What is the effect of the dimensions of aluminum heating radiators

One of the most important parameters is the gap between the axes of the radiators. Most often, you can find aluminum devices on sale, in which the distance between two collectors - the lower and the upper one - is 350 or 500 millimeters. True, there are products with an indicator equal to 200, 400, 600, 700 and even 800 millimeters.

The dimensions of aluminum radiators are practically unlimited in length. The longer the battery, the higher its capacity. To reach the required power level, it is necessary to purchase a certain number of heating sections.

The total length of the device depends on the power required to heat the room, on the dimensions of the heating batteries, sections and heat transfer.

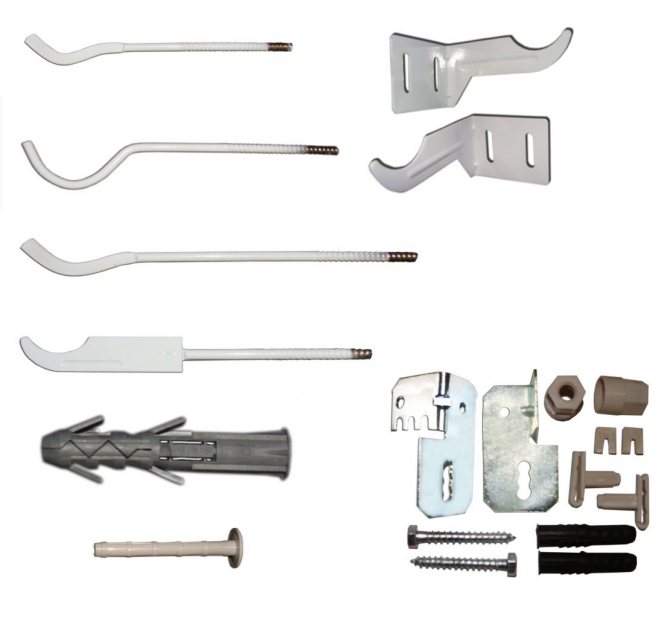

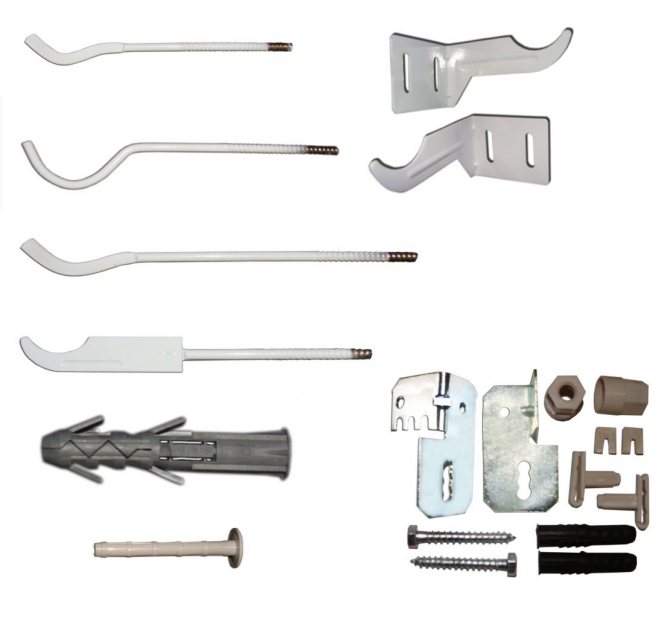

To dock the individual elements of the aluminum radiator with the pipelines of the heating structure, use the installation kit for installation, which includes:

- special brackets for hanging the battery on the wall in the amount of 2-4 pieces;

- Mayevsky crane - a device for bleeding air that has entered the system;

- key for the crane;

- straight through radiator plugs with a diameter of 3/4 or ½ of the right or left type;

- plugs for the heater, they are also called blind plugs;

- sometimes dowels are also provided to secure the brackets.

Depending on the type of manufacture of an aluminum alloy radiator, the heater can be cast or extrusion:

- thanks to the molding, the battery becomes durable and reliable. In this case, the sections are made up of individual parts, cast as a whole and then assembled into a single heater. Its lower part is welded very last;

- in the process of using extrusion equipment, the heated aluminum alloy is pushed through a special metal plate with holes. This method allows you to make a long aluminum profile of the required shape. When it cools down, it is divided into segments that correspond to the dimensions of the device. Only then the top and bottom of the battery are welded. In this case, it is impossible to adjust the length of the radiator, and sections cannot be added or subtracted to it. Extrusion devices are rarely found on the market.

