- Room characteristics

- Thermal insulation of warehouses and hangars

- Warehouse heating methods

- Air heating systems

- Radiant heating systems

- Air-thermal curtains

- Water infrared panels

Send a quick request Heating of warehouses, hangars, storage facilities and other similar buildings differs significantly from heating, say, residential buildings - both the overall dimensions of the room and the special requirements for the conditions of the internal microclimate play an important role.

INTECH-Klimat is ready to implement professional solutions for climatic and other engineering equipment. We will perform a full cycle of turnkey works: design, selection, delivery, installation and maintenance. Call now: +7

... Submit your application

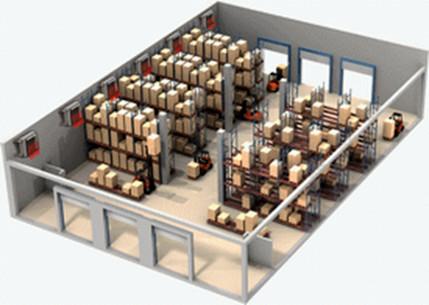

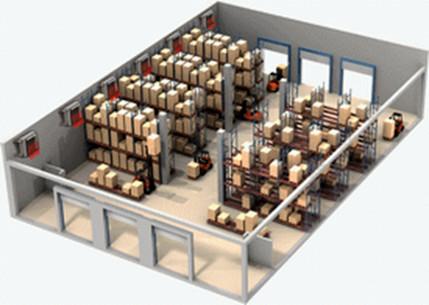

In particular, it is usually required to heat not the entire warehouse, but only certain working areas and places of cargo storage, moreover, the temperature and humidity level in such areas can be completely different. In this regard, the issue of heating the warehouse must be approached with the utmost responsibility - in order to be able to fully use the functionality of the premises.

Standard water heating, with which any of us are well familiar, is of little use for heating air in such a spacious room - the heated air masses will simply rise upward into unused areas. Accordingly, costs will rise significantly - with minimal useful return. So, what kind of warehouse heating system should you use?

Room characteristics

When choosing a heating system, you should pay attention to some characteristics of the building. First of all, it is necessary to take into account the height of the ceiling and the area of the building. If the height from floor to ceiling is more than 3 m, then it is not recommended to use water systems, because they are unable to provide the required temperature in large rooms.

The second important indicator is thermal insulation. Insulated walls and ceiling will significantly save money spent on heating a workshop or warehouse. If it is not possible to avoid heat loss, it is recommended to use heat sources that heat certain work areas.

You should also take into account the technological temperature requirements for the storage of raw materials or products.

Thermal insulation of warehouses and hangars

The warehouse can be either a brick, block or concrete building, or a metal hangar. If in the first case, insulation is not always required, then the hangar insulation is simply necessary. Without this, it will be cold in winter, and very hot in summer, even hotter than outside.

Heating the hangar should be done only after high-quality insulation, since the main task of heating is to replenish heat loss. The less heat loss, the cheaper heating costs. Therefore, you need to carefully select the material according to its characteristics and correctly calculate the insulation layer.

As a rule, warehouses are insulated from the inside. The speed of work is of great importance. The price of the event is also important. What parameters should the thermal insulation layer meet:

- minimum thermal conductivity;

- incombustibility;

- moisture resistance;

- speed of application;

- operation without finishing.

The lack of finishing will not affect the work of the warehouse in any way, beauty is not needed here, the main thing is practicality and reliability.

Taking into account all the above parameters, the thermal insulation of the warehouse with polyurethane foam will be an ideal option.

PPU is a polymer insulation with a closed-cell structure, and for a hangar, foamed polyurethane foam is generally the only option. It has the lowest thermal conductivity coefficient in comparison with all modern heaters, which is 0.029 W / m * C. It does not allow steam to pass through and does not absorb moisture. The material does not burn, even if an open flame is directed at it; accordingly, it does not emit poisonous gases. PU foam has high adhesion to almost all materials, that is, it adheres firmly to any surface. The insulation is light, does not shrink, and is not afraid of rodents.

Thermal insulation of a PPU warehouse is carried out in one day, depending on the area, but often not more than a day. Insulation is applied by spraying using a special blow molding machine. Nobody conducts such work with their own hands, they hire contractors.

