IN Recently, hybrid heating systems have begun to appear on the heating equipment market, combining an electric and a water heating system. The representative of such a hybrid system is the XL-PIPE liquid underfloor heating system, the manufacturer of which is the Korean company DAEWOO ENERTEC. We will talk about whether it is worth installing this system in this article.

Why is it profitable to make warm floors?

The main advantage of underfloor heating over all other types of heating is that they are hidden from view and are ideal for families with small children. In addition to the fact that babies can crawl safely for health, they will not get burned by the heat sources, which are reliably hidden under the topcoat. There are no drafts in the room with warm floors.

Underfloor heating reduces heating costs in houses with very high ceilings, where it is difficult to rationally organize heating of the entire volume of the room. In apartments located on the ground floor, above damp, cold basements, underfloor heating will provide a comfortable microclimate.

In addition, they do not dry the air, and this is especially appreciated by sensitive people prone to allergies. When underfloor heating is an autonomous type of heating, they will help out on cold days of the off-season. Ceramic tiles, even with the best heating system, remain cold, and the use of underfloor heating will help out here.

Thus, the decision to install underfloor heating is for the benefit of the health of family members. It is important to choose which system is best to apply.

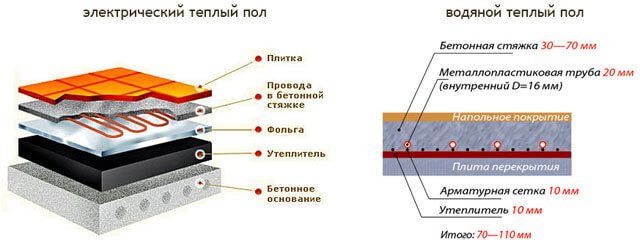

When it comes to which type of heating is better, the controversy does not stop: with the help of a liquid heat carrier or electric heating elements? These methods differ in cost and complexity of work during their installation and connection, have their own characteristics for installation and operational characteristics.

Water floors: features of installation and operation

Water floors are economical types of heating due to the use of water as a heat carrier. After installing them, you do not need to think about where to put the furniture. There will be no radiators on the walls, floors with a water circuit are not afraid of heavy interior items.

The main distinguishing feature of water floors is the complexity of their connection. For example, to make water-heated floors in an apartment, you need a document of consent from the management company to connect to central heating.

When the heating is individual, it is required to install a unit to heat the heating medium. This means that all the difficulties associated with the installation and maintenance of the boiler are added: gas, electric, solid or liquid fuel. It is necessary to allocate a certain place for its installation, and at the same time adhere to all norms and rules.

Installation of the underfloor heating water circuit requires a lot of preparatory work. This is a rather time-consuming process that requires care and professionalism, because in the event of a leak, you will have to open the entire finishing coating of the room.

Experts do not recommend leaving warm water floors as the main source of heat in houses where there is no good insulation of walls and windows. In addition, wall-mounted radiators will be more appropriate on staircases or in small corridors.

Outcomes

Water electric underfloor heating is an interesting option in all aspects of underfloor heating.XL Pipe (X-L Pipe) seems to be more advantageous, but it also costs more, but it provides for the possibility of using it as the main heating (there is enough power with good insulation). If you just need a comfortable floor temperature in relatively small rooms, including those with high humidity, then the UNIMAT AQUA capillary underfloor heating looks more acceptable, although this is your choice.

Electric floors: pros and cons

Rooms with electric cables or heating mats in the floors are always warm and cozy. To obtain heat energy in this case, only electricity is needed. Electric floors are demanding on the premises: they must comply with the norms for the installation of electrical appliances, that is, dry.

If, with the water method of heating, the surfaces are heated unevenly, since they have time to cool down, plying through the pipes, then the electric ones are stable in this respect and give heat evenly over the entire area.

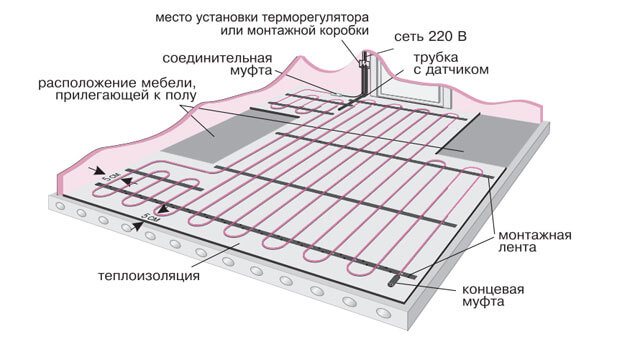

But there are also disadvantages of underfloor heating. Electric floors are not always convenient to use. Many factors must be taken into account: what kind of finish will be in the room, how to arrange furniture. Before starting the installation of electric underfloor heating, a floor plan is drawn, which is then adhered to.