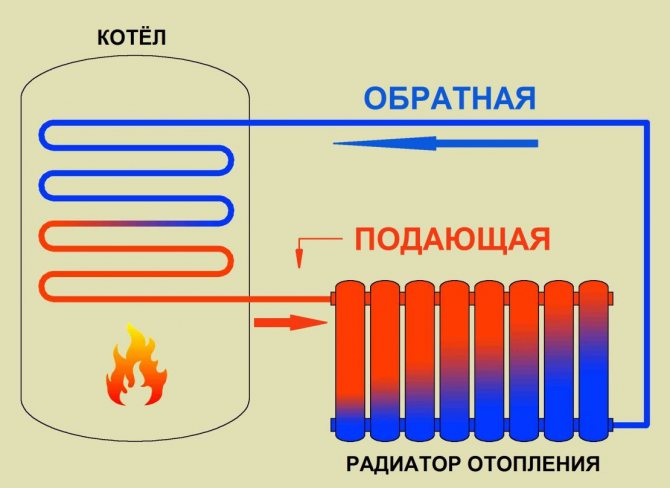

The structure and principle of operation of radiators

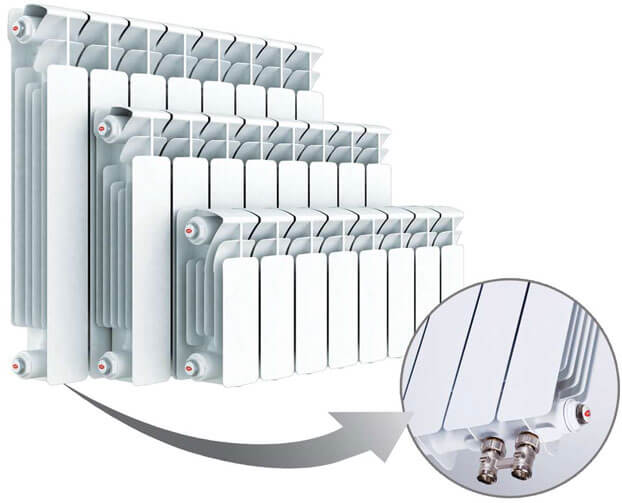

Sectional devices are considered the best choice for owners who want to increase or decrease the number of elements, simplify the process of repairing and replacing parts. In panel batteries, the defect is eliminated by a complete replacement of equipment or with the help of specialists, which is sometimes more expensive than buying a new device.

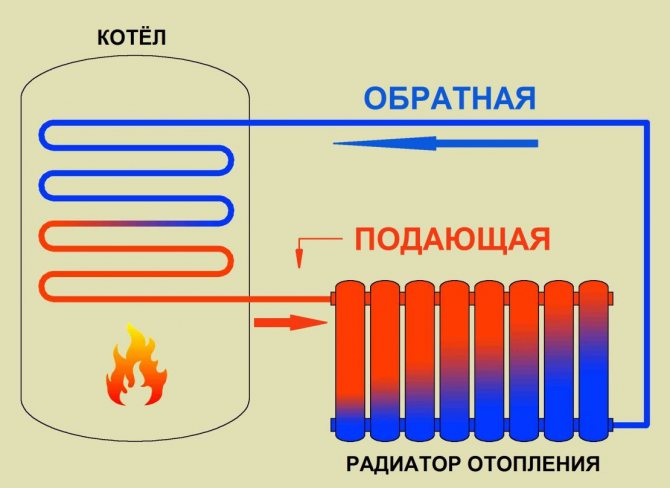

The structure of the unit is as follows - a coolant is transported along the supply pipeline, which passes through the upper, lower and vertical channels, transfers heat to the device fins, and they heat the panels. The heating rate depends on the distance between the axes - this is the gap between the center of the pipe and the inlet. The center distance is a nuance taken into account when replacing batteries with new ones.

The principle of operation is radial, that is, the air in the room is heated only from the coolant supplied to the batteries. The speed of warming up the room depends on how hot the water in the radiators is.

On a note! Silumin devices quickly heat up and cool down quickly, therefore, during the cold season, the coolant in the system of aluminum heating radiators must be maintained at a constant temperature level. This is especially true for autonomous heating systems, where the heat source is the boiler.

Indicators of permissible pressure in aluminum radiators

Considering which aluminum heating radiators are better, the pressure in the system is taken into account.The technical data sheet of the device contains data on the working and pressure (maximum) pressure. Operating indicators are a constant level of pressure in the system during the period of circulation of the coolant, a pressure test is needed to start the network in test mode.