Autonomous gas heating of apartments is now the norm for new buildings. It is very convenient indeed.

Using the smart home system, heating is controlled remotely, only the Internet is needed.

Warehouse heating methods

The following heating systems are used to heat the air in the warehouse:

- centralized water;

- air;

- radiant.

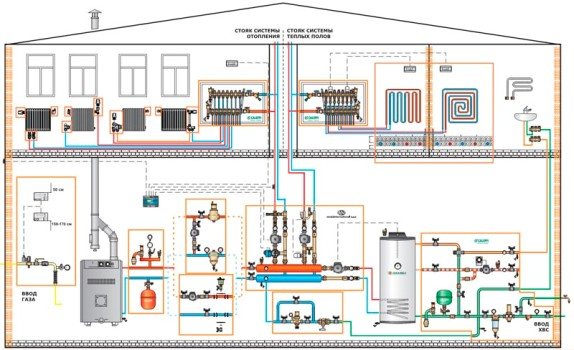

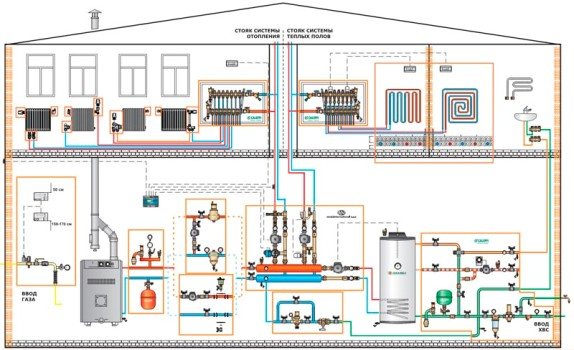

In the first case, heating occurs due to hot water moving through the water pipe system and heating the radiators. The water comes from the central heating system; depending on the storage conditions, heating in the boiler room is possible, if any, as well as when using special electrical appliances.

It is used only in small warehouses with low ceilings due to the reasons already described above; Also, this system is not very popular due to the complexity of installation, as well as the large amount of occupied space, which does not allow using the warehouse area with maximum efficiency (this mainly concerns retail warehouses and bases where rack structures are used).

Heating of warehouses and warehouses

In most cases, heating warehouses and storage facilities is reduced to obtaining a stable temperature evenly throughout the entire territory. There are several ways to do this, and each has its own characteristics.

Our country is rich in resources, therefore, first of all, entrepreneurs consider gas heating a warehouse. Indeed, the low cost of gas initially attracts, but this is followed by numerous approvals and confirmations from various authorities, which complicate the whole process of organizing heating and that's not all, a separate room for the boiler room, chimneys, personnel for servicing gas equipment and solving emerging issues is needed associated with the operation of gas equipment.

