Electrical installations

In recent years, with the development of solar energy, when it became possible to receive free electricity, heating a house using various electric convectors and infrared heaters has gained popularity in the domestic market. Such devices are reliable, they quickly heat up the room, while there is no need to lay a pipe system around the house, the homeowner will be relieved of the need to install heating radiators.

The advantages of electric heating include the following:

- ease of maintenance;

- an electric boiler can also be used to heat water;

- reducing the cost of installing and purchasing the necessary equipment;

- environmental Safety;

- efficiency and full automation of the heating system.

It is customary to refer to electrical heating systems as underfloor heating, which is often installed in the kitchen, bathroom and toilet. Today, there are various technologies for arranging a warm floor system, which are effective, they allow you to quickly heat up rooms, while consuming a minimum of electricity.

Of the minuses of this technology for heating a private house, only a significant consumption of electricity is singled out, which leads to a significant increase in utility costs. There may also be problems with heat in the house during power outages, which can be observed in remote villages, dachas and farms.

Pros and cons of using natural coal for heating

Fuel has a number of significant advantages:

- The possibility of using in equipment of different types. Coal for heating is used in stationary, portable type boilers, used for steam and water heating systems.

- Burning duration. One full bookmark is enough for 10 hours, but it all depends on the volume of the combustion chamber.

- High efficiency. The heat transfer of even the lowest-grade coal is higher than that of firewood.

- Relatively affordable cost, ease of transportation. Manufacturers offer fuels of different fractions, which can be moved in bulk (in bodies), bags, boxes.

- When arranging a furnace, it is not required to lay steam lines and gas lines, it is not necessary to obtain a permit for the use of fuel furnaces.

- The heat transfer of the material is high, energy is transferred during the combustion of fractions and after the main combustion, therefore, the heat in the room remains for a long time.

- To maintain a constant temperature of the coolant, you should not fill the furnace to failure all the time; after the first portion, a small amount of energy will be enough to keep the temperature of the water and air comfortable.

- Coal can heat very large areas in regions with the most severe winters.

There are also disadvantages, in particular:

- it is necessary to form a chimney of the correct design for the formation of draft;

- it will not work to automate the process of bookmarking in a private house;

- a lot of slags are released during the combustion process, the ash pan will have to be cleaned regularly;

- fuel storage is carried out in a well-ventilated and dry area.

For the efficiency of the solid fuel boiler, it is recommended to throw coal into the firebox heated with wood.

Where to buy a coal boiler for heating a private house

In Moscow

- Comfort-Eco, Dmitrovskoe highway, 100, building 2, tel. +7 (495) 921-37-61.

- My Kotel, Volokolamskoe highway, 116 bld. 2, tel. +7 (495) 221–56–79.

In St. Petersburg

- TekhnoDom, 57 Stachek ave., Komsomolskaya square, tel. +7 (812) 671–00–88.

- Kit-Teplo, st. Litovskaya, 8, +7 (812) 295–00–05, +7 (812) 248–18–88.

To summarize, it should be said that coal-fired boilers are the "golden mean" between ease of use and fuel costs, so if the house is not connected to the gas main, then its installation is fully justified. Even better - the automatic version: it will help you survive even the harsh winter with comfort.

How to heat so that coal burns as long as possible

The correctness of the furnace of a long-playing coal boiler largely depends on the availability of regulating automation and, of course, the quality of the coal itself.

Which coal is better to use

Manual boilers can operate on any coal fraction. But it should be borne in mind that the temperature of gases in the chimney during prolonged combustion is much lower than during direct combustion: the use of raw fuel can lead to the accumulation of excess moisture in the pipe and the formation of condensate - a black viscous liquid with a tar smell. Therefore, the relative humidity of coal (like any other solid fuel) should be no more than 15–20%.

Correct firebox

The long-burning boiler is fired according to the following scheme:

- Fuel filling - the distributor rises to its original position so that it is just above the loading door, and all the coal is immediately filled up.

- Kindling - dry chips and paper are placed on top of the coal, after which they are ignited and burned with the upper door open and the air duct closed.

- Combustion - when the temperature in the heat exchanger reaches 50-60 ° C, the door closes tightly, then the telescopic air duct regulator opens.

- Temperature control - the boiler automatically goes to the optimal mode, but if necessary, the temperature is corrected by the air duct damper.

At the end of the complete combustion cycle, it is required to remove the caked pieces of coal from the loading chamber, clean the ash pan and fill in a new batch of fuel.

Coal-boiler traditions

Solid fuel boilers of long burning, by the way, were not at all invented "from scratch". In the Russian hinterland, Finnish and Baltic villages, coal stoves of a wide variety of sizes and designs made by local craftsmen are not at all uncommon. Foreign manufacturers simply took the finished model and improved it using modern materials and technologies.

Look at the video example of heating a house with a solid fuel boiler on coal:

By the way, it was from the craftsmen that another interesting idea was spied on - the use of corner radiators. Such batteries are not only convenient in terms of the beneficial use of living space. It is the corners of the house or the joints of the walls that are the most vulnerable places for the penetration of cold into the home. So it is worth protecting them with a thermal curtain in the first place.

Coal heating equipment

Coal stoves

An ordinary stove can only heat one or two rooms, even if you use coal instead of wood to heat the house. True, it can be improved by embedding a heat exchanger for water heating inside the brickwork. The stove is good in its own way, but sometimes it can be dangerous due to the fact that it provokes carbon monoxide poisoning.

Important. The chimney damper can be closed only after the coal has completely burned out and the flames disappear in the firebox.

For heating a cottage with coal, a heating unit such as a boiler is much more efficient, reliable and safe.