For heating devices made of aluminum, the pressure indicator is 10-15 bar. In central-type networks, the pressure level is not more than 15 bar, and in the mains it can reach 30 bar - this causes parameter jumps, due to which it is not recommended to install silumin batteries in apartments. But there are no restrictions for autonomous networks, where the pressure rarely exceeds 2 atm.

Advice! Heating boilers made in Germany often show a device pressure of 10 bar (atmospheres). Installation of silumin batteries is possible, but only with correct calculations of the circulation rate of the coolant.

Additional parts and devices for radiator mounting

Additional parts are useful for installing the equipment. There are mounting kits and installation kits on sale, these are different types of equipment. In particular, the kit contains valves, adapters, plugs, and the mounting kit contains clamps and other parts for attaching the battery to the wall.

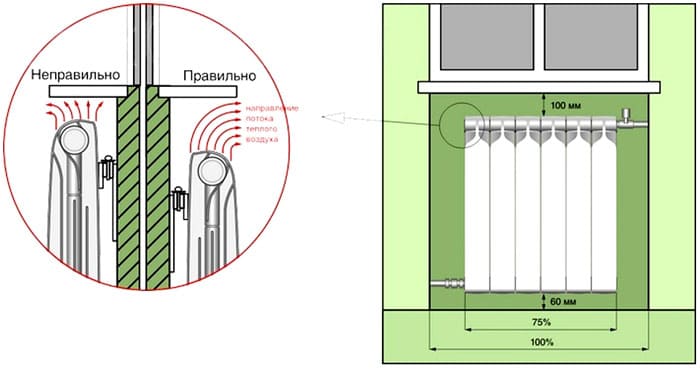

Advice! In a private house, the heating device can be installed anywhere, in an apartment - under the window. When changing the installation area in a multi-storey building, you will need to obtain permits.

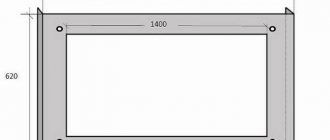

To pre-determine the dimensions of aluminum heating radiators, select the installation area, a standard indicator of 50 cm is taken into account.

For fixing the equipment and putting it into operation, it will come in handy:

Types, photos and sizes of heating radiators

- Mayevsky crane for lowering air jams;

- fasteners (brackets);

- stubs;

- threaded adapters.

You should buy accessories for aluminum radiators only after accurately determining the dimensions of the unit. The easiest way is to take batteries immediately complete with mounting devices. The price of the kit is higher, but purchasing the parts separately will cost more. All fittings are selected taking into account the installation area, the connection method, which can be one-sided, bottom or diagonal. Here, the size of the pipeline cross-section is taken into account.

Advice! The owner will have to buy a sealant, fum tape or linen thread for winding, evaporators, thermal heads, controllers, fans and other devices to control and set the heating mode.

Parameters and dimensions of ROVALL aluminum radiators

The company producing aluminum radiators TM ROVALL is one of the divisions of the Italian concern Sira Group. This company manufactures aluminum alloy batteries with a distance between the two collectors equal to 200, 350 and 500 millimeters. The kit for their fastening, which is purchased separately, includes the following products: plugs, adapters, for connecting sections - nipples with gaskets, and for wall mounting - brackets, as well as a Mayevsky crane. Main parameters of ROVALL aluminum radiators:

- the permissible operating pressure is 20 bar, and when tested - 37.5 bar;

- maximum temperature - no more than 110 ° С.

All Rovall Alux 200 models, according to the official sources of the manufacturer, with a distance of 200 millimeters between the axes, have a height of 245 and a depth of 100 millimeters. In this case, the minimum length is 80, and the maximum is 1280 millimeters. In turn, heat transfer can be at a minimum of 92, and at a maximum - 1472 watts. The number of sections varies from one to 16.

The Rovall Alux 350 radiator models, with a distance of 350 millimeters between the collectors, have a height of 395 and a depth of 100 millimeters. At the same time, the minimum length of the devices is 80, and the maximum is 1280 millimeters. In turn, heat transfer can be from 138 to 2208 watts. The number of sections is from one to 16.

Rovall Alux 500 instrument models, with a center distance of 500 mm, have a height of 545 mm and a depth of 100 mm. At the same time, the length of the devices is minimum - 80, and maximum - 1280 mm. In turn, the power can be at - a minimum of 179, and at a maximum - 2840 watts. The number of sections is from one to 16.