Electric floors are film and cable. The films are laid on a flat, clean subfloor under the topcoat. Cable, by analogy with the water circuit, is poured with a concrete screed. By choosing any heating option, you can build underfloor heating in any house or apartment. There is a third way, where the advantages of a water and an electric floor are combined: these are liquid electric underfloor heating.

What are liquid electric floors

Consumers have already appreciated the advantages of underfloor heating of a new generation, which autonomously provide electric floor heating with a liquid heat carrier. It is not correct to call these floors electric-water, since the coolant is not water, but antifreeze. Therefore, it is correct to say "liquid floors".

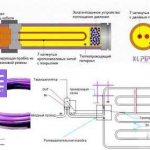

The liquid heat-insulated floor includes a set of polyethylene pipes with a coolant poured into them. An electrical cable is embedded along the entire length of the tubes. When the electric heating is turned on, the coolant is warmed up by the cable and begins to give off heat to the environment.

In various models of liquid underfloor heating, antifreeze or distilled water acts as a heat carrier.

Advantages of liquid electric floors

The new form of heating compares favorably with its counterparts in many respects.

The advantages of electro-liquid systems in comparison with conventional water systems are as follows:

- does not need to be connected to a heating boiler or central heating system;

- to perform its function, the coolant does not need the help of a circulation pump;

- installation is extremely simple: there is no need to build a manifold and a switchboard;

- the operation of the system is ensured by a very small amount of coolant, therefore, even with a leak, the apartment is not threatened with flooding;

- warm floors are warmed up as evenly as possible over the entire surface;

- much less labor is required during their installation, in contrast to water heated floors.

If we talk about the advantage over electric underfloor heating, then the following qualities should be noted:

- overheating of the cable, which is located inside the liquid, is excluded;

- repair of liquid floors does not cause problems.

Add antifreeze or change electrical components through a convenient back box. Damaged spots are identified instantly by wet circles on the screed. The heating effect ensures maximum floor heating due to the fact that heat energy is stored not only under the screed, but also in the pipe.

There are certain advantages of liquid floors over infrared foils:

- can be mounted in rooms with any humidity, which is very important in many cases;

- liquid floors can be installed under any floor covering.

There are currently two model lines of electric water floors: XL Pipe and Unimat Aqua. The first ones are made in Korea, the second ones - in Korea and Russia. These models work according to the same principle, but have their own design features.

We heat the house in a new way. Overview of the XL PIPE electric water floor system

With the rise in heating tariffs, more and more home and apartment owners are thinking about saving. An alternative to the classic methods of heating a house or apartment is the installation of underfloor heating, that is, refusal to use a heating boiler and heating radiators. Until recently, there were two types of warm floors: water and electric. Now a new type has appeared - an electric-water heat-insulated floor.

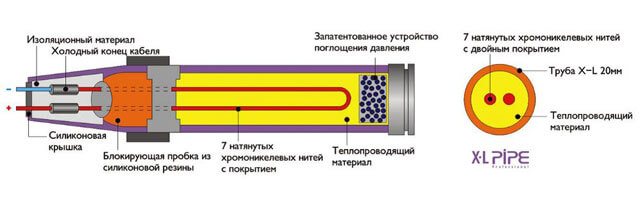

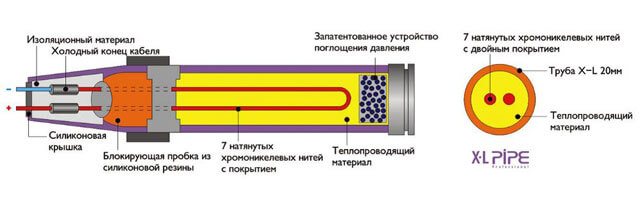

In the Belarusian market, electric water floors are represented by the Korean XL PIPE system. It consists of a polyethylene pipe with a diameter of 2 cm with a special liquid inside (antifreeze), a heating element (7-core nichrome cable with two-layer insulation) and a junction box with dimensions of 18 × 18 × 4 cm.

The principle of the system is as follows. The cable heats the liquid in the pipe. The heating medium reaches a high temperature and heats up the floor screed. After heating the floor to the set temperature, the heating is turned off, and after cooling to a certain mark, it turns on again. In this case, heat is retained not only in the screed, but also in the pipe.

The system power is 40 W per linear meter. Power consumption, on average, is from 17 to 39 W / m2. The manufacturer claims that the system has high heat dissipation, its efficiency is close to 100%. Due to the absence of liquid circulation, electric-water floors are more economical than classical water floors by 8-15% and by 12% - radiator heating. The average energy consumption for a house with an area of 100 m2 will be from 615 to 2975 kW per month, depending on the temperature outside and the heat loss of the house itself (data are given for a house with average insulation).

Testing the system at the Russian Institute of Thermophysics showed the following. In the climatic zone of Krasnoyarsk (Russia), where the heating season lasts 233 days and the average temperature of the heating season is –6 degrees, to maintain a temperature of 21 degrees in a house with a living area of 100 m2 (heating area 53 m2), electricity consumption per month will be 1254 kW. The experiment was carried out in a house with a medium degree of insulation, with thermal insulation of the floor using extruded polystyrene foam 5 cm thick.

