One of the most popular floor coverings is linoleum. The big advantage of this material is a huge variety of textures and colors. Not so long ago, insulated samples with a dense base appeared on sale. In this article we will try to figure out what they are, what are their advantages and whether there are any disadvantages.

Insulated linoleum

Linoleum properties

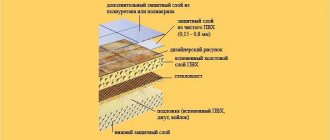

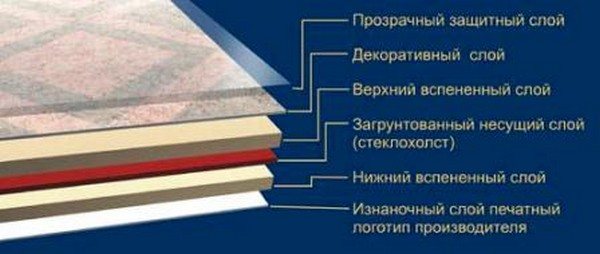

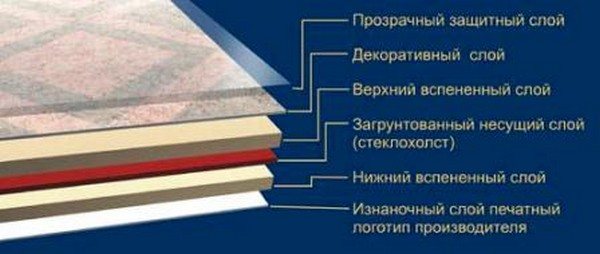

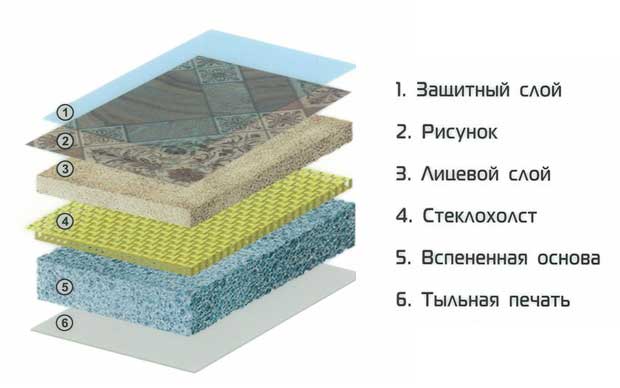

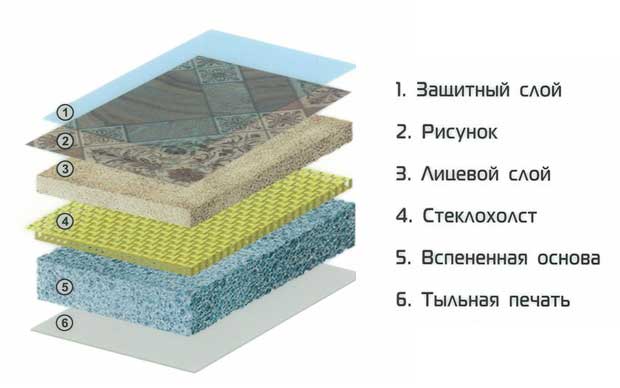

Linoleum with a dense base consists of 5 layers.

- A protective coating that protects against abrasion and mechanical stress.

- Decorative. It looks like a film decorated with an ornament.

- The third layer is polyvinyl chloride. Thanks to him, the coating has a softness and the ability to isolate sounds.

- Fiberglass. It provides strength to the coating.

- Insulation. It is the thickest of all layers. It is he who allows the material to provide thermal insulation.

After it, a finishing layer can be located, which is a film. It may display the manufacturer's brand. But this layer goes separately from linoleum, the base of which consists of felt.

Insulated linoleum consists of five layers

Reviews of felt-based linoleum

View gallery

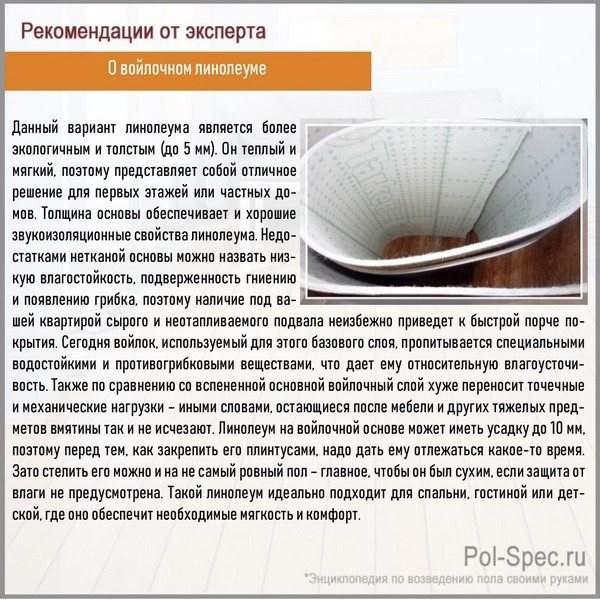

Thick insulated linoleum can be made on a felt basis. According to the manufacturers, it consists of two layers, the bottom of which is made of an antiseptic pad. The top layer is made on the basis of a polyvinyl chloride film. In order to lay such material, it is recommended to clean the base from debris and dust. The rough surface must be firm and level.

Experts say that it is important to exclude moisture absorption by the fibrous part of the material. For this it is important to make sure that the moisture content of the substrate does not exceed 5%. For this, it is recommended to use a small piece of glass that is placed on the surface and remains for 2 days. If after this time you notice traces of moisture on the inner surface of the glass, then the base is not suitable for laying the felt base, since such linoleum after a while may simply begin to rot. Failure to dry the surface properly can result in additional costs in the future. In this case, it is necessary to carry out surface treatment with special solutions that prevent the spread of mold.