Coal solid fuel heating boilers

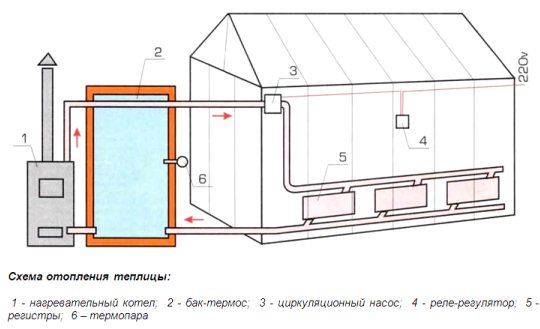

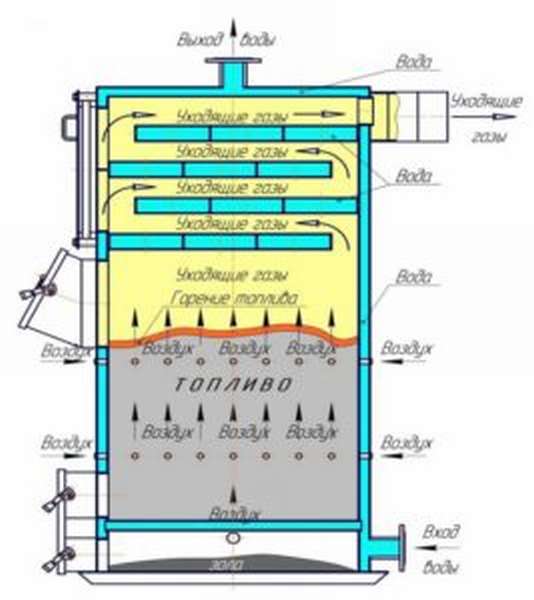

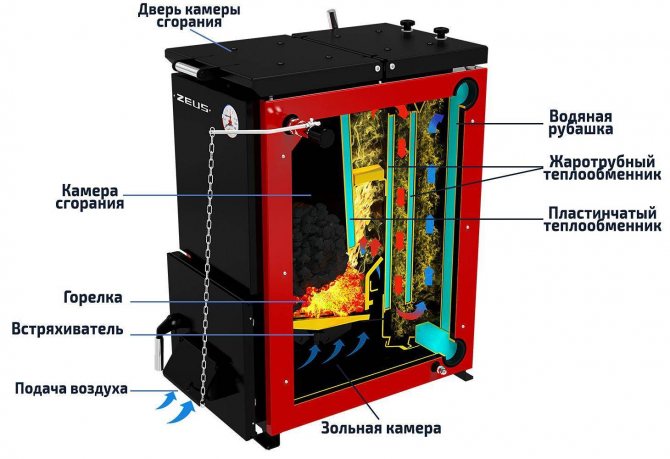

The diagram shows the device of an improved coal boiler

By design, a coal-fired heating boiler is simple, but very effective. Its cast iron heat exchanger and powerful grate are resistant to burnout and corrosion. Even the simplest of these devices have been regularly heating homes for many decades. But still, old-style boilers are inferior in performance and heat transfer to their current competitors.

The principle of operation of a heating boiler looks like this:

- as soon as a fire is lit in the firebox, a draft is created in the chimney and air is drawn into the fuel chamber;

- the coal is heated and partially burned;

- the gaseous products of coal combustion are mixed with the secondary air supplied inside and finally burned;

- the resulting gases give their temperature to the coolant, and then are removed through the chimney.

Modern coal-fired heating boilers steadily heat living quarters and outbuildings. They consume 2 times less fuel compared to outdated models. Advanced technologies have improved not only the construction and design of heating units, but also the very principle of fuel combustion. As a result, the homeowner no longer has to load another batch of coal into the boiler several times a day and remove the accumulated slag.

The enlarged combustion chamber is designed for a one-time loading of a large amount of coal, which gradually burns out over 6-12 hours. Forced airflow contributes to the fullest possible combustion of the fuel. This significantly reduces the consumption of coal for heating the house.

Large hopper of the automated heating boiler ensures long-term burning of coal

The automated supply of fuel from the bunker to the boiler "frees the hands" of the user. He becomes free from the obligation to constantly monitor the operating heater. The hopper has enough capacity for non-stop coal burning for a week.

Reviews of coal heating demonstrate how satisfied users are with the practicality of automated coal boilers. This is very convenient - at the beginning of the heating season, start up the boiler, and all winter only add coal to the hopper as it is emptied. It is also not necessary to remove ash and slag too often, only a couple of times a month.

Lighting coal for heating in a boiler, especially anthracite, can be difficult for an unaccustomed person. First, the boiler is fired with wood or a special mixture, and then little by little coal is added. When the combustion becomes stable, you can fill in anthracite in large portions. How much and how often will depend on the boiler model and will be more precisely determined in the practice of its use.

Do not use gasoline to ignite coal in the heating boiler!

But what if the electricity in the house goes out? In this case, the automatic supply of coal to the boiler fuel chamber will stop. At the same time, the circulation pump will stop working and water will stagnate in the heat exchanger. But the boiler will not boil, because coal combustion will go into a weak mode. Then, when the power supply is restored, the coal will ignite again.

Maintenance of a solid fuel boiler

Boiler maintenance measures are reduced to the need to clean the heat exchanger and flue ducts. Soot settles on their surfaces, and this phenomenon reduces the efficiency of the heating unit by 15%. The frequency of cleaning the coal heating boiler can vary: old cast iron models have to be cleaned 2-3 times per season, and modern ones once every 2 years.

Features of coal-fired boilers

Boilers that use coal for heating have one significant advantage over other heating systems - their versatility. So, in addition to coal, such a heating boiler can also be loaded with other solid fuel - firewood, waste (household waste), briquettes, pellets, sawdust, etc.

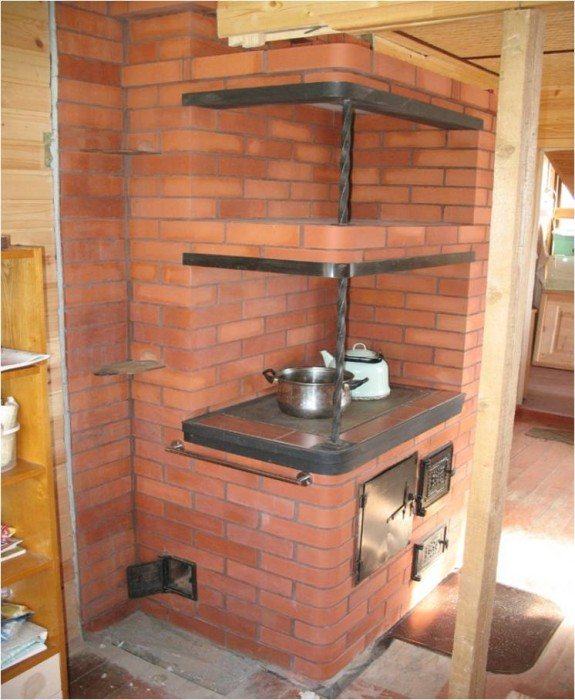

Note that corner heating and cooking stoves can not only heat your home, but you can cook food on them.