Review of popular models and manufacturers

Another question that worries consumers who choose aluminum heating radiators: which are the best companies? Traditionally, it is believed that the best quality and reliability are aluminum batteries from Italian manufacturers, although many domestic models are not inferior to them in many respects. Reviews on aluminum heating radiators of these brands also speak of their quality and reliability.

The most famous brands include:

| Brand | Model | Center distance, mm | Dimensions (height / width / depth) of the section, mm | Max. Working pressure, bar | Thermal power, W | Section capacity, l | Weight, kg |

| Faral, Italy | GREEN HP 350 | 350 | 430/80/80 | 16 | 136 | 0,26 | 1,12 |

| GREEN HP 500 | 500 | 580/80/80 | 180 | 0,33 | 1,48 | ||

| TRIO HP 350 | 350 | 430/80/95 | 151 | 0,4 | 1,23 | ||

| TRIO HP 500 | 500 | 580/80/95 | 212 | 0,5 | 1,58 | ||

| Radiatori 2000 S.p.A., Italy | 350R | 350 | 430/80/95 | 16 | 144 | 0,43 | 1,4 |

| 500R | 500 | 577/80/95 | 199 | 0,58 | 1,6 | ||

| ROVALL, Italy | ALUX 200 | 200 | 245/80/100 | 20 | 92 | 0,11 | 0,83 |

| ALUX 350 | 350 | 395/80/100 | 155 | 0,11 | 0,82 | ||

| ALUX 500 | 500 | 545/80/100 | 179 | 0,23 | 1,31 | ||

| Fondital, Italy | Calidor Super 350/100 | 350 | 407/80/97 | 16 | 144 | 0,24 | 1,3 |

| Calidor Super 500/100 | 500 | 557/80/97 | 193 | 0,30 | 1,32 | ||

| Rifar, Russia | Alum 350 | 350 | 415/80/90 | 20 | 139 | 0,19 | 1,2 |

| Alum 500 | 500 | 565/80/90 | 183 | 0,27 | 1,45 |

That is, the main criteria by which aluminum heating radiators are assessed: technical characteristics and price.

And in accordance with these criteria, one of the best in the middle price range can be called domestic brands Rifar and Thermal, which have excellent physical and technical qualities and have a cost that is 1.5-2 times lower than their foreign counterparts.

Radiator volume parameters from Climatic Control Corporation LLP

This company from the UK produces BiLUX AL aluminum heating devices, which have an excellent degree of heat transfer, and are manufactured taking into account the peculiarities of autonomous heating systems. The surface area of these batteries is significant, and the cross-section of a vertically located pipe, when the calculation of aluminum heating radiators was made, was determined optimally.

The plant that manufactures the BiLUX AL M 300 and BiLUX AL M 500 radiators is located in China. Between both axes of the collectors, the distance is 300 or 500 millimeters. During the manufacturing process, the die-cast heads of the devices are connected to the bottom, which is manufactured using a specially developed welding technology.

When the products are ready, they are subjected to chemical and mechanical processing after assembly. Only then are the aluminum devices tested and checked for strength and tightness. Their painting is carried out in several stages. In addition, they are exposed to an electrostatic field and at the same time they are sprayed with enamel produced on the basis of epoxy resins. Then, when heated to a high temperature, the surfaces of the radiators are polymerized.

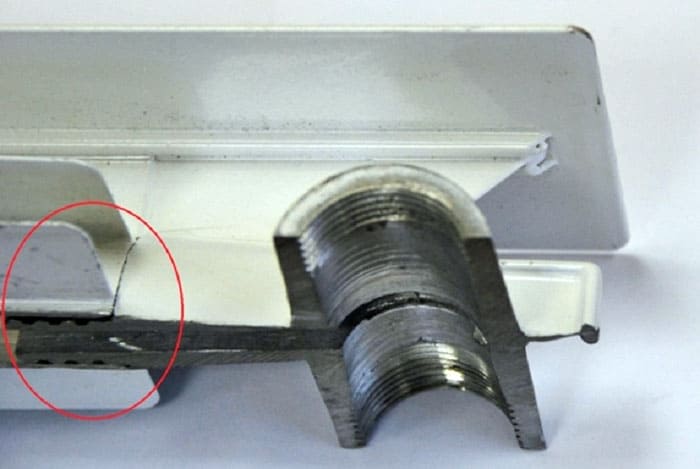

The peculiarity of BiLUX AL devices is that their ends have a special design solution, which allows using a special ring for laying. The material of its manufacture completely seals the joints. Nipples for them use cadmium plated, as a result, the probability of coolant leakage is reduced to zero.

