Did you like the article? Stay tuned for new ideas and useful auto tips in our channel. Subscribe to us on Yandex.Dzen. Subscribe.

The radiator is a technically complex unit, on which the efficiency and uninterrupted operation of the engine depend. Considering this, it is not recommended to carry out diagnostics and repair work on your own.

Types of radiators

Radiators may differ in assembly method, material of manufacture and optional components. They can be divided into the following options:

- Prefabricated radiators. In them, the components were connected mechanically. Such an assembly is notable for its affordable cost, the joints of such models needed sealing gaskets, which are resistant to antifreeze and temperature extremes;

- Copper radiators. They are more expensive, but damage to them can be easily repaired by sealing;

- Aluminum radiators. Such products are more durable and reliable, but aluminum gives off heat worse than copper.

Specifications

The technical characteristics of aluminum heating radiators allow for complex heating of the room, in which half of the heat is transferred by thermal radiation from the radiator panel, and the other half - by convection air currents.

One section, from which heating aluminum radiators are made up, has the following indicators:

- depth - 70-110 mm;

- coolant capacity inside the radiator - 0.4 - 0.6 l;

- heater panel area - 0.5 m2;

- thermal power - 120 W;

- coolant temperature - 90 ° С;

- weight - no more than 2 kg.

Benefits and advantages

- Aluminum heating radiators during operation make it possible to save up to 35% of fuel;

- Aluminum radiators for heating have a reduced volume of coolant in the sections. This allows them to heat up quickly and cool down quickly. This creates the required room temperature within a short time. In practice, warmth in a cold room is felt within ten to fifteen minutes after starting the heating system;

- These heaters are perfectly controlled by thermo valves, thermosensitive heads and thermostats. With the help of these thermoregulated elements, the flow of the coolant through the radiator is limited when the required temperature in the room is reached;

Thermal valves

- Such radiators have low thermal inertia, so the thermostats react to any temperature changes in the room quickly enough - within 5-7 minutes, shutting off the pipeline or reopening it for the hot coolant to enter. It is due to this that serious savings in heat consumption are formed;

- Aluminum radiators have a modern ergonomic design and fit perfectly into the interior of both the living room and the office space.

Radiator in the interior

Radiator manufacturing

Aluminum radiators are made using casting. Thanks to this, they can be produced in any form, even rather complex ones. This method of production allows you to select the size of aluminum heating radiators for individual conditions. Aesthetic appearance and high technical characteristics are achieved.

Due to their compact size, these batteries require less space. Their compactness means that they are lightweight, which makes them easy to install. Installation of aluminum heating radiators can be done on any wall surface.

On the market, these devices are presented in a wide range, which makes it possible to choose equipment that would ideally fit into the room, taking into account all the features of the architectural design (style, dimensions of openings and niches). Many options are offered by manufacturers who produce products under the brands: "Nova Florida", "Oasis", "Radena".

Radiators of this type make it possible to change the number of heating sections. This allows you to easily select the required configuration, taking into account both the size and power of the device. The radiators "Global" and "Fondital" are especially worth noting in this respect.

Fondital radiators

Battery care

Heating batteries are easy to clean. Dust does not settle inside the radiator itself, because convection currents prevent this. And if the installation was carried out correctly, then this minimizes the risk of corrosion.

To extend the life of these radiators, you must adhere to certain rules:

- Aluminum alloys are themselves corrosion resistant... However, when used together with copper (provided that non-distilled water is used as a heat carrier), these processes are quite intense. This is due to the so-called electrical corrosion. This process occurs when the water that is used as a heat carrier has a high electrical conductivity. This occurs, for example, when an aluminum radiator is connected to a copper riser or if a heat exchanger in a heating boiler is made of copper pipes;

- If the heating system is open, then in this case it is better to use plastic pipes for main pipelines.... In closed heating systems with a special heat carrier, this problem practically does not manifest itself;

- Repair of aluminum heating radiators may be required if the installation was not carried out correctly. For example, if the force when screwing in the nipple (valve) was exceeded. With an increase in the hydrodynamic pressure in the network, this leads to deformation of the thread, causing water to flow in the places of threaded connections;

- Aluminum radiators are designed for a working pressure of 7-9 atmospheres... They are also quite sensitive to the quality of the coolant used in it. That is why it is better to install such heating devices in autonomous heating systems of private houses and country cottages.