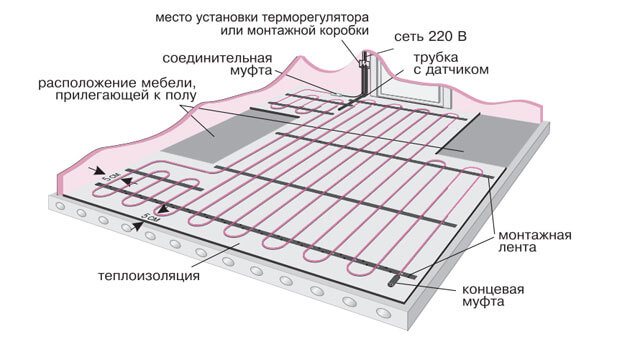

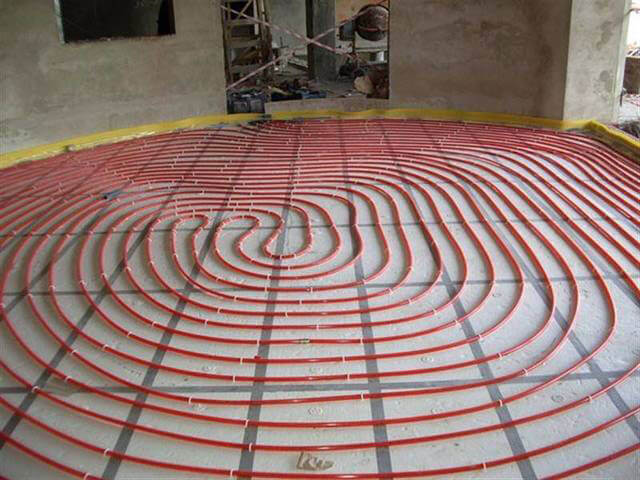

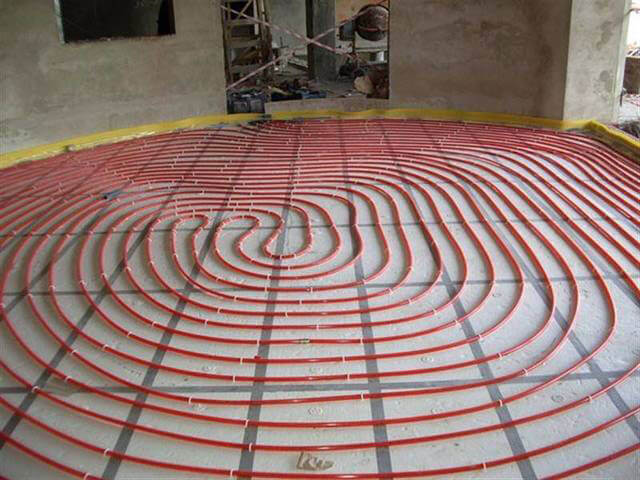

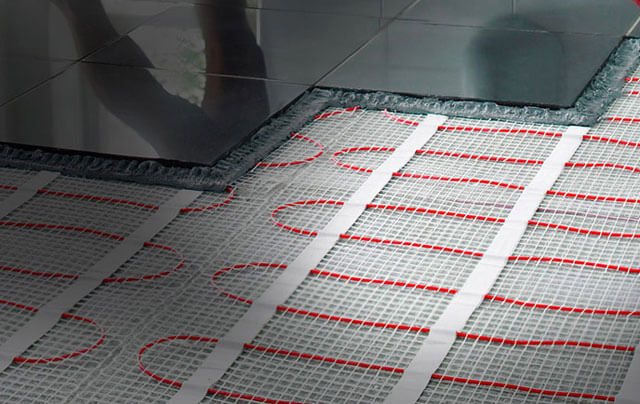

The system is fairly easy to install. Heat-insulating material is laid on the floor. As a rule, this is extruded polystyrene foam with a thickness of 5 cm. Then a layer of reflective foil thermal insulation is installed. After that - a reinforcing mesh with a rod thickness of 3-5 mm. The mesh should be 10 × 10 or 20 × 20 cm. The XL PIPE system is attached to the mesh with plastic clamps. The recommended distance between pipes is 20–30 cm, the minimum allowable is 5 cm. The distance from the wall is at least 5–10 cm.

A thermostat is installed to regulate the floor temperature. Up to 84 m of pipe can be connected to one thermostat. Next, a screed 4–8 cm thick is poured. After that, you can lay any type of flooring: linoleum, tiles, laminate, parquet. It should be borne in mind that when laying parquet, floor heating is allowed no more than 28 degrees with a humidity of at least 60%.