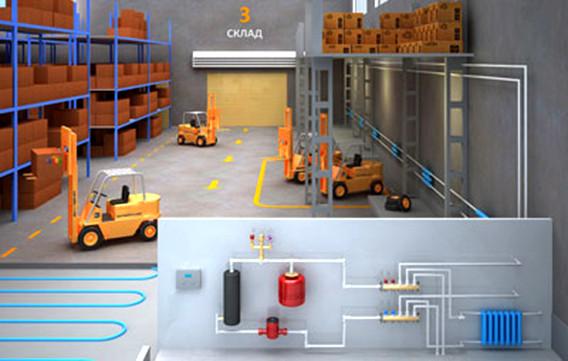

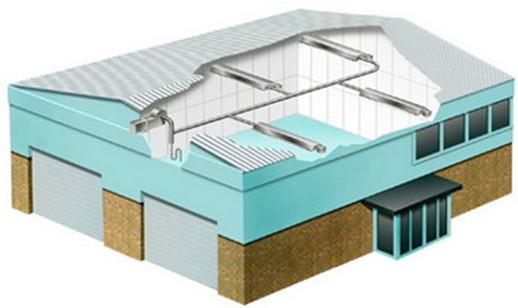

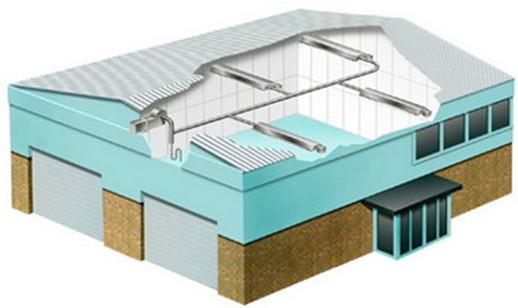

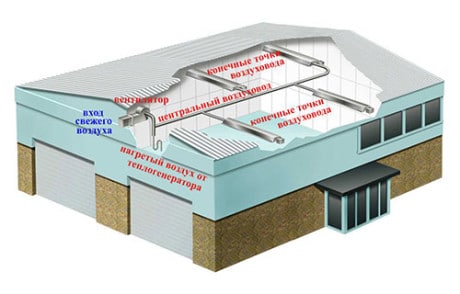

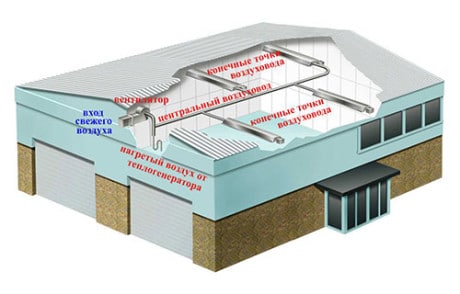

Air heating systems

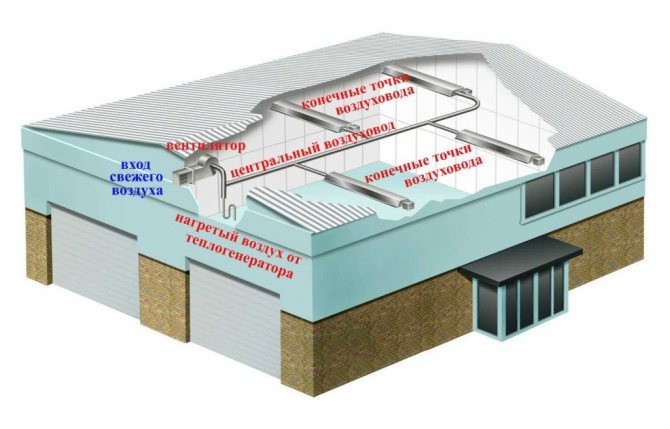

Much more popular is the air heating of the warehouse, which was first used in the seventies of the last century and is being effectively improved to this day. These systems do not interact with any external sources, and the heating of the air in the room is provided by the operation of heat generators and heaters - water and steam.

The heated air enters through the box-shaped collectors to those rooms where it is necessary to maintain a certain temperature regime. To reduce or increase the air flow, special adjustable flaps or louvers are used.

This method also has some disadvantages, although there are fewer of them than the previous system. However, the air system is one of the most commonly used warehouse heating systems due to its ease of installation and relatively low cost of equipment.

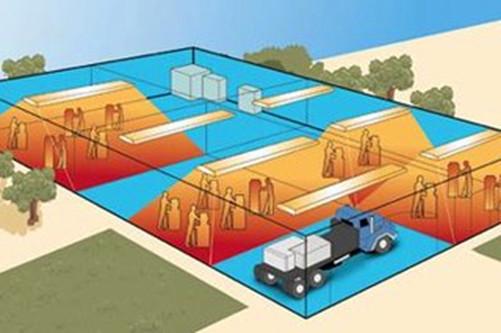

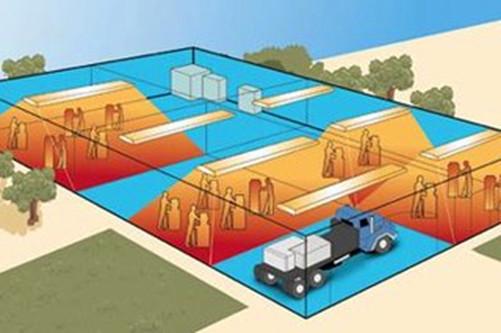

Radiant heating systems

Radiant heating is even more economical and easy to install and use than air heating. Infrared heaters do not generate dust and do not dry the air. The principle of operation of such a system is extremely simple - like the rays of the sun, the elements of this system do not heat the air, but the objects at which they are directed - the floor, walls, objects - and these, in turn, give off part of the heat received to the environment.

This is most convenient in cases where heating of a certain small area is required; the luminaires themselves are easily mounted at a height of 1.5-2 meters from the floor, and the concentration of emitted heat particles can be regulated.

