Here you will find out:

- The essence of energy saving

- Ways to Improve Energy Efficiency at Home

- Infrared heating systems

- Induction electric boilers

- Thermal panels - energy saving heating

- Energy saving using monolithic quartz thermal electric heaters

- The use of solar energy

- Control system "Smart home"

- Heat pumps of two types

- Heating with wood

- Heat recovery

More and more people are interested in energy-efficient heating systems. Energy saving methods are a significant nuance when choosing a heating system. The latest technology in this matter is infrared heating and induction boilers, solar heating and smart home systems.

The essence of energy saving

First, we want to reveal one little secret. You might be surprised, but any electric heaters are energy efficient. After all, what does this term mean for a device that releases thermal energy? It means that the energy contained in fuel or electricity is converted by a boiler or heater into heat as efficiently as possible, and the degree of this efficiency is characterized by the efficiency of the unit.

So, all electrical appliances for heating rooms have an efficiency of 98-99%, no heat source that burns different types of fuel can boast of such an indicator. Even in practice, the so-called energy-efficient electric heating systems generate 98-99 watts of heat, using up 100 watts of electricity. We repeat, this statement is true for any electric heaters - from cheap fan heaters to the most expensive infrared systems and boilers.

Comparative example. 1 kg of dry wood on average releases 4.8 kW of heat during combustion, but in reality we can only get 3.6 kW, since the boiler efficiency is 75%. An electric heater is much more efficient, having consumed 4.8 kW from the network, it will give 4.75 kW to the house.

A truly energy efficient heating system is a heat pump or solar panel. But there are no miracles here either, these devices simply take energy from the environment and transfer it into the house, practically without consuming electricity from the network, for which you need to pay. Another thing is that such installations are very expensive, and our goal is to consider, as an example, the available market innovations that are declared as energy saving. These include:

- infrared heating systems;

- induction energy-saving electric boilers for heating.

Steam

A number of parameters that may differ for water heating are also applicable for steam:

- One- and two-pipe schemes can be found here;

- Layout can also be vertical or horizontal;

- The movement of steam and condensate is passing and dead-end.

But there are also characteristics that are relevant only for a couple.

- In vacuum-steam systems, the pressure is less than the atmosphere. In low pressure systems, it is no more than 1.7 kgf / cm2; anything beyond that is high blood pressure.

- Low pressure systems are not only closed, but also open (communicating with the atmosphere).

- Steam heating can be closed (with the return of condensate directly to the boiler) and open (condensate is collected in a separate container, from which it is then pumped into the boiler for reheating).

- In addition, the condensate lines can be dry (that is, not completely filled with water during heating operation) and wet.

Closed loop steam heating system.

Ways to Improve Energy Efficiency at Home

Various methods can be used to reduce the cost of energy used for heating:

- increasing the energy efficiency of the building;

- the use of the "Smart House" system, as well as other automation that allows you to minimize costs;

- reduction of electrical losses with the help of radiators and other devices;

- increasing the efficiency of heating boilers or furnaces;

- using environmentally friendly types of energy (firewood, solar panels).

For best results, you can use a combination of two or more options.

Even the most reliable and high-quality heating system will not bring much benefit if a large-scale heat loss occurs in the house, therefore, measures should be taken to prevent heat energy from leaking through cracks and open vents.

It is important to take simple but effective steps by covering floors, walls, doors, ceilings, and window frames with insulating material. In addition to thermal insulation according to regulatory requirements, additional insulation can be placed. This will further reduce heat loss, thereby increasing the building's energy efficiency.

To carry out high-quality thermal insulation, you can call a specialist energy auditor. He will make a thermal imaging survey of the house, which will reveal the places of the most intense heat loss, the isolation of which must be carried out first.

As a rule, the greatest heat loss occurs through the walls, the ceiling of the attic, as well as the floor along the logs. These areas require high-quality thermal insulation. Shutters that close at night can be used to prevent heat leaks through the windows.

Infrared heating systems

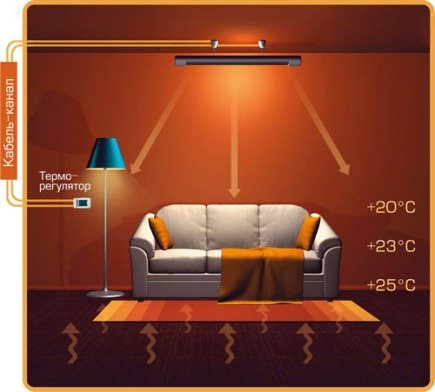

The principle of operation of infrared heating devices of any design is to convert electricity into heat, giving the latter in the form of infrared radiation. With the help of this radiation, the device heats up all surfaces in the area of its action, and then the air in the room is warmed up from them. Unlike convective heat, such heat does not affect a person's well-being and in this regard is considered the best option.

For reference. The heat flux includes 2 components: radiant and convective. The first is infrared radiation emitted from heated surfaces. The second is direct heating of the air. All infrared heating systems made using energy-saving technology transmit 90% of the heat by radiation and only 10% is spent on heating the air. At the same time, the efficiency of the heaters is unchanged - 99%.

New products on the modern market, gaining more and more popularity, are 2 types of infrared systems:

- long-wave ceiling heaters;

- film floor systems.

Unlike the usual UFO-type heaters, long-wavelength emitters do not glow, since their heating elements work according to a different principle. The aluminum plate is heated by a heating element attached to it to a temperature of no more than 600 ºС and gives out a directed stream of infrared radiation with a wavelength of up to 100 microns. The device with the plates is suspended from the ceiling and heats the surfaces located in the area of its action.

In fact, such energy-saving electric heating systems will give the room exactly as much heat as the energy consumed from the network. Only they will do it in a different way, through radiation. A person can feel the heat flow only when they are directly under the heater.

Such systems, unlike convective ones, take a long time to raise the air temperature in a room. This is not surprising, because the transfer of heat does not go directly to air, but through intermediaries - floors, walls and other surfaces.

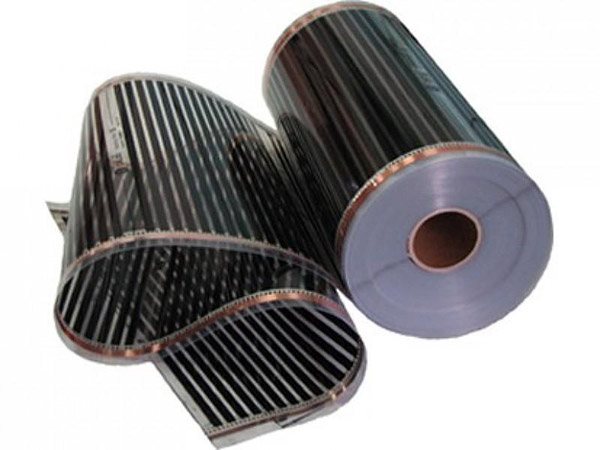

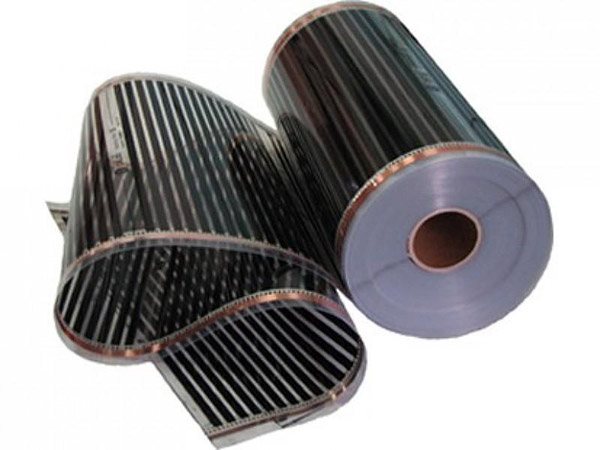

Intermediaries also use floor heating systems PLEN. These are 2 layers of a strong film with a carbon heating element between them, to reflect heat upwards, the bottom layer is covered with silver paste.The film is laid on the screed or between the joists under the floor covering made of laminate or other materials. This coating serves as an intermediary, the system first heats up the laminate, and from it the heat is transferred to the air in the room.