And long-burning stoves have another important advantage - it is that a lot of time passes between refueling. So, coal heating can work for quite a long time without human intervention. Also, such boilers are easy to operate - you just need to throw coal into the boiler. The systems are quite economical, while having high heat transfer parameters. The boiler can be used for the entire heating season - without interruption.

Heating and cooking stove

Of course, coal-fired boilers of old models will not be able to compare in terms of heat transfer and performance with new models. Modern equipment is able to efficiently heat different types of premises, while burning half the fuel than older models.

Little nuances

Boilers for heating and cooking

It is important to take into account that each boiler model has its own specific fraction of coal, which it can efficiently process. And if you have chosen this indicator incorrectly, then there is a possibility that the boiler's furnace, or rather, its grates, will clog

Its efficiency will decrease and fuel consumption will increase.

You will have to clean the firebox yourself, and this, frankly, is an unpleasant process - dusty and dirty. Experts agree that the best coal is anthracite

It doesn't matter what size it is, because such a material gives off heat well in any form.

But here the indicator of time matters. Fine anthracite burns faster, so a new coal charge will be required. Hence the conclusion, supported by experts - choose anthracite the size of a fist. This is heat, and a long burning time, and the efficiency of the heater.

And one more thing that concerns traction-based efficiency. If this indicator is weak, then you cannot count on good boiler performance. Therefore, advice - be sure to heat the chimney. How? For example, if the boiler is small, then a lit newspaper inserted into the chimney will gradually warm it up. However, coal heating has its drawbacks:

- Troubles for fuel filling and cleaning from slags.

- Waste and slag must be disposed of.

- The ubiquitous coal dust - no matter how carefully you work, it will still make itself felt in one form or another.

- Coal procurement.

All these disadvantages would be less noticeable if the boiler room could be organized in the basement of the house. Unfortunately, this is not always possible.

Choosing coal for a solid fuel boiler: which coal is better for heating a house?

Anthracite coal

January, 11 00:17 2016

by Energo Consulting team Print article

If you are choosing a reliable solid fuel boiler for a private house, it is undoubtedly worth considering the options for coal-fired boilers.

The main advantages of solid fuel coal-fired boilers:

- Coal burns longer than wood, and therefore requires less fuel loading;

- With shallow coal, automatic loading is possible;

- There is a class of boilers that simultaneously work as stoves for cooking food;

- Most of the coal-fired boilers are versatile and you can get by with other fuels in the absence of coal;

- Easier to store and takes up less space than firewood;

- Due to the peculiarities of heat transfer, this boiler does not immediately cool down, therefore it retains heat in the house for some time (even when it is turned off).

The disadvantages of coal are associated with the relative high cost of equipment, the problem of procurement, delivery and storage of fuel, as well as safety requirements: the correct installation of the boiler and chimney.

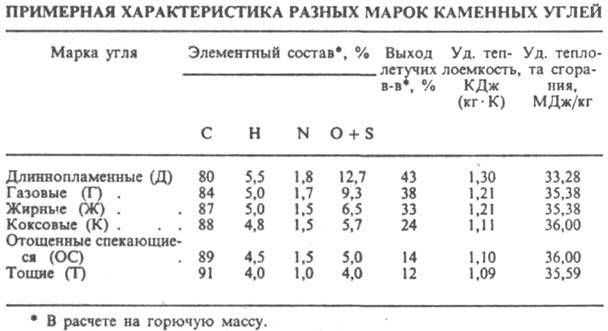

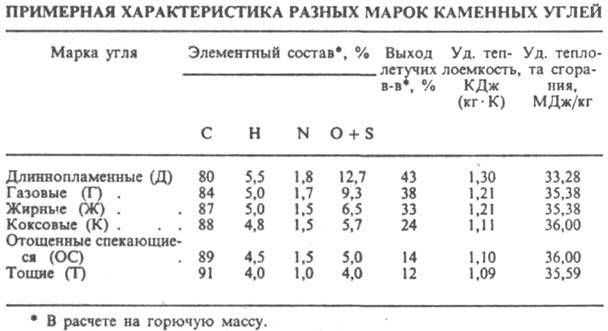

Coal marking, coal grades

There are many varieties of this fuel, the main types of coal are brown coal, bituminous coal and anthracite. In the marking of coal grades, they are indicated by the first letter: B (brown) or A (anthracite). Bituminous coal is more difficult to mark: long-flame (D), coke (K), lean (T), fat (F), gas (G). The second letter of the marking is the size of the coal. For example:

- slab, more than 10 cm (P);

- large, 5-10 cm (K);

- walnut, 2.5-5 cm (O);

- small, 0.13-0.25 cm (M);

- seed, 0.6-0.13 cm (C);

- pin up to 0.6 cm (W);

- private, different sizes (P).

Key quality indicators for coal

These three indicators will determine which coal is best for heating the house, your personal brand of boiler and, in particular, for your convenience.

The first indicator is calorie content, it is also the heat of combustion.In terms of grades, except for anthracite (8600 Kcal / kg), coking coals give a high combustion temperature (8700 Kcal / kg), but I should not use them for domestic household boilers. The lowest temperature is shown by brown coals (4500 Kcal / kg). They are also usually not used for heating, since they are ineffective in comparison with other varieties (but in the absence of other varieties, they are also drowned brown).

The second quality indicator is ash content. This is the percentage that will not burn during the heating process. The larger this percentage, the worse the quality of the coal. Low-grade grades often contain more than half of the ash, and high-grade grades no more than a quarter. This indicator also tells how often you will clean your boiler or stove. The best ash content is in anthracite, followed by slightly sintered and gas ones.

Moisture is the third factor for the quality of coal. Distinguish between surface moisture of coal and internal moisture. And if the surface can be removed by drying the coal, then the internal one is found only during the combustion process. The higher the humidity, the less energy the coal gives off for heating, and the more energy is spent on evaporation of moisture during combustion. Sometimes it is advised to moisten the coal so that the dust settles, but it is not always advisable to do this.