Depending on the microclimate maintained inside the warehouse, "light" and "dark" infrared heaters are used. The release of heat in them is facilitated by natural or liquefied gas. Heaters can either be installed directly into walls or wall niches, or be part of entire radiant panels located along the entire length of the building. Portable models are also produced, which are used in conditions of impossibility of installing the heating system. Depending on their dimensions, they can be either manual or placed on special wheeled units.

"Light" infrared heaters are characterized by extremely high temperatures - the surface of the burner can heat up to 900 degrees. "Dark" ones provide less heating - only up to 500 degrees - but at the same time they are equipped with special reflectors that allow dissipating heat particles and, thereby, providing heating of much larger areas. They also differ in design - the former are solid ceramic tiles (it heats up and produces infrared radiation), while the latter are a pipe structure with an external heat-resistant coating, inside which the gas combustion process takes place.

The most versatile type of infrared heaters are radiant panels, which are widespread in most standard storage warehouses and are standard fire safety codes. It is also convenient to use them for air conditioning - when connecting a steam generator. At the same time, steam can be heated up to almost 200 degrees, which contributes to a significant increase in the rate of air exchange inside the room.

Thus, we can say that today radiant heaters of both types are the best options for heating systems - efficient, economical and convenient. However, the following restrictions on the use of these units should be mentioned:

- inability to use heating panels at a height below 4 meters. Otherwise, the heating temperature of the area will be too high - moreover, such intense radiation will have a bad effect on the health of people passing under them;

- in rooms with increased fire safety requirements. This applies to warehouses of fuels and lubricants and other flammable liquids, petroleum products, oils, etc .;

- in rooms where goods are stored that are sensitive to infrared radiation.

Plumbing works Tyumen

A warehouse is an uninhabited storage facility intended for organizing the storage of raw materials, products, products and other goods, which guarantees the fulfillment of the necessary proper conditions for organizing storage and is equipped with a storage mechanism and devices and structures that are comfortable for unloading and loading. By designation, warehouses are divided into production, wholesale procurement, supply and commercial. By the types of stored products of the enterprise, warehouse premises are grocery, non-food, provisional and specific purposes. The conditions for each variant of the warehouse are dependent on its predetermination.

Heating of warehouses must be calculated to maintain a specific temperature in them, based on the mode of storage of the product. In unheated warehouses, heating should be installed only in service rooms, which are intended for a long presence of service personnel / during the working day /.

According to the standards of sanitary and hygienic norms, almost every warehouse must be equipped with one or another type of ventilation or heating devices.

Gas heating of the warehouse

Gas heating of a warehouse is called a heating system using gas air heaters. Those. the technological process of heating the ambient air in them occurs due to the ignition of the gas. At first it may seem that this is the most common and affordable way to organize heating in a warehouse.

WITH 1-th side - it is. The initial amount of equipment and installation work is several times lower than the price of a similar system using air ducts. However, the whole “difficulty” in this variant lies in the coordination of the gas project and the distribution of gas pipelines. So it is necessary that a pink gas pipe be brought close to any gas air heater and an individual chimney is brought out. In certain situations, the possibility of coordinating a gas project for such a warehouse air heating system is reduced to zero. However, everything may depend on the specific situation and the additionally taken gas trust.

In addition to the warehouse heating systems listed above, there is also a warehouse heating system using electrical energy. However, due to the high cost of electrical energy, we will not take it into account in the above section of Our Internet project with you.

Water warehouse heating

The positive side of water heating is considered to be the determination of the parameters of hydraulic pressure, and similarly to water; the ability to choose the type of necessary heating devices and their design of the entire system. In preference to steam, the usefulness of a water heating system for warehouses is that it provides uniform heating of heating elements with a low temperature, and this, in turn, guarantees sufficient humidity for storing various products in the warehouse that specifically do not tolerate dried ambient air.

The hot water heating system is not advisable to use in warehouses with a height more - 5,0 m. This is explained by the fact that convection jets from the heating elements lift hot air upward, where it accumulates under the ceiling. As a result, thermal energy is wasted to no avail - the lower zone of the warehouse does not heat up, and thermal leaks through the roof of the building increase.

