The Russian company Rifar entered the market for the production of aluminum and bimetallic radiators in 2002. Such moments as incorrect connection of the hot water supply, which can cause water hammer in the system, contamination with chemical impurities, were taken into account by the designers in the development and manufacture of heating radiators.

Rifar products are intended for consumers in Russia and the CIS countries. A test pressure of 30 atm guarantees the operation of radiators at a working pressure of up to 20 atm. Thanks to the inner protective layer, the batteries are not subject to corrosive processes, and the outer powder painting under special conditions gives the surface not only an attractive appearance, but also a great resistance to external damage.

- 2 Rifar radiator range

- 3 Comparison with other models on the market

- 4 Price table of bimetallic radiators

- 5 User Reviews

Features of Rifar radiators

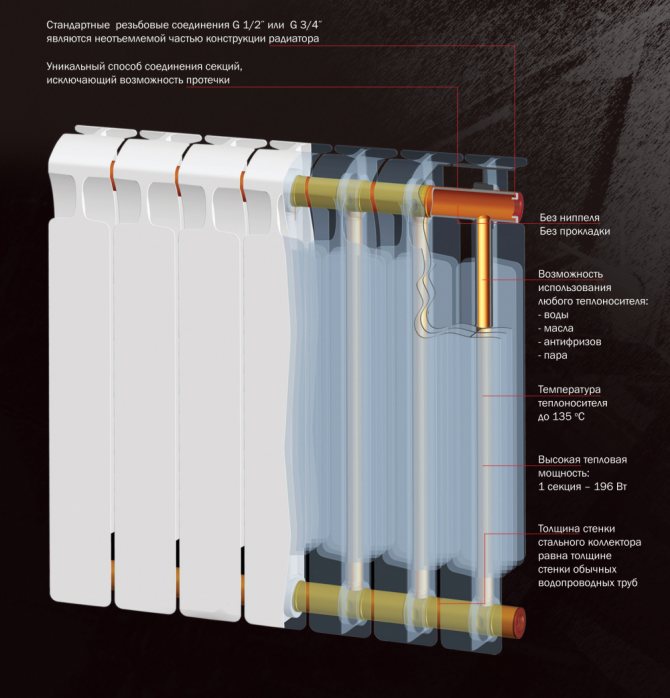

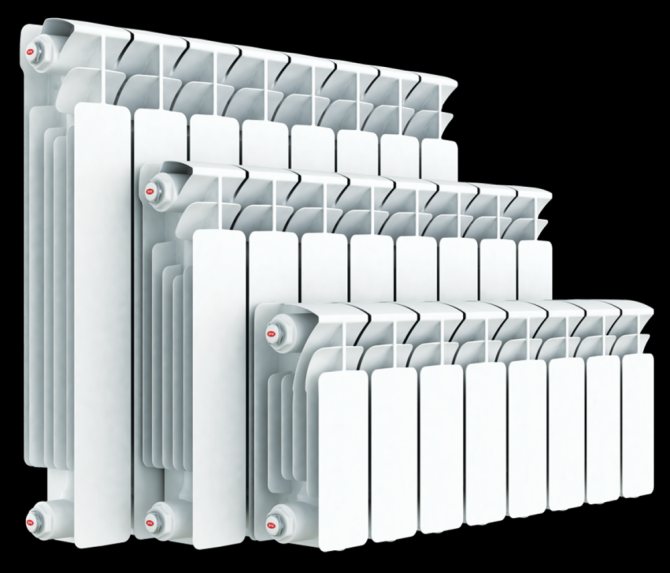

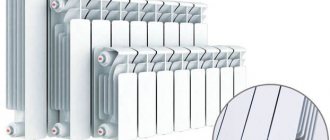

Rifar bimetallic batteries have a core made of special steelable to withstand significant loads, it has low heat transfer, while aluminum fins, on the contrary, have a high heat transfer.

