The main malfunctions of hydraulic tanks

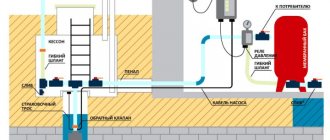

In fact, the device of the hydraulic accumulator is not particularly complex. It consists of:

- main tank;

- membrane or rubber container for water storage;

- pressure switch, pressure gauge and other fittings.

However, despite their simplicity, these devices can break. The main malfunctions of the accumulator for private water supply systems:

- too frequent switching on and off of the pump. This can be due to various reasons. The most common are a decrease in air pressure in the tank, damage to the membrane and damage to the tank body. In addition, the pressure switch may be incorrectly set;

- air pressure below normal - most likely, the nipple is damaged, which does not hold pressure;

- water leaks from the air valve - this indicates membrane damage;

- the required water pressure is not accumulated - there is not enough air in the tank.

Of course, the best option is to call a specialist or send the hydraulic tank to a service center for repair. However, if you wish, you can make repairs with your own hands.

Accumulator repair

The reason that can lead to repair work is the rupture of the rubber membrane. Determining that the pear has broken is quite simple. It is necessary to remove the protective roof from the nipple and press it, for example, with a match. If water poured out, it means that the membrane is torn and the liquid has filled the entire tank.

The repair consists in replacing the torn pear:

- the pump is disconnected from the power supply;

- the water pressure in the water supply system is released by opening one of the consumers;

- the flexible hose is disconnected, with which the accumulator is connected to the water supply;

- a wrench unscrews six bolts that attach the flange to the tank body;

- the membrane is pulled out;

- the tank is washed and dried;

- a new membrane is inserted inside;

- a flange is installed, which is tightened with bolts;

- air is pumped through the nipple;

- the accumulator is connected to the plumbing system with a flexible insert.

It is not necessary to use a sealant to seal the joint between the flange and the device body. The rubber bulb, or rather its flange ledge, is itself a sealing element.

Sometimes there are situations where the steel flange of the diaphragm is corroded and cannot perform its function. It just needs to be replaced with a new one. The replacement method is exactly the same. Just don't take the bulb out of the accumulator and rinse it.

The maintenance and repair of a hydraulic accumulator for the water supply system of a private house must be approached responsibly. All manipulations do not take much time. But it is on them that the operability of the tank with the pump depends, and their long-term trouble-free operation. If it is not possible to carry out repairs on your own, for example, the flange bolts are not unscrewed, it is recommended to take the accumulator to a service center. A broken thread or a broken bolt is a breach of the tightness of the device.

House heating:

- Repair of the water supply pressure switch After connecting the pressure switch. it may need to be adjusted - adjust the on and off pressures. By default, it has factory settings, you can clarify them in the passport of the device, usually they are set like this: turning on the pump at a pressure below 1.4-1.8 bar and turning it off at a pressure above 2.5-3 bar. To adjust the pressure switch, you first need to know [...] ...

- Replacing the water expansion tank A drop in pressure in the heating system may indicate a problem.In such cases, even with an increase in power, normal operation of the device cannot be achieved in such situations. If the equipment does not maintain the pressure in the heating system, the expansion tank must be replaced. There is a possibility of rupture of the tank membrane. In the cold season, it is necessary to act as quickly as possible, when the equipment comes out [...] ...

- Water expansion tank maintenance ...

- Replacing the water supply accumulator A well-designed and properly installed water supply system can operate smoothly for years, much depends on the correct choice of components. This review will focus on hydraulic accumulators, their principle of operation, installation options, repair and maintenance. Why does a pumping station need a hydraulic accumulator The main function of a pumping station is to continuously supply the consumer with water, while ensuring the required operating pressure range both for the points of water intake and for operation [...] ...

- Maintenance of a water supply accumulator Many people mistakenly think that the main task of a hydraulic accumulator is to serve as a storage tank. In fact, it is too "expensive" device for simple water storage. The task of the accumulator is to maintain a constant water pressure in the system within the limits of the pressure switch adjustment, as well as to exclude water hammer in the water supply system. To cope with these tasks, the hydraulic tank is helped by a rubber bulb located inside [...] ...

- Replacement of water supply equipment ...