For existing warehouses with raised tops and hot water heating systems, ceiling propellers can be installed today. Ceiling fans in winter will let the heated air down to the nominal zone, and in summer they will make some perception of freshness due to the increased speed of air movement.

Air heating of a warehouse

Air heating of a warehouse is an especially good method of heating a warehouse. This is mainly due to the fact that warehouse complexes, like all kinds of other industrial buildings, have rather elevated strong ceilings and a correspondingly impressive size.

Heating the warehouse with hot air is based on a heat generator. This is a prototype of a hot water boiler with only one fundamental difference: the heat generator heats the air, not water. Natural and liquefied gas, diesel fuel, waste and vegetable oil can be used as an energy carrier for heat generators.The air space heated by the heat generator is divided by the air duct system according to the structure of the warehouse, thereby heating the warehouse to the required ambient temperature. The heating of the warehouse with such methods is more uniform, which helps to manage the temperature from the inside of the room with the support of receivers and stabilizers of the ambient temperature.

The air heating system of the warehouse is very similar to the ventilation system, which makes it possible to use it as a cooling system in the warm season. For this, air-conditioning structures are added to the air heating system of the warehouse. It is necessary not to forget that for the efficient operation of the air heating of the warehouse, it is necessary from the outset to make thorough calculations of the capabilities of the heat generator and the laying of pipelines. For this reason, the fact of having a project of a similar warehouse heating system is required!

Infrared warehouse heating

An infrared heater is considered the basis of an industrial heating system. When creating a project plan for infrared heating of production, our qualified specialists take into account all the subtleties that relate to the specifics of the client's enterprise. The availability of this or that type of heat carrier / gas, hot water or steam / is taken into account. Equipment for infrared heating of production, workshop, warehouse are selected in strict accordance with the fire hazard group of the building. At the same time, the set includes modifications of equipment for infrared heating, which are suitable even for the most significant fire hazard groups.

Specialists of a specialized company will select the power and the required number of infrared heaters, based on the heat loss of the production structure. When creating a project for an infrared heating system for industrial facilities, warehouses, workshops, the existing engineering heating systems, communications, industrial equipment, the position of crane beams, roof trusses are provided. This is required in order to properly install infrared heating of a warehouse, workshop, production, without introducing limits to the industrial technological process. When solving all tasks assigned by the customer, without exception, our experts apply all their practical experience and stock of knowledge, which makes it possible to recommend a production heating solution that best suits the needs of the client.

Subsequently, infrared heating of workshops, warehouses and commercial facilities is spent up to - 45,0 % fewer resources than with classic methods. This will contribute to a significant reduction in the financial costs of each enterprise and a rapid return on investment in infrared industrial heating. You can get additional advice on the selection and calculation of industrial equipment by contacting the employees of a specialized company.

Heating and water supply is a multifaceted engineering process,

requiring the knowledge and skills of a PROFESSIONAL.

We will clarify your situation and answer your questions free of charge + 7-932-2000-535

Plumbing works Tyumen

Air-thermal curtains

Air curtains are required to separate zones with different temperature conditions. The equipment is mounted in the aperture of doors, windows, gates. The curtain is formed by the movement of a high-speed air flow. It is a kind of invisible barrier that does not allow warm air to escape and does not let cold air in from outside. In addition, the air curtain isolates the warehouse from exhaust gases, dust and other negative phenomena without interfering with the movement of special vehicles.

The curtain width is 0.6-2.5 meters. In wider openings, several devices are mounted close to each other. When calculating the heat curtain, the following factors are taken into account:

- the maximum temperature of the supplied air is 50 ° С at the entrance;

- temperature of air entering from outside 5-14 ° С;

- air speed no more than 8 m / s at the entrance and no more than 25 m / s at technological openings and gates;

- installation of thermal curtains is justified for entrance doors without vestibules that are opened five or more times a day or for 40 minutes per shift.