Types of linoleum

Regardless of its basis, linoleum can be of several varieties.

| View | Description |

| Domestic | This type is intended for residential premises in which there is no large-scale congestion of people. Since this is the most economical option, its surface has a rather simple color, which weakly imitates high-quality expensive coatings. Household linoleum is soft enough and can be placed in a room on the ground floor or in a country house. |

| Semi-commercial | This variety is able to withstand increased loads, so it can be used for laying both in residential premises and in offices. If the floor is very cold in the room, then this type of coverage can get rid of such a problem, but provided that there are not many people there.The colors of linoleum are often the same as those of tiles or parquet, but there are also quite interesting patterns or ornaments. |

| Commercial | Commercial insulated linoleum is not often found on sale. It is rarely purchased, since in workrooms where this material is used, people walk in shoes, which allows them to keep their feet warm and without insulated linoleum. |

There are several types of linoleum

There is another, rather original type of linoleum called "homogeneous". This variety has a base of polyvinyl chloride mixed with a variety of dyes. The peculiarity of such linoleum is associated with its structure. Thanks to her, the material, even after being used, does not lose its decorative appearance. This is due to the fact that the material is painted in full thickness and the abrasion of the surface does not affect the pattern in any way. This type of coating can be made on an insulated basis. It is perfect for classrooms in educational institutions.

homogeneous linoleum

Another variety - material incapable of conducting electrostatic stress. It is used for rooms where there is a large accumulation of electrical equipment. The outer layer of the material is an insulator against electric current, since it is not capable of conducting it. However, copper tapes are embedded in it, which are connected to ground. They are necessary to dissipate static electricity collected by the floor.

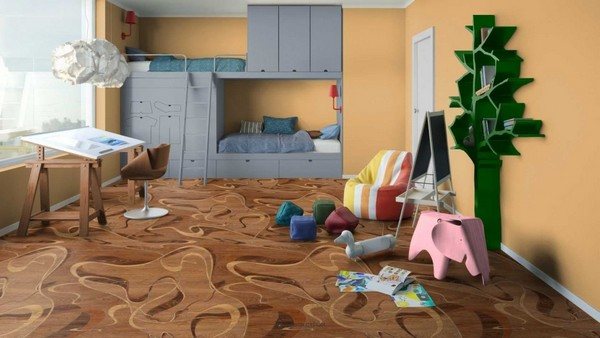

Everything is known, linoleum is a very slippery coating, especially when wet. It is easy to slip on even in socks. In this regard, manufacturers have developed a coating that has an anti-slip effect. This flooring material is ideal for children's rooms. In addition to having a soft base, it will prevent children from slipping on slippery floors.

You can buy linoleum with an antistatic effect, anti-slip, natural - there are a lot of options

Consumers are used to thinking that linoleum is a completely synthesized material. However, thanks to the latest technologies, manufacturers create a natural material with an insulated base on resins of natural origin. Such a coating will be a good solution even for an eco-house, as it is harmless to health and does not cause allergies. However, the prices for such coverage are also not low.

The advantages of insulated linoleum

If we compare the presented variety of linoleum with its simplest analogue, then a number of rather significant advantages can be distinguished:

- Increased level of thermal insulation.

- Significantly longer service life due to the high density and thickness of the material.

- The coating is able to adapt better to small irregularities.

- Better at absorbing noise and vibration from steps and falls.

- The surface begins to spring a little, which makes it much more difficult to break glass and ceramic objects against it.

Insulation types

In addition to the top layer, linoleum also differs in the type of insulation used in the manufacture of this floor covering. Various materials can be used for thermal insulation.

Insulated types of linoleum are produced with different parameters. In this case, the dimensions are not only set by the manufacturer's wishes, but also depend on the type of substrate. Each manufacturer produces any type of linoleum with a minimum width of 1.5 meters. Further, the width continues to increase by 50 cm.

The width of the foam-based material is 5 meters. Such parameters are in great demand, as they are convenient for laying in apartments with a standard layout. In this case, it is usually not necessary to resort to joining or gluing the canvases.

The felt material is produced with a maximum width of 3 meters.

Insulated linoleum is felt, on a foam basis, from jute

The natural jute backing is quite brittle, so it will be no more than 2.5 meters wide.

The maximum roll length can be 60 meters, but usually their length does not exceed 15-45 meters. Due to its fragility, natural canvas cannot be longer than 6 meters.

To select the parameters of insulated linoleum for your home, you need to measure the perimeter of the room. Due to the fact that when building a house and repairing the parameters of a regular rectangle are very often violated, it is necessary to carefully measure all four sides.

To the obtained value of the length and width, it is necessary to add another 5 cm each. Thus, you can get the size of the canvas that is suitable for the floor in this room.

Since the width of the linoleum is set in advance and it makes no sense to cut it, you need to choose the optimal size. For example, if for a room 3 * 3.9 m you need a canvas with parameters 3.05 * 3.95 m, this canvas will have to be cut to a minimum. Thus, some of the funds will be saved.

insulated linoleum

It is important to measure the room in advance in order to buy enough material.

How to choose insulated linoleum: 4 important tips

You can quickly and inexpensively insulate the floor in a room using insulated linoleum One of the most popular coatings is linoleum. It contains materials that provide high strength, wear resistance and reliability of the coating. Such material is relatively inexpensive, while it has high performance. Linoleum can be commercial, semi-commercial and household. Insulated linoleum is used in rooms with too cold concrete or wood floors. It can have a different basis: you need to pay attention to this when purchasing it.

Content:

When the floor is cold in the room, either its thorough insulation or the use of materials that are capable of providing the surface with thermal insulation is required. Linoleum is an excellent coating that does not require large material costs, unlike installing a warm floor. Insulated linoleum is used to insulate the floor without additional material costs.

Thick linoleum is often used to cover uneven surfaces to hide cracks and deformations in the floor.

Linoleum can have a different base with a complex structure. At the same time, manufacturers offer a wide range of coatings with a variety of patterns: geometric, abstract, thematic. Such linoleum is distinguished by its elasticity, which ensures comfortable movement on the surface.

Today, felt-based linoleum is popular and in demand.

Types of bases for linoleum:

- Foamed. It is characterized by a complex structure. It consists of an upper decorative layer. The middle layer is made of foam rubber. It creates excellent thermal insulation and also protects against the penetration of excess noise. The material is quite effective despite its thinness. The coating is practical and easy to maintain.

- Warm. Consists of a film that is glued onto a jute or felt surface. The coating has a soft, pleasant surface. The disadvantage is the vulnerability of the top layer to damage. You should not lay this material in a room with high traffic, as well as in a room with high humidity.

