for the selection of slide gates for flue gas communication are as follows:

- if the heating device operates due to gas processing, it is better to purchase a rotary valve model. This is due to the fact that such models exclude the possibility of complete blocking of the chimney duct. Thus, the heating system will be safer. The chimney that removes the combustion products from the gas stove must be closed by at least 40 percent during operation;

- there are heating systems that do not function permanently (periodic). A closed damper installed in such a heating structure, as a rule, allows steam to pass through during delivery, and an open damper contributes to the formation of a large amount of soot on the pipe, which is located below the plate;

- It is strongly discouraged to use rotary elements for installation in sauna chimneys.

A rotary device is the most acceptable option for a system that consumes gas

Experts recommend making a careful measurement of the cross-section of the chimney duct before purchasing a gate product. Perhaps this is the main thing that must be done before purchasing a gate.

We offer you to familiarize yourself with the BBQ area with a sauna and a gazebo

There are 3 options for positioning the damper in relation to the chimney:

- Placement in the firebox of a fireplace or stove;

- Pipe-to-pipe fastening;

- Installation in a ventilation pipe.

Consider the first 2 options:

- Placing the valve in the furnace of the furnace, or in the outlet

In this case, the damper is located at a height of no more than 1 m from the firebox, on a non-insulated section of the pipe. This location is convenient for flap adjustment.

Applicable for metal chimneys. This installation option does not require additional fasteners. When purchasing a ready-made system, the valve should be installed strictly according to the manufacturer's instructions.

Adjusting thrust with a gate is quite simple. By changing the position in the direction of increasing the gap, we increase the flow of air to the fire and the flame flares up more strongly. We reduce the clearance - the thrust is reduced. The shutter is closed after the flame has completely extinguished - this way the furnace cools down much faster.

What is it and what is it for?

There are several standard options for gate placement. The valve is installed in the firebox of a stove or fireplace. This arrangement is often used, because.is convenient for adjusting the position of the plate in the pipe. The device is inserted into the pipe at a height of no more than 1 m from the top of the heating compartment in an area that is not insulated.

The damper is installed according to the principle of one pipe in another. This is done in the case of a metal chimney. As standard in factory systems, the gate valve comes complete with pipes, its installation does not require additional fasteners. The product is mounted in accordance with the manufacturer's instructions.

To simplify the work of heating, obstacles to the warm flow are installed, for which a gate is needed in the chimney. It performs the functions:

- Partially or completely obstructs the passage in the pipe, which makes it possible to open the exit of smoke from the furnace or stop its movement outside. When the oven is off, the scraper is in the closed position.

- The valve regulates the draft in the pipe. The open plate increases traction, and the closed position allows for less air outflow, which saves firewood and coal. The impact on the air flow occurs as a result of a decrease or increase in the cross section of the chimney.

- With the help of the part, the intensity of combustion in the furnace is changed - the degree of heating of the room is regulated.

It is possible to answer the question of what a gate is by considering its positive aspects. The damper retains heat in the fireplace or stove, when choosing the right position, the energy of the fuel is used to heat the interior of the room and does not go outside. Fuel economy is an important factor for home owners. The latch regulates the draft, does not extinguish the fire in the hearth.

The use of a gate in the construction of a smoke channel has several disadvantages:

- After installing the device, it is difficult to clean the inner space of the pipe from carbon deposits and soot, since the damper prevents the passage of the ruff.

- The gate gets dirty quickly and requires periodic maintenance. Its upper surface is cooled by the supplied outside air, and the lower plane is heated by hot streams from the furnace mouth. Contact of 2 different temperatures leads to the appearance of condensation drops, which contributes to the rapid destruction of the damper.

- An incorrectly mounted gate causes a lot of troubles during use: it gets jammed, unaccounted heat fluxes go through the left slots.

- To install the damper yourself, a minimum understanding of how the gate works is required.

The valve serves for different periods of time in changing operating conditions. The term of use without failure is influenced by the type of material used for the body and plate. Stainless steel up to 3 mm thick will withstand 7-9 years without replacement, cast iron will last 12-14 years.

Smooth stainless steel gate valve, polished during manufacture, collects little soot but builds up over time. Periodic cleaning of the fixture is required so that the moving part does not jam. Anti-corrosion lubricants are used to treat the rubbing parts of the gate.