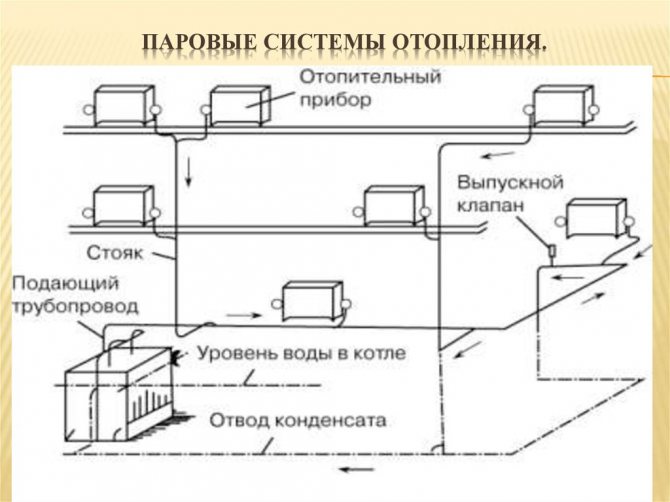

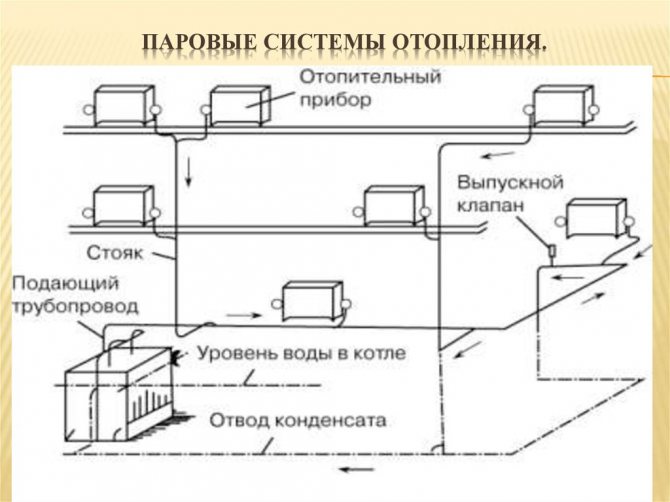

Steam systems

The heat carrier is dry saturated steam with a temperature not exceeding 130 ° С. The system can be open-loop, when the condensate is transferred to the heat exchanger by a pump, or closed, when the condensate moves by gravity. Main advantages:

- minimal heat loss in heat exchangers;

- fast heating of radiators and other heating devices;

- low inertia;

- the possibility of heating multi-storey buildings;

- compactness of equipment;

- low hydrostatic pressure in the system.

Disadvantages:

- high heat losses in steam lines, as a result - a decrease in efficiency;

- noisiness;

- you cannot make the temperature of the coolant below 100 ° C;

- intensive corrosion of the metal elements of the circuit.

Steam heating is permitted for terminals with non-flammable and non-toxic dust, non-flammable and non-flammable vapors and gases. Steam lines are installed separately from the ventilation and air conditioning system.

Types of heating systems with different heat carriers

By the type of coolant, steam, air and water heating of the warehouse are distinguished. In some cases, the systems are combined, arranging steam-air, steam-water or water-air heating. Everything in order.

Steam systems

The heat carrier is dry saturated steam with a temperature not exceeding 130 ° С. The system can be open-loop, when the condensate is transferred to the heat exchanger by a pump, or closed, when the condensate moves by gravity. Main advantages:

- minimal heat loss in heat exchangers;

- fast heating of radiators and other heating devices;

- low inertia;

- the possibility of heating multi-storey buildings;

- compactness of equipment;

- low hydrostatic pressure in the system.

Disadvantages:

- high heat losses in steam lines, as a result - a decrease in efficiency;

- noisiness;

- you cannot make the temperature of the coolant below 100 ° C;

- intensive corrosion of the metal elements of the circuit.

Steam heating is permitted for terminals with non-flammable and non-toxic dust, non-flammable and non-flammable vapors and gases. Steam lines are installed separately from the ventilation and air conditioning system.

Air systems

Air heating systems for warehouses are the most common today. The heat carrier is air that heats up when passing through the generating set. The heated air is distributed evenly throughout the warehouse volume through the air duct system. The units are mounted on the roof and along the walls. The system is well suited for heating large high-rise buildings.

Main advantages:

- the possibility of combining the heating circuit with ventilation for the flow of fresh air into the room;

- high efficiency up to 95%;

- rapid heating of the air due to the absence of an intermediate heat carrier;

- the ability to automate the heating system, adjust the exact parameters.