Which grade of coal is best for heating a house

Even if you will immediately be advised anthracite, as the most profitable, "clean" in combustion (minimum consumption, maximum heat transfer, minimum slag and waste emissions into the atmosphere, only 1% sulfur and 10% ash residues, uniform combustion, etc.), do not rush to buy it right away. So what is the best coal for home heating? Everything is individual. Best - means the best for your boiler. First of all, look at the marking of the boiler - there should be indicated the types of coal that are suitable for your unit. Indeed, anthracite is the best coal in terms of heat transfer. But due to the peculiarities of combustion (it is capable of reaching high temperatures, and only during these temperatures it gives up its full potential), you run the risk: either with your boiler (the boiler may simply not withstand the temperature), or with your wallet (anthracite simply will not give the required efficiency) ... There are boilers adapted for burning anthracite (their furnaces are designed for high temperatures), and there are those that are designed for the worst grades, but from them they receive the maximum useful energy.

If there is no marking, or it does not suit you, try to buy different varieties for testing and conduct an experiment: record the burning time, the heat of return, the amount of ash.

The main varieties and their suitability for heating:

- Anthracites - only for specialized boilers;

- Coke coals are dangerous in everyday life, they usually do not heat;

- Brown coals - low efficiency, they usually do not heat (unless the brand of the boiler disposes of this);

- Gas coals are divided into two subspecies, only 1G group for this coal grade is suitable for heating, group 2G is used in industry;

- Fatty coals are valuable grades of coals used in industry;

- Long-flame coal is the best choice after anthracite;

- Stone "DPK" (long-flame plate "fist") - the best grade of coal for conventional boilers;

- Stone "DO" - a lower indicator of efficiency, but it is easier to arrange the automation of the fuel supply;

- Stone "DS" (long-flame seed) - similar;

- Stone "TPKO" (skinny "nut") - even less efficiency, but cheap, used for heating small houses;

- Coal "SS" (weakly caking) and "TS" (lean weakly caking) are also cheap types of coal used in industrial boiler houses and households.

Some experts advise to heat boilers with grades with lower efficiency, but easier to ignite, and then add coal grades with high efficiency to the furnace (for example, start heating with a long-flame seed, and continue with anthracite). In the case of a stove, it is even recommended to start with wood (and continue, for example, with a seed).

The entry also belongs to categories: Technology »Equipment

Types of coal for the furnace

Depending on the material

Material for coal-fired stoves is the main criterion for choosing a fuel and stove. Let us examine these qualities in more detail.

For cast iron stove

Cast iron, by its characteristics, easily tolerates high temperatures, therefore, such stoves, and brick ones, are better suited for burning them with coal. Coals designated by letters:

- "A" - anthracite;

- "D" - long flame;

- "DG" - long-flame gas coal.

Expert opinion Pavel Kruglov Pechnik with 25 years of experience

This coal is better for the furnace than other types. Furnaces equipped with long-burning systems are recommended to use long-flame and similar gas types for them. Fuel "DG" is most suitable for pyrolysis types of furnaces - they have an increased formation of exhaust gases during fuel combustion, from an oxygen-depleted furnace atmosphere.

Brown coals are not suitable for cast iron stoves - a high ash content will require cleaning the chimney after 20-25 days of operation.

For brick oven

The best coal for furnaces and boilers is the rock under the letter "A". But some stove-makers recommend melting such stoves with long-flame coal nuts. After the temperature is set, anthracite is poured.

This option allows you to maintain the temperature in the room and save expensive anthracite. This bookmark lasts until the evening. At night, a seed is poured, which maintains the temperature in the house for 8-10 hours.

Important! Boilers and stoves of different designs can change their tastes, so go to the forum and ask what kind of fuel is suitable for your equipment.

This will not only save you money, but also allow the heater to operate normally. When choosing, a lot depends on your capabilities. You can buy fuel, grade "A" and provide yourself with anthracite with excellent characteristics.

Expert opinion Pavel Kruglov Pechnik with 25 years of experience

But for heating small garden houses, it is better to buy coke or even brown coal. They will cope with their task no worse than anthracite, but are much cheaper. The low price of lingitis makes such fuel in demand among summer residents or rural residents.

For steel furnace

It is recommended to use expensive anthracite, but coke-oven fuel is also suitable. It is more important to choose the size of its fractions and apply a mixed scheme of use.

We note right away - such ovens must necessarily be made of thick and only heat-resistant steel. If you make a stove - a potbelly stove from an old barrel, it may not be finished until the end of the heating season. The high temperature during fuel combustion will require the purchase of expensive stoves with parts with a thickness of 8-10 mm. This increases the mass and its price.

If you purchased a coal-fired steel stove, be sure to read the instructions. In it, manufacturers indicate its brands and types.

Important! Regardless of the material of the stoves, before firing up the unit, be sure to open the air damper on the chimney, the firebox door and the blower and pull out the box for collecting ash. Only after making sure that there is sufficient draft, you can fill the firebox.

To do this, it is recommended to use firewood for kindling, then pour the "nut" into the compartment and use the "seed" before the night.

Depending on the destination

Such fuel can be used to heat a house, greenhouse or sauna. Let's analyze the main installation sites and the choice of types for them.

For baths and saunas

If you like the smell of burnt wood, then this fuel will not work for you. Coal burns without smell and flashes of fire. Coal for the stove in the bath, gives heavy and humid steam for the steam room. We also add a high level of ash toxicity to humans.

These are the disadvantages of such a sauna fuel. But the high temperature in a short period of time is an advantage for large baths. For a small steam room, it is better to use an old, time-tested fuel - wood.

For home heating

The choice depends on the size of the room.For a small garden house, coke oven or even brown coal is suitable, but you will need to clean the chimney more often.

Such fuel has a low heating temperature than anthracite, but costs an order of magnitude lower. Long flame and long flame gas coal are preferred for heating medium to large homes. But the highest rates are given by the use of anthracite.

The choice depends on the money that you can allocate for the purchase of fuel. Using the mixed coal loading described above can significantly reduce the cost of purchasing coal. Unlike stoves in a bathhouse, the house needs to be constantly heated.

Therefore, you will need to accurately calculate the entire annual coal supply and purchase several types of fuel.

Views

Coal stoves for home heating can be characterized by the following indicators:

- By appointment. The coal stove can be used not only for heating, but also perform additional functions. This parameter can be distinguished:

- Heating stoves. Coal is an efficient fuel. Such coal-fired stoves, especially made of bricks, are much more powerful than their wood-fired counterparts. They are able to provide heat to the entire house, and not 1-2 rooms. Such an oven is large in size and weight. In the manufacture, materials with increased strength characteristics and maximum heat resistance are used. Such a heater requires a solid foundation on a perfectly flat base.