Important! Centralized heating systems have an operating pressure of 10 atmospheres and higher. Therefore, the use of aluminum radiators in central heating networks is limited.

- In this case, it is necessary to take into account the physical properties of aluminum alloys. Aluminum itself is a fairly soft metal, and if handled carelessly, the aluminum section can be easily damaged. In other words, these batteries need careful and careful handling.

Radiator and corrosion

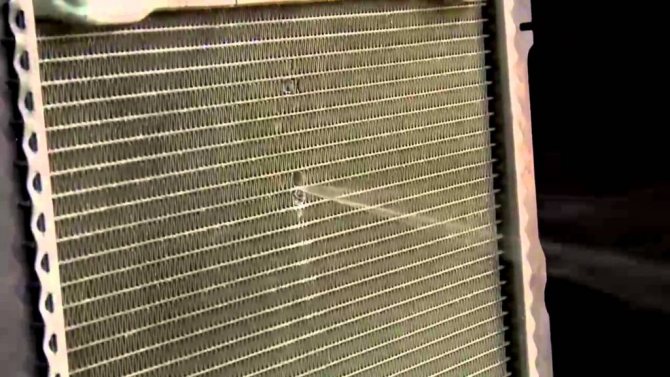

When the cooling system stops functioning, it is necessary to carefully examine it to determine the defect. Spent refrigerant can cause corrosion on the radiator surface. It begins to ionize almost immediately after refueling. In this case, the liquid begins to destroy surfaces of metal, to which it can come into contact, moving through the system.

Old ionized refrigerant can cause damage after just a few weeks of operation. When the radiator starts to leak, it can be due to mechanical damage or corrosion. It can occur for many reasons, including poor quality coolant, the presence of salts in the water, or damage to the protective coating of the device.Timely elimination of the defect will help prolong the performance of the automotive part.

Let's start by understanding what a radiator is?

Radiator

- this device is designed to release heat energy. In a heating system, a radiator is needed in order to release heat into a room to heat it. And in cars in order to isolate excessive engine temperature, that is, to cool the engine.

In this article, I will help you choose a radiator, you will learn how to use a radiator correctly.

Ways to connect radiators. Properties and parameters.

In this article I will tell you:

This is how aluminum and bimetallic radiators look like.

This radiator consists of a certain number of sections, which are interconnected by an intersection nipple and a special sealing gasket.

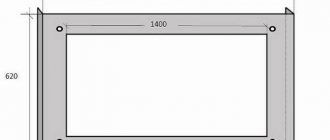

The height can be different depending on the project solution and design.

Center distance (from the center of the upper to the lower thread) Typically: 350mm, 500mm. But there are more, but they are difficult to find and they are not in great demand.

350 mm, power up to 140 W / section. At 500mm, up to 200W / section.

What about the heat generated by the radiator?

I can only say that with low temperature heating, the amount of heat generated is greatly reduced. For example, if a power of 190 W / section is indicated in the passport, this means that this power will be valid at a coolant temperature of 90 degrees and an air temperature of 20 degrees. More information about heat generation is written here: Calculation of heat loss through a radiator

What is the difference between bimetallic radiators and aluminum radiators?

Bimetallic radiators are actually steel radiators coated with aluminum for better heat dissipation. That is, two metals are used in bimetallic radiators - steel (iron) and aluminum.

The bimetal radiator withstands high pressure and is specially designed for central heating. Therefore, in apartments with central heating, only bimetallic radiators are installed.

Why not put an aluminum radiator on your central heating?