Radiators have many advantages, thanks to which they gained great popularity:

- One of the main advantages is versatility of radiators, they can be installed both in multi-storey buildings with centralized heating, and with an autonomous mode. They are designed for 20 atm working pressure at test pressure - 30 atm.

- Special inner coating protects from rust and other aggressive chemical compounds in water.

- Surface monolithic layer prevents scratches.

- The maximum temperature regime is 135˚С.

- High heat dissipation- with standardized heat supply from the boiler room, it is 200 W for each battery element.

- The small internal volume of one radiator element makes it possible to achieve low inertia.

- The price is lower than for identical batteries in terms of technical parameters imported radiators.

- Give in temperature regulation.

- Radiators can be painted in any color.

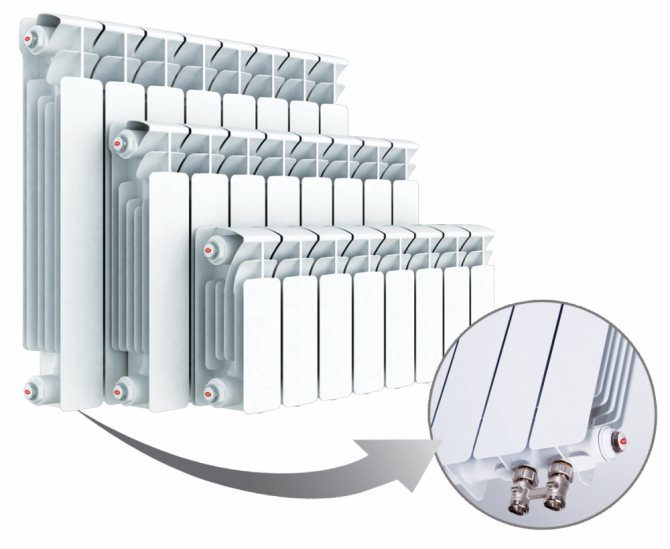

- Can be combined with a different number of sections.

- Work guarantee - 10 years.

How Rifar radiators are made

Famous Russian scientists, constructors and designers, as well as specialists of the Milan Polytechnic University took part in the development of this product. Rifar batteries are manufactured using the most modern equipment of well-known Italian, Swedish, Japanese and German brands. A complete autonomous cycle reduces the risk of defect associated with a human factor to zero.

Control of aluminum melting is carried out in laboratory conditions. Each product that leaves the conveyor undergoes a hydraulic leak test under a pressure of 30 bar. The latter parameter is 5 times higher than the working pressure in standard heating systems. At the final stage, pneumatic testing is also carried out. Rifar gives a 10-year guarantee for its products. In fact, these radiators can last 25 years or more.

The finished product is painted in an electrostatic field at high temperatures. The quality of the resulting coating is checked using the lattice notch technique. At the moment, Rifar batteries are being produced, the design reviews of which are also very good, in a variety of colors. However, the most popular among the population are white models.

Range of radiators Rifar

Models of this brand differ in the following indicators:

- center distance;

- overall dimensions;

- thermal power;

- the volume of the coolant;

- mass;

- design.

The technical parameters of one radiator element depend on the distance between the radiator axes, which is indicated in the name of the radiator.

| Rifar Element Parameters | Base 200 | Base 350 | Base 500 |

| Height, cm | 26,1 | 41,5 | 57,0 |

| Width, cm | 7,9 | 7,9 | 7,9 |

| Depth cm | 10,0 | 10,0 | 10,0 |

| Weight, kg | 1,02 | 1,36 | 1,92 |

| Heat transfer, W (at t = 70˚ C) | 104 | 136 | 204 |

The price of these devices is 480 rubles, 490 rubles, and 500 rubles. per section. These are basic radiators, suitable for any typical apartment.

The ALP series is long and shallow, and is very convenient for indoor use. with large windows and narrow window sills.