It turns out that the flooring converts infrared heat into convective heat - this also takes time. The so-called energy-saving heating of a house using film-heated floors has the same efficiency - 99%. What, then, is the real advantage of such systems? It lies in the uniformity of heating, while the equipment does not occupy the usable space of the room. And the installation in this case cannot be compared in complexity with a water heated floor or a radiator system.

Heat source

This role can be played by:

- Gas... Gas heating boilers provide the lowest cost of heat energy. Where there are no gas pipelines, gas tanks or cylinders can be used instead.

However: in this case, the price of a kilowatt-hour of heat will increase significantly.

- Firewood and coal... Solid fuel boilers for these energy carriers are usually unified. Their main disadvantage is limited autonomy of work: fuel filling and ash pan cleaning are required several times a day.

However, gas generators and overhead combustion boilers are able to slightly increase the gap between the tabs.

- Pellets... Pellet boilers with hoppers and dispensers allow achieving autonomy of several days.

Pellet boiler with automatic fuel supply system.

- Solarium... Here autonomy is already calculated in weeks; the disadvantages include the high noise level of the equipment and the need for a bulky container for diesel fuel.

- Electricity... Along with direct heating devices, heat pumps use electricity to pump heat from a relatively cold environment (air, water or soil) into a warmer room.

The principle of operation of a heat pump.

Here is a rough estimate of costs for different sources.

| Heat source | Price per kilowatt hour |

| Gas boiler (mains) | 0.7 p. |

| Solid fuel boiler (firewood) | 1.1 p. |

| Heat pump | 1.2 p. |

| Solid fuel boiler (coal) | 1.3 p. |

| Gas boiler (gas holder) | 1.8 p. |

| Gas boiler (cylinders) | 2.8 p. |

| Diesel boiler | 3.2 p. |

| Electricity (direct heating) | 3.6 p. |

Induction electric boilers

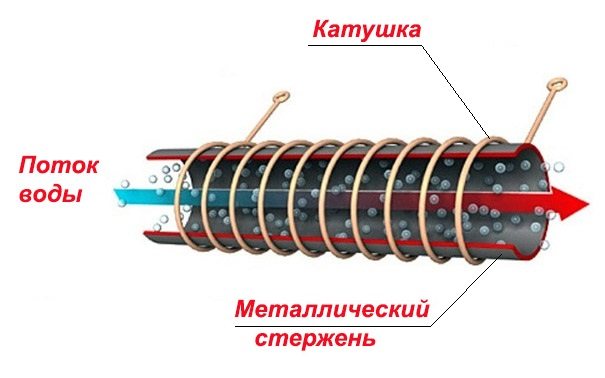

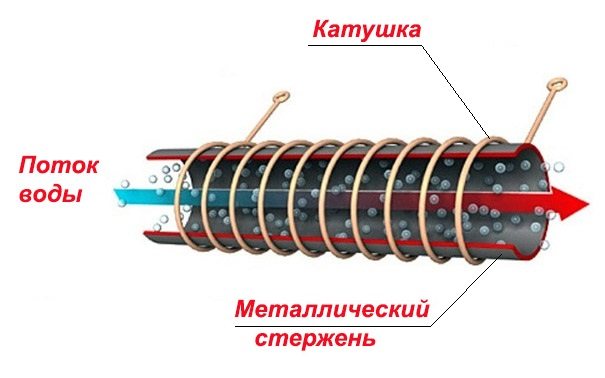

This novelty appeared on the market relatively recently and aroused considerable interest, since it was advertised as another energy-saving installation. In reality, this water heater uses the law of electromagnetic induction, according to which a stationary steel bar placed inside a coil with a current flowing through it will heat up. There are no tricks here, the so-called energy-saving boiler operates with an efficiency of about 98-99%, like its other electrical "brothers".

A clear advantage of the unit is that the coolant passing through it does not come into contact with important elements, but only with a metal rod. Therefore, the boiler is able to reliably serve for many years without any maintenance, except for periodic flushing. Other advantages of the induction apparatus are:

- small dimensions and weight, which is very important when placing a heat generator in a furnace room;

- rapid heating of the coolant.

Heating of greenhouses

Greenhouse heating systems can be classified according to the following criteria:

- the type of coolant used;

- type of equipment used.

By the type of coolant, all heating networks used in such structures are divided into:

- air;

- water.

By the type of equipment used, they are:

- gas;

- electric.

Heating systems for greenhouses work on approximately the same principle as the networks of residential buildings.

Thermal panels - energy saving heating

Among energy-saving heating systems, thermal panels are gaining special popularity. Their advantages are economical power consumption, functionality, ease of use. The heating element consumes 50 watts of electricity per 1 m², while traditional electric heating systems consume at least 100 watts per 1 m².

A special heat-accumulating coating is applied to the back of the energy-saving panel, due to which the surface heats up to 90 degrees and actively gives off heat. The room is heated by convection. The panels are absolutely reliable and safe. They can be installed in nurseries, playrooms, schools, hospitals, private homes, offices. They are adapted to power surges and are not afraid of water and dust.

An additional "bonus" is a stylish look. The devices fit into any design. Installation is not complicated; all the necessary fasteners are supplied with the panels. From the very first minutes of turning on the device, you feel warm. In addition to the air, the walls are warming up. The only drawback is that the use of panels is unprofitable in the off-season, when you only need to slightly heat the room.

Energy saving using monolithic quartz thermal electric heaters

You can save energy if, for example, you use quartz heating electric heaters. Such efficient heating of a private house converts electrical energy into heat. The quartz sand contained in the heating elements retains heat for a long time after the power supply is turned off.

What are the advantages of quartz panels:

- Affordable price.

- Long enough service life.

- High efficiency.

- Relatively low power consumption.

- Convenience and ease of equipment installation.

- No oxygen burnout in the building.

- Fire and electrical safety.

Monolithic quartz thermal electric heater

Energy-saving heating panels are made using a solution made using quartz sand, which provides good heat transfer and a long service life. Due to the presence of quartz sand, the heater retains heat well even when the power is cut off, and can heat up to 15 cubic meters of a building. The production of these panels began in 1997; every year they become more and more popular due to their energy saving. Many buildings, including schools, are switching to this energy saving in heating systems.

This heating system is made of modules connected in parallel, and how many there will be depends on the size of the room. Another plus is the possibility of automatic control.

Classification of heating systems and their types: autonomous networks

Engineering communications of this type are most often used to heat low-rise suburban buildings. They are also often equipped in all sorts of outbuildings, garages and baths.

The classification of heating systems in low-rise buildings is primarily based on the type of heating equipment used. In old small suburban residential buildings, stove heating is sometimes equipped. But most often in residential private houses in our time, autonomous trunk networks are still used, in which boilers are responsible for maintaining the desired temperature of the coolant.