On top of the electric-water floor, it is allowed not to pour the screed, but to use one of the two listed options:

1. Installation of wooden blocks and sheet metal. The bars are laid with a gap of 2 cm, in which the pipes are placed. Further, steel sheets with a thickness of 0.1–0.36 mm are attached to the bars.

2. Laying of pipes in sheets of polystyrene, in which slits are made by industrial methods. In the foam plastic 5 cm thick, in production, with a step of 20–25 cm, slots are made 2 cm wide and deep, where the pipes are placed. The recommended density of the foam is 35–50 kg / m3.

One of the undoubted advantages of electric water floors is their complete maintainability. If the system breaks down, all repair manipulations are carried out through the back box. In addition, there is practically no possibility of overheating the cable, since it is located inside the pipe with the coolant. If a pipe with a coolant is damaged (for example, it was accidentally drilled during repairs), the damaged part can be easily replaced with a new one using standard double-sided pipe fittings, you do not have to "blow up" the entire floor - opening will only be required at the place of damage.

Comparison of heating systems for a house with an area of 100 m2 - electric water floors and heating with boilers using different types of fuel - is shown in the table.

| House heating type | System installation costs, USD | Electricity or fuel consumption per month | Costs per month, USD |

| Electric water floors | from 3000 | 615-2380 kW * | 45–170 ** |

| Gas heating, liquefied gas | from 7000 | 1019 l | from 130 (more than 1 cylinder is required, 27 liters per day) |

| Diesel heating | from 7000 | 1019 l | from 300 (at a price of 0.68 per liter) |

| Solid fuel coal-fired boilers (not automatic) | from 3500 | 1060 kg | 27–80 (price per ton 25-75) |

| Combined boilers (automatic) | from 7000 | 676 kg | 27–88 (price per ton 40-130) |

| Electric boiler | from 6000 | up to 3600 kW | 60–300 |

* For well insulated houses

** For citizens living in houses that are not equipped with electric stoves and centralized hot water supply and natural gas supply systems

Electric water floors are a great alternative for those who do not want to allocate space in the house for a boiler room. Or even use a boiler. And since there is no boiler, there is no risk of explosion or fire. Heat loss of such floors is minimal, since there is no circulation of the coolant from the boiler to the heated room. You will not flood your neighbors from below, as is the case with choosing a water floor. The risk of cable burnout in the pipe is minimal - it is immersed in liquid. The system is maintainable and economical. However, these floors take the height of the room (insulation + reinforcing mesh + pipe + screed). They are more economical than standard underfloor heating and heating with an electric boiler, but the monthly costs for them may be higher than when using solid fuel boilers or heating with main (natural) gas. It all depends on the cost of energy resources in each specific locality and scenarios for the use of floors.

XL Pipe: device and principle of operation

The floor heating xl pipe is arranged as follows. The reservoir for the coolant is a system of thick-walled polyethylene pipes with a diameter of 20 mm. The coolant in this case is antifreeze (of a certain brand). A seven-core electric cable made of chromium-nickel alloy, covered with a Teflon insulator, is laid in the tubes.

The pipe is hermetically sealed at both ends. That is, there is no need for the coolant to circulate. The entire system warms up very quickly and as evenly as possible.

The energy consumption of the xl pipe underfloor heating system is 14.5 watts / m2.

One of the advantages of XL Pipe is that furniture can be placed on top of the covering where they are mounted. Heavy objects will not bring harm, since the installation is carried out under a five centimeter cement screed.

The pipes are laid according to a special scheme. To regulate the temperature, a thermostat and a temperature sensor are installed. They are connected here in the same way as for other underfloor heating. However, a special thermostat is needed, which is suitable specifically for liquid underfloor heating.

The manufacturer gives a 10-year warranty for the operation of his product. However, if the installation is done correctly, then such a system will serve up to half a century.

Disadvantages of the XL-PIPE system

The XL-PIPE system has the same temperature of the liquid, and therefore the floor, throughout the entire length. This is a disadvantage of all electrical systems. Our main task, when installing heating, is to make a barrier to the cold that comes from the outer contour (walls, windows, doors).Therefore, it is necessary to supply the maximum temperature to these places. There is no point in heating the inner walls. In this sense, an ordinary water heat-insulated floor is designed like that. The temperature of the coolant decreases as the pipe moves away from the walls, making the entire area of the room comfortable.

The XL-PIPE system is not afraid of locking. I agree that in an ordinary water floor there are locks of circuits, but this comes from an incorrect calculation of the system and its unskilled installation.

To service the XL-PIPE system, special technical boxes are provided, which are mounted flush with the floor and are designed for its maintenance. You immediately need to tune in that you will have such a box in your room, and if there are several circuits, then not one.

For the XL-PIPE system, the circuits are already pre-cut at the factory and supplied ready-made. This suggests that you will never be able to accurately select the system according to the calculation. You will always be forced to buy more, and this is the cost of the pipe itself, and then on electricity.