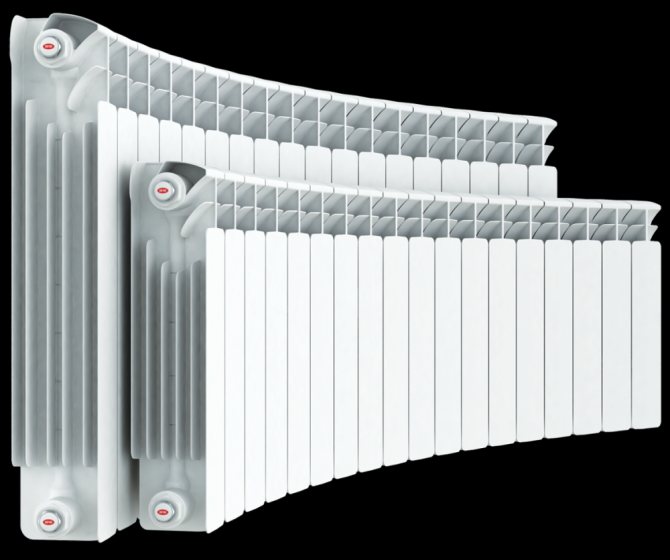

FLEX series radiators can receive any degree of curvature, and look good in rooms with a non-standard layout such as concave or convex walls.

VENTIL series radiators can be called universal. This is equipment in which the coolant can be antifreeze or oil.

The MONOLIT series is designed for systems with poor-quality heat carrier and high working pressure, the internal part of the structure of this device is made in one piece, not divided into sections.

ALUM radiators can work as oil heating devices, distinctive properties - a different design of vertical channels, there is plug and gasket.

FORZA series is an improved BASE radiator, its top layer is even more resistant to mechanical damage.

The cost of Rifar radiators depends on from the number of sections, necessary to create comfortable indoor conditions. And the number of sections directly depends on the size and thermal insulation of the heated room. You can choose a different layout, the important condition of which is that the radiator must be equal to the length of the window opening or be 2/3 of its part.

Average price of Rifar radiators

| Name | Heat transfer, W | Section price, rub. |

| BASE 200 | 104 | 425 |

| BASE 500 | 204 | 443 |

| MONOLIT 350 | 134 | 610 |

| MONOLIT 500 | 196 | 620 |

| ALUM 350 | 153 | 405 |

| FORZA 500 | 202 | 490 |

| FORZA 350 | 190 | 490 |

Rifar - advanced technologies from Russia

Alexander Alexandrovich, please tell us how it all began.

A.L .: founded in 2002. The name stands for "Russian-Italian factory of aluminum radiators", since there were initially agreements with Italian colleagues to develop the project jointly. Then they refused, and later we realized that it was for the best: our engineering and organizational approaches to production differ markedly.

Our plant was built in the city of Gai, Orenburg region. At the launch stage, we faced a lot of technical and technological problems, studied the technology, equipment, and trained employees. As a result, we learned the equipment to the last screw, mastered the technology, but what is most valuable - gained experience. After that, almost every year, new foundry complexes were installed and production expanded, new production buildings were built. Successful overcoming of problems at the beginning of the path allowed us to draw an important conclusion: you cannot blindly repeat other people's decisions, you need to look for your own path, try everything on yourself, take into account specific conditions. The company is now 16 years old. During this time, more than 60 million radiator sections have been produced. The products are well known throughout Russia, as well as in Kyrgyzstan, Belarus, Kazakhstan and Azerbaijan. The heating appliance market is conservative, new items that are significant from a technical point of view very rarely appear. But you managed to stir up this sphere.

A.L .: For large-scale production, both new solutions and constant, sometimes imperceptible from the outside improvement, improvement of production and development processes are important. And we have something to be proud of. was the first in the world to produce aluminum radiators with a design in which crimped bottom plugs and new seals ensured a burst pressure of at least 60 atmospheres. We developed and launched the production of the first monolithic radiators, and in 2012 set a world record for the productivity of foundry complexes in the production of radiator sections.We have managed to create a modern enterprise with one of the most highly developed automation models in the industry.

What is your idea of an ideal radiator?