Main dimensions of BiLUX AL aluminum radiators:

- the permissible operating pressure is 16 bar, and when testing the device - 24 bar;

- the pressure that can break the device is 48 bar.

Single-cell batteries BiLUX AL M 500 with a distance of 500 millimeters between axles and 180 watts have the following parameters (in millimeters):

- height - 570;

- depth - 75-80;

- length - 75.

One-section BiLUX AL M 300 with a distance of 300 millimeters between axles at a power of 128 watts have the following dimensions of an aluminum radiator section (in millimeters):

- height - 370;

- depth - 75-80;

- length - 75.

Selection criteria and calculation of the number of sections

When choosing an aluminum heating radiator, pay attention to the following parameters:

- the presence of a protective oxide film or additional processing on the inner surfaces;

- mandatory availability of a technical passport for products indicating the main technical characteristics;

- the seller has a certificate of conformity to exclude the purchase of counterfeit products;

- as a rule, prefabricated heating radiators are supplied in 10 sections. Some manufacturers offer radiator options from 3 to 15 sections. Remember that factory assembly is more reliable than home assembly. Therefore, it is advisable to purchase assembled batteries;

- if, according to calculations, a radiator with more than 10 sections is needed to heat the room, then it is more efficient to purchase two batteries with the corresponding number of sections;

- most European manufacturers are very jealous of the quality of their products, so they order various expertise. The presence of an independent test report is a significant advantage of the products of this manufacturer.

Additional parameters of the form factor of an aluminum radiator

Important! It is strongly discouraged to purchase aluminum radiators (mainly made in China) marked with NF / 68 /. Research conducted by the independent laboratory AIRAL has identified a critical asbestos content in such products.

Temperature control

When determining the number of sections for heating a room, the following nuance must be taken into account. Manufacturers indicate the heat transfer rate of one section at a certain temperature. As a rule, it is 70-75 ° C. However, in most cases, the temperature of the coolant in heating systems rarely rises above 60 ° C. Therefore, the indicator indicated in the technical passport must be reduced by 15-20%.

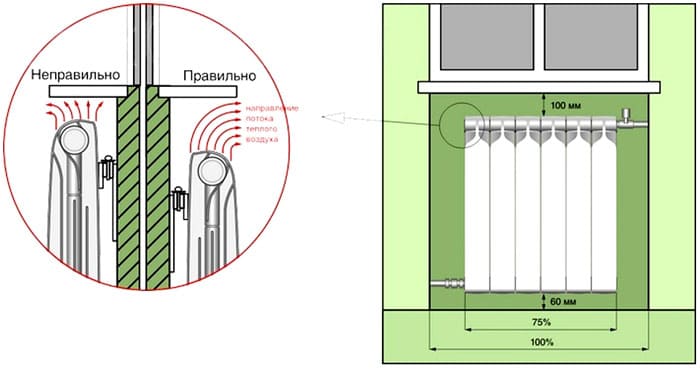

Correct location in a niche under the window

Dimensions of aluminum radiators from the Fondital company

The Fondital company (Italy) produces Calidor Super aluminum batteries adapted for the climatic conditions of Russia and the CIS countries (see photo). In their manufacture, European standards are taken into account, such as EN 442 and Russian, according to GOST R RU.9001.5.1.9009.

The method of their manufacture is high pressure casting. Painting is carried out in two stages: initially, one layer of enamel is applied using anaphoresis as protection, and then, using powder enamel, the product is given a decent appearance. You will have to buy a mounting kit for the radiator separately. It includes: adapters; brackets; blind plugs and Mayevsky's tap.

The distance between the axles is:

- 350 millimeters for the S4 model, which has 4 side ribs and a section depth of 97 millimeters;

- 500 mm for S4 and S3 models (3 ribs and 96 mm depth).

Main parameters of Calidor S aluminum radiators:

- allowable working pressure - 16 bar, and when testing the device - 24 bar, maximum breaking limit - 60 bar;

- limiting temperature - no more than 120 ° С.

Radiator models Calidor Super 350 S4, with a gap of 350 millimeters between the two axles, according to the manufacturer's official sources, have a height of 428 millimeters and a depth of 96 millimeters. In this case, the length of the devices is minimum - 80, and maximum - 1120 millimeters. In turn, heat transfer can be at a minimum of 145, and at a maximum - 2036 watts. The number of sections is from one to 14.

The dimensions of aluminum heating radiators Calidor Super 500 S4 with a center-to-center distance of 500 millimeters are as follows: height 578 millimeters, section depth - 96 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at the minimum 192, and at the maximum - 2694 watts. The number of sections varies from one to 14.