The XL-PIPE system works only for heating, while the boiler used to heat the heat carrier in the hot water floor can simultaneously work in the hot water supply system.

Be prepared that the companies that work with the XL-PIPE system will refuse you general construction work (screed filling), as happened to me. In this case, you will have to either purchase polystyrene foam, mesh, mixture and make a screed yourself, or look for another XL-PIPE system

Energy efficiency compared to electric cable floor. As an advantage, the manufacturer emphasizes that the coolant inside the pipes accumulates heat, which allows the system to cool down 2 times slower than cable floors. In my opinion, complete cunning, tk. water has appeared in the system between the floor and the cable, which requires additional energy to heat up. In addition, the coolant does not significantly affect the cooling rate of the floor. Everything will depend on the material that will cover your floor. When turned on, the system will always consume the power put into it, while many electric boilers can be adjusted in steps of power and connected as needed.

Heating medium for XL-PIPE system

In the XL-PIPE system, a special composition of antifreeze is used as a coolant. The manufacturer does not say which one. This is most likely due to bubble boiling, which the manufacturer presents as an advantage, not saying that bubble boiling in a closed environment also has disadvantages. By installing this system in your home, you will be forever tied to the supplier of this coolant. Regular water floors are filled with ethylene glycol-based automotive antifreeze, which can be purchased at any auto parts store.

Mounting the XL-PIPE system

When pouring the screed, in ordinary water floors, excessive pressure is created in the pipe, so that the concrete does not deform the pipe with its weight. You cannot do this here. In theory, when a pipe is compressed, the cable can come into contact with the pipe, excessively heating its walls. It is impossible to predict what the consequences may be in this case.

XL-PIPE system inertia

The system is intended for permanent residence, as it takes a long time to heat the floor. If you are visiting your home, this system is not your option. The system with conventional water floors and a boiler allows in this case to install additional radiators, which will quickly heat the air in the room until the warm floors take over the main function.

I hope this article will help you understand what the XL-PIPE liquid underfloor heating system is. In the next article, I will talk about how to set up heating in a private house.

RECOMMEND TO READ MORE:

Performance characteristics of XL Pipe

In terms of its operational capabilities, the electric water heated floor xl pipe has several indisputable advantages:

- does not create an electromagnetic field;

- no need to install additional expensive equipment;

- no risk of system overheating;

- there is no negative effect on the finish flooring;

- from above you can install furniture and heavy household appliances;

- it is possible to repair the system without the need to dismantle the finishing coating;

- economy in terms of energy consumption (it takes 20-30 percent less electricity than with conventional electric floor heating);

- not complicated installation, which can be done independently.

XL PIPE advantages

XL PIPE electric-water underfloor heating has the following advantages:

Comparison with a solid fuel boiler

- the power of the heating elements is fully sufficient to use the XL PIPE system as the main heating. It is 40 W / running. m. If desired, the system can be used as an additional source of heat energy in the room;

- high efficiency of the system is achieved due to the absence of a circulating heat carrier;

- the coolant is an excellent accumulator of thermal energy. This allows it not to cool down for a long time if the electricity supply is cut off;

- uniform heating of the entire surface without pronounced areas with more intense radiation of thermal energy;

Comparison with a gas boiler - the possibility of heating by zones. There is no need to turn on the underfloor heating system throughout the house when it is necessary to increase the air temperature in a certain room;

- Repair of XL PIPE heating elements takes place through a junction box, which makes it possible to avoid opening the floor covering. If there is mechanical damage to the pipelines in the problem area, it is necessary to install a 2-end coupling. After that, the electric underfloor heating will continue to work;

- installation of XL PIPE heating elements takes place over the entire area of the room. Furniture or large household appliances do not interfere with the efficient operation of the system;

Comparison with a diesel boiler - the premises are heated autonomously using electricity. Such a system can be customized depending on your needs;

- during operation XL PIPE does not emit carbon dioxide, electromagnetic radiation. Such warm floors are completely safe for humans and the environment;

- high fire safety of the warm floor, since the heating cable is placed inside the liquid heat carrier.

How to install XL Pipe liquid floor

Stages of installation of electric water heating xl pipe:

- Prepare a rough base. They clean out debris, level out irregularities, close up cracks. Plates of extruded polystyrene foam are laid on the base. It plays the role of a heat insulator.

- The heat insulator is fixed with "umbrellas". To do this, holes are made in the plate for fasteners, dowels-umbrellas are inserted there.

- A reinforcing mesh is placed on top of the thermal insulation plates. Mesh sizes from 100 to 200 mm.

- The mesh sections are tied with a metal knitting wire.

- The heating cable from the underfloor heating kit is checked for compliance with the resistance.

- Then the pipes are laid out according to the scheme specified in the instructions. The tubes are fixed with plastic clamps to the reinforcing mesh.

- The supply cable is laid from the thermostat to the junction box.