A.L .: Our philosophy is expressed in the phrase “Buy and forget”. The consumer should not understand heating devices, should not be an expert in this. He should be able to buy a high-quality heating device, the details of which he will forget immediately after installation and for the entire period of operation.

To achieve such a result, special requirements are needed for the materials used, the creation of a control system for each technological process. Mass production with a large number of operations should be organized only according to special industrial laws. This applies to the control of incoming materials and components, to interoperational quality control.

As an example of this approach, all RIFAR radiators, without exception, are tested for tightness twice: after assembly and after painting. We give a guarantee for our products and are responsible to people!

The current topic is mandatory certification. What has changed in the radiator market?

A.L .: Mandatory certification of heating radiators - this means that each radiator sold in a store or installed in your new apartment, house, office, is produced according to uniform and understandable safety rules for everyone, has the necessary safety margin, and the thermal power indicated in its characteristics, true and confirmed by a reliable testing laboratory. This means that the stores will stop asking questions about why the heat output of the radiators is the same, but the weight is two times different. People are tired of the amount of unreliable, sometimes overstated information about the technical characteristics of radiators in voluntary certificates of unknown origin.

Before the introduction of mandatory certification in Russia, industry professionals who design buildings and structures were not required to adhere to any standards when choosing heating equipment. The situation with the choice of radiators for heating systems was left to chance, often cheap models with overestimated thermal and strength characteristics were included in the projects.

After the entry into force of the mandatory certification, everything has changed: now the distribution of radiators that do not comply with GOST is impossible.

However, only the introduction of the mandatory certification procedure is not enough; a permanent control system is also needed. What did her absence from Europe lead to? In addition, for example, in the pursuit of low cost, some manufacturers of steel radiators use rolled products with a thickness of 10-15 percent less than required by European standards.

How does this affect the service life of the heater?

A.L .: The service life of a radiator largely depends on the quality of the coolant in heating systems, the quality of the materials used and the wall thickness of the heater.

The regulatory document establishing the requirements for the water-chemical preparation of the coolant in Russia is not being implemented in many cities and towns. If we turn to the methodological guidelines, we will see that the permissible value of the aggressiveness index of the network water leads to the corrosion rate of the steel surface by 0.085 millimeters per year.

As for the general situation in our sector, it can be stated: Russian enterprises produce radiators, not knowing in what conditions they will be used. Imagine that a kettle manufacturer does not know which electrical network his equipment will be connected to. This is an unthinkable situation! And it is explained by the fact that according to the standard, the characteristics of the coolant in terms of the amount of dissolved oxygen, salts and pH should correspond to very high indicators, only slightly different from European ones.

At the same time, another regulatory document states that the value of steel corrosion can be "low" (less than 0.03 millimeters per year) and may be "acceptable" (less than 0.085 millimeters per year). There is another standard that indicates the minimum life of a heating radiator in open heating systems is 15 years, in closed ones - 30 years. And, of course, the main document for a radiator manufacturer is GOST 31311-2005, it states that the minimum wall thickness of a steel radiator in contact with water is 1.2 millimeters, of an aluminum one - 1.5 millimeters.

With similar characteristics, the service life of a heater with very good water will be more than 30 years, with water of acceptable quality - no more than 12 years. For the radiator manufacturer, the input is clear, except for one - the aggressiveness of the water that will flow through the radiator.

We have adopted the path of manufacturing heating devices for the worst operating conditions. Walls made of steel and aluminum are enlarged to provide the necessary reliability. We also use only steels without corrosive non-metallic inclusions, which ensures the absence of the most dangerous pitting corrosion. Yes, this results in high rates of metal consumption and an increase in production costs, but in the existing conditions we do not see other technical solutions.

We hope that the situation with the quality of network water will improve. There are positive examples for this. So, in the Nordic countries, the average corrosion rate of steel pipes of heating networks is 0.02 millimeters per year. For such operating conditions, it could have produced a radiator with completely different parameters.

Consumers should pay special attention to the mass of purchased radiators. A cheap and lightweight radiator, by definition, cannot be reliable and highly efficient.