The choice of material quality directly depends on where the linoleum will be laid. It is important to take into account the characteristics of the room, its permeability, the level of humidity and the finish of the floor. Reviews about each type of warm linoleum can be read on the Internet.

How to choose the right warm linoleum

Modern warm linoleum is no longer made from natural materials. Artificial materials have proven their reliability, strength and durability.Warm linoleum can be divided into several types, depending on what basis it has. The methods of laying linoleum also depend on what materials it is made of.

For example, linoleum with a felt base can be laid on the floor without prior screed.

For laying in living quarters with a cold floor, especially on the first floors, felt linoleum is used, which perfectly stores heat and does not allow cold to pass through. It is this linoleum that is best used for giving, if it is not possible to install a warm floor. In order for linoleum to last a long time, when choosing it, you need to follow the advice of professionals.

When choosing insulated linoleum, attention should be paid to its quality and main characteristics

Tips for choosing warm linoleum:

- Linoleum based on jute or felt is the best to lay in a room with a high level of humidity.

- If there is a heavy load on the floor, it is better to lay foam linoleum on it.

- It is important to choose linoleum decor for the overall style of the interior. When laying, make sure that the pattern or pattern matches.

- The width of the linoleum should be such that there are not too many joints on the floor.

The choice of linoleum should be influenced by how durable it is. The service life of the surface will depend on the class of linoleum. When buying, it is important to pay attention to product quality certificates.

Foamed linoleum layers

The structure of linoleum on a foam basis is quite complex. The thickness of the linoleum is large enough to provide the surface with warmth and make it even. Linoleum with this type of base has a beautiful appearance, which contributes to its popularity among consumers.

One of the well-known types of linoleum, which is widely popular and is distinguished by quality characteristics, is Tarkett.

This is linoleum with a heat-insulating surface, wear-resistant, durable and at the same time breathable. Its basis consists of six layers, each of them performs its own function. Linoleum is thinner than felt-based coating, but the addition of fiberglass makes it much stronger.

Many people prefer to choose insulated linoleum, since it is easy to care for it.

Foamed linoleum layers:

- Transparent layer for protection;

- Decorative;

- Foamed layer;

- Primed layer;

- Bottom foam layer;

- Seamy layer.

This is the most practical type of flooring. It is easy to care for and wash. It is only important to remember that it is better to clean linoleum daily, and not once after washing it from accumulated dirt and dust will become impossible.

The process of laying linoleum with pile

This type of coating requires specific attention. It should be noted that the choice of linoleum is a simple matter, because they choose it for a long period of time. The material has a two-sheet structure, which affects the characteristics of linoleum and its performance.

Linoleum with pile is perfect for those who love warmth, comfort and coziness: it is soft, resilient and easy to cover the floor surface with.

But it is worth noting that this material can be laid exclusively in a dry room, since moisture can destroy the structure of linoleum and render it unusable. If the floor will experience heavy loads, then it is likely that linoleum with pile may not withstand this. Therefore, before buying, it is important to take into account all the nuances and characteristics of the room in which the linoleum is supposed to be laid.

It is not difficult to lay linoleum, the main thing is to correctly approach this process

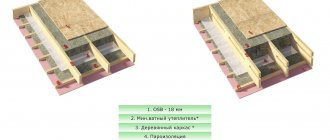

How to prepare the floor:

- Remove old coating. Assess the condition of the floor without it. Finishing must be good, otherwise repair work will need to be carried out.

- Lay the underlay, which will be the transition layer. It is better to choose the jute version - it has a natural base.

- Covering the floor with plywood sheets will give the surface strength.

- Carry out waterproofing if the floor is covered with wood. To do this, put a film. Cover it with fiberboard, prime it, cover it again with foil.

The film floor is laid on top of this entire floor structure. Experts do not advise laying chipboard under the linoleum - this is a rather fragile material that can lead to the failure of the floor. Linoleum with pile is perfect for dry living spaces with normal humidity levels.

Types of insulated linoleum (video)

Insulated linoleum allows you to significantly save on the installation of warm floors. It is usually applied to cold concrete wood surfaces. Linoleum can have several bases, but they all differ in heat and sound insulation function. This quality largely depends on the thickness of the coating. You need to choose the material very responsibly, take into account the characteristics of the room in which the linoleum will be laid. There are three types of linoleum: household, commercial and semi-commercial. When buying, be sure to check the product quality certificate.

Examples of insulated linoleum (photo)

Attention, only TODAY!

kitchenremont.ru

Selection criteria

When choosing any type of linoleum, you need to take into account the general classification in order to purchase a coating that is suitable for all criteria. It is worth considering the wear resistance class:

- household - from 21 to 23;

- for public places - from 31 to 43;

- for industrial use - from 41 to 43.

There is a division into such groups:

- F - the smallest thickness, including wear resistance;

- M - low level of wear resistance;

- H - average level of wear resistance;

- T is the most wear-resistant type.

When buying, be sure to pay attention to the wear resistance class of linoleum

Criteria for choosing a coating on a foamed interlayer

When choosing linoleum on a foam basis, it is necessary to take into account that such a coating is similar in structure to a multilayer cake - this explains its thickness. In order for the coating to fit into the interior, it must be consistent in color and design with the room. To avoid problems with laying the flooring, you can spread it in the room where it will be laid.

This surface is very practical, since even with prolonged use it does not wear off, due to the fact that the pattern passes through the entire structure of the material. This allows it to be used for rooms designed for heavy loads.

Quite popular and inexpensive foam-based linoleum

Choosing linoleum with a natural base

This type of linoleum is good for rooms with low traffic, such as a bedroom. But this natural coating requires selection, taking into account the criteria for use, because mechanical damage is formed on it very quickly. However, this type of linoleum should not be exposed to high humidity, otherwise the natural base will begin to rot.

Natural insulated linoleum does not really "like" high humidity, so it should not be used in the kitchen, in the bathroom

General recommendations for selection

Such a thick floor covering can create a comfortable environment for living indoors, if the choice was made correctly. Of the main conditions, the following can be noted.

- If the level of humidity in the room is increased, then it is better to refuse a two-layer felt or jute coating.

- With increased traffic in the room, the best choice is linoleum on a foam base.