- The wires from the pipe are connected to the power cable. For this, terminals are usually used.

- The grounding cables are connected to the reinforcement mesh.

- Fix the temperature sensor approximately 50 mm from the tube.

- Close the back box. Seal the cracks with a sealant.

- Then they perform the concrete screed and wait for it to dry. Then make a topcoat on top.

When installing XL Pipe electric water floors, the pipes must not be twisted or pinched. The work is carried out taking into account all the recommendations of the manufacturer.In winter, for the fastest drying of the concrete screed, it is allowed to start the system in an average temperature regime.

This system is expensive and should be handled with care during installation, avoiding breakage of the tubes. The XL Pipe heating method is suitable for premises of any purpose: for residential, office and industrial.

Maintenance work on XL Pipe is carried out by specialists. As a rule, it is required to replace the coolant. This is done about once every 10-15 years. The final floor covering is not touched at the same time. This is a great advantage of XL Pipe over other systems.

The main disadvantage of this heating method is the rather high price of the system itself. However, the reliability, durability and efficiency of heating such underfloor heating justify these costs.

System Description

The electric-water heat-insulated floor works thanks to the special design of the heating elements. They are formed using structured polyethylene pipelines. Their diameter is 20 mm. There is a heat transfer fluid inside the pipelines. It is heated by two 7-core cables made of a special nickel-chromium alloy. Teflon insulation is used to protect electrical wires. It does not collapse under the influence of the high temperature of the coolant.

Characteristics of X-L PIPE underfloor heating

XL PIPE water floor works effectively without a pump, manifold and boiler. This is possible due to the fact that there is no circulating liquid in the pipes of the system. Antifreeze acts as a coolant, which is characterized by a special composition.

During its heating, the pressure in the system increases significantly. This improves the distribution of heat energy, which leads to an increase in the efficiency of the underfloor heating.

Heating of the liquid occurs at lightning speed, since its volume is small. Therefore, when the system is put into operation, it is possible to achieve the required temperature parameters very quickly.

The most economical floor heating

Another feature of XL PIPE underfloor heating is the presence of a special device inside the pipelines to absorb excess pressure. It is unique and is a patented development of the company. Also, a distinctive feature of the system is the presence of couplings at both ends of the pipelines.

They are made of rubber gaskets, which significantly prolongs their service life. Wires for connecting to the thermostat come out of the sleeve. With the help of this device, the operating parameters of the system are adjusted depending on the needs of the user.