The fact is that special additives are added to the central heating water to reduce scale. Make it more alkaline. And the alkali eats up the aluminum. Therefore, in order not to talk about metals that are resistant to corrosion, there is still something that can destroy any metal. Even copper and copper pipes are not immune to corrosion. I heard that iron powder or steel chips, when in contact with copper, destroy copper.

The aluminum radiator is suitable for autonomous heating systems. In private houses, where their own heating and their own coolant without any cunning additives. Keep in mind about antifreeze, when you pour in more antifreeze, find out how it will affect your pipes made of various metals. Unfortunately, the aluminum radiator emits hydrogen, but in what proportions it is difficult to say. Because of this hydrogen, air is often formed, which must be constantly vented.

A bimetallic radiator, too, does not represent anything good. It corrodes strongly, and all because there is always a certain amount of oxygen in the water, which destroys iron (steel). A bimetallic radiator, like iron pipes, will corrode.

Aluminum is less susceptible to corrosion, but still there are all kinds of chemicals that will eat aluminum.

Very often, even water from a well happens to have some kind of chemical properties. For example, it can be highly acidic, which can also only increase pipe corrosion. Reinforced-plastic pipes and pipes made of cross-linked polyethylene are not subject to corrosion, but they are afraid of high temperatures above 85 degrees.(If the temperature is higher, then the life of the plastic pipes drops sharply.). Polypropylene pipes allow oxygen to pass through. We will talk about pipes in other articles, I will only say that it has been experimentally discovered that oxygen penetrates through plastic. In the reinforced-plastic pipes there is an aluminum layer that prevents the passage of oxygen into the heating system.

In order for your iron pipes and steel radiators to last longer, you need to make the water or coolant more alkaline. There are special additives.

And yet, after weighing all the pros and cons, it is better to put aluminum sectional radiators for a private house. For an apartment for central heating, a bimetallic sectional radiator.

Radiator pressure.

As for the working pressure, for aluminum radiators it is from 6 to 16 atmospheres.

For bimetallic radiators, this is from 20 to 40 atmospheres.

As for the pressure in central heating systems, it can reach 7 Bar. In private houses with about a three-storey building, the pressure is about 1 - 2 bar.

Corrosion and hydrogen formation can be reduced by any chemical treatment of the radiators during the manufacturing stage. What can be written in the passport. And then it still needs to be proved. Who will benefit from it, even the cheapest radiator will last at least 10 years. And with all sorts of protective layers for 20-50 years. The results will be in 15 years. And when 15 years have passed, they will simply forget about some kind of protective layer. And after 5 years, you will no longer show the consequences of the destruction of radiators to the manufacturer.

Convectors for heating.

Convector

- this heating device is made according to this technology. It's just that an ordinary pipe goes through many plates that transfer heat to the air.

For beauty, this device is covered with a decorative panel.

As for the power, they are indicated in the passport for each individual model.

Cast iron radiator.

This is a cheap heater, but terribly heavy.

You can't hang it on a weak wall, you need to hang such radiators on reinforced brackets.

In terms of power, they are up to 120 W / section

They are also exposed to corrosion and can withstand high pressures up to 40 atmospheres. Due to the fact that their wall thickness is large, such cast-iron radiators serve for a very long time. It will take more than a dozen years to destroy such a radiator with corrosion.

I don't remember any old cast-iron radiator starting to leak due to corrosion.

Steel panel radiators.

It is better not to install steel panel radiators in an apartment for central heating, firstly, their wall thickness reaches 2.5 mm. There is also a wall thickness of 1.25 mm. And then the corrosion will quickly eat them. They withstand pressure less than bimetallic sectional ones.

Working pressure up to 10 Bar.

Each individual panel has its own heat output indicated in the passport.

Such radiators are cheap and are usually suitable for a private house as the cheapest option. Compared to heat dissipation and space requirements, they bypass sectional radiators. That is, such a radiator will take up less space and at the same time generate more heat.

Why is steel bad for a heating system?