- Fireplace stoves. The coal-fired stove is able not only to reliably protect the room from the cold, but also performs a decorative function. Such ovens are required to have an attractive appearance and often become a central design element. The main attention is paid to the correct selection of materials for finishing. It must meet several parameters: be environmentally friendly, retain heat well, protect against injury, and have an attractive appearance. Most often, natural stone is used for decoration.

- Stoves with a hob. They have an additional hob that allows you to cook food. The dishes for this must be thick enough to withstand the heat. Cast iron is ideal. This dish will never burn out and the food cooked in it has a special taste. This material is also suitable for the manufacture of a hob, but it has a big drawback. Cast iron is very brittle and cracks easily. Therefore, you have to be extremely careful when operating. Alloy steel is also used for the hob. This material is not afraid of temperature extremes and is very durable. Use it more efficiently.

- Stoves for household needs. It is a furnace with a heat exchanger. This option will not only save you from the cold, but also provide hot water that can be used for household needs. You can arrange a warm floor system. This will allow the room to warm up more evenly.

- By the type of material used. For a furnace that runs on coal, you need to use a material with increased resistance to high temperatures. Experts recommend making a stove from the following materials:

- Brick — is the most common material for making ovens. Its advantages lie in its high heat capacity - the material is able to accumulate heat and give it off evenly for a long time. The disadvantages are also obvious: the large mass of the structure and the laboriousness of manufacture. In terms of financial costs, it is the most economical option.

- Steel — has become frequently used recently. The material is quite strong and durable. It is used for the manufacture of factory products. It is better to make a steel stove for coal with your own hands. The complexity of the work is much lower than in the manufacture of a brick analogue. The room heats up faster, but there is a significant disadvantage. Steel, unlike a coal-fired brick oven, is not able to retain heat.As soon as the fuel runs out, it instantly cools down.

- Cast iron — cast iron is intermediate between steel and brick. The weight of such a furnace should be significantly greater than that of a steel one. It will heat up and cool down faster than brick. With careful operation, such a structure will serve for several decades. It is quite problematic to make such a stove on your own. A factory analog will not be cheap.

- Talcomagnesite. The material has excellent thermal conductivity - ten times higher than that of bricks. And this despite the fact that its ability to store heat is only 44% worse. What does this mean in practice? Such a stove will heat up almost as quickly as a metal stove, but it will give off enough heat to not add fuel overnight. This material is also not without its drawbacks. Such a heating stove will be heavier than a brick one with the same dimensions and is not cheap.

- Combined. It is impossible to find an ideal material for a heating stove. As you can see above, each material has its own pros and cons. What if you take their strengths and combine them with each other. The strengths of one material can successfully neutralize the weaknesses of another. This technique has been used for a long time. A cast iron boiler can be faced with talc magnesite (another name for the mineral is talcum chloride or stove stone) and add a water heating circuit.

- By the method of fuel combustion. Separate furnaces with a conventional firebox and devices with an implemented function of long-term combustion, which are capable of operating up to 3 times longer on the same fuel load.

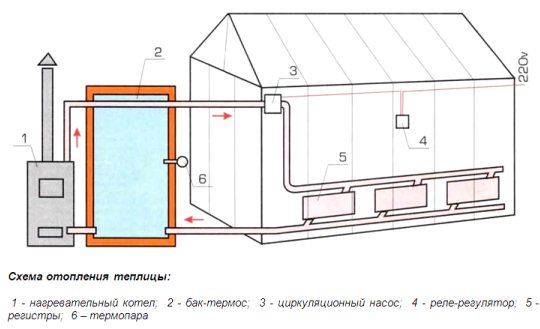

Water heating

This type of heating belongs to the category of the most simple and reliable. The principle of operation of hot water heating is based on the heating of water by means of a boiler and its subsequent distribution to the room radiators thanks to the piping system.

The use of a circulation pump ensures constant circulation of water in this closed system. The coolant in the water heating system, as a rule, is water or antifreeze, and the boiler can operate on coal, wood, natural gas, kerosene and other types of fuel.

The pipelines used for the hot water heating device can be made of various materials:

- Steel.

- Copper.

- Polymeric materials.

Steel pipelines, unlike stainless or galvanized ones, are characterized by a low value of corrosion resistance. Copper piping is highly reliable and can withstand high temperatures and pressures.

Pipelines made of polymeric materials are quite durable, exclude the formation of deposits on internal surfaces, and are highly resistant to corrosion.

Their disadvantage is the presence of a large coefficient of thermal expansion, which contributes to the formation of leaks.

Thus, the most effective water heating of a cottage or a private house can be arranged using copper pipelines. This opinion is shared by the overwhelming majority of experts.

The only drawback of pipelines made of copper is the relative high cost, which is compensated for by the absolute reliability and the ability to last for several generations.

Water heating circuit. Click to enlarge.

Indoor piping can be single-pipe, double-pipe or collector.

Single-pipe wiring does not allow to fully manage the performance of the entire system due to the impossibility of blocking the access of the coolant to one of the radiators.

The variant with the use of a two-pipe system is the most efficient (for individual houses) heating, which allows you to freely adjust the temperature inside each room.

This type of wiring involves the supply of cold and hot pipelines to each radiator. The distribution of pipelines can be carried out in a star-like manner or in the form of a "loop".

Collector wiring involves the connection to each heating device from a common collector of the supply and return pipelines.

Collector systems are distinguished by a high degree of versatility due to ease of installation and adjustment, the ability to replace damaged pipe sections (without destroying the floor structure).

What heating is better (single-circuit, double-circuit or collector) for a country house? The answer is obvious - two-pipe and collector.

Principle of operation

The principle of operation of a coal stove is not much different from a wood-burning stove. This is a very common misconception. Heating coal and wood-burning stoves differ radically. And here's what:

- For the combustion of coal, air must be supplied from below.

- Coal requires preheating before being sent to the furnace. Raw coal simply won't burn.

- The chimney should provide a faster passage of air than in a wood-burning stove. With this design, the damper is completely absent. The air supply is regulated from below, through the blower.

The burning process of coal takes much longer. Coal does not burn quickly like wood, but smolders for a long time. The combustion temperature is higher, which places special demands on the materials for the manufacture of the furnace. We will talk about this later.

Speaking about the process of burning coal, it is worth paying attention to one feature. If firewood in the process of pyrolysis easily decomposes into coke and gases, which have a high temperature and heat transfer, then coal burns differently. On the surface, it will have the highest temperature, and the temperature of the outgoing gases will be much lower.