Why is such a situation with the coolant in Russia?

A.L .: The preparation of a high-quality coolant is expensive for heating networks and management companies. Companies are saving on this. As a result, pipes, radiators, heat exchangers and other heating equipment fail ahead of schedule.

According to the research "Russian market of radiators in 2017" by Litvinchuk Marketing agency, it ranks first in Russia and Eastern Europe in terms of production of bimetallic heating radiators. What allowed domestic production to reach this level?

A.L .: If you take any industry and single out a leader, it often turns out that the components of success are simple: to introduce advanced ideas, continuously improve technologies and improve quality characteristics, not bypassing even the "little things" (which in fact play quite a big role for the people who use the products). do not save on equipment and materials, strictly control the quality of products. We were fortunate enough to assemble a team of unique professionals, give them the opportunity to develop and clearly define goals. It is necessary to be in touch with the consumer, to understand and even anticipate his desires and preferences. At the same time, it is important to offer the market new solutions without fear of going against the tide. It would seem obvious things, but, as they say, the devil is in the details.

The emphasis is placed on the quality of products, this is a determining factor in decision-making: from the design stage to the finished product. To ensure the stability of the result, it was necessary not only to debug and automate production processes, but also to control all the original components - the chemical and physical properties of metals, the quality characteristics of components. If we solved the problems with aluminum with the help of traditional metallurgical methods of cleaning and special processing, then for steel the only way is to use raw materials that have an increased resistance to corrosion.

As a result, in order not to depend on suppliers and to obtain products with parameters exceeding the norms of industry standards, in 2017 we launched the production of electric-welded pipes.

At the same time, we use steel, which is used for the manufacture of high-reliability trunk pipelines. This is a new development of domestic metallurgists, a material without corrosive non-metallic inclusions. We use the steel pipes produced by us for the manufacture of embedded elements for bimetallic radiators.

We are forced to follow the same path of development of the enterprise that was in the Soviet Union: we cannot find suppliers of components that would meet our requirements, so we are launching our own production. The plant uses modern equipment from Italy, Germany, Switzerland, Japan and Korea. A serious service department has been created to service it. We have one of the largest laboratory facilities in the industry - metallurgical and physicochemical; We need it to control and research the properties of materials and components, search and test new technologies, analyze and predict the processes that will occur with our products during their operation. On the one hand, such a development has advantages: the ability not to depend on the situation outside the enterprise, autonomy, technological flexibility.

On the other hand, this imposes a high degree of responsibility on us, we would like to have a large selection of reliable suppliers who produce quality products and just use it.

Why can't other companies repeat the path of RIFAR, copying especially successful solutions, since it is easier to follow the beaten track?

A.L .: We have unique equipment designed with our participation in a single copy. In addition, individual solutions can be copied, it is more difficult to build a technology. This requires qualified specialists, education, knowledge and a clear understanding of goals, a desire to go forward. Simply by copying, it is impossible to become a leader, you need to create something new, plan and anticipate the way the industry will develop.

Are new radiator models expected in the near future?

A.L .: At this stage, under its own brands, our company produces bimetallic radiators MONOLIT, SUPReMO (new model released in 2020), Base, Alp and aluminum Alum. Variants of execution of these models for bottom connection have been developed. In 2005, we were the first in the world to release and still produce curved bimetallic radiators for bay windows.

In addition, customers can order models painted in any color from the RAL palette and any other available color systems. Even if a person wants to make only one radiator of the color he needs, we will do it!

The listed models are enough to meet the needs of our dealers, so we do not plan to release radiators with a new design in the near future. We analyze demand, monitor changes in the heating equipment market, and are constantly looking for new forms. We do not want to follow the path of producing traditional radiators with design and technical parameters of fifty years ago.

On the contrary, each new model of ours will be a new milestone, a new look at the seemingly simple task of heating a room, it will be a reliable and aesthetic solution ahead of its time.