- When purchasing linoleum for several rooms at once, you need to take into account the combination in color and style.

- When connecting separate fragments of the coating, you need to follow the clear joining of the pattern.

- The correct selection of parameters will reduce the number of seams and joints on the flooring.

If the calculations are correct in advance, you can avoid a large number of joints. - For each individual room, you need to choose linoleum with suitable wear resistance. For example, for a pantry or a bathroom, a very durable coating is not required.

- For the lower floors of private or apartment buildings, you need to purchase linoleum on a foam base.

- A two-layer surface on a natural surface does not need to be fixed to the floor, because this has a bad effect on the thermal insulation of the material.

- For children it is better to choose jute linoleum - it is very convenient and safe for children.

For children, it is better to choose natural linoleum, for example, jute or felt

Important nuances of selection

First of all, in order to get a really high-quality covering of your floor, you should treat the selection very carefully and with due attention to many factors that will not influence this. You must take the process very seriously and make your choice slowly.

You should take into account the following nuances during your choice:

- Additional protection against moisture.

- Texture and color scheme.

- Manufacturer.

- Coverage class.

- Cost. Choose between a cheap and an expensive model.

Now we will talk about each of the points in more detail, so that you understand exactly what we are talking about.

Extra layer of moisture protection

This criterion is especially important when there is a risk that moisture will seep under the coating. It can cause a large number of the most unpleasant problems, from the formation of fungi and mold, to the complete unsuitability of the coating after a very short period of operation.

Such a layer can be a film that is fixed under an insulating layer, it is she who perfectly helps to prevent moisture penetration to the insulation and keeps your warm linoleum.

When laying linoleum on a "warm floor" system, it is recommended to use ordinary insulated linoleum due to its greater naturalness.

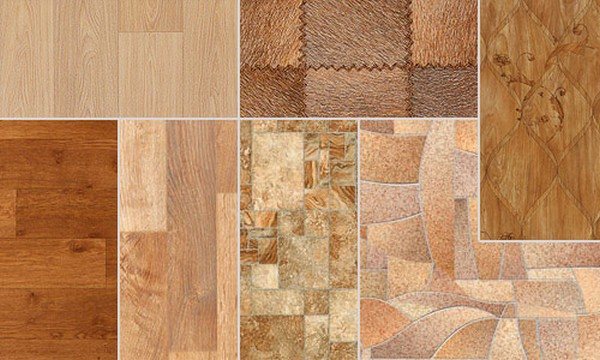

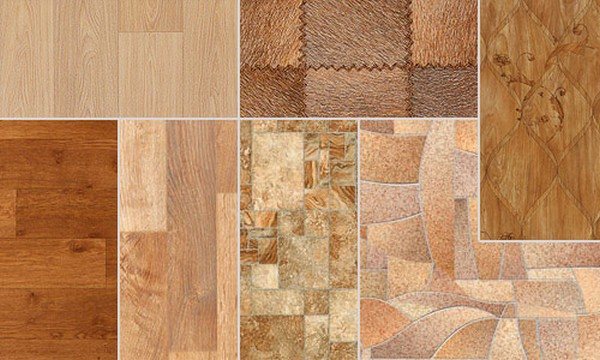

External design

Choosing a covering for the kitchen, the best solution would be a design in natural styles. It can be in the form of wood, with various elements of carving on it. The textures of small and large parquet boards of various colors and designs will also fit well in the kitchen.

Try to choose darker tones, as they will less visible dirty spots, fat deposits, and more. Then you don't have to wash your warm linoleum very often.

Manufacturers

There are an incredible number of linoleum manufacturers and each of them has its own modifications and features. But nevertheless, not all of their products are of the same quality and the way they meet all the requirements that consumers put before them.

If you are lost among a huge number of manufacturers, then insulation for linoleum should be bought from the following brands:

- Tarkett.

- Sinteros.

- Juteks.

- Sinteros.

- IVC.

The presented list of manufacturers has the greatest popularity and they all managed to prove to consumers the level of their quality and high performance of products.

Linoleum class

This criterion shows the resistance to wear of the surface, it happens in three main classes, which in turn are divided into three additional categories, namely:

- 21, 22, 23 is the lowest.

- 31, 32, 33 is an average indicator, most often you can find it at home, the cost is affordable and the quality indicators are very high.

- 41, 42, 43 - this is the highest level, such linoleum is the most dense and, accordingly, has a greater degree of thermal insulation.

Features of laying felt linoleum

The pile coating needs special attention. It is worth noting that the selection of linoleum is not an easy task, because it will be used for a long time. Linoleum has a structure consisting of two cavities: they will determine the properties of linoleum and its performance.

About felt linoleum

Felt linoleum will be appreciated by people who prefer convenience, coziness and warmth. It is resilient, soft and easy to lay.

However, only a dry room is suitable for the operation of such material, otherwise moisture will destroy the coating from the inside and make it unusable. But if the flooring is subjected to heavy loads, it is likely that the surface with a fleecy surface will not be able to withstand it. Thus, before purchasing linoleum, you need to take into account all the features of the room in which it is planned to be laid.

It is better not to use felt linoleum in rooms with high traffic.

Laying linoleum will not be a problem if you take a responsible approach to this task and take into account the recommendations of specialists.

Types of insulated linoleum (video)

Insulated linoleum allows you to significantly save on the installation of warm floors. It is usually applied to cold concrete wood surfaces. Linoleum can have several bases, but they all differ in heat and sound insulation function. This quality largely depends on the thickness of the coating. You need to choose the material very responsibly, take into account the characteristics of the room in which the linoleum will be laid. There are three types of linoleum: household, commercial and semi-commercial. When buying, be sure to check the product quality certificate.

Floor preparation

First, you need to remove the old coating and evaluate the subfloor. If it is of inadequate quality, you need to eliminate various defects, irregularities.

Then you need to roll out the substrate, which acts as a transition layer. The best option is a jute base, it is the safest.

First, remove the old flooring, then lay the substrate under the linoleum

To increase the strength of the floor, it is covered with plywood sheets.

If the floor surface is wooden, it is worth providing waterproofing. This can be done by placing a film, then cover it with fiberboard sheets, then prime them and cover with another layer of film.