- Replacement of water supply filters Our company sells and installs branded water purification equipment for private houses and individual city apartments. The list of services includes maintenance of ATOLL and ANGSTRA water purification systems. The service contract is concluded even if the installation of the equipment was carried out by specialists from other companies. Conclusion of a service agreement allows: not to worry about [...] ...

- Service of water supply filters We will perform service of water purification systems of any complexity, installed both by our masters and by any other company. Scheduled maintenance will prevent malfunctions in the operation of complex technical units, will allow timely replacement of worn out mechanical parts of the system. List of works: Checking the performance of filters: iron remover, softener, coal, sedimentary and aeration complex; Setting or changing the automatic filter program [...] ...

- Replacement of water supply pressure switch Production, repair, maintenance of wells is the work of professionals. Even a skilled electrician is not able to perform all types of electrical work on a well pump! An artesian well can perfectly solve the problem of independence from centralized water supply. Its owner will have his own source of high-quality deep water all year round. A well is a complex technical structure. In its composition, it contains pumping equipment operating from [...] ...

- Maintenance of the water supply pressure switch The pressure switch is responsible for the correct operation of the borehole pump. As a rule, it is installed on the accumulator or directly on the pipeline, but at a distance of no more than 3 meters from the accumulator. It is the pressure switch that gives the command to turn the pump on and off. Very often the relay fails due to burning of the contacts. This occurs when the power supply to the pump [...] ...

- Replacing the water supply pump The well does not supply water to the house by itself. For this, a borehole pump and automation are used. With proper use and timely maintenance, the autonomous water supply system in a private house is reliable and durable. An autonomous water supply system functions without human intervention.Like any electrical appliance, the deep-well pump has its own service life and over time it is necessary [...] ...

- The main functions of automation units for pumps A large number of suburban areas are equipped with wells and wells. Owners strive to have an autonomous water source. More often it is a technical resource that is used for irrigation. But also as drinking water such water is used quite actively. In terms of chemical composition, it can significantly surpass tap water, especially if the intake is carried out from a great depth. In order for the process to be optimal in [...] ...

- Types of protective automatics for a borehole pump When choosing an automation unit for a borehole pump, you should pay attention to the voltage indicator recommended for the normal operation of the latter, and to the permissible deviations. To protect the device from running out of water, a U-shaped relay must be installed. This element will turn off the pump if no water is supplied to it. Modern manufacturers offer several types of protective mechanisms to ensure the safe operation of pumps: start-up protection, [...] ...

- Automatic control system for a submersible pump The automatic control system that regulates the operation of the pump consists of several elements. The main one is the control relay, which is supplemented by the electrical part. Depending on the features of the configuration, two principles of operation of the devices are distinguished. Regulation of water pressure in the pipeline. It works when water is supplied from a well and the system has a hydraulic tank. After the first ascent, it fills the container, then it is fed into the system [...] ...

- Replacing water supply sensors ...

- Maintenance of water supply shut-off valves ...

- Repair of water supply filters Any mechanical equipment requires maintenance. Water treatment equipment is no exception! Here are a few answers why you need to carry out maintenance of water treatment: - control and maintenance of equipment in working condition; - verification of water indicators by express analysis at the outlet of the installation; - replacement of consumable components. Here are some examples of installation before performing preventive maintenance and after work: Basic list of works for the service of water treatment: […]…

- Repair of water supply automation As is known through practice, the main reasons for the failure of a deep ECV pump is long-term operation in the "dry" mode. This term means that the ECV pump worked without water, which leads to breakdown. This reason is more common than unstable energy savings or poor maintenance, and as a result, the repair of a borehole pump will be much more difficult. In principle, a dry run will bring [...] ...

- Repair of water supply equipment In order for water supply systems to work effectively, providing access to hot and cold water, it is necessary to periodically diagnose and repair them. If you neglect preventive work, then shut-off valves, pipes and couplings at the joints may become unusable. This is due to metal corrosion - the threads at the joints are oxidized, rendering individual parts of the system unusable. Company "Holding [...] ...

- Repair of the expansion tank of the water supply If you have your own well with a pump and at the same time: - the water from the tap flows normally, then barely, - the water from the hot tap flows either hot or cold, - you noticed that the relay of the borehole pump constantly clicks , - you have noticed that the needle of the water supply pressure gauge jumps from minimum to maximum, then carry out an independent diagnosis: [...] ...