In a heating system where steel or iron is present, the entire heating system is very littered with sludge and the consequences of steel corrosion. Crumbs of rusty steel begin to accumulate in the strainers and impair the circulation of the heating system. Therefore, if you have steel pipes or steel radiators, then filters should be used with a good margin. Or you might have to clean your filters every month. If the filters are not cleaned, the heating system stands up and does not circulate heat through the pipes.

Why is aluminum bad for a heating system?

Aluminum gives off hydrogen.With aluminum radiators, it is very often necessary to bleed air from the heating system. By the way, aluminum radiators last much longer than steel ones. But in sectional radiators, the first thing to do is to leak joints due to poor quality gaskets or connections. Or if you are using an anti-freeze liquid, which also increases the leakage at the joints. By the way, copper pipes, where the coolant circulates through aluminum radiators, do not last long. Therefore, there is a rumor that copper and aluminum are incompatible. I also heard that copper and steel are incompatible. And modern gas boilers have copper pipes inside. But this is not scary, the difference may not be big and can reduce the life of copper pipes by one and a half to two times. According to my forecasts, the pipe can serve quietly for 10 years. It might just be a scary story, though. Since, while working for a firm, how many cottages we have set up with copper pipes and aluminum radiators. And we still continue in the same spirit. For me, Duc - more destructibility is due to non-freezing liquid and water displaced towards an acidic environment. And aluminum radiators are afraid of water hammer and electrochemical corrosion.

The difference between steel and aluminum is not big

, air can be formed up to 30% more with aluminum. And destructive corrosion can differ by 10-30%. And then it all depends on the coolant. Poor heat transfer fluid can ruin your heating system faster than any combination of metals. On water, your heating system will last much longer than on non-freezing liquid - a fact. But it can also be the other way around, if the water is strongly shifted towards acidity. I advise you to find out about additional additives in the heating system. Scientists in the housing and communal services laboratory know this better, since special processed water circulates in the central heating system. In-store consultants may not be aware of this.

I heard that zinc is not compatible with antifreeze liquid

... Therefore, it is better not to pour antifreeze liquid into galvanized pipes.

With regard to sectional radiators.

Very often people and installers are faced with the following question:

How many sections can be installed on one radiator?

Some experts point out that no more than 10 sections are needed per radiator. The main reason why the number of sections is not exceeded is the flow rate of the coolant!

Explaining!

If the flow rate is not sufficient for a powerful radiator, then a cooler coolant will come out of it! Accordingly, the difference will be large. As a result, no matter how many sections you hang, if the consumption is small, then the benefit becomes ineffective. Since the main heat transfer comes from the coolant, and the number of sections increases the receipt of this heat from the coolant. With a large number of sections, the temperature head of the radiator increases. That is, the supply temperature is high, and the return temperature is low.

The answer is that you can put a radiator with 20 sections! It is only necessary to have a sufficient flow rate of the heating medium! If you want to understand the hydraulics and heating technology of the heating system, then I recommend that you familiarize yourself with my course:

ENGINEERING CALCULATIONS

Keep in mind the thermostatic valve, it reduces the flow through the radiator.

Ways to connect radiators. Properties and parameters.

This concludes the article! Write comments.