Stainless steel gate (Photo: Instagram / ventilyciy.dumoxod.kondicioner)

Shiber varieties

Retractable

Sliding gate

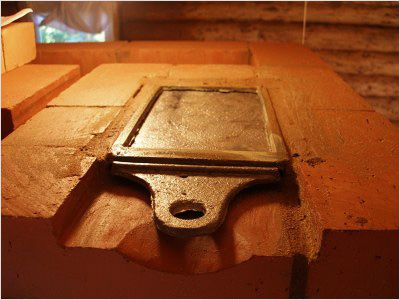

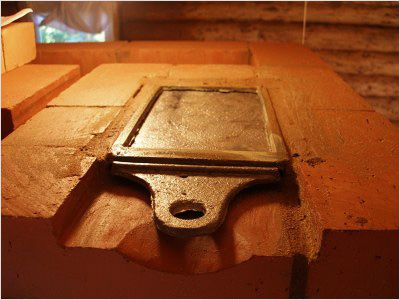

The sliding gate is considered to be the most convenient and reliable to use. It is a smooth plate with a small longitudinal hole moving along the grooves in the chimney. It is mounted in a horizontal position, the traction force is regulated by the movement of the plate, which reduces or increases the cross-section of the pipe. This type of valve is intended for brick ovens, although it can also be used in chimneys made of steel pipes.

Gate with plate

Rotary gate. The plate is visible, which regulates traction

The swivel gate is a metal plate with a guide welded in the center. It is installed inside the chimney, while the end of the guide must be brought out. The thrust is adjusted by rotating the plate around its axis.This design is less reliable, as over time the welding fixture looses and the flap comes off. The rotary gate is used in steel chimneys.

No less important is the material from which the valves are made.

Cast iron gates

Cast iron is a very strong and durable material traditionally used for the manufacture of stove valves. The cast iron gate has only one drawback - a lot of weight.

Cast iron gate for sauna stoves, fireplaces

Cast iron gate

Stainless steel

High quality steel gate assembly

Stainless steel is not afraid of corrosion, lasts a long time, weighs little and does not reduce the efficiency of the furnace. The smooth, polished surface of the stainless steel slide prevents soot build-up for easy cleaning. Such gates can be of any design and can be installed in both brick and steel chimneys.

Steel gate in a brick oven

How a homemade gate is made

The gate can not only be installed, but also designed by yourself. Most often, such a need arises when an old stove heating is being re-equipped. There is already a chimney in the house, but its design does not allow you to choose a standard valve.

Gate drawing

Since during operation the valve is exposed to aggressive effects of high temperatures, condensate and other negative emissions from flue gases, stainless steel remains the optimal material for its manufacture. First, you need to weld a frame into which the shutter will be installed. Corner frames with shelf widths of 35–45 mm are well suited for frames.

Further in the frame, a hole is drilled for the axle. For straight pivot structures, drilling is done in the center of parallel parts; for angular pivoting, holes are drilled diagonally. Bushings made of small pipe sections are welded. They must be positioned so that the axle can rotate freely.

The damper itself is cut to the required dimensions from sheet steel 2-3 mm thick. The blank plate is inserted into the frame and welded to the axis. The gap between the frame and the flap should be no more than 1 mm. To keep the damper in a fully closed position, a limiter is welded, and a gate control knob is attached to the axis.

It is advisable to install a wooden decorative element on the handle. It will provide not only visual appeal, but also ensure safety, since the gate gets very hot during the heating of the furnace.

Installation features

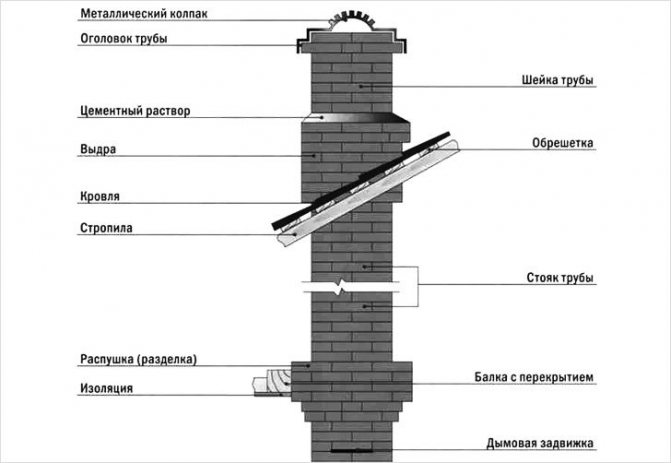

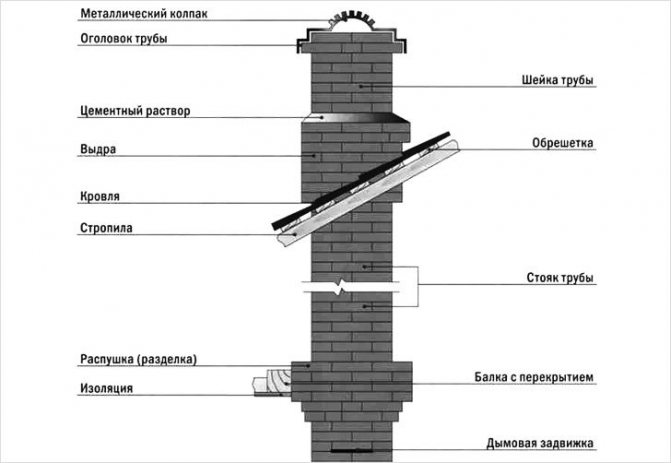

- When installing the gate at the stage of bricklaying, the frame is placed at a height of 6-8 rows from the base of the pipe;

- The frame should be level without overlapping the chimney contour;

- In stainless chimneys, the valve is mounted using pipe-to-pipe technology. It is necessary to match its size with the channel diameter;

- An important nuance - the damper is installed on a non-insulated section of the chimney;

- The height from the firebox to the gate should not exceed 1m (for metal ducts);

- The height of the pipe from the floor to the valve is -1.8-maximum 2m (for brick);

- The damper in the grooves must move freely;

Installing a gate in a brick chimney

Installed gate damper The gate damper is sized according to the diameter of the chimney on which it will be installed. The damper is installed at the initial stage of the chimney device.