Professionals do not recommend placing chipboard sheets under linoleum, since this is a fragile material that can deform.

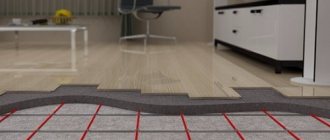

Varieties of underfloor heating

Such technology of home comfort as underfloor heating can be performed in several versions. The implementation of this system in conjunction with a properly selected coating provides a pleasant tactile sensation.

Underfloor heating with linoleum finishing can also effectively complement the heating system. This is achieved by covering the entire area of the room with heating elements and its optimal heating - with a higher temperature at the bottom of the heat source (22 - 24 ° C) and slightly lower, but quite comfortable, under the ceiling (18 - 22 ° C).

Comparison of heat exchanges for different types of heating

According to the technology of transferring thermal energy, underfloor heating structures can be divided into two main types:

- Water.

- Electric.

Electrically heated and liquid-cooled systems can differ in the way the project is implemented.

Water heat-insulated floor

The standard version of the water warm flooring is performed according to the following scheme:

- laying on the base of hydro- and heat-insulating materials;

- fixing pipelines on a metal mesh;

- filling pipes with concrete.

The thickness of the screed over pipes with a diameter of 16-18 mm, as a rule, is at least 30 mm.

Water Heated Pipe Laying Option

Due to the need to turn the pipes, the laying spacing is limited and should be within the range of 22.5 - 35 cm. The hydraulically heated base is compatible with marmoleum and PVC material.

Heating cables

Another solution for warm flooring under linoleum is the use of an electric heating cable.

Heating cable

The electrical cabling system using resistive cables is equipped with a thermostat and a temperature sensor.

Modern self-regulating thermal cables are gaining great popularity. The basis of such a heating cable is a cross-linked polymer heating matrix with graphite additives. This matrix contains two copper conductors.

The heating power of the system is adjusted by changing the resistance of the matrix depending on the temperature of the heating element.

Self-regulating heating cable

A covering with a cable heating system can be universal, including linoleum, compatible with the "warm floor" system.

Infrared floor

The infrared technology is based on the use of a special film.

Infrared technology with low heat transfer intensity is quite compatible with the option of linoleum flooring.

The infrared floor heating system is one of the most energy efficient. Compared to a heating cable, the energy consumption is 25% less.

Heating elements are sealed in polypropylene film, supplied in rolls.

Infrared film material

The strips are heated by a source of electrical energy transmitted over the copper / silver conductive busbars located along the edges. The carbon paste deposited on the film heats the surface of the flooring in the form of infrared radiation and is transferred to the environment.

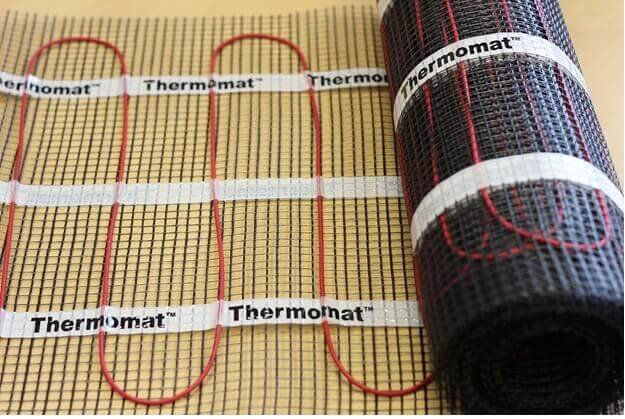

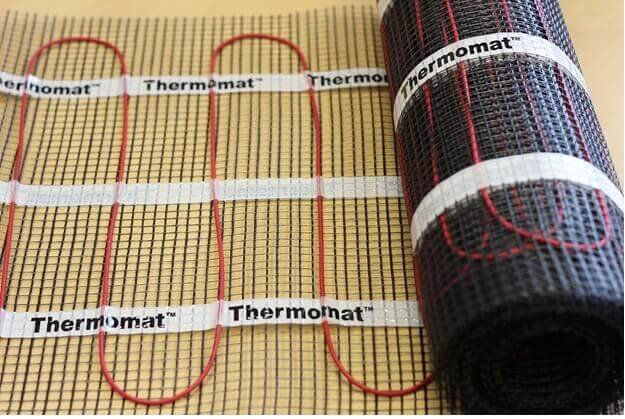

Cable thermomat

The operating principle of the thermomat is based on the heating of resistive cables woven into a dielectric fiberglass mesh. To reduce the level of electromagnetic radiation, the cable cores in the mats used for residential premises are double, shielded and protected by an outer sheath.

Thermomat roll

The design and operation of the heating system using thermomats is simple. Automatic regulation of the heating temperature makes it possible to combine not very heat-sensitive coatings with heating mats.

Bonding linoleum joints - analysis of methods

When buying linoleum, you should pay attention to its width. It is good if it matches the width of the room. In this case, it will be possible to lay linoleum without connecting the joining points. Thus, the base will acquire the optimal level of sound and heat insulation, as well as tightness.

In a situation where linoleum has already been purchased, but its width does not correspond to the width of the room, then the seams will need to be glued. This technology is suitable for both foam-based linoleum and warm varieties.

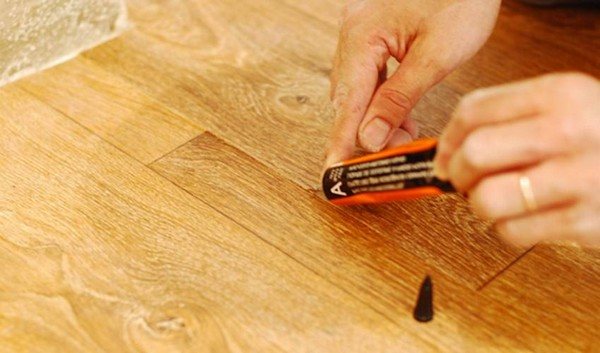

Welding of joints can be done in two ways: hot or cold. The latter can be done using a tube of glue containing tetrahydrofuran, plasticizers and chlorine.

cold welding for linoleum

Linoleum joints can be joined by cold or hot welding

The hot method involves the use of a hair dryer and wire, which must melt under the influence of high temperature. The resulting liquid mixture must fill the joints in order to obtain a tight and impermeable connection. This method is the best, but it requires special equipment and skills to work with them.