| Like |

| Share this |

| Comments (1) (+) [Read / Add] |

All about the country house Water supply Training course. Automatic water supply with your own hands. For Dummies. Malfunctions of the downhole automatic water supply system. Water supply wells Well repair? Find out if you need it! Where to drill a well - outside or inside? In what cases well cleaning does not make sense Why pumps get stuck in the wells and how to prevent it Laying the pipeline from the well to the house 100% Protection of the pump from dry running Heating Training course. Do-it-yourself water-heating floor. For Dummies.Warm water floor under a laminate Educational video course: On HYDRAULIC AND HEAT CALCULATIONS Water heating Types of heating Heating systems Heating equipment, heating batteries System of underfloor heating Personal article of underfloor heating Principle of operation and scheme of operation of underfloor heating Design and installation of underfloor heating materials for underfloor heating Water underfloor heating installation technology Underfloor heating system Installation step and methods of underfloor heating Types of water underfloor heating All about heat carriers Antifreeze or water? Types of heat carriers (antifreeze for heating) Antifreeze for heating How to properly dilute antifreeze for a heating system? Detection and consequences of coolant leaks How to choose the right heating boiler Heat pump Features of a heat pump Heat pump operating principle About heating radiators Ways of connecting radiators. Properties and parameters. How to calculate the number of radiator sections? Calculation of heat power and the number of radiators Types of radiators and their features Autonomous water supply Autonomous water supply scheme Well device Do-it-yourself well cleaning Plumber's experience Connecting a washing machine Useful materials Water pressure reducer Hydroaccumulator. Principle of operation, purpose and setting. Automatic air release valve Balancing valve Bypass valve Three-way valve Three-way valve with ESBE servo drive Thermostat to the radiator Servo drive is collector. Choice and rules of connection. Types of water filters. How to choose a water filter for water. Reverse osmosis Sump filter Check valve Safety valve Mixing unit. Principle of operation. Purpose and calculations. Calculation of the mixing unit CombiMix Hydrostrelka. Principle of operation, purpose and calculations. Accumulative indirect heating boiler. Principle of operation. Calculation of a plate heat exchanger Recommendations for the selection of PHE in the design of heat supply objects Contamination of heat exchangers Indirect water heating water heater Magnetic filter - protection against scale Infrared heaters Radiators. Properties and types of heating devices. Types of pipes and their properties Indispensable plumbing tools Interesting stories A terrible tale about a black installer Water purification technologies How to choose a filter for water purification Thinking about sewage Sewage treatment facilities of a rural house Tips for plumbing How to evaluate the quality of your heating and plumbing system? Professional recommendations How to choose a pump for a well How to properly equip a well Water supply to a vegetable garden How to choose a water heater An example of equipment installation for a well Recommendations for a complete set and installation of submersible pumps What type of water supply accumulator to choose? The water cycle in the apartment, the drain pipe Bleeding the air from the heating system Hydraulics and heating technology Introduction What is hydraulic calculation? Physical properties of liquids Hydrostatic pressure Let's talk about resistances to the passage of liquid in pipes Modes of fluid movement (laminar and turbulent) Hydraulic calculation for pressure loss or how to calculate pressure losses in a pipe Local hydraulic resistance Professional calculation of pipe diameter using formulas for water supply How to choose a pump according to technical parameters Professional calculation of water heating systems. Calculation of heat loss in the water circuit. Hydraulic losses in a corrugated pipe Heat engineering. Author's speech. Introduction Heat transfer processes T conductivity of materials and heat loss through the wall How do we lose heat with ordinary air? Heat radiation laws. Radiant warmth. Heat radiation laws. Page 2.Heat loss through the window Factors of heat loss at home Start your own business in the field of water supply and heating systems Question on the calculation of hydraulics Water heating constructor Diameter of pipelines, flow rate and flow rate of the coolant. We calculate the diameter of the pipe for heating Calculation of heat loss through the radiator Heating radiator power Calculation of the radiator power. Standards EN 442 and DIN 4704 Calculation of heat loss through enclosing structures Find heat loss through the attic and find out the temperature in the attic Select a circulation pump for heating Transfer of heat energy through pipes Calculation of hydraulic resistance in the heating system Distribution of flow and heat through pipes. Absolute circuits. Calculation of a complex associated heating system Calculation of heating. Popular myth Calculation of heating of one branch by length and CCM Calculation of heating. Selection of pump and diameters Calculation of heating. Two-pipe dead-end Heating calculation. One-pipe sequential Heating calculation. Double-pipe passing Calculation of natural circulation. Gravitational pressure Water hammer calculation How much heat is generated by pipes? We assemble a boiler room from A to Z ... Heating system calculation Online calculator Program for calculating Heat loss of a room Hydraulic calculation of pipelines History and capabilities of the program - introduction How to calculate one branch in the program Calculation of the CCM angle of the outlet Calculation of CCM of heating and water supply systems Branching of the pipeline - calculation How to calculate one-pipe heating system How to calculate a two-pipe heating system in the program How to calculate the flow rate of a radiator in a heating system in the program Recalculating the power of radiators How to calculate a two-pipe associated heating system in the program. Tichelman's loop Calculation of a hydraulic separator (hydraulic arrow) in the program Calculation of a combined circuit of heating and water supply systems Calculation of heat losses through enclosing structures Hydraulic losses in a corrugated pipe Hydraulic calculation in three-dimensional space Interface and control in the program Three laws / factors for the selection of diameters and pumps Calculation of water supply with self-priming pump Calculation of diameters from central water supply Calculation of water supply of a private house Calculation of a hydraulic arrow and a collector Calculation of a hydraulic arrow with many connections Calculation of two boilers in a heating system Calculation of a one-pipe heating system Calculation of a two-pipe heating system Calculation of a Tichelman loop Calculation of a two-pipe radial wiring Calculation of a two-pipe vertical heating system Calculation of a single-pipe vertical heating system Calculation of a warm water floor and mixing units Recirculation of hot water supply Balancing adjustment of radiators Calculation of heating with natural circulation Radial wiring of the heating system Tichelman loop - two-pipe passing Hydraulic calculation of two boilers with a hydraulic arrow Heating system (not Standard) - Another piping scheme Hydraulic calculation of multi-pipe hydraulic arrows Radiator mixed heating system - passing from dead ends Thermoregulation of heating systems Pipeline bifurcation - calculation of a hydraulic pipeline branching Calculation of the pump for water supply Calculation of the contours of a warm water floor Hydraulic calculation of heating. One-pipe system Hydraulic calculation of heating. Two-pipe dead-end Budgetary version of a one-pipe heating system of a private house Calculation of a throttle washer What is a CCM? Calculation of the gravitational heating system Constructor of technical problems Pipe extension SNiP GOST requirements Requirements for the boiler room Question to the plumber Useful links plumber - Plumber - ANSWERS !!! Housing and communal problems Installation works: Projects, diagrams, drawings, photos, descriptions.If you are tired of reading, you can watch a useful video collection on water supply and heating systems