- Water supply pressure gauge repair ...

- Repair of a water supply water heater Hot water in a house or apartment is the norm for a modern person, so everyone strives to provide himself with it.If connection to the central water supply for hot water supply is not possible, then water heaters are used. Different models solve this problem in different ways. To meet everyday needs, instantaneous gas or electric water heaters are very popular, which are economical and [...] ...

- Water supply boiler repair Many modern people cannot imagine their life without water heaters. Often, devices serve their owners for quite a long time, but sooner or later they fail. The simplest, but most expensive, repair method is to call the master. Alternatively, you can repair the boiler yourself. The procedure is not particularly difficult, you just need to understand the device [...] ...

- Water supply water heater flushing ...

- Replacing the water heater ...

- Water supply water heater maintenance ...

- Replacing the water heater ...

- Water supply water heater maintenance ...

- Replacement of water supply shut-off valves ...

- Types of automation for a pump without a hydraulic accumulator It is also possible to organize a high-quality water supply from a well or well without a membrane tank in the system. The main condition is a high-quality pump, the technical characteristics of which will correspond to the operating conditions of the unit. It is also important to select automation for the deep pump, which will allow maintaining constant water pressure in the system: pressure switch and protection against voltage surges. The operation of water supply without a battery can be [...] ...

Previous post Repair of water supply equipment

The next entry Repair of the expansion tank of the water supply

Replacing the membrane

Quite often, you have to change the membrane in the accumulator. However, before disassembling the tank, you should make sure that the reason is in the membrane. After all, the matter may be in the wrong setting of the pressure switch, or in a small volume of air in the hydraulic tank.

One of the most common problems is membrane breakage.

The main signs by which you can determine the damage to the membrane:

- too frequent switching on of the pump;

- water flows from the nipple and air valve.

In this case, the membrane is repaired in the following sequence:

- first of all, you need to purchase a new pear and prepare a set of keys;

- after that, the accumulator is disconnected from the water supply system;

- water is drained from it and air is lowered;

- now you need to unscrew the flange and take out the old pear;

- further, it is advisable to carefully examine the inside of the tank - if there is dirt or rust, then you need to clean it;

- after that, the new membrane is straightened out and installed in the seat;

- then, it is pressed against the flange.

Now, it is required to pump its operating pressure into the accumulator, usually 1.5-2 atmospheres. And then do a test run. At the same time, water must be supplied to a new pear under low pressure - this will exclude the possibility of its damage. You can read more about the nuances of repair in the article "How to replace a membrane in a hydraulic accumulator".

Pressure problems

This problem can be caused by a number of reasons:

- damage to the nipple - air escapes through it;

- incorrect setting of the pressure switch;

- damage to the tank body.

Sequence of actions for repair:

- first, it is worth checking the integrity of the body itself - if it is rotten, then the accumulator may need to be replaced;

- if everything is in order with the case, it is worth checking the operation of the pressure switch. It is possible that his settings are out of order;

- for this, it is worth trying different operating modes for the hydraulic tank - if the relay is active, then you need to look for the cause elsewhere;

- now you need to check the nipple - it can bleed air, if so, then the repair will be reduced to replacing it.

The pressure gauge may show incorrect values

Another reason is a malfunction of the pressure gauge. Those. it may show incorrect numbers. This point is also worth considering.

Too frequent pump starts

This phenomenon indicates a lack of air pressure in the tank for water supply systems. Therefore, the very first thing to do is to check the readings of the pressure gauge.

Here you need to take into account the fact that this device may show incorrect values. Therefore, you can simply bleed the air completely from the system through the air injection valve and pump it up again. If the pressure gauge is out of order, you need to replace it.

Another possible reason is that the pressure control relay is out of order. In this case, you need to adjust it. It is possible that the malfunction will be rectified.

A breakdown of the pressure switch is also one of the possible malfunctions.

You also need to inspect the accumulator itself - if the integrity of the case is violated, the air will be vented. Depending on the size of the damage, you will need to either seal it or buy a new one.

Another common reason is the air nipple is out of order. If so, then you just need to change it. To do this, disconnect the hydraulic accumulator from the water supply system and bleed air from it. After that, you need to unscrew the old nipple and insert a new one in place.