The gluing procedure must be performed very carefully so that the melted glue does not drip onto the linoleum.

Before buying linoleum from the seller, you need to get information on how to connect it. Many types of household coatings cannot be hot glued because soft coatings are not suitable for high temperatures.

Experts recommend using cold welding for living quarters.

To perform cold welding, you will need a ruler, masking tape, a tube with welding, a knife with a sharp blade. Let's describe the sequence of actions.

| Sequencing | Description |

| Linoleum is laid joint to joint.In this case, you need to ensure that the connection of the canvases is very tight and the drawing coincides. After this, the joints are connected using masking tape. With good gluing, the seam should be in the center of the tape. Then an incision is made through the tape at the joint. |

| Read the instructions carefully before applying the mixture. After opening the tube, a special needle is placed on it, which is placed in the incision. Then the joints are filled with welding along the entire length of the seam. |

| The gluing process must be carried out very carefully. If the welding gets on an uncovered canvas, then it will be difficult to remove it without damaging the surface. After 10 or 15 minutes, the masking tape can be removed. The weld will dry completely only after 2-3 hours. |

The hot method is more complicated. To complete it, you will need to purchase a welding gun with a special attachment. Instead of glue, in this case, instead of glue, you will need a special wire, which has a similar composition with linoleum.

When performing work, in addition to equipment, you will need a knife with a sharp blade and a vacuum cleaner in order to collect the debris.

hairdryer for welding

| Sequencing | Description |

| When the quality of the joining and registration of the pattern is assessed, it will be possible to trim the seam for a chamfer. For this, both a construction knife and a curved knife designed for docking are suitable. After that, you will need to collect all the trash. The joints of the canvases must be thoroughly cleaned with a vacuum cleaner. |

| For work, a building hair dryer is heated to a temperature of 350 or 400 degrees. Then a nozzle is put on it and a wire is inserted. The first wire burn is carried out. |

| After that, you can start gluing the seams. Filling the joints with the composition is carried out along the entire length. |

| When the seam dries, its remnants are cut off with a knife. For this, special blades are sold. First, the most protruding part of the welding is cut, and then the final trimming is performed at the same level with the felt surface. |

How to lay linoleum with insulation

Before starting work, you will have to perform a number of measures that will ultimately allow you to get a high-quality and durable finishing base. The sub floor must be prepared for installation... Regardless of what material it is made of (wood or concrete), the base must be flat and free from defects. First, the old coating should be removed. Various kinds of cracks, chips or potholes can significantly reduce the service life of the pavement, especially where there is significant permeability. Naturally, the protruding screws and nails need to be removed, and the bulging of the rough covering should be eliminated.

Important! Linoleum can be laid on the old finishing base, if, of course, it is strong and reliable: ceramic tiles, old linoleum, parquet, etc.

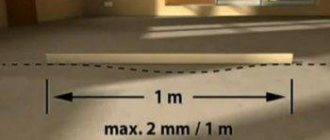

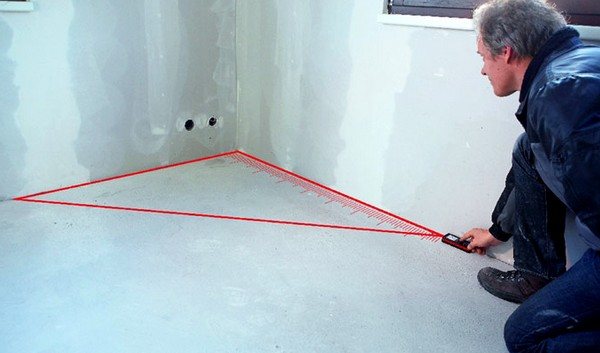

The evenness of the base is determined using a two-meter rail. If the gap between it and the floor surface exceeds 2 mm, leveling will have to be done. For this, pouring a concrete screed or self-leveling floor is used.

Checking the evenness of the subfloor

The strength of the rough base should not be less than 100 kgf / cm. Cracks and other defects can be eliminated with repair mortars or putty (its type is chosen depending on the base material). The moisture content of the subfloor should not exceed 5%.

- Before laying linoleum, dirt and dust must be removed from the base.

- Installation of the coating is carried out at an ambient temperature of at least +18 degrees.

- Two days before the start of work, linoleum should be rolled out in the room to be finished and left unfolded. This is necessary to eliminate undulation (if there is a need for quick leveling of the material, you can use special heated rollers) and acclimatize the coating.

- The configuration of linoleum should be adjusted in such a way that a gap of about 5 mm remains between its edges and walls.

What else do you need to pay attention to?

- As already noted, an adhesive composition can be used for laying the coating, but it is possible to do without it. However, in places where it is possible to moisten the floor during operation (spray from washing, moisture from watering indoor plants, etc.), it is recommended to coat the edges of the cladding with glue to a depth of about 20 cm.

- Skirting boards covering the gaps between the walls and the edges of the linoleum should only be attached to walls or partitions.

Calculator for calculating the area of a quadrangular room

Go to calculations

Installation without the use of glue

In small rooms, you can lay the coating without the use of adhesives. The floor must be level. The felt backing is able to neutralize minor flaws. Furniture and other interior items should, if possible, be taken out, baseboards should be dismantled.

Important! It is not forbidden to use the floating method of laying the coating in spacious rooms. In this case, the joints of the canvases are welded by cold or hot welding.

The material can be laid without glue, but not always

No special tools are required. Of the necessary - only a construction knife and a tape measure. To fix the skirting boards, you need a drill (or perforator), with which you can make holes for installing dowels and self-tapping screws, as well as a screwdriver or screwdriver. Skirting boards are cut with a metal hacksaw.

Step 1... Linoleum, rolled out and having time to acclimatize, is distributed over the surface. An overlap is made on the walls.

Linoleum rolls out

Step 2... The cover is adjusted to size. Using a sharp knife, sections are cut out on structural protrusions (at corners, near heating pipes, etc.), trimming is performed around the perimeter (a small gap is left from the walls, otherwise, as a result of thermal expansion of the material, you can subsequently get a wavy coating). To make the cutting lines more accurate, you can use, for example, a rule.