Water-electric floor heating system X-L PIPE

Features of the capillary underfloor heating Unimat Aqua

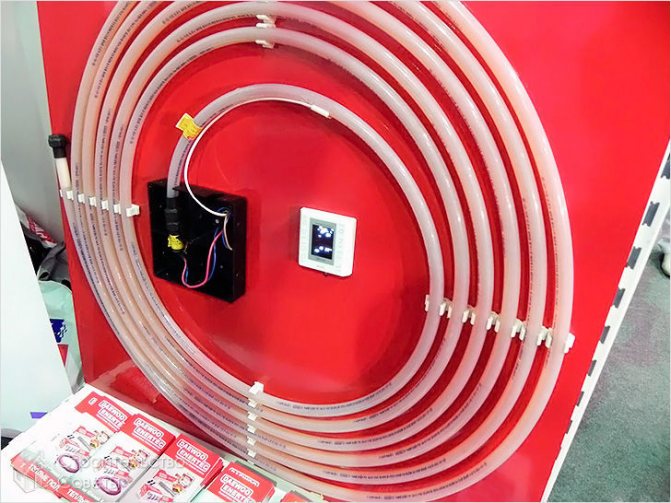

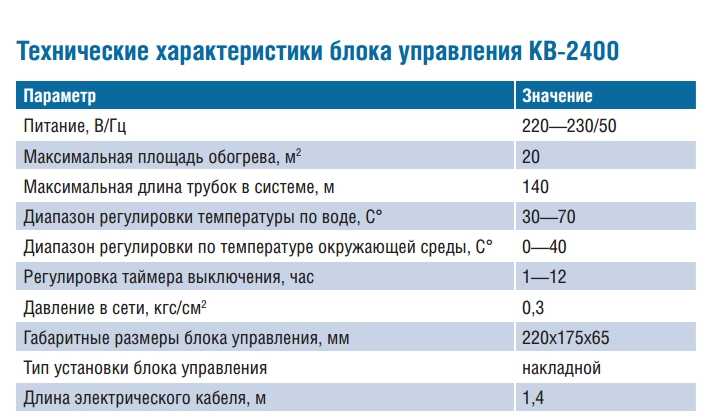

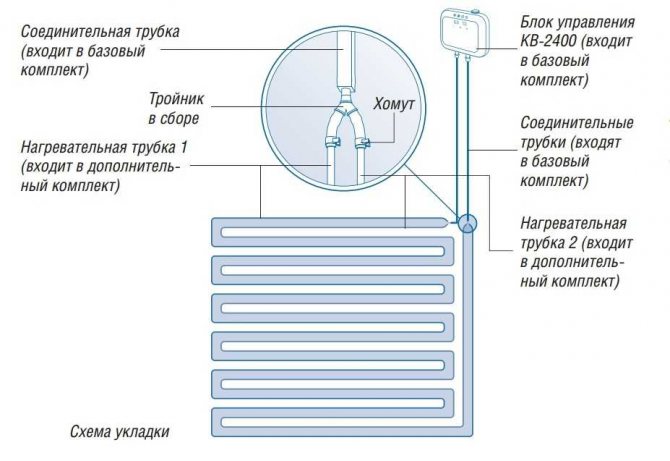

Unimat Aqua liquid underfloor heating differs from XL Pipe in that the system does not consist of one thick pipe, but is equipped with many small diameter pipes. Hence the name of the system - capillary. Connect it to a device that has a power of 2.4 kW. In this way, the coolant is heated and heat is released. The whole system is closed. Installation of an additional heating unit is not required.

Distilled water is the heating medium in the Unimat Aqua system. It will require no more than 6 liters. The size of the heated area that one set can heat is approximately 20 square meters. How warm the room will be depends on the insulating properties of the walls and ceilings. Warm floors very quickly create a comfortable indoor climate.

Several Unimat Aqua systems can be installed in one room, if necessary. However, it is most often used to heat a small room. The operational life of the capillary underfloor heating is approximately 5 years.

The Unimat Aqua is of two types. Basic, which includes a control unit, a mounting kit, two pipe sections for connections. All this is required to form a small pipeline. An additional set consists of a coil of small diameter tubes, which are enough to heat an area from 10 to 20 square meters. meters.

For installation, you need a damper tape, pipe fasteners and heat-reflecting material. After installation, the floors are poured with a cement screed.

Pros and cons of the Unimat system

The Unimat system is very smart. It is equipped with a multifunctional control unit that can adjust the temperature in the room or the heating of the coolant to the desired level. You can also set the period and time of the system.

Unimat underfloor heating is characterized by high safety. They are installed in a room with any humidity (for example, in bath complexes).

The disadvantage of Unimat underfloor heating is that the heating of the floor is not uniform. This is due to the fact that the coolant comes from the heating block hot, then gradually cools down. That is, the disadvantage is similar to conventional underfloor heating with a water circuit.

How Unimat Aqua Caleo underfloor heating is installed

Installation of electric water underfloor heating Unimat Aqua is performed as follows:

- Preparation of the rough base is the same as for XL Pipe: cleaning, removal of irregularities.

- Prepare a place on the wall for the thermostat.

- A strobe for the temperature sensor is made on a rough base.

- The heat-reflecting plates are laid out. Fasten them together with staple staples.

- On the side where the thermostat is located, they begin to unfold the Unimat Aqua.

- When laying out the system in the places where the mat turns, one of the connecting wires is cut, the mat is turned 180 degrees. In this case, the tubes should not touch or intersect. The power wire is cut strictly in the middle. The maximum permissible strip length is 25 meters.

- The entire system is carefully taped to the heat reflector.

- Mats are connected with mounting wires. This is done as follows: the ends are cleaned and the sleeves are installed, which are clamped with pliers.

- Heat-shrinkable tubes are put on the wires. The power cable is spliced with the connecting cable.

- The system is connected to a thermostat according to the diagram that is attached to this device.

- To connect the concrete screed to the subfloor, small through holes are cut into the heat reflector.

- A temperature sensor is installed along the rods, previously laid inside the corrugated pipe.

- Check how the Unimat Aqua works.

- If the pipes warmed up within 15 minutes, no malfunctions were detected, the warm floors are poured with a concrete screed.

Liquid electric floors are an excellent source of comfortable warmth. They can become both the main and additional heating device and will perfectly cope with their function in any room.

Choose one of the gifts

- Description

- Characteristics

- Installation

- Shipping and payment

- Return

- Testimonials

Electric-water heated floor XL PIPE-050 2800W 70m - heating area: 14m2.

The XL PIPE system is a 20 mm high strength polyethylene pipe with a liquid and a heating cable inside:

- Seven-core teflon-insulated nichrome cable

Each system uses its own special nichrome cables of a special alloy. Teflon, over the years, does not lose its properties, does not allow liquid to pass through, and withstands the highest temperatures.

- Heat carrier - antifreeze liquid based on harmless propylene glycol

So that the XL PIPE system can be installed and used in very cold regions of the country, antifreeze is poured into the pipe, which does not freeze down to -30 ° C. If the temperature drops below this mark, and the system is not turned on, then the liquid can go into a gel-like state, but nothing will happen to the system itself. As soon as the temperature rises above -30 ° C, the antifreeze will become liquid again.