Sometimes electric radiators, air heaters or heat guns are also used as heating equipment in private homes. In some cases, in such buildings, combined networks with a boiler and, for example, a stove or fireplace, can be equipped.

The use of solar energy

Solar heat is an environmentally friendly and efficient enough source for a variety of heating systems. Some modifications use electricity as an additional power supply, others operate only from solar cells. In some cases, additional equipment is not necessary - there is enough sunlight.

Modular air manifolds

Solar panels (collectors) are installed on the south side of the building at an angle so that they are heated by the sun's rays to the maximum. The system works in automatic mode: when the air temperature drops below the set point, the air is driven by the fans through the heating modules. One air battery allows you to heat a room with an area of up to 40 m², respectively, a set of collectors is able to serve the whole house.

For the southern regions, solar air collectors of modular type are quite effective and inexpensive equipment for creating a heating system.

Solar modules are environmentally friendly and cost-effective, they can be conveniently used in conjunction with other heating systems as a backup energy source. The design of the devices is simple, so there are diy diagrams for assembling solar panels. Ready-made collectors are also affordable and pay off quickly. The only thing that needs to be done before buying them is to calculate the power of the equipment and the sizes of the modules.

In cottages and country houses, solar panels are installed for backup DC power supply of low power volts or AC loads of 220 Volts

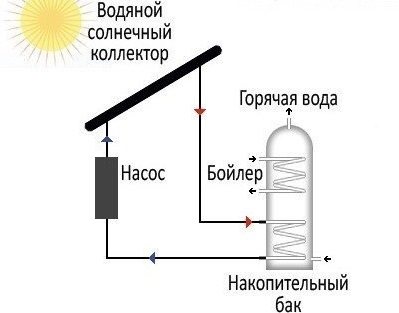

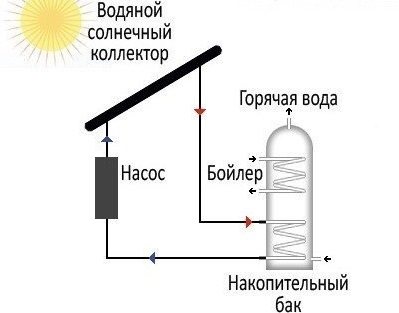

Air-water collectors

Solar hot water systems are also suitable for any climate. The principle of operation of the system is simple: the water heated in the collectors flows through the pipes into the storage tank, and from it - throughout the house. The liquid is constantly circulated by the pump, so the process is continuous. Several solar collectors and two large reservoirs can provide heat to a summer cottage - provided there is enough sun, of course. High-temperature collectors allow you to install a "warm floor".

Solar hot water systems absolutely do not pollute the air and do not create noise, but their installation requires additional equipment: a pump, a pair of storage tanks, a boiler, a pipeline

The advantage of equipment operating on water collectors is environmental friendliness. Silence and clean air inside the house are just as important as heating and hot water. Before installing solar collectors, it is necessary to calculate how effective they will be in a particular case, because all the nuances are important for full operation: from the installation site to the expected power of the devices. One drawback should also be taken into account - in areas with a long summer period, an excess of heated water will appear, which will have to be drained into the ground.

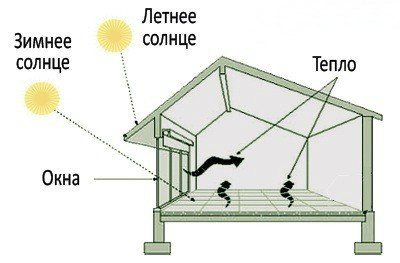

Passive solar heating

No additional equipment is required for a passive solar heating device. The main conditions are three factors:

- perfect tightness and thermal insulation of the house;

- sunny, cloudless weather;

- optimal location of the house in relation to the sun.

One option suitable for such a system is a frame house with large glass windows facing south. The sun heats the house both from the outside and from the inside, as its heat is absorbed by the walls and floors.

With the help of passive solar equipment, without the use of power supply and expensive pumps, you can save 60-80% of heating costs for a private house

Thanks to the passive system in sunny areas, heating costs savings exceed 80%. In the northern regions, this heating method is not effective, therefore it is used as an additional one.

All energy-saving heating systems have advantages over conventional ones, the main thing is to choose the most optimal, possibly combined, option that combines work efficiency and resource saving.

Control system "Smart home"

Automatic devices of the “Smart House” complex are capable of making a huge contribution to saving energy resources used to generate heat.

The maximum level of efficiency can be achieved by choosing a system equipped with a number of additional functions, namely:

- weather-dependent control;

- indoor temperature sensor;

- the possibility of external control with the provided data exchange;

- the priority of the contours.

Let's consider all of the above benefits in more detail.

Weather-dependent temperature control in the house involves adjusting the heating level of the coolant depending on the outside temperature. If it's freezing outside, the water in the radiator will be slightly hotter than usual. At the same time, with warming, heating will be carried out less intensively.

The lack of such a function often leads to an excessive increase in the air temperature in the rooms. This not only leads to excessive consumption of energy resources, but also is not very comfortable for the inhabitants of the house.

Touchscreen control panels provide a choice of energy-saving options, allowing you to quickly and easily adjust the temperature in your home

Most of these devices have two modes: "summer" and "winter". When using the first, all heating circuits are turned off, while only devices intended for year-round use, for example, heating a pool, remain functional.

The room temperature sensor is needed not only to control the maintenance of the automatically set temperature. As a rule, this device is combined with a regulator, which allows, if necessary, to increase or decrease the heating.

An external temperature sensor is an indispensable part of most Smart Home control units. Such devices must be installed in the room, and if the heat supply is carried out floor by floor, then on each floor.

The thermostat can be programmed to lower the temperature in rooms during certain hours, for example, when the inhabitants of the house leave for work, which leads to significant savings in heat costs.

Priority of heating circuits with simultaneous operation of different devices. So, when the boiler is turned on, the control unit disconnects the auxiliary circuits and other devices from the heat supply.

Due to this, the power of the boiler room is reduced, which allows reducing fuel costs, as well as evenly distributing the load over a given period of time.

The climate control system, linking the control of air conditioning, heating, power supply, ventilation into a single network, not only increases comfort in the house and minimizes the risk of emergency situations, but also saves energy.

Climate control drives that regulate all the functions of maintaining the temperature parameters in the room, as a rule, are hidden from view, for example, they are located in a manifold cabinet

External control - the ability to transfer data to smartphones allows owners to monitor the situation in order to quickly make adjustments if necessary. One of such solutions is a GSM module for a heating boiler.

Modern heat supply systems

MODERN HEAT SUPPLY SYSTEMS

(,, Khabarovsk Center for Energy Saving)

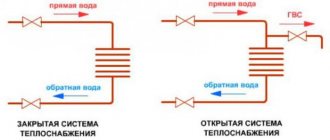

In Khabarovsk and Khabarovsk Territory, as in many other regions of Russia, "open" heat supply systems are mainly used.

An "open" system in thermodynamics is understood as a system that exchanges mass with the environment, that is, a "non-dense" system.

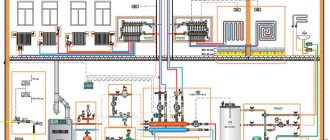

In this publication, an "open" system means a heat supply system in which the hot water supply (DHW) system is connected via an "open" system, that is, with direct water intake from the heat supply pipelines, and the heating and ventilation system is connected according to a dependent connection scheme to heating networks.