Linoleum trimmed

Step 3... The skirting boards are fixed on dowel-nails or self-tapping screws (it all depends on the material of the walls). The installation step of the fasteners is from 25 to 50 cm (determined by the configuration of the room). A hacksaw is used to trim the skirting board.

Fixing the plinth

The floor is ready for use.

Linoleum laid successfully

The advantages of floating cladding of a small room is the ability to lay a monolithic seamless coating. In this case, the fixation of linoleum is carried out by means of baseboards.

Installation of linoleum on glue

In this case, you will need a lot more tools and materials. In addition to the fact that it is necessary to fix the coating, the seams of the canvases will be welded (while it is necessary to ensure that the docking is carried out without losing the overall pattern).

When carrying out work, you can not do without: a tray, a roller and a primer for preliminary surface treatment, a spatula and an adhesive composition (it also needs to be kept indoors for a day) to fix the coating, an assembly knife, devices for smoothing linoleum and trimming welding seams, a construction hair dryer with a nozzle, a plastic cord for filling the seam, tools and fasteners for fixing the skirting boards.

Step 1... Just as in the previous version, linoleum is rolled out over the cleaned surface and cut to size.

Step 2... The base is primed (it will not be possible to do without this stage, the primer provides high-quality adhesion of materials). The primer should dry.

Step 3... Half of the linoleum sheet is folded back. Using a spatula, the adhesive is evenly applied to the open subfloor.

The adhesive is applied to the open subfloor

Step 4... Linoleum returns to the place treated with adhesive.

The material is returned to its place

Step 5... The coating is smoothed out (from the center to the edges).To do this, you can use any available means (roller, clean rags, soft spatula, etc.). This treatment will remove excess glue and air, and will also ensure a tighter adhesion of the coating to the base. There should be no protrusions (due to excess glue inside) on the surface. Especially carefully it is necessary to smooth the coating near the walls and at the seams.

Linoleum is smoothed

Step 6... The second half of the cladding is glued in the same way.

Step 7... Seams are prepared for welding (chamfer is cut). This creates a lot of debris. It must be removed, otherwise it will interfere with the bonding process.

Step 8... After the glue has dried, the seams are hot-welded. To do this, a mounting cord (matching in color) is inserted into a special nozzle of a heated building hair dryer. The melted compound is gently spread over the seam.

The molten composition is distributed along the seam

Step 9... The welding cord is trimmed at the joint so that the surface is flat.

Cutting the welding cord

Step 10... At the final stage, the skirting boards are installed.

At the end, you need to install the skirting boards

Famous manufacturers

Insulated linoleum from several companies is sold in the markets of our country. Let's list the most popular ones.

Tarkett

This manufacturer is a leader among the companies involved in the creation of flooring. He has been producing a wide variety of floor surfaces since the early 20th century. In terms of quality, the product meets not only domestic sanitary standards, but also European ones. The company produces both felt-based and foam-based products. In addition, all material has a high fire safety class.

Linoleum Tarkett

IVC

This manufacturer manufactures its products in Belgium. His product has excellent characteristics and unique design, so a room with such a floor looks very chic. Thermal insulation is provided in this case by felt. Therefore, the surface will not only be soft and warm, but it will also be possible to move on it barefoot.

Linoleum IVC

Forbo

This company specializes in the production of eco-linoleum. Her products contain about 97% natural ingredients. One of the company's lines creates a cork-based coating. It not only perfectly prevents heat loss, but also blocks sounds. Other lines are used for thermal insulation jute.

Forbo linoleum

Komitex Lin Parma

The specialization of this company is to create economy class household coverage. Felt acts as a heater in this case. Such linoleum is well suited for temporary housing or summer cottages. Its cost allows it.

Linoleum Comitex Lin Parma

Linoleum brands popular in Russia

| Photo | Name | Rating | Price | |

| #1 |

| "Tarkett" | ⭐ 99 / 100 | Find out the price |

| #2 |

| Forbo | ⭐ 97 / 100 | Find out the price |

| #3 |

| Grabo | ⭐ 96 / 100 | Find out the price |

# 1. "Tarkett"

The company has been producing linoleum for a long time. All products are certified not only by domestic but also by European organizations. The range of coatings includes both foam-based and felt-based materials (grades 21 to 34). Moreover, the first option consists of seven layers, which ensures its excellent functionality (including fire resistance). The variants of the offered textures can satisfy any taste.

Tarkett Admiral Adriano 2

Linoleum Tarkett Grand Aston 2

Tarkett FAVORITE AMUR.1 (Cupid.1)

Prices for linoleum "Tarkett"

linoleum tarkett

# 2. Forbo

The products of the international concern are in demand today in Europe and in our country. More than 40 factories have been opened in different states. The main focus of the manufacturer is on the production of eco-linoleum (from natural ingredients). But PVC coating, including jute-based linoleum, is produced in a wide range.

Forbo linoleum

Prices for Forbo linoleum

Forbo linoleum

No. 3. Grabo

Floor coverings for various purposes have been produced under the French brand for 60 years. The range of the company includes: commercial, household, acoustic and anti-slip linoleum. The protective layer thickness of 0.4 mm ensures excellent performance of the material.

Commercial linoleum Grabo

Prices for Grabo linoleum

Linoleum Grabo

Today, linoleum is chosen as a floor covering not only for finishing country houses and budget housing.The quality of the material with insulation, durability and aesthetic characteristics allow it to become as competitive as possible in the market for products used in finishing work.

Linoleum care

Proper care will keep your floor looking cozy, beautiful, and warm. Most users do not consider such measures necessary, but if they are not followed, then its surface will quickly become unusable. In addition, all these activities are not labor intensive:

- regular cleaning of dust and dirt;

- polishing, it will be useful even if the coating is already shiny.

If you do not neglect such manipulations, then the coating will delight the eye for a long time.

To prevent linoleum from losing its original appearance, it is worth taking care of it properly.

Linoleum

View gallery

You can insulate the floor with linoleum using material from, which offers its products from 181 rubles. per square meter. This material has a protective layer with a thickness of 0.15 mm. The coating belongs to the G4 flammability class.