RIFAR radiators enjoy support. If the person doing the renovation asks the installer for advice, he will advise the RIFAR model. If a customer enters a store with a large selection of radiators of different brands and asks a consultant which radiator is the most reliable, you can be sure that RIFAR MONOLIT will be recommended to him. And this is a real revolution in the radiator market.

Tell us about the creation of a structure that can only be destroyed by a pressure of over 250 atmospheres.

A.L: In 2009, RIFAR produced the world's first monolithic bimetallic radiator MONOLIT.This is a fundamentally new heater with particularly high technical characteristics. The sections of this model are connected by contact-butt welding, due to which, in principle, there are no potentially dangerous areas in the radiator for leaks.

The motto was the phrase: “Without a nipple. Without gasket. No leaks. "

And by the way, now you can't be sure that the consultants in the store will offer MONOLIT, because they can also recommend RIFAR SUPReMO.

Interesting, tell us more about this model.

A.L .: SUPReMO is a new step, both in terms of design and technology, which ultimately made it possible to obtain high heat transfer - 202 watts per section. The design, judging by the attention from the market, liked the buyers. We see the great interest of interior designers, they are attracted by the unusual shape, the opportunity to order radiators in a color suitable for the project. Two-tone staining options are popular.

Due to the side panels (another feature of SUPReMO), which cover the sharp "ribs", the model is in demand among families with children. According to our dealers, there is a stable demand in medical and childcare facilities.

There are no hidden cavities in the design of the radiator, so wet cleaning is easy and convenient, the model has a hygienic certificate.

What are your goals for the future?

A.L .: First of all, we will continue to improve the quality of our radiators: to continuously improve the models, to create them more practical and aesthetic, comfortable and safe. After all, our main goal is warmth in the homes of Russians!

Comparison with other models on the market

Typically, radiators are selected for their ability to withstand system pressure and heat dissipation. You can compare the technical parameters of Rifar radiators with heating devices Sira and Global.

The Italian company Global has been producing radiators for over 30 years. All models are designed for the conditions of Russian reality, have a reinforced structure and can be installed in our heating systems. The main attention was paid by the developers of the company quality, durability, reliability and design. Global radiators undergo a two-stage painting, as in the automotive industry. They have stable anti-corrosion properties and high heat transfer.

The Italian firm Sira is a longtime partner of the holding company SanTechKomplekt. Aluminum and bimetallic radiators supplied by this company to our country are suitable for work in any heating system. They come from the manufacturer in paired sections, the edges of the radiators have rounded shape, to avoid injury in families with children. The technical parameters of the radiators comply with the SNiP requirements for the operation of devices in urban heating systems, for example, the Gladiator batteries are perfectly operated at operating pressure 35 atm, they have a shallow depth, which saves space, high anti-corrosion parameters, there is no noise when the coolant passes. Syrah radiators can be easily installed, the package includes all the necessary installation elements.

Bimetallic Radiator Price Table

| Name | Number of sections | Price in rubles |

| Rifar Monolit Ventil 500 | 6 | 5936 |

| Rifar Monolit Ventil 350 | 6 | 5860 |

| Rifar Monolit 500 | 6 | 4048 |

| Rifar Monolit 350 | 6 | 3660 |

| Rifar ALP 500 | 6 | 2820 |

| Rifar Base 200 | 6 | 2880 |

| Rifar Base 350 | 6 | 2682 |

| Rifar Base 500 | 6 | 3000 |

| Sira Gladiator 200 | 6 | 3180 |

| Sira Gladiator 350 | 6 | 3240 |

| Sira Gladiator 500 | 6 | 3300 |

| Global Sfera 350 | 6 | 3774 |

| Global Sfera 500 | 6 | 3834 |

| Global Stile Extra 500 | 6 | 4200 |

| Global Stile Plus 500 | 6 | 4200 |

| Global Stile Plus 350 | 6 | 3960 |

| Smart 500 | 6 | 1740 |

| Vector Lux 500 | 6 | 2100 |

| Royal Thermo Trend 500 | 6 | 2520 |