Open heating systems have the following disadvantages:

1. High consumption of make-up water and, therefore, high costs of water treatment. With this scheme, the coolant can be used both productively (for the needs of hot water supply) and unproductively: unauthorized leaks.

Unauthorized leaks include:

- leaks through shut-off and control valves;

- leaks in case of damage to pipelines;

- leaks through the risers of the heating system (discharges) with misaligned heating systems and with insufficient pressure drops at the elevator inputs;

- leaks (discharges) during repairs of the heating system, when you have to completely drain the water and then refill the system, and if the outlet valves "do not hold", then you have to "de-energize" the whole block or tie-in.

An example is the accident in November 2001 in Khabarovsk in the Bolshaya-Vyazemskaya microdistrict. In order to repair the heating system in one of the schools, an entire block had to be turned off.

2. With an open DHW circuit, the consumer receives water directly from the heating network. In this case, hot water can have a temperature of 90 ° C or more and a pressure of 6-8 kgf / cm2, which leads not only to excessive consumption of heat, but also potentially creates a dangerous situation for both sanitary equipment and people.

3. Unstable hydraulic regime of heat consumption (one consumer instead of another).

4. Poor quality of the heat carrier, which contains a large amount of mechanical impurities, organic compounds and dissolved gases. This leads to a decrease in the service life of pipelines of heat supply systems due to increased corrosion and to a decrease in their throughput due to "fouling", which violates the hydraulic regime.

5. The impossibility, in principle, of creating comfortable conditions for the consumer when using elevator heating systems.

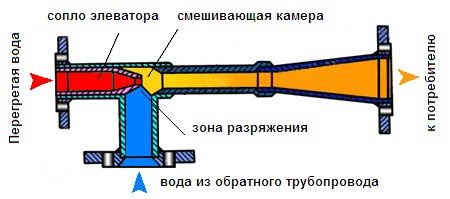

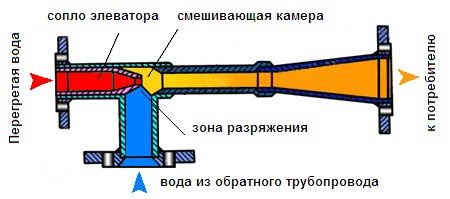

It is necessary to answer that almost all heating points of subscribers in Khabarovsk are equipped with an elevator heating input.

The main advantage of the elevator is that it does not consume energy for its drive. There was an opinion that the elevator has a low efficiency, and this would be true if it would be necessary to consume energy for its operation. In fact, for the mixing operation, the pressure difference in the pipelines of the heat supply system is used. If it were not for the elevator, then the flow of the coolant would have to be throttled, and throttling is a loss of energy. Therefore, as applied to heat inputs, an elevator is not a low-efficiency pump, but a device for the reuse of energy spent on the drive of CHPP circulating pumps. Also, the advantages of the elevator include the fact that highly qualified specialists are not required to maintain it, since the elevator is a simple, reliable and unpretentious device in operation.

The main disadvantage of the elevator is the impossibility of proportional regulation of the heat power, since with a constant diameter of the nozzle orifice, it has a constant mixing ratio, and the regulation process assumes the possibility of changing this value. For this reason, in the West, the elevator is rejected as a device for heating stations. Note that this drawback can be eliminated by using an elevator with an adjustable nozzle.

However, the practice of using elevators with an adjustable nozzle has shown their low reliability with poor quality of network water (presence of mechanical impurities). In addition, such devices have a small control range. Therefore, these devices have not found wide application in Khabarovsk.

Another drawback of the elevator is the unreliability of its operation with a small available pressure drop. For stable operation of the elevator, it is necessary to have a pressure drop of 120 kPa or more. However, up to now, elevator units with a pressure drop of 30-50 kPa are being designed in Khabarovsk. With such a difference, normal operation of elevator nodes is, in principle, impossible and therefore very often consumers with such nodes work for "dumping", which leads to excess losses of network water.

The use of elevator units slows down the introduction of energy-saving measures in heat supply systems, such as the complex automatic regulation of the parameters of the heat carrier in the building and the design of the heating system adequate to these tasks, ensuring the accuracy and stability of comfortable conditions and economical heat consumption.

Get full text

Tutors

Unified State Exam

Diploma

Complex automatic regulation includes the following basic principles:

regulation in individual heating points (ITP) or automated control units (AUU), which, in accordance with the heating schedule, change the temperature of the coolant supplied to the heating system depending on the outside air temperature;

individual automatic control on each heating device using a thermostat that maintains the set temperature in the room.

All of the above has led to the fact that, starting in 2000, a large-scale transition from "open" dependent heat supply systems to "closed" independent systems with automated heating points began in Khabarovsk.

Reconstruction of the heat supply system with the use of energy-saving measures and the transition from "open" dependent systems to "closed" independent systems will allow:

- to increase the comfort and reliability of heat supply by maintaining the required temperature in the premises, regardless of weather conditions and the parameters of the coolant;

- will increase the hydraulic stability of the heat supply system: the hydraulic regime of the main heating networks will be normalized due to the fact that the automation does not allow excessive excess of heat consumption;

- to obtain a heat saving in the amount of 10-15% by regulating the temperature of the heat carrier in accordance with the outside temperature and the night temperature decrease in heated buildings by up to 30% during the transitional period of the heating season;

- to increase the service life of pipelines of the building heating system by 4-5 times, due to the fact that with an independent heating system, a clean coolant circulates in the internal circuit of the heating system, which does not contain dissolved oxygen, and therefore heating devices and supply pipelines are not clogged with dirt and corrosion products;

- drastically reduce the recharge of heating networks and, consequently, the costs of water treatment, as well as improve the quality of hot water.

The use of independent heat supply systems opens up new perspectives in the development of intra-quarter networks and internal heating systems: the use of flexible pre-insulated plastic distribution pipelines with a service life of about 50 years, polypropylene pipes for internal systems, stamped panel and aluminum radiators, etc.

However, the transition in Khabarovsk to modern heat supply systems with automated heat points posed a number of problems for design and installation organizations, an energy supply organization, and heat consumers, such as:

Lack of year-round circulation of the coolant in the main heating networks.

An outdated approach to the design and installation of internal heat supply systems.

The need for maintenance of modern heat supply systems.

Let's consider these problems in more detail.

Problem No. 1 Lack of year-round circulation in the main pipelines of heating networks.

In Khabarovsk, the main pipelines of the heat supply system are circulated only during the heating season: from about mid-September to mid-May. The rest of the time, the coolant enters through one of the pipelines: supply or return, and part of the time it is supplied one by one, and partly through another pipeline.

Get full text

This leads to great inconvenience and additional costs when introducing energy-saving technologies in heat supply systems, in particular, in hot water supply systems (DHW). Due to the lack of circulation in the inter-heating season, it is necessary to use a mixed "open-closed" DHW system: "closed" in the heating season and "open" in the inter-heating season, which increases the capital costs of installation and equipment of the heating point by 0.5-3% ...

Problem # 2. An outdated approach to the design and installation of internal heating systems for buildings.

In the pre-perestroika period of development of our state, the government set the task of saving metal. In this regard, the massive introduction of one-pipe unregulated heating systems began, which was due to lower (compared to two-pipe) metal costs, installation costs and higher thermal and hydraulic stability in multi-storey buildings.

Currently, when commissioning new facilities in Russian cities, such as Moscow and St. Petersburg, as well as in Ukraine, in order to save energy, it is mandatory to use thermostats in front of heating devices, which, in fact, with minor exceptions, predetermines the design of two-pipe heating systems.