Steam heating: advantages and disadvantages

implies the following mechanism: in the boiler, water is heated to the boiling point, and the resulting steam enters the radiators. The steam is then condensed into liquid and returned back to the boiler.

Advantages:

- high heating rate regardless of the area of the house;

- no heat loss in heat exchangers;

- ecological cleanliness of the coolant;

- the cyclicity of the coolant - steam can be used several times;

- the minimum probability of freezing of the structure.

There are also negative aspects of such heating:

- there is no possibility of regulating the temperature inside the house;

- short service life of the system due to the high temperature of the coolant;

- high likelihood of corrosion by vapors;

- the need to install a lattice.

The boiler can operate on the basis of gas, solid, liquid or combined fuel. In order for the heat transfer of the equipment to be as efficient as possible, it is necessary to choose it correctly. So for heating a private house with an area of 60-200 m², a unit with a capacity of 25 kW is required (if the area is 200-300 m², then the boiler power must be at least 30 kW).

Competently combining fuel, you can save on heating your home.

How much fuel is required

Example 2. Calculation of gas consumption for steam heating. Suppose the area of a private house is 100 m². Accordingly, the power of the boiler for heating is 25 kW.

- 25 kW * 24 hours * 30 days = 18,000 kW / hour. This figure does not reflect an adequate situation, since the boiler does not always work at full capacity. The average value is more acceptable in this case. 18000/2 = 9000 kW / h.

- 7 months * 9000 kWh = 63000 kWh - annual fuel consumption.

- Considering that 1 m³ of fuel produces 10 kWh of energy, we get: 63000/10 = 6300 m³.

- In monetary terms: 6300 * 4.97 = 31311 rubles per year.

Firewood, coal, etc.

Many people can now me - and why are we considering this option, no one has been heating this way for a long time, and the apartment cannot be heated like that! But no guys, it's still relevant, remember the same "pellet" boilers, of course, this is only logical for a private house, in an apartment we justly will not mount such a system.

Firewood

I don't even know how to present the calculation to you, here it is impossible to somehow deduce the amount of firewood and heat received from them. It all depends on the material, what kind of firewood it is (oak, birch, pine, etc.) because they all burn differently and give different heat. But I can say with confidence that you need to make some kind of shed for storing these firewood or coal - 100%, which is already burdening many owners.

Heating with firewood can be really cheap and even free, if you yourself chopped it up and brought it somewhere. But if you buy, then KAMAZ (about 6 cubic meters), and this is how much will be needed for the heating season, it costs about 10 - 12,000 rubles, if divided by 6 months of heating, this is about 1.5 - 2,000 rubles. per month!

Coal

Coal will come out a little more expensive, but it is needed less and it keeps the temperature longer (we buy about 3 cubic meters). If tamped in the dry residue, these are the same 2000 rubles. - month.

Pellets

A new heating system, special, expensive boilers, which, by the way, can be well automated.

They are fueled with special pellets - "pellets", it is also not easy to calculate the consumption! But again, based on my experience, I will say - the consumption of pellets per month for 2 - 2.5 thousand rubles - our 100 squares.

Coal and coal consumption for heating

Of course, an important issue is the problem that affects everyone who has already installed coal heating - which coal is better for heating? Many experts say that the most acceptable type of coal is anthracite - bituminous or brown coal. These types of coal for heating can be purchased almost everywhere and in any quantity. You can buy coal for heating in bags, as well as order even several tons with delivery to the storage location.

For ease of transportation, coal is often transported in bags.

What kind of coal is there for heating?

Note that the concept of "coal" includes several types of minerals:

- Brown coal: has the lowest combustion temperature, and is currently not used for heating, as it is ineffective.

- Bituminous coal, grade D: in order to carry out coal heating at home, it is ideal, since it has a long flame.

- WPC coal: very often this type of coal is called long-flame "nut" and "fist". It is usually used for heating small boiler rooms in private houses.

- TPKO coal: lean coal, usually used for private purposes.

- Anthracite: ideal for powerful boilers.

|

|

Compressed coal is also used for heating.

Undoubtedly, all experts will say that anthracite is the best option. But why? And all because of its properties, since this particular type of coal is very hard and has excellent heat transfer during combustion. It has a glassy luster and bright black color. The carbon content in this coal is almost 90%, and there is only a small amount of impurities. When burned, anthracite gives off almost no smell or smoke. It is also non-flammable.

For those boiler houses that have special stoves, anthracite coal is an ideal solution. When burning 1 kg of coal, about 3 kg of CO2 is released - therefore, in this case, up to 6.5 kW / h of energy is obtained.

Coal consumption

As for the consumption of coal, a scheme for calculating the amount of firewood for one heating season is used here, since coal is the same solid fuel. This calculation of the consumption of coal for heating is the most accurate and simplest. So, the simplest unit of measurement in everyday life is a bucket. On average, a bucket filled with coal weighs about 18 kilograms. If you believe those who constantly use solid fuel heating, then based on their readings for coal heating of a house of 200 square meters, the consumption is:

- September-October - 1 bucket per day (18 kg);

- November-February - 10 buckets per day (180 kg);

- March-April - 1-2 buckets per day (22-24 kg).

Now we will calculate the total consumption of coal for heating the house in buckets:

60+120+400=580

What we get, we multiply by 18 kg to get the consumption in kilograms: 10 440 kg. Thus, the consumption of coal for heating for one heating season is 10-10.5 tons.

But if you do not like such a simple method for determining the consumption of coal for heating, then you can use a more "scientific" method, using the rates of coal consumption for heating. To obtain 1 kW of energy, you will need about 0.2 kg of coal. On average, about 50,000 kW of energy is consumed in one heating season. So, we multiply 0.2 kg by 50,000. We get a result similar to the previous one - 10,000 kg (10 tons).

Characteristics of different grades of coal

But it is worth noting that when buying coal, be sure to take into account its type, since each type of coal has a different level of energy output.

Which coal is best for the furnace and boiler

If there are no instructions for the boiler, or an ordinary brickwork stove is used as a heating unit, then coal will have to be selected experimentally or by listening to the advice of "experienced" ones.