All models of Calidor Super 500 S3 devices with a distance of 500 millimeters between the axes have a height of 578 and a depth of 100 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters.In turn, the minimum power can be 178, and the maximum - 2478 watts. The number of sections varies from one to 14.

Variants

This type of radiator is made of an aluminum alloy with silicon additives, pressed in the form of ordinary sections or collectors. There are two main options:

- cast, when each section is made separately;

- extrusion, when the sections consist of three elements connected by bolts.

The sections are manufactured by high pressure casting and are connected from the inside using special threaded elements. Further, the joints are sealed using paronite gaskets, high-temperature silicone or other materials. The manufacturer also offers aluminum panel batteries.

The most popular are aluminum radiators, the dimensions of which reach a depth of 100 mm and a height of 350 to 1000 mm.

Characteristics of aluminum radiators from Faral S.p.A.

This company, exclusively for the Russian market of heating equipment, produces durable radiators FARAL Green HP (Italy), capable of withstanding an operating pressure of 16 atmospheres. In their manufacture, the injection method is used. The outer and inner surfaces are covered with a zirconium protective layer that penetrates deeply and is not washed off during operation. As a result, no gas evolution occurs when the device comes into contact with water. The possibility of electrochemical corrosion is excluded.

The Green HP batteries are 80 millimeters deep, while the Trio HP batteries are 95 millimeters deep. The distance between the axes is 350 or 500 millimeters. The separately sold instrument mounting kit contains: a bleeder valve; brackets; adapters with plugs; self-tapping screws with plugs and silicone gaskets.

The main parameters of FARAL aluminum radiators:

- operating pressure up to 16 bar is allowed, and when testing devices - 24 bar;

- limiting temperature - no more than 110 ° С.

All models of FARAL Green HP 350 devices, according to information from the manufacturer's official data, with a distance of 350 millimeters between two collectors, have a height of 430 and a depth of 80 millimeters. In this case, the length is from 80 to a maximum of 1120 millimeters. The power can be at - a minimum of 134, and at a maximum - 1904 watts. The number of sections is from 1 to 14.

The radiator models FARAL Green HP 500, with a distance of 500 millimeters between the axles, have a height of 580 millimeters and a depth of 80 millimeters. In this case, the length of the devices is from 80 (minimum) to 1120 millimeters (mausimum). In turn, heat transfer can be at a minimum of 180, and at a maximum of 2520 watts. The number of sections is from one to 14.

FARAL radiators of the Trio HP 500 model range have a center-to-center distance of 500 millimeters, the height of the devices is 580 millimeters, and the depth is 95 millimeters.

At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 212 watts, and the maximum is 2968 watts.

The number of sections, depending on the capacity, can be from 1 to 14.

FARAL radiators of the Trio HP 350 model range have a center-to-center distance of 350 millimeters, the height of the devices is 430 millimeters, and the depth is 95 millimeters.

At the same time, the length of the devices is from 80 to a maximum of 1120 millimeters. With regard to heat transfer, its minimum value is 151 watts, and the maximum is 2114 watts. The number of sections can be, depending on the power, from one to 14.

Technical and consumer qualities and features

In addition to its practicality, visual appeal and low cost, the technical characteristics of aluminum heating radiators are a very decent set, which includes:

| Options | Indicators |

| Working pressure level | 6-25 atm. |

| Heat transfer of one section (heat output) | 150-212 W |

| Maximum allowable coolant temperature | 110 ⁰C |

| Section volume | 250-460 ml |

| Section weight | 1-1.47 kg |

| Center-to-center distance (gap between upper and lower manifolds) | 200-800 mm |

| Life time | 10-15 years old |

Please note that the most common sizes for aluminum radiators are:

350, 500 and 200 mm. They indicate the value of the center-to-center distance between the collectors. But on sale there are models with a distance between the axes that differ from the standard. It can be from 200 to 800 mm. And in order to calculate the height of the aluminum radiator, 80 mm must be added to this value.

One of the most important indicators characterizing the quality and efficiency of aluminum batteries is their operating pressure. However, in the passport of these devices, the pressure test is also indicated, which has a slightly increased value. This characteristic of radiators is very important, since it is used in tests when starting the heating system after draining it. The standard value of the pressure test is 20, 25 or 30 atm.

In our separate article, you will learn to use. There you will find their characteristics, prices and the names of reliable manufacturers.