Therefore, the widespread use of one-pipe systems when equipping each heater with a thermostat has lost its meaning. In controlled heating systems, when a thermostat is installed in front of the heater, a two-pipe heating system turns out to be highly efficient and has increased hydraulic stability. At the same time, the discrepancies in metal costs in comparison with single-pipe are within ± 10%.

It should also be noted that one-pipe heating systems are practically not used abroad.

The schemes of two-pipe systems can be different, however, it is most advisable to use an independent scheme, since when using thermostats (thermostats), the dependent scheme is unreliable in operation due to the low quality of the coolant. With small holes in the thermostats, measured in millimeters, they quickly fail.

In [1], it is proposed to use one-pipe heating systems with thermostats only for buildings of no more than 3-4 floors. It also notes the inexpediency of using cast-iron heating devices in heating systems with thermostats, since during operation they wash out molding earth, sand, scale, which clog the holes of the thermostats.

The use of independent heat supply schemes opens up new prospects: the use of polymer or metal-polymer pipelines for internal systems, modern heating devices (aluminum and steel heating devices with built-in thermostats).

It should be noted that a two-pipe heating system, in contrast to a one-pipe heating system, requires mandatory adjustment using special equipment and highly qualified specialists.

It should be noted that even in the design and installation of automated heating points with weather regulation in Khabarovsk, only one-pipe heating systems without thermostats in front of heating devices are being designed and implemented. Moreover, these systems are hydraulically unbalanced, and sometimes so much (for example, an orphanage on Lenin street) that in order to maintain a normal temperature in the building, the end risers work “for discharge” and this is with an independent heating scheme!

Get full text

I would like to believe that underestimating the importance of balancing the hydraulics of heating systems is simply due to a lack of the necessary knowledge and experience.

If the Khabarovsk designers and installation organizations ask the question: "Is it necessary to balance the wheels of the car?", Then the obvious answer will follow: "Undoubtedly!" But why, then, balancing the heating, ventilation and hot water supply system is not considered necessary. After all, incorrect flow rates of the coolant lead to incorrect air temperatures in the room, poor automation, noise, rapid failure of pumps, uneconomical operation of the entire system.

The designers believe that it is enough to carry out a hydraulic calculation with the selection of pipes and, if necessary, washers, and the problem will be solved. But this is not the case. Firstly, the calculation is approximate, and, secondly, during installation, a lot of additional uncontrollable factors arise (most often installers simply do not install choke washers).

There is an opinion [2] that the hydraulics of heating systems can be linked by calculating the settings of thermostatic valves. This is also wrong. For example, if for some reason a sufficient amount of coolant does not pass through the riser, then the thermostatic valves will simply open, and the air temperature in the room will be low. On the other hand, if the coolant is overrun, a situation may arise when the vents and thermostatic valves are open. All of the above does not at all diminish the need and importance of installing thermostatic valves in front of heating devices, but only emphasizes that for their good operation, balancing of the system is necessary.

Balancing the system means setting up the hydraulics so that each element of the system: radiator, heater, branch, shoulder, riser, main line has design costs. In this case, the definition and setting of the thermostatic valve settings is part of the commissioning process.

As mentioned above, in Khabarovsk, only hydraulically unbalanced one-pipe heating systems without thermostats are designed and installed.

Let us show by examples of new, commissioned facilities what this leads to.

Example 1. Orphanage No. 1 on the street. Lenin.

Commissioned at the end of 2001. The DHW system is closed, and the heating system is one-pipe, without thermostats, connected according to an independent scheme. Designed - Khabarovskgrazhdanproekt, installation of the heating and hot water supply system - Khabarovsk installation department No. 1. Design and installation of a heating point - specialists of KhTsES. The substation is undergoing maintenance at KhTsES.

After the start of the heat supply system, the following shortcomings emerged:

The heating system is not balanced. Overheating was observed in some rooms: 25-27оС, and in others, underheating: 12-14оС. This is due to several reasons:

for balancing the heating system, the designers provided for washers, and the installers did not cut them in, citing the fact that "they will clog up in 2-3 weeks anyway";

individual heating devices are made without closing sections, their surface is overestimated, which leads to overheating of individual rooms.

In addition, in order to ensure circulation and normal temperature, in subcooled rooms, the end risers worked for "discharge", which led to water leaks of 20-30 tons per day and this with an independent scheme !!!

The supply ventilation system does not work, which is unacceptable, since thermostatic windows with low air permeability are installed in the building.

At the request of the Customer, the specialists of KhTsES installed balancing valves on the risers and carried out balancing of the heating system. As a result, the temperature in the premises leveled off and amounted to 20-22 ° C, the system's make-up was reduced to zero, and the thermal energy savings amounted to about 30%. The ventilation system was not adjusted.

Example 2. Institute for advanced training of doctors.

It was put into operation in October 2002. The DHW system is closed, the one-pipe heating system without thermostats is connected according to an independent scheme.

After starting the heating system, the following shortcomings were identified: the heating system is not balanced, there are no fittings for adjusting the system (the project does not even provide for throttling washers). The air temperature in the premises varies from 18 to 25 ° C, and in order to bring the temperature in the corner rooms to 18 ° C, it was necessary to increase the heat consumption by 3 times compared to the required one. That is, if the heat consumption of a building is reduced by three times, then in most rooms the temperature will be 18-20 ° C, but at the same time in the corner rooms the temperature will not exceed 12 ° C.

These examples apply to all newly introduced buildings with independent heating schemes in the city of Khabarovsk: a circus and a circus hotel (the vents are open in the hotel (overheating), and in the backstage part it is cold (underflow), residential buildings on Fabrichnaya street, Dzerzhinsky street, therapeutic building of the Railway Hospital, etc.

Problem no. 2 is closely intertwined with problem no. 3.

Problem number 3. The need for maintenance of modern heat supply systems.

As our three-year experience shows, modern heat supply systems for buildings, made with the use of energy-saving technologies, need constant maintenance during operation. To do this, it is necessary to attract highly qualified, specially trained specialists using special technologies and tools.

Let us show this with examples of automated heating points introduced in the city of Khabarovsk.

Example 1. Thermal points not serviced by specialized organizations.

In 1998 in the city of Khabarovsk the Khakobank building on Leningradskaya Street in the city of Khabarovsk was put into operation. The heating system of the building was designed and installed by specialists from Finland. Finnish equipment is also used. The heating system is made according to an independent two-pipe scheme with thermostats, equipped with balancing fittings. The DHW system is closed. The system was serviced by bank specialists. During the first three years of operation, a comfortable temperature was maintained in all rooms. After 3 years, complaints were sent from tenants of individual apartments that the apartment was “cold”. Residents turned to KhTSES with a request to examine the system and help establish a "comfortable" regime.

Inspection of the KhCES showed: the automatic control system does not work (the ECL weather regulator is out of order), the heat exchange surfaces of the heat exchanger of the heating system are clogged, which led to a decrease in its heat output by about 30% and an imbalance in the heating system.

A similar picture was observed in a residential building on the street. Dzerzhinsky 4, where the modern heating system was serviced by residents.

Example 2. Heat points serviced by specialized organizations.

To date, about 60 automated heating points are serviced in the Khabarovsk Center for Energy Saving. As our operating experience has shown, in the process of servicing such units, the following problems arise:

cleaning of filters installed in front of DHW and heating heat exchangers and in front of circulation pumps;

control over the operation of pumps and heat exchange equipment;

control over the work of automation and regulation.