As for domestic boilers, it is better to fire them with long-flame coal "walnut". As it burns, anthracite is poured on top in an even layer. It allows you to provide heat throughout the day due to its long burning. In the evening, it is already allowed to fill the boiler with a "seed", it will be enough to keep the temperature at the same level until the morning. However, do not forget about the type of device installed. The described instruction is not universal, therefore, in some cases, the fuel use scheme may be different.

Brick ovens are best heated with wood. When they burn out, it's time to lay coal briquettes, it is also allowed to use a "seed", ideally a long-flame one. Until the fire engulfs the coal completely, the stove dampers must not be closed to ensure the flow of oxygen. When the furnace is on fire, you can use coarse coal, a "fist" or "nut" is suitable for these purposes. Another scheme is also allowed: first, "nut" is used, and in the late evening time and at night - "seed".

Which coal to prefer

A modern solid fuel boiler can work normally on both hard coal and brown coal. However, if you have a choice, it is best to choose the highest quality coal - anthracite. This kind of coal has the highest heat capacity and burns almost without a trace. True, it is somewhat more expensive than other varieties. It is necessary to estimate the cost of fuel, delivery and its heat capacity and choose the best option.

Don't forget about the fuel storage room. You can try to save on coal by choosing an inexpensive variety. However, you will need a lot of it, so you will have to overpay for shipping, and even find a place to store it.

And vice versa - you will need less high-quality coal for heating, so you will save money on delivery and storage. This way you can significantly reduce the consumption of coal for home heating. Read also: "How to heat a boiler with coal - theory and practice."

The best known manufacturers and models: characteristics and prices

Recently, Russian coal-fired boilers have become more and more popular: their quality is constantly improving, and the cost remains quite low in comparison with foreign counterparts. Nevertheless, the most functional and automated boilers are still from European manufacturers.

Please note that almost all models have different power versions.

Direct combustion

ZOTA "Master" 20

ZOTA "Master" with a power of 20 kW is a very budget insulated (basalt cardboard) boiler that can withstand pressure up to 3 bar and runs on almost any fuel: coal, wood, pellets and gas (optional). He also uses electricity as an auxiliary heat source (TEN).

Country of origin: Russia, OOO TPK KrasnoyarskEnergoKomplekt.

Cost: 25,690–31,889 rubles.

Protherm "Beaver" 20 DLO

Protherm "Beaver" with a capacity of 20 kW is a non-volatile boiler with an operating pressure of up to 4 bar, which has an increased service life, since it uses a high-tech (GG20) cast-iron heat exchanger that is resistant to corrosion and thermal shock. It can only be heated with various coal and wood.

Country of origin: Slovakia, Vaillant Group LLC (Vailant Group rus).

Cost: 67,600–68,445 rubles.

Bosch "Solid" 2000 B SFU 12

Bosch "Solid" 2000 B SFU with a power of 13.5 kW is a simple, reliable boiler, sharpened for the use of brown coal, but can also burn coal, coke, firewood and wood waste. Equipped with a built-in pressure control device (max. 2 bar), thermal protection and gas swirlers.

Country of origin: Germany, Bosch LLC (Bosch Thermotechnika rus).

Cost: 48 764 - 51 436 rubles.

Long burning

Stropuva S15U

Stropuva S15U with a capacity of 15 kW - thanks to a volumetric furnace that can hold up to 240 kg of coal, this innovative boiler is the unrivaled leader (among compact devices) in terms of burning time per tab: up to 7 days. It consumes coal, pellets, briquettes and firewood, at a maximum pressure of up to 3 bar.

Country of origin: Russia-Lithuania, STROPUVA LLC (STROPUVA).

Cost: 81,500-99,778 rubles.

Buderus "Logano" S181-15 E

Buderus "Logano" S181-15 E with a capacity of 15 kW is one of the best bunker automatic coal boilers for heating a private house, with built-in water and gas temperature sensors. The improved design of the heat exchanger ensures long burning of coal / pellets and can withstand pressures up to 3 bar.

Country of origin: Germany, Bosch LLC (Bosch Thermotechnika rus).

Cost: 252,000–258,840 rubles.

LIEPSNELE L20U

LIEPSNELE L20U with a power of 20 kW is an almost "omnivorous" solid fuel unit that consumes coal, firewood, coal briquettes and pellets, peat, wood chips, other wood waste, etc. With full coal filling, it supports combustion for up to 7 days The pressure level is limited to 1.5 bar.

Country- UAB (Vakaro Race).

Cost: 85 449–90 456 rubles.

Galmet "CARBO" 21

Galmet "CARBO" 21 with a capacity of 22 kW is a Polish semi-automatic coal-fired boiler already in its basic configuration has a fairly rich equipment: an intelligent PID controller that controls all boiler components and controls the combustion process, a flue gas sensor, a thermometer and a pressure gauge. Pressure limit - up to 2 bar.

Country of origin: Poland-Russia, GALMET LLC (GALMET-RUS).

Cost: 113,890-116,759 rubles.

Varieties of coal for home heating

When choosing which coal is best for heating a house, you should carefully understand the types of fuel.

There are several types of energy carriers:

- Weakly baking stone. Coking coal with a high level of metamorphism. This means that the efficiency is high, but the ignition process is associated with some difficulties. A very large heat transfer of fuel for small private buildings is a minus, therefore, the brand is most often used for heating public buildings. Advantages in the minimum amount of fire and smoke during combustion, prolonged smoldering - the properties explain the largest gap between the tabs. If the house is more than 150 m2, it is worth considering coal for fuel, but it is expensive, although it allows you to save well on volume.

- Long-flame bituminous coal. The most popular type of fuel suitable for autonomous heating systems. It is used for any boilers, it can be ordinary, high-quality, it burns well and for a long time, it emits a lot of heat. The advantages include the minimum amount of firewood for ignition and the absence of the need for blowing during combustion.

- Anthracite. The carbon content in the raw material is more than 95%, therefore, the fuel burns almost without residue, does not emit smoke, odor, ash pan cleaning is minimized. You can recognize anthracite by its gray-black shade with steel highlights. The pieces are very strong, similar in weight and shade to a stone. The efficiency is extremely high, but the fuel price is low.

- Peat coal. Low calorie content and reduced heat transfer are disadvantages, low dustiness and affordable cost are advantages. Peat briquettes burn well, but quickly, so more often you will have to make bookmarks.

- Brown coal is a fuel that has average performance. Slightly worse than anthracite, but better than peat coal. Advantages of the application in the minimum amount of slag, smoke and a fairly high efficiency.