Then air is pumped into the tank to 1.5 atmospheres, and then water is drawn into the membrane.

Expansion tank and pressure switch device

During intensive operation, various kinds of malfunctions may arise in the operation of the equipment, in which it becomes necessary to set the pressure switch again.

For example, situations often occur when the device simply stops turning on, or works without stopping for quite a long time. These are clear signs of a malfunctioning water pressure switch.

Specialist recommendation: do not change the settings in the pressure switch unless absolutely necessary. Otherwise, the product will lose its warranty.

Usually this device is a small box with wires coming out of it. To get to the adjusting springs, you need to unscrew the plastic screw located at the top.

Two springs are installed inside - one more, the second less, as well as a contact group automation mechanism. A small spring is needed to adjust the pressure difference. Large - to adjust the shutdown pressure.

You may be interested in an article on how to install a pumping station with your own hands. Read the article on units with and without a hydraulic accumulator here.

If the air pressure in the hydraulic tank is not set correctly, then the readings on the water pressure gauge will be incorrect. Therefore, the first step is to set the air pressure in the hydrophore.

For this procedure, it is imperative to de-energize the electrical part of the station and drain the water.

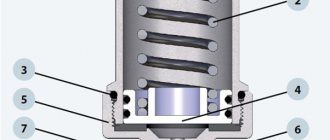

Hydrophor consists of only three parts:

- body;

- nipple;

- rubber diaphragm.

The rubber bulb is attached to the hydrophore body by a non-return valve (nipple) through which pressure is either added or released.

You can measure the pressure using a car pressure gauge, which is used by motorists to measure the pressure in the wheels.

You can pressurize the receiver with a car or bicycle pump.

The pressure is also selected depending on the volume of the expansion tank. Air pressure is considered normal, which is 10% less than the pressure at which the equipment is turned on.

For example, if the pressure at which the electric motor starts to operate is 2 bar, then the air pressure should be set to 1.9 bar, that is, deflate or inflate the rubber bulb.

Masters advise: the air pressure should be monitored even if you have not made any changes to the pressure switch.

Water comes out from under the flange

Sometimes such a breakdown happens. However, it is easy to treat - usually just tightening the nuts on the flange is enough. If this does not help, then you will have to drain the water from the tank and release the air pressure, and then remove the flange.

Then you can try to make an additional rubber pad and conduct a test run of the system. The fact is that the accumulator is under constant pressure and from this, microcracks may appear in the rubber.

Water can flow through the flange

If the additional gasket did not help, you will have to buy a new flange. At the same time, you need to inspect the seat - there should be no mechanical damage, burrs and rust on it. If there are any defects, they must be eliminated. they can cause leakage.

Battery Prevention

In general, these devices do not break down so often; after all, their design is quite simple. However, in order to avoid or diagnose a malfunction in time, it is necessary to periodically service the accumulator. Moreover, there is nothing complicated in this, and such a procedure does not take much time.

Service is carried out according to the following schedule:

- a simple visual inspection of the device is done every 1-2 months. The accumulator is checked for leaks, in addition, on some models, excess pressure must be relieved;

- the next inspection is done every six months. The tank is also checked visually, but in addition it is necessary to check the condition of the air pressure and, if necessary, pump it up. Also, it is worth checking the serviceability of the pressure switch - and, if necessary, adjust the settings.

If the hydraulic accumulator has worked for more than three years, it is advisable to carry out comprehensive prophylaxis. For this, the device is disconnected from the water supply system and the pear is replaced. Flange and nipple replacement may also be required.

Perform prophylaxis every 3 years

You can do it yourself without any problems. However, when replacing parts, it is advisable to buy original products. This is especially true for the membrane.

Accumulator pressure switch setting

Use the following algorithm:

- Turn off the pump and remove the water.

- Turn on the equipment and increase the pressure, followed by draining the fluid. Record the motor on / off levels.

- The threshold at which voltage is applied to the engine is increased with a nut on a large spring (clamp it).

1 - setting the pressure value; 2 - setting the differential

- The opening level of the relay contacts is adjusted by the height of the small spring.

On some models it is possible to adjust the upper and lower limit of the set point

Consult the manufacturer's instructions for how to set up the accumulator electronic pressure switch.

Electronic device