Pros and cons of flow and storage type water heaters

Instructions for making your own shower tray can be studied by following the link

Calculation of aluminum radiators from Global

Global radiators from the company of the same name (Italy) can be installed in apartments of multi-storey buildings, and in their own houses. Their distinctive characteristics are elegant and original appearance. The most popular are the ISEO and VOX models with a center distance of 350 or 500 millimeters. A mounting kit is standard and sold separately.

Main parameters of Global aluminum radiators:

- maximum working pressure is 16 bar, and when testing the device - 24 bar; the limiting temperature of the heated water is no more than 110 ° С.

For Global VOX 350 models, according to the manufacturer's official sources, with a distance of 350 millimeters between the axes, the height is 440 and the depth is 95 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at a minimum of 145, and at a maximum - 2030 watts. The number of sections varies from one to 14.

Global radiators of the VOX 500 series have a center-to-center distance of 500 millimeters, the height of the devices is 590 millimeters, and the depth is 95 millimeters.

At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 193 watts, and the maximum is 2702 watts. The number of sections can be, depending on the power, from one to 14.

For Global ISEO instrument models, according to the manufacturer's official sources, with a distance of 350 millimeters between the axes, the height is 432 and the depth is 80 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at a minimum of 134, and at a maximum - 1976 watts. The number of sections varies from one to 14.

The Global radiators of the ISEO model range, which have a center-to-center distance of 500 mm, have a height of 582 mm and a depth of 80 mm.

At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 181 watts, and the maximum is 2534 watts. The number of sections can be, depending on the power, from one to 14.

Parameters of aluminum radiators from Torex

The Italian company of the same name offers aluminum sectional heating devices, which are manufactured by casting. Their peculiarity lies in the presence of unusual light transitions on the front. For models that have a center distance of 350 millimeters, the depth is 78 millimeters. But for batteries with a gap between the axes of 500 millimeters, the depth of the radiators can be 70 or 78 millimeters. They can have one or an even number of sections. The mounting kit must be purchased separately.

Main parameters of Torex aluminum radiators:

- the permissible operating pressure is 16 bar, and when testing the device - 24 bar;

- limiting temperature - no more than 110 ° С;

- the required pH of the water is 7-8 (6.5 - 8.5 is acceptable).

For Torex B 350 models, according to the official sources of the manufacturer, with a distance of 350 millimeters between the axes, the height is 420 and the depth is 78 millimeters. At the same time, the minimum length is 80, and the maximum is 1120 millimeters. In turn, the power can be at least 130, and at the maximum - 1820 watts. The number of sections can be from one and then an even number up to 14.

Torex radiators of the B 500 model range have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 78 millimeters. At the same time, the minimum length of the devices is 80, and the maximum is 1120 millimeters. With regard to heat transfer, its minimum value is 172 watts, and the maximum is 2408 watts. The number of sections can be from one and then an even number to 14.

Torex radiators of the C 500 model range have a center-to-center distance of 500 millimeters, the height of the devices is 570 millimeters, and the depth is 70 millimeters. At the same time, the minimum length of the devices is 75, and the maximum is 1050 millimeters. With regard to heat transfer, its minimum value is 198 watts, and the maximum is 2772 watts. The number of sections can be from one and then an even number to 14.

Output

Any heating device has its own technical parameters, in this case we are talking about an aluminum heating radiator with a distance between the centers of the collectors equal to 500 mm.

The industry offers customers various sizes of heating devices so that they can be installed with their own hands as comfortably and in the chosen place as possible. The video in this article will allow you to find additional information on the above topic.

Did you like the article? Subscribe to our channel Yandex.Zen

Dimensions of the section of aluminum radiators from Rifar

The company manufactures aluminum batteries of BASE models with a distance between two axes of 200, 350, 500 millimeters. ALP products have an improved design, increased heat dissipation and a center distance of 500 millimeters. Alum models are specially designed devices that can be used both in standard heating systems and as an electric oil heater. The unique design of Flex allows you to give the device the desired radius of curvature.

The main characteristics of radiators made of aluminum Rifar:

- permissible working pressure is 20 atmospheres;

- limiting temperature - no more than 135 ° С;

- the required pH of the water is 7-8.5.

Advantages and disadvantages of aluminum radiators

Positive traits

- Aluminum batteries are very economical.

- Their low weight does not cause any inconvenience during assembly and disassembly.

- There is a regulator for temperature control.

- The installation of such heating devices is not difficult.

- The heat transfer coefficient is the highest.

- These radiators look very presentable and original, therefore they can be used both in ordinary apartments and in elite premises.

Negative points

- Water leakage is possible at intersection joints.

- Heat is distributed extremely unevenly, mainly concentrating on the ribbed surface of the sections.