Fiberglass is used as a protective layer, and the abrasion is 35g / m2. According to tests, the change in linear dimensions can be 0.2%. The manufacturer indicates that the service life of the material reaches 20 years. This linoleum is insulated, the price of which is acceptable for the average consumer, has the quality of moisture resistance and can be used for warm floors.

Which coating is suitable for a cold floor?

The choice of floor covering for thermal insulation is determined by a number of factors. The budget allocated for the purchase of the material will play a key role. If its size does not matter, then it is better to opt for natural linoleum. But if the amount intended for the purchase is rather modest, it is worth purchasing a household type of coating or looking in stores for the remains of high-quality linoleum, which are sold at a low price.

The choice of linoleum can be influenced by the purpose of the room for which a new thing is planned. For example, for a nursery or a bedroom, you can choose a household floor, and for the rest of the common rooms, you can buy a semi-commercial floor.

The base for linoleum is also important. For uneven wooden surfaces, a felt-based coating is the best option. This recommendation is due to the fact that the felt hides the gaps between the boards and small differences. But for a perfectly flat surface, you can choose any linoleum.

If the surface of the subfloor is perfectly flat, you can choose any type of linoleum

For a bathroom, it is worth making a choice in favor of linoleum with foam insulation. It is not afraid of the effects of fungi or mold, moreover, it calmly reacts to temperature changes and high humidity.

Choice for an apartment

For the installation of linoleum, special glue is used

To choose linoleum for an apartment, you need to consider the following factors:

- Appointment of the premises. If the room is not inhabited, it is not always advisable to lay such a floor covering. If the building is not heated or the heat loss is high and costs need to be reduced, pile linoleum can be used.

- Heating quality. When using weak equipment, the use of insulated flooring will bring little benefit.

- If the room has a high temperature humidity, you need to choose a material based on artificial components.

It is important to consider the compatibility of shades and patterns with the design of the rooms, as well as the color scheme of the entire room.

Insulated linoleum types

This material has two main modifications:

- on a foam base;

- on a warm substrate.

Foam cover

This species is characterized by a multilayer structure. It can, on average, have at least five layers that perform different functions.

- The bottom layer is located directly on the subfloor, therefore, increased requirements are imposed on such qualities as tensile strength and resistance to breakdowns or cuts. Therefore, it is made from a combination of ingredients, the most important of which are PVC and expanded polystyrene. Thanks to this combination, the substrate acquires not only plasticity, but also low thermal conductivity.

- The next layer, made of fiberglass, is reinforcing. It is he who is "responsible" for the strength of the coating.

- Next is the expanded polyvinyl chloride. Its main function is noise absorption and softening of the entire structure.

- The next layer is decorative and is a film with an image applied to it.

- The final layer is also film, but transparent. It protects the design from abrasion and excessive stress. It can have different thicknesses, which depend on the purpose of the coating. In addition, the film protects the structure of the material from dirt penetration.

Thanks to its multi-layer nature, the synthetic material has excellent performance characteristics:

- resistance to high humidity;

- immunity to mechanical stress;

- excellent sound and heat insulation performance, etc.

Warm Pad Models

This coating is perhaps the easiest to install and the most affordable. It has two layers:

- base - provides heat saving, mainly made of jute or felt;

- the working surface is a reinforcing layer of polyvinyl chloride film, which also serves as a decorative function.

This gender:

- quite soft and elastic;

- installation is simple and does not take much time;

- supports both glue and glueless styling;

- has good thermal insulation properties.

Unfortunately, in addition to the obvious advantages, it has many disadvantages:

- insufficient strength of the surface layer, it is quite vulnerable in terms of mechanical stress. For example, there are obvious heel marks on such a coating. If necessary, we recommend that you consider the option of acquiring a homogeneous species;

- cannot be used in places with a high level of traffic, since the natural base quickly becomes thinner, and the coating quickly loses its main quality - thermal insulation;

- the jute or felt used in the base does not allow laying linoleum in places with high humidity or with insufficient waterproofing. They practically do not tolerate moisture and quickly enough under these conditions are destroyed, mold forms under the working layer, fungi appear.

Currently, coatings with a warm substrate have largely given way to synthetic ones on a multilayer basis. [

On a note

However, felt-based materials are more suitable for underfloor heating, since they tolerate high temperatures better.

Foamed (PVC) base

Vinyl or PVC-based flooring is more durable and moisture-resistant, making it suitable for kitchens, bathrooms, corridors and other damp areas.

The advantages of a mechanically produced foam base include high resistance to point and mechanical loads. This means that the heel marks on your linoleum, as well as the prints of the furniture legs after rearrangement, will quickly disappear.

Linoleum on such a basis has a relatively small shrinkage of 2 mm, but it is recommended to lay it as flat as possible on the floor.

The disadvantages of such a base can be called the fact that it is thinner (1.5-3.5 mm), respectively, such linoleum is more rigid and less shock-absorbing. In addition, the PVC base loses its properties under the influence of temperatures exceeding 27 degrees, which should be taken into account in the presence of underfloor heating.

Laying thermal insulation under linoleum

Quite often, home craftsmen ask themselves how to insulate the floor under linoleum.In order to exclude the absorption of moisture by the material, it is necessary to lay a waterproofing film on the concrete coating, for this simple polyethylene is suitable. Linoleum is laid on top of the film, and the joints are glued with construction tape. If you want to additionally insulate the concrete surface, then you must first apply heat-insulating paint to the base, it will act as liquid thermal insulation. After applying it, you must wait until it dries completely, and lay plywood on top of it, on which the linoleum will be spread.

The main rules for laying

The product can be laid on a concrete base or on a wooden floor.

Preparation of the base consists in removing debris, if necessary, to repair cracks.

Before laying linoleum, the base must be dry.

The material is spread on the floor and allowed to lie down in the room where it will be installed.

The air temperature must be kept from 18 degrees and above.

After this coating has acclimatized and settled down, it should be glued.

Such a product is attached to the base by means of plinths.

The seams between the individual parts of this coating should be hot or cold soldered.

High operational properties, simple installation, beautiful appearance, a large selection of varieties - positive reviews from buyers of this floor material are simply off the charts!

Affordable price and the ability to meet the requirements for premises for various purposes from a residential building, offices to sports facilities, laboratories, hospitals - makes linoleum a popular material that is in great demand among consumers.