Elimination of radiator defects

The condition of the radiator should be checked regularly. This is especially important before a long trip. When a leak appears in the radiator due to corrosion, it is necessary to use special sealants or cold welding. Small leaks in the cooling system will help fix the seals. For these purposes, the sealant is poured into the tank of the cooling system. In contact with air, such substances solidify, forming a polymer film that reliably closes the leak. Cold welding is a more difficult type of repair. It is used in the presence of large cracks.

Heat-resistant adhesive sealants, which resemble plasticine, are applied to the damaged surface. The sealant sets within a few minutes, but full hardening may occur much later. Sometimes this takes a whole day. These remedies are, in fact, emergency. In the near future, it will be necessary to contact a car service for more substantial repairs, otherwise the radiator will have to be replaced with a new one. Even if "cold welding" can last for several years, it is still not worth the risk.

Prevention and prevention of problems with radiators in the heating system

There is an easy way to prevent most of the hassles associated with radiators. For guaranteed disconnection of devices from the system, shut-off valves should be used. To ensure uninterrupted heating for neighbors in one-pipe heating systems, it is necessary to use the bypass principle, a bypass, which is a pipe connecting the inlet and outlet directly in front of the radiator. It is also recommended to equip a bypass in cases where you intend to install individual thermostats for temperature control in a single-pipe (standing) heating system.

To reduce the heating of the radiators, a partial shut-off of the coolant supply is used. At the same time, by limiting its passage through the radiators in the apartment, in the absence of a bypass, you slow down the circulation of the coolant from the neighbors. To avoid this undesirable effect, install a bypass upstream of the regulator - the water will bypass, and you will not block heating in other people's apartments.

To reduce internal corrosion, do not drain radiators for more than 15 days during summer. It is best to leave them filled with water by closing the ball valves on the supply line. But do not forget at the same time to slightly open the radiator air vent (Mayevsky's valve).