- Convection heat dissipation is very low.

- They do not serve very long - up to fifteen years. However, some manufacturers have corrected this - they have increased the warranty to twenty and twenty-five years.

- The formation of gases is possible.

- Aluminum is highly reactive, so corrosion is its strong enemy. To keep the batteries safe from this enemy, the manufacturers carry out a special anti-corrosion treatment on the batteries. Or they are covered with a layer of oxide film.

The chemical activity of aluminum is perhaps the main drawback of batteries made of this material. Therefore, when there are chemical impurities in the hot water circulating in the central heating system, an accelerated destruction of the radiator walls occurs as a result of the chemical reaction.And aluminum radiators are very sensitive to pressure instability in the heating system.

Because of these disadvantages, such radiators are best used only in autonomous heating systems. There you will definitely be sure that there will be no "chemistry" in the neutral hot water flowing through the radiators, the pH of the coolant will be neutral, and the pressure in the system will not jump to infinite values. But it is dangerous to install aluminum radiators in an apartment - even there is a ban on this from the relevant authorities.

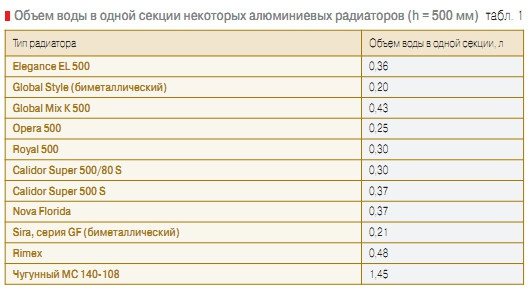

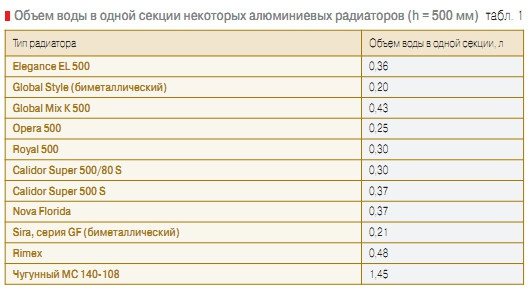

Aluminum radiator section volume

Knowing the volume of one section of an aluminum radiator is very important for autonomous heating systems. To determine how much antifreeze is needed to fill the heating system, use calculation tables.

To find out the volume of water in one section, use the information that is available in thematic reference books:

- in a standard device, the volume of the aluminum radiator section is 0.45 liters of coolant;

- a running meter of a pipe with a diameter of 15 millimeters contains 0.177 liters, and a pipe with a diameter of 32 millimeters contains 0.8 liters.

Types and method of production

Since aluminum is a rather soft metal, it is not used in its pure form for the manufacture of radiators. To provide the devices with strength, the alloy is diluted with special silicon additives, and the already obtained mass is used for the production of both individual sections and collectors.

The volume of a section of an aluminum radiator of 500 mm is different for each model

Most often, two main methods are used in the manufacture:

| Casting |

|

| Extrusion |

|

Radiator 20 by 500 by 500 - 500 mm center distance, 500 mm - device width, 20 bar - withstand pressure

Let's consider the type of radiator 500 by 80 - what is it:

- 500 mm - the distance between the centers of the collectors;

- 80 mm - width of one section.

Battery anodized type

- The manufacturing process for this type of product is rather complicated.

- For the manufacture of such batteries, high quality purified aluminum is used.

- Finished radiators are anodized, thereby changing the structure of the metal, which increases its resistance to corrosion.

- In order to increase heat transfer, the internal space of the radiators is made absolutely smooth. This effect is achieved by the fact that all parts of the radiator are connected from the outside with couplings.

Thanks to the special method of metal processing and the internal structure, such devices are able to withstand exorbitant loads of up to 70 bar. However, their price is not affordable for every consumer.

Aluminum radiator 500 to 80 from

Calculating the number of sections

There is a simple option how to calculate the number of sections.

To do this, you need to know the area of the room and the standard capacity, which is equal to:

- if the ceiling height is 2.5 - 2.7 meters, there is one outer wall and one window - 100 watts;

- if the ceiling height does not exceed 2.7 meters, there are two outer walls and one window - 120 watts;

- if the ceiling height is not more than 2.7 meters, there are two outer walls and two windows - 130 watts.

Before calculating the number of aluminum radiators, you need to find out the power of one section in the passport for the device. Now you need to multiply the standard power by the area of the room and divide by the power of one section. The result obtained needs to be rounded up (about