The quality of the heat carrier and even cold water in Khabarovsk is very low and therefore the problem of cleaning the filters that are installed in the primary circuit of the DHW and heating heat exchangers, in front of the circulation pumps in the secondary circuit of the heat exchangers, constantly arises. For example, when commissioning in the heating season 2002/03. block of residential buildings on Fabrichniy lane, in each of which IHP was installed, the filter installed in the primary circuit of the heating heat exchanger had to be washed 1-2 times a day during the first 10 days after starting and then, in the next two weeks, at least one once every 2-3 days. On the building of the circus and the circus hotel in the heating season 2001/02. I had to rinse the cold water filter 1-2 times a week.

It would seem that cleaning the filter installed in the primary circuit is a routine operation that can be performed by an unqualified specialist. However, to clean (pour) the filter, it is necessary to stop the entire heating system for some time, turn off the cold water, turn off the circulation pump in the DHW system and then start it all up again. Also, when the heat supply system is turned off, it is advisable to turn off and then restart the automation system to clean the filters so that no water hammer occurs when the heat supply system is started. In this case, if, when the primary circuit of the DHW system is disconnected, the secondary circuit for cold water is not disconnected, then due to temperature expansions in the DHW heat exchanger, a "leak" may appear.

The second problem that arises during the operation of automated heat points is the problem of monitoring the operation of equipment: pumps, heat exchangers, metering and regulation devices.

For example, before starting after the inter-heating period, circulation pumps are often in a "dry" state, that is, they are not filled with network water, and their stuffing box seals dry up, and sometimes even stick to the pump shaft. Therefore, before starting, in order to avoid leaks of heating water through the stuffing box seals, it is necessary to turn the pump smoothly several times by hand.

Also, during operation, it is necessary to periodically monitor the operation of the control valves so that they do not work constantly in the "closed" or "open" mode, pressure regulators, differential pressure, etc., in addition, it is necessary to monitor the change in hydraulic resistance and heat transfer surface of heat exchangers ...

Changes in the hydraulic resistance and the area of the heat transfer surface of heat exchangers can be monitored by registering or periodically measuring the temperature of the coolant in the primary and secondary circuits of the heat exchanger and the pressure drop and flow rate of the coolant in these circuits.

For example, in the heating season 2001/02. in the hotel of the circus, a month after the start of operation, the temperature of the hot water dropped sharply. Studies have shown that at the beginning of operation, the flow rate of the coolant in the primary circuit of the DHW system was 2-3 t / h, and a month after the start of operation it was no more than 1 t / h. This happened due to the fact that the primary circuit of the DHW heat exchanger was clogged with welding products (scale), which led to an increase in hydraulic resistance and a decrease in the area of the heat transfer surface. After the heat exchanger was disassembled and washed, the hot water temperature reached normal.

Get full text

As the experience of servicing modern heat supply systems with automated heat points has shown, during their operation it is necessary to carry out constant monitoring and make adjustments to the operation of automation and regulation systems. In Khabarovsk, in the last 3-5 years, the temperature schedule 130/70 has not been observed: even at temperatures below minus 30 ° C, the temperature of the coolant at the subscribers' inlet does not exceed 105 ° C. Therefore, the specialists of the KhCES serving automated heating points, on the basis of statistical observations of the heat consumption regime of objects, before the start of the heating season, for each object enter their temperature schedule into the controller, which is then adjusted during the heating season.

The problem of servicing automated heating points is closely related to the lack of a sufficient number of highly qualified specialists who are purposefully not trained within the Far Eastern region. In the Khabarovsk Center for Energy Saving, the maintenance of automated heating units is carried out by specialists - graduates of the Department of Heat Engineering, Heat and Gas Supply and Ventilation of the Khabarovsk State Technical University, trained at equipment manufacturers (Danfos, Alfa-Laval, etc.).

Note that KhTSES is a regional service center of companies supplying equipment for automated heating points, such as: Danfos (Denmark) - a supplier of controllers, temperature sensors, control valves, etc .; Vilo (Germany) - supplier of circulation pumps and pump automation; Alfa Laval (Sweden-Russia) - supplier of heat exchange equipment; TBN Energoservice (Moscow) - supplier of heat meters, etc.

In accordance with the service partnership agreement concluded between HCES and Alfa-Laval, HCES carries out maintenance work on heat exchange equipment of Alfa-Laval, using personnel trained at the Alfa-Laval service center, and using for this purpose only permitted for operation Alfa-Laval original spare parts and materials.

In turn, Alfa-Laval supplied HCES with equipment, tools, consumables and spare parts necessary for servicing Alfa-Laval plate heat exchangers, trained HCES specialists in its service center.

This allows KhTSES to carry out collapsible and CIP flushing of heat exchangers directly from consumers in Khabarovsk.

Therefore, all issues related to the operation and repair of the equipment of automated heating points are resolved on the spot - in the city of Khabarovsk.

Note also that, unlike other companies involved in the implementation of automated heating units, KhTSES installs more expensive, but more reliable and better equipment (for example, collapsible rather than brazed heat exchangers, pumps with a dry rather than a wet rotor). This guarantees reliable operation of the equipment for 8-10 years.

The use of cheap, but less quality equipment does not guarantee the uninterrupted operation of automated heating points. As our experience shows, as well as the experience of other firms [3], this equipment breaks down, as a rule, after 2-3 years and the consumer begins to feel thermal discomfort (see, for example, example 1 from problem No. 3).

Thermal tests of heat exchangers, carried out in St. Petersburg [3], showed:

- the decrease in the thermal efficiency of the heat exchanger is 5% after the first year, 15% after the second, more than 25% after the third, 35% after the fourth, and 40-45% after the fifth;

- a decrease in the heat output of the apparatus and the heat transfer coefficient is associated with contamination of the heat exchange surface both from the side of the primary circuit and from the side of the secondary circuit; these contaminants appear in the form of deposits, and on the side of the primary circuit the deposits are brown in color, and on the side of the secondary circuit they are black;

- the brown color of deposits is determined mainly by iron oxides, which are formed in the network water due to corrosion of the inner surface of heating pipelines; These contaminants from the primary circuit can be easily removed with a soft cloth under running warm water;

- the black color of deposits in the secondary circuit is determined mainly by organic compounds, which are in large quantities in the water of the secondary circuit, which circulates in a closed circuit of the building heating system and is not subjected to any cleaning; it is not possible to remove deposits from the side of the secondary circuit in the same way as from the primary circuit, since they are not loose, but dense; to clean the heat exchange plates from the side of the secondary circuit, the plates had to be soaked in kerosene for 15-20 minutes, and then they were wiped with considerable effort with damp rags soaked in kerosene;

- due to the fact that biological deposits formed on the plates from the side of the secondary circuit have a very strong adhesion (adhesion) to the metal surface, CIP chemical flushing of the secondary circuit does not give satisfactory results

.

Cheap equipment, as a rule, is used by those implementation firms that are not engaged in servicing the equipment they have implemented, since this requires the availability of appropriate equipment and materials, as well as qualified personnel, i.e., invest heavily in the development of their production base.