- The first row of bricks for the chimney is laid out.

- In the side bricks of the second row, grooves are cut along the thickness of the gate valve.

- A through hole is cut in the front brick to accommodate the damper handle.

- No clamps are required to secure the gate, it stays in place thanks to a snug fit.

Brick chimney with slide damper

For installation, a finished part made of cast iron or stainless steel is taken. The grooves in the bricks are made with a grinder with a stone circle.After installing the damper, you need to inspect the chimney to exclude the occurrence of cracks. If gaps are found, they should be covered with a solution of chamotte clay.

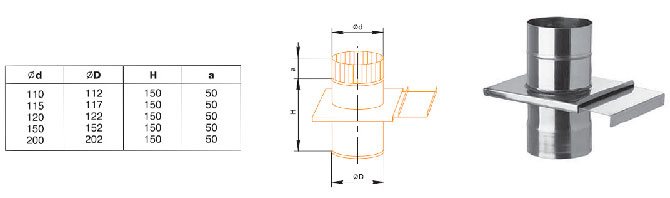

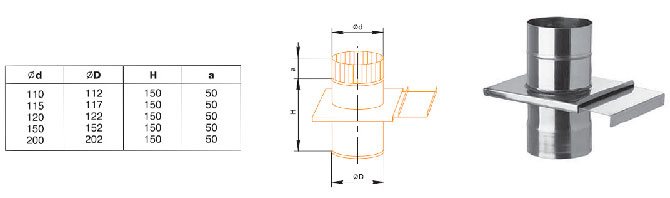

Another mounting method is suitable for a throttle valve, it is called a pipe in a pipe. A structure representing a pipe fragment is inserted into a chimney of the corresponding diameter.

Note! The installation has no means of fastening, and the part itself is held due to its tight fit to the surface of the channel.

Features of the gate service

A gate made of stainless steel sheet is usually polished to a perfect smoothness. Soot settles badly on it, but still settles. Therefore, it needs to be cleaned periodically.

The horizontal valve can be cleaned simply by pulling it to the maximum and applying a special solution. Swivel - cleaned through the chimney with a special plastic brush. You should also monitor the free movement of the damper along the guides. It is allowed to periodically lubricate them with an anti-corrosion compound.

Types and designs

The slide device is influenced by various factors: temperature, pipe dimensions, flow conditions. The construction is based on a sheet of metal of different thickness, moving along the slotted pocket, guiding corners.

Depending on the base, the gates are shut-off, throw-over. They serve to restrict the movement of air flows.

There is a classification of devices according to the principle of operation, depending on the type of drive: manual, pneumatic, hydraulic, electric. Gates are available with straight and oblique designs. The first option is a classic damper. Designed for forced-air supply and exhaust ventilation systems.

The chimney damper is available in several versions.

Retractable

Represents a round or rectangular frame with a plate. The plate extends and retracts, thereby adjusting the cross section of the chimney.

This option is most often used with brick and ceramic ducts. For incomplete sealing and to avoid carbon monoxide poisoning, a small hole is made in the plate. The main advantage of this option is ease of installation.

A rotary, or throttle, damper (aka hog) is a plate of steel or cast iron rotating around an axis. Axle - a metal rod welded inside the chimney. Used in steel chimneys.

We suggest that you familiarize yourself with How to make a ceiling in a steam room with your own hands, what is the permissible ceiling height in a sauna, features of the insulation of the structure, a detailed photo and video

It differs in less reliability - over time, the welding fastening of the plate and axis weakens. You should refuse to install a rotary damper in the bath - even in a closed form, this type of damper partially lets in steam.

In addition, the gates differ in material (the most common are stainless and cast iron) and in the way they are adjusted.

How the gate works

Structurally, the gate is a locking device with an adjustable gate valve. It is thanks to the displacement of the valve that the movement of gases in the chimney is regulated. It can be installed in round, square and rectangular chimneys. It is a metal plate that moves inside the smoke channel in a certain way.

Gate dampers can be of two types:

- Retractable. Moves back and forth in the same plane.

- Swivel. Regulates air access by turning around its axis.

In addition, the gate valves can be manual and equipped with an electric actuator. The cost of the latter is an order of magnitude higher and they are not used in chimneys.