- All components are manufactured in South Korea

Factory-made accessories in the XL PIPE system: connecting fittings and other parts. Only in the factory, with the help of high-precision machines and units, you can achieve high quality assembly. All parts fit tightly to each other and ensure the tightness of the system.

- A patented pressure absorption system is installed in every XL PIPE system.

Extends the life of the system. It absorbs the excess pressure that occurs in the pipe when the coolant is heated and increases the operating temperature of heating from 60 to 80 degrees. Without it, the system could explode. Features and Benefits

- Delivered ready-made: 9 models in lengths from 7 to 84 m.

- Due to the accumulation of heat in the pipe and screed, the XL PIPE system cools down for at least 4 hours.

- Not afraid of being locked by furniture.

- Suitable for any flooring.

- Service life: more than 50 years.

- Warranty: 10 years.

The XL PIPE system is protected from counterfeiting not only in Russia, but also internationally:

- Eurasian patent No. 026689 dated May 31, 2020 issued by the Eurasian Patent Office.

- Russian patent No. 169214 dated March 9, 2020 issued by the Federal Service for Intellectual Property ROSPATENT.

XL PIPE is the only underfloor heating to be repaired, therefore the device for its repair is also patented:

- Eurasian patent No. 025842 dated May 18, 2020 issued by the Eurasian Patent Office.

- Russian patent No. 166378 dated November 2, 2020 issued by the Federal Service for Intellectual Property ROSPATENT.

Rapid installation of underfloor heating XL PIPE on a turnkey basis:

- Installation of thermal insulation with clamps 100 rubles / m2

- Installation of electric-water underfloor heating 250 rubles / m2

- Installation of XL Pipe junction box RUB 500

- Installation and connection of the thermostat 900 rubles.

- Filling the screed by machine 500 rubles / m2 Material + work (Minimum cost 50,000 rubles)

- Manual pouring of floor screed up to 5 cm 1000 rubles / m2 Material + work

- XL PIPE Certificate of Conformity

- Instructions for floor heating XL PIPE

Vendor code:

XLPIPE-050;

Installation Type:

In the screed;

Linear power per meter of length, W / m:

40;

Power consumption, W:

2800;

Heating area, m2:

14;

Supply voltage, V:

220;

Brand country:

South Korea;

Thickness, mm:

20;

Guarantee:

10 years;

Heating part length, m:

70;

Manufacturer:

XL PIPE;

Methods of receiving the goods:

- Pickup from the warehouse (Leninsky Prospect, 140I, BC "Cosmopro", office 123)

- Free delivery on the day of order in St. Petersburg within the ring road, except for Peterhof, Lomonosov, Strelna, Kronstadt

- Free delivery of underfloor heating by a transport company to the cities: Kolpino, Krasnoe Selo, Pushkin, Kirovsk, Vyborg, Sosnovy Bor, Gatchina, Kingisepp, Luga, Kirishi, Volkhov, Tikhvin. (Delivery time 2-3 days, payment upon receipt)

- Delivery on the day of order in the Leningrad region 30 rubles / km from the free delivery zone

- Delivery to other regions - Federal State Unitary Enterprise "Russian Post" (Except for large-sized goods)

- Delivery by a transport company (We deliver to the terminal in St. Petersburg free of charge, then according to the tariff of the transport company)

Payment options:

- Cash upon receipt at the office or courier upon delivery

- Payment by VISA, Master Card and MIR payment cards in the office or upon delivery

- On account for legal entities and individual entrepreneurs (We work with VAT)

- Cash on delivery for delivery to the regions by transport company or mail

Return or exchange of goods

You can return the products purchased in our online store within 30 days and get the money back or exchange for another product.

- The return of goods is accepted during the working hours of the store on Mon-Fri from 9-00 to 18-00 at Leninsky Prospect, 140I, BC "Cosmopro", office 123

- Cash refunds are made immediately (if the required amount is available at the cash desk) or no later than three working days from the date of registration of the return.

- Refunds paid when buying with a bank card are returned only to a bank card

Basic conditions for the return of goods:

- Products have not been used

- The integrity of the packaging is not broken

- The complete set of goods has not been changed

- The return of water heaters is carried out only after the examination of the service center

Documents required for return:

- Passport (Copy of passport when sending from the region)

- Cashier's check or its copy

- Original bank card and slip-check (payment was by bank card upon receipt)

- Return application (To be completed in our office at 140I Leninsky Prospect, office 123)

In the absence of documents confirming the purchase, you can refer to other evidence of the purchase of goods in the online store lepspb.ru

Return or exchange of products from another region

- Tell us about your intention to return or exchange the product by phone or email

- Send an application for return and goods in proper form with a list of postal attachments to our address: 198216, St. Petersburg, Leninsky Prospect, house 140, letter I, BC "Cosmopro", office. 201

- After receiving the product and checking it, we send a new product or return the money to the buyer's account

+ Add review

Product added to cart

Product Name

Go to shopping cart Continue shopping