Warm air outlets are designed so that there are no massive building structures in the path of the air flow. At a warehouse height of less than 8 meters, the release is carried out with covering jets, at a height of more than 8 meters - with non-covering jets. The air jet, when the air is discharged, is applied to the ceiling at a height equal to 0.85 times the height of the terminal (H). Non-overlapping jets are formed at a height of 0.35-0.65 N from the floor.The distance between the diffusers when installed in a row is no more than three room heights.

Air heating of a warehouse is economical in operation, pays off quickly, and can be installed with or without air ducts. The system works effectively in terminals with high ceilings, it allows you to evenly heat the entire volume of air. Combining heating with ventilation and air conditioning reduces the financial costs of the project.

If there is no need for constant heating of warehouses, but a strong drop in temperature cannot be allowed, heat guns are used as more compact devices. The equipment is placed around the perimeter of the terminal and connected to the thermostat sensors. When the temperature drops to the set value, the equipment turns on and starts generating heat. The device of such heating does not require drawing up a project, it allows you to quickly warm up the room. But after turning off the heat gun, the air cools down just as quickly.

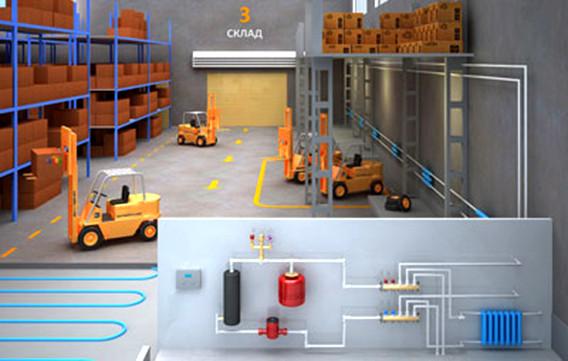

Water systems

The heating medium in the water heating system can be water or water-based antifreeze. For small rooms, arrange a circuit with natural circulation. The pipes are angled so that the water moves by gravity. For warehouses of a large area, such a solution will not be effective; installation of pumps is required. Forced circulation systems are highly efficient but require electricity.

Water heating is often chosen by warehouse owners as the most optimal option. In places where there is a possibility of connecting to the central network, the task is simplified. In the absence of such an opportunity, the calculation of heating the warehouse should include the choice of a boiler and the device of a separate room for the boiler room. As a disadvantage of such a system, the aesthetic component is indicated - the pipes along the walls do not decorate the warehouse.

The advantage of water systems over steam systems is uniform heating of heating devices, the air does not dry out, and optimal conditions for goods are maintained. But such heating is not recommended for storage terminals higher than five floors. This is because warm air rises and collects at the top, increasing heat leakage through the roof and leaving areas of the ground floor cold. In warehouses with high tops and hot water heating, specialists install ceiling fans to increase efficiency. The rotation of the propellers in winter allows warm air to circulate throughout the warehouse, while in summer it provides some coolness.

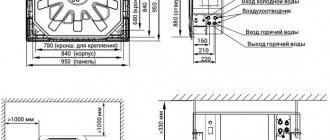

Water infrared panels

Today, another very profitable way is known, with the help of which it is possible to equip the heating of a hangar or any other large utility room - the use of water IR panels.

In this case, the heat transfer fluid is heated up to 160 ° C and enters the radiating tubes located under the ceiling. The infrared radiator effectively dissipates heat throughout the entire volume of the heated room. Thus, the equipment operates not on the convective, but on the radiant principle.

The uniqueness of such equipment lies in the fact that the air in the room is not heated. Various types of surfaces are subject to heating, including the surface of equipment, goods, shelving, walls, floors, ceilings, and even people in the room.

With the help of IR water panels, it is possible to effectively organize the heating of the workshop, in which welding, carpentry and other production work is carried out.

In this case, the purpose of the method is not to heat the room itself or raw materials, but to provide heat to the working personnel.

Cold storage heating

Weather conditions often require high-quality heating in a cold warehouse.In fact, space heating in this case is no different from heating for a warm warehouse, it just requires the system to run smoothly. Despite its small dimensions, the EOU provides the necessary circulation of the coolant in the water heating system, which evenly distributes heat throughout all rooms.

There are many options for organizing autonomous heating of the warehouse. The methods described above are the most popular, however, under current conditions, the use of Energy-Saving Heating Units looks like the most optimal solution, both in terms of its efficiency and the cost of installation and further maintenance.