Therefore, the consumer is faced with a choice:

- spend a minimum of capital investments and introduce cheap equipment (wet rotor pumps, brazed heat exchangers, etc.), which in 2-3 years will largely lose its properties or become completely unusable; at the same time, the operating costs for the repair and maintenance of equipment will increase sharply after 2-3 years and can be of the same order as the initial investment;

- spend maximum capital investments, introduce reliable expensive equipment (gasketed heat exchangers of proven companies, for example, Alfa-Laval, dry-rotor pumps with a frequency drive, reliable automation, etc.) and thereby significantly reduce their operating costs.

The choice is up to the consumer, but one must not forget that "the miser pays twice."

Summarizing the above, the following conclusions can be drawn:

1. In Khabarovsk, in the last 2-3 years, the process of transition from outdated "open" systems to modern "closed" heat supply systems with the introduction of energy-saving technologies has begun. However, in order to speed up this process and make it irreversible, it is necessary:

1.1. To break the psychology of Customers, designers, installers and operators, which is as follows: it is easier and cheaper to introduce outdated traditional heat supply schemes with one-pipe heating systems and elevator units that do not need maintenance and adjustment, than to create additional pain and financial difficulties for yourself, moving to modern heat supply systems with automation and control systems. That is, to build an object with a minimum of capital costs, then transfer it, for example, to the municipality, which will have to look for funds for the operation of this object. As a result, the consumer (citizen) will again be extreme, who will consume "rusty" water from the heating system, freeze in winter from underflooding and suffer from heat during the transition period (October, April) during overheating, carrying out window regulation, which leads to colds from - for drafts.

1.2. Create specialized organizations that would deal with the entire chain: from design and installation to commissioning and maintenance of modern heat supply systems.For this purpose, it is necessary to carry out purposeful work on the training of specialists in the field of energy saving.

2. When designing these systems, it is necessary to closely link together all the elements of heat supply systems: heating, ventilation and hot water supply, taking into account not only the requirements of SNiPs and SPs, but also considering them from an angle from the point of view of operators.

3. Unlike outdated, traditional systems, modern systems require maintenance that can only be carried out by specialized organizations with special equipment and highly qualified specialists.

LIST OF REFERENCES

1. On the practice of using two-pipe heating systems. Inzhenernye sistemy. ABOK. North-West, No. 3, 2002

2. Lebedev of hydraulics of HVAC systems // AVOK, No. 5, 2002.

3. Ivanov of operation of plate heaters in the conditions of St. Petersburg // News of heat supply, No. 5, 2003.

Heat pumps of two types

These designs are very popular. The device is considered the most efficient option for heating, since it is environmentally friendly. There is a type of heat pump called "mini-split". It has an outdoor unit and one or more indoor units that supply both hot and cold air. There are two types of models on sale:

- Air heat pumps. These are structures that have devices that, even at -20 degrees, take heat from the external air masses and distribute it throughout the house due to the installed air ducts.

- Ground source heat pumps. Devices with which you can use the energy of the soil. In the ground, they are laid horizontally in rings at a depth of 1.5 meters, no less (soil freezing should be taken into account). The pumps can be positioned vertically. For this, wells are drilled to a depth of 200 m.

Although they run on electricity, the devices are energy efficient. Considering the costs, their efficiency is very high (1: 3 for air, 1: 4 for geothermal structures).

In addition, the units are environmentally friendly and absolutely safe. Another advantage of heat pumps is reverse operation. They not only heat but also cool the air. The geothermal device can be combined with a water heater, which will supply water up to +60 degrees.

Types of air networks

Such networks are also sometimes used to heat office, industrial and residential premises. Air heating systems are classified:

- by the method of transferring heated air;

- the principle of work.

In the first case, there are:

- natural circulation systems;

- supplemented by fans.

According to the principle of operation, air networks can be:

- direct-flow;

- with full recirculation;

- with partial recirculation.

Air heaters are used as the main heating equipment in such networks. In systems with full recirculation, air is ducted into the rooms and then returned back to the heater. In direct-flow networks, after passing through rooms and giving off heat, it is removed to the street. Further, a new portion of air is taken from the outside. In systems with partial recirculation, air from both the premises and the street simultaneously passes through the heater.

Heating with wood

Since ancient times, wood has been widely used for heating houses: it is a renewable resource available to the population. It is not necessary to use full-fledged trees, you can also heat the room with wood waste: brushwood, twigs, shavings. For such fuel, there are wood-burning stoves - a prefabricated structure made of cast iron or welded from steel. True, such devices have negative characteristics that hinder their widespread use:

- The most environmentally friendly heaters. When fuel is burned, toxic substances are emitted in large quantities.

- Preparation of firewood is required.

- Cleaning of burnt ash is required.

- Most fire hazardous heaters. If you do not know the technique of cleaning chimneys, a fire may occur.

- The room in which the stove is installed is heated, and in other rooms the air remains cool for a long time.

When choosing a wood-burning stove, you should pay attention to an effective modern model, which is equipped with a device - a catalytic converter. It burns unburned liquids and gases, thereby increasing the efficiency of the unit and reducing the emission of harmful substances.

Heat recovery

Using heat recovery will be a step towards creating an energy efficient private home, as well as a good way to save on utility bills. Heat recovery is the return of warm air through a ventilation system. When ventilating, we not only let in cold air, but also let out warm air, thus discrediting the central heating system and throwing money away.

With recuperation, not only the temperature regime is maintained, but the air is also cleaned. Every modern "passive" private house has a heat recovery system. The organization of recuperation is inexpensive, especially in comparison with the benefits that it brings. As statistics show, about 40% of the heat goes to the street when ventilated. But you have already paid for this warmth!

So, there are many different energy-saving heating systems and the main question is how to choose the most optimal one. To do this, you need to devote time and effort to its selection, purchase and installation.

Water

What criteria can be used to classify schemes of this type?

Central and autonomous

The definitions are intuitive. The heat source for district heating is outside the building; the coolant is transported to it and back through two heat-insulated pipes - the heating main. Thermal energy is generated by a boiler house or CHP.

Autonomous heating, on the other hand, heats only the building in which it is located. This category includes boilers, ovens and heat pumps of various types.

Independent and dependent

Central heating systems, in turn, are also divided into two subcategories:

- Dependents use the coolant that comes from the heating main for circulation in the heating system and for the needs of hot water supply. For its dosage and control of the thermal regime, an elevator unit is used. This is the scheme used by the vast majority of Soviet-built apartment buildings.

The main unit of the elevator unit, which regulates the temperature of the batteries in the house.

- The independent scheme implies a closed loop with a constant volume of the coolant, for which a heat exchanger is used to heat it with water from the heating main. In the same way, hot water for household use is heated. The scheme is more progressive already in that it allows the use of any type of coolant without debris and impurities from the route; however, substations are much more expensive than elevator units.

Closed and open

But only an autonomous system can be open. The open circuit and the heating devices are filled without overpressure; the circuit opens directly to atmosphere (usually through an open-type expansion vessel). All central heating circuits are of an exclusively closed type.

Please note: In an open system, not only natural circulation can be used. The circulating pump can operate without excess pressure, as long as it is not airy.

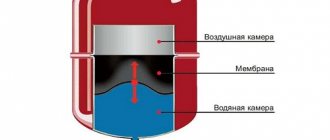

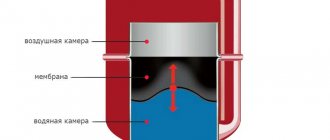

As you might guess, in a closed-type system, the pressure is higher than atmospheric pressure. Typically it is maintained at 1.5 kgf / cm2. To compensate for the expansion of the liquid during heating, a membrane-type expansion tank is used, which can be mounted in any part of the circuit.