The most common boiler coal is long-flame coal.Vendors offer different factions and can trick a newbie

However, anthracite, brown coal is extremely rare on sale, so it is important to clearly understand the labeling, look at the certificates

What are solid fuel coal boilers

Solid fuel coal boiler is a modern heating unit, in which anthracite, coal, long-flame, gas, black, brown coal, pressed briquettes, and also some other types of solid fuel can be burned to obtain energy and then heat the coolant.

The modern coal-fired boiler Teplodar Kupper in section.

In fact, boilers of direct (bottom-up) combustion are the successors of the traditional Russian stove, but if a massive stone (brick) structure should be laid even at the preliminary stages of building a house, then a more compact device can be connected to an existing system.

Application and effectiveness

Coal-fired boilers are installed in residential and commercial buildings (summer cottages, cottages, offices) located in areas where connection to the gas supply system is problematic. It is ideal to use a coal boiler for heating a private house with an area of up to 100-150 m2.

Comparison of the efficiency of boilers using different types of fuel:

| Energy resource type | Calorific value, mJ (kW) / kg (m3) | Fuel price, rubles / ton (m3) | Efficiency | Cost of kW of energy, rub. |

| brown (w ≈ 20–40%) | 12,9 (3,6) | 2700–3200 | 70 % | 1,71–1,27 |

| stone (w 7-15%) | 27,1 (7,5) | 6000–7000 | 70 % | 1,14–1,34 |

| anthracite (w ≈ 1-3%) | 31,1 (8,7) | 8000–8500 | 70 % | 1,31–1,40 |

| natural gas | 36,5 (10,3) | 5400–5700 | 90 % | 0,63–0,65 |

| firewood (w ≈ 60-50%) | 8,1 (2,2) | 1300–1500 | 60 % | 0,98–1,05 |

| firewood (w ≈ 30–20%) | 11,2 (3,1) | 1500–1800 | 60 % | 0,76–0,83 |

| granules (pellets) | 17,2 (4,7) | 7000–9000 | 85 % | 1,75–2,25 |

| briquettes (euro wood) | 16,1 (4,3) | 6000–8500 | 85 % | 1,65–2,32 |

Compared to gas, which burns almost completely, coal leaves behind a lot of ash, which means that it has a lower combustion efficiency and part of the money spent on fuel will inevitably go to pay for "garbage waste", in the truest sense of the word.

The second closest competitor to coal is firewood. They are obviously cheaper, but not so convenient to use: in addition to the fact that they will have to be brought to the desired fraction (or buy chopped, but more expensive), you also need to throw firewood into the furnace every 3-5 hours, while coal burns for 6-10 hours.

Device and principle of operation

Schematic representation of the principle of operation of coal-fired boilers.

The fundamentally constructive device of a coal-fired boiler does not differ from any other solid-fuel unit, that is, it consists of the following units:

- outer capacious cylinder, which is also a body;

- a layer of insulating material covered with cladding panels;

- an inner cylinder located along the same axis (coaxial) with the first;

- combustion chamber (firebox) diverted to the lower part of the inner cylinder;

- a hole adjustable by the flap (blower) to create and enhance traction;

- variable system of air outlet and air supply pipes;

- compartment for collecting ash and instrumentation (optional).

The principle of operation is extremely simple: due to the draft of the chimney, air enters the furnace, which causes the combustion of coal and the release of thermal gases. They, in turn, heating the inner walls, convert heat into hot steam or transfer it directly to the water circulating in the heat exchanger system.

Some boilers, like TeplodarCupper Carbo 26, are equipped with heating elements for additional heating of the coolant.

The heated water supplies the pipes of the home heating system and / or hot water supply (DHW), and then, after passing through a full cycle (circuit), it returns back to the boiler. Waste heat gases enter the chimney, where, due to their energy, the optimum temperature for creating draft is maintained.

How to calculate coal consumption correctly

Having figured out how to choose coal for heating a private house, consider the amount of fuel. For a correct calculation, you need to know the insulation index, the area of the building, standard temperatures in winter and the type of boiler.The volume of purchase of coal for a brick house is the highest, in comparison with wooden buildings, brick ones require 35% more fuel, subject to poor insulation and severe winters, the consumption increases by 50%.

Objects made of cinder concrete with a wall thickness of 45 cm and an area of 90 m2 consume up to 3.5 tons per season, other buildings of the same area - up to 8 tons of coal. The calculation is given for the northern regions; for zones with a mild climate, the volume of fuel is reduced by a third.

Example: in Novosibirsk, Krasnoyarsk, for a house made of wood with an area of 40 m2 with good insulation, at least 6 tons of WPC grade O, K, P coal will be needed - this is a fraction size of up to 10 cm, a long-flame grade. When calculating an average temperature of -30 C, the cost of coal is significantly lower than when arranging a gas, electric heating system.

In a new home, the amount of coal is selected by testing. Several bags of fuel are bought, the stove is heated up to standard indicators, measurements of the combustion period are taken, air heating in the house, taking into account the temperature outside the window. The standard heating level of the house is +18 C at +0 C outside the window, to calculate the heating of the house at low temperatures, the heating time interval is multiplied by 3. It turns out that if at -5 C the house warmed up to +18 C in 20 minutes, then at -25 With outside the window, the warm-up time will increase to 60 minutes.

Thus, it will become clear which grades of coal should be chosen for household boilers in each individual building. It is worth knowing that during storage the fuel slightly reduces the characteristics and indicators, therefore it is better to buy the first time with a margin of 25%. This will allow you not to be left without heat during the spring frost.

Standard indicators of energy consumption for solid fuel boilers in a house with an area of 100 m2 by season:

- September October. One bucket for 12 hours of burning, taking into account that the night temperature in the room will be +17 C.

- November - February. Up to 3.5 buckets per day. In terms of kg, it turns out up to 65 kg per day.

- March, April. Up to 2 buckets in 24 hours, if in April the temperature rises to +10 C, one bucket of coal is enough. Reducing the volume is not recommended for drying the walls and floor of the building.

When calculating the weight of a 20 kg bucket with coal, up to 10 tons of fuel will be required per season. This is provided that the building is well insulated, residents do not freeze at +18 C at night, and during the day the house is not heated with 100% boiler output.

When choosing coal, be sure to look at the certificates. Having bought skinny varieties, the owner will be left without heat and freeze the entire heating system, provided that it is a water network.