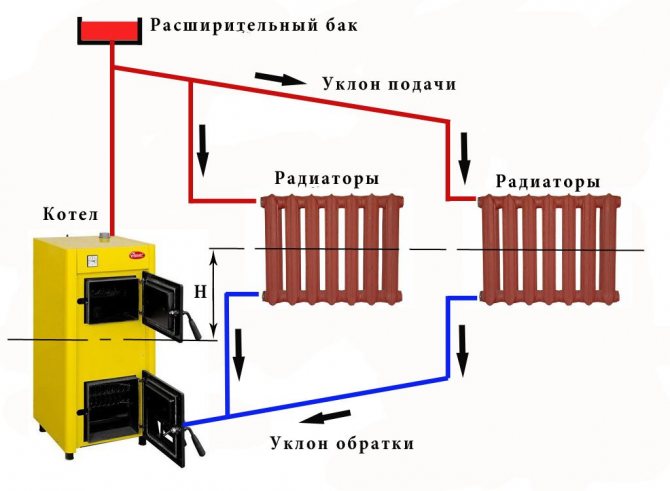

Natural and forced circulation

And here division is possible only in autonomous systems: circulation in central heating is always forced. The coolant sets in motion the pressure difference between the supply and return pipelines of the heating main.

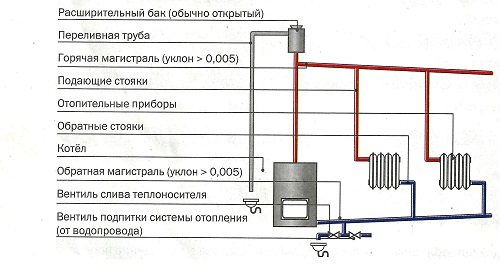

In natural circulation (gravitational) circuits, the coolant is driven by the density difference between hot and cold fluid. The coolant heated by the boiler is continuously displaced into the upper part of the circuit; from there, he, describing a circle around the house and gradually giving off heat to the heating devices, returns back to the boiler.

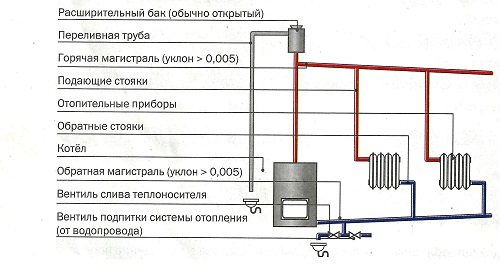

Diagram of a gravitational heating system.

Forced circulation in an autonomous system is provided by a low-power pump. Its use allows you to use the filling of a smaller diameter, warm up the house faster and more evenly; the price of this is the volatility of heating.

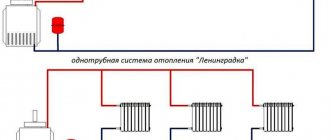

Two- and one-pipe

One-pipe schemes, as you might guess from the name, use a coolant wiring for all heating devices with a single pipe. The obvious consequence is that the contour should be a closed circle, which is not always convenient.

However, there are also a number of important advantages:

- Minimum costs. Pipes aren't that cheap; it is clear that one ring around the perimeter of the house will cost much less than two.

- Fault tolerance. If the water circulates in the circuit, stopping the movement of the coolant in any heating devices is impossible. You can not be afraid of defrosting.

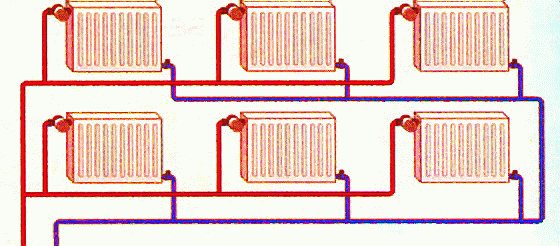

The two-pipe scheme gives more possibilities in terms of possible wiring schemes: for example, the circuit can be broken in half by the door located in the middle, representing two half rings. In addition, it allows for a more uniform heating of heating devices.

The downside is the need to balance the system with throttling valves. The instruction is quite understandable: if all radiators are connected with pipes of the same cross-section, while some are closer to the boiler, while others are farther away, the water will circulate only through the nearest ones.

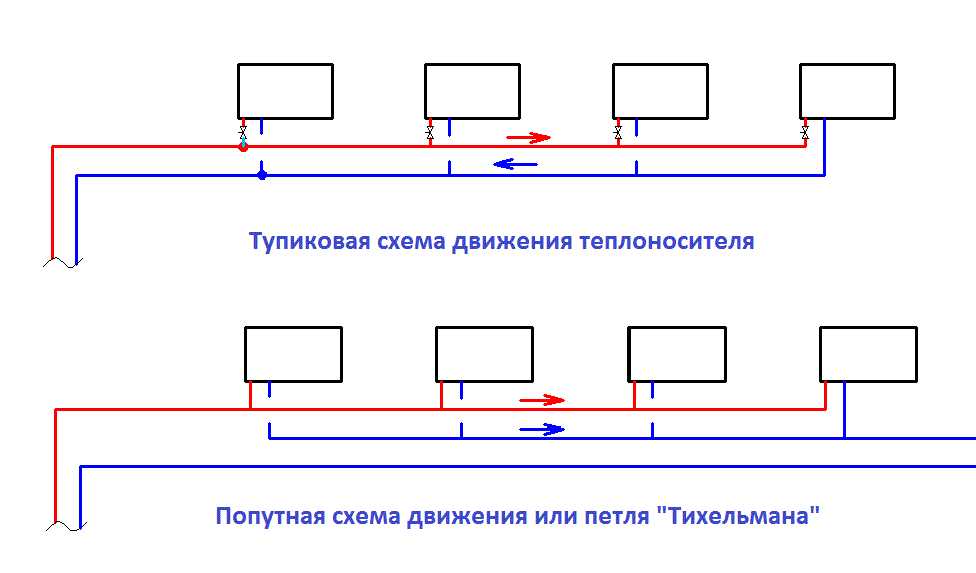

Passing and dead-end

Two-pipe schemes can be, in turn, associated and dead-end. What is the difference?

- If the coolant reaches the distant radiators and returns through the return pipeline, moving in the opposite direction, the circuit is dead-end.

- If the water, having passed through the radiators, continues to move in the same direction, we can talk about a passing wiring scheme.

Double-pipe heating with a passing movement of the coolant.

Vertical and horizontal routing

What is the difference is easy to understand: for example, the Leningradka single-pipe heating system, typical of a one-story house, has horizontal wiring, but several radiators, united by a common riser in an apartment building, are vertical.

However: in practice, a combination of the two is very common. The most vivid example is the current new buildings. From the horizontal spills in the basement there is a pair of vertical risers; from them, in turn, in the apartment there is a horizontal wiring of the coolant to the heating devices.

Radiator connection diagram

Water heating may also differ in the way sectional radiators are connected.

If other heating devices (for example, convectors) can be connected in only one way, dictated by the manufacturer, then different schemes are possible with sectional heating batteries.

- Side connection leaves a minimum of pipes visible; however, a multi-section radiator in this case will be heated unevenly, and the last sections will inevitably silt up.

- Diagonal will make it warm up completely and evenly. Sludge will accumulate only under the upper liner: flushing is occasionally required.

- Connecting from bottom to bottom is the most practical: in this case, all sediment will be carried away by the water. In this case, the radiator must be supplied with an air vent of any type.

This is how heat transfer changes with different connections.