Why use vapor barrier materials

To create conditions in the steam room with high humidity and temperature requires considerable effort and knowledge. Particular attention is paid to protecting the thermal insulation layer from excessive moisture. Thermal insulation in a bath is usually done with basalt wool. In dry conditions, it retains heat well and is not afraid of high temperatures.

But under the influence of moisture, its thermal insulation properties deteriorate significantly - the bath begins to lose heat. And if, at the same time, the insulation is also affected by frost, then it will very quickly collapse completely. It is for this reason that it is necessary to lay a layer of vapor barrier for the bath.

Reasons for the destruction of thermal insulation:

- Due to moisture from inside the room. The Russian bath is distinguished by its rather high humidity, so the steam will always try to get into the rooms adjacent to the steam room. Additionally, to the street, it leaves through a heat insulator. This cannot be allowed.

- Due to moisture due to temperature differences in the steam room, outdoors and in the attic. Condensation appears even before steam is supplied, when the air in the steam room warms up by itself.

Materials (edit)

On the construction market there is a huge selection of materials for the vapor barrier of the bathhouse structure. They are divided into several categories:

- film;

- kraft paper;

- membrane;

- foil;

- coating.

Films based on polyethylene and polypropylene

Polyethylene film is the most inexpensive and available roll material, with a width of 2.5 to 6 meters, a thickness of 10 to 200 microns. It is suitable for covering wall and ceiling surfaces due to its resistance to decay and high humidity.

The main disadvantage of the film is its relative fragility and the ability to break down with prolonged exposure to high temperatures. For this reason, such a vapor barrier is best used for a dressing room or rest room.

Polypropylene films are a reliable and practical option that can withstand elevated temperatures, resistant to cracking and damage. In addition, they do not lose their vapor barrier characteristics when exposed to hot air and ultraviolet radiation. Often a similar material is used for the external cladding of the wooden structure of the bath.

Films are made on the basis of cellulose and viscose fibers, they can have a rough matte surface. Due to the porous structure, they are able to retain excess moisture, protecting the heat-insulating layer.

Kraft paper

In rooms with low humidity, it is allowed to use special construction cardboard - kraft paper with a protective foil or lavsan coating.

How to properly lay a vapor barrier in a bath

For the correct functioning of such material, you need:

- seal seams and joints as efficiently as possible;

- provide a gap between the finish and the foil.

Sealing

Absolute sealing of the insulation seams will most likely not work, but it is quite possible to significantly reduce the amount of steam that will enter the insulation. You will need a foil vapor barrier for a bath to overlap, somewhere by 5-10 cm.

The joints must be glued with either double-sided or foil tape. You can buy it at any hardware store.

The bath foil insulation must not be damaged. Holes will appear where the film will be fixed with bars. To minimize them, you should use a construction stapler.To achieve maximum quality, at the attachment points, you can go over the top again with tape.

There is another good method of attaching panels - wooden clamping strips. Nails are driven into them every 15-20 cm. In this case, excellent protection against steam penetration is achieved.

Creation of a gap for ventilation

The gap is provided in the process of sheathing the frame for finishing. It should exceed 2 cm. After the bars are selected, they are nailed over the vapor barrier. Next, a wooden lining is already attached. Again, remember to keep the foil completely intact.

As a result, some of the steam that rises up will condense on the vapor barrier film. The formed droplets will immediately be dried by natural air currents passing in the space between the insulation and the lining. With the work done correctly, rotting is out of the question.

Disadvantages of this material

Foil film for vapor barrier is divided into three types:

- with a layer of foil;

- with aluminum spraying;

- with aluminum foil.

If you choose a film with a layer of ordinary foil, you must be prepared for the occurrence of corrosive processes. Simply put, the foil layer can be rusty.

Films with aluminum spraying and aluminum foil are not subject to such processes.

It is important to fill the joints between the elements of the film with an adhesive that forms a film. Otherwise, all positive effects will be lost.

It is important to keep the aluminum-coated material from overheating. Otherwise, it may damage the finishing layer.

If you buy aluminum-coated film, remember that it does not retain heat well. In general, the most useful option is film with aluminum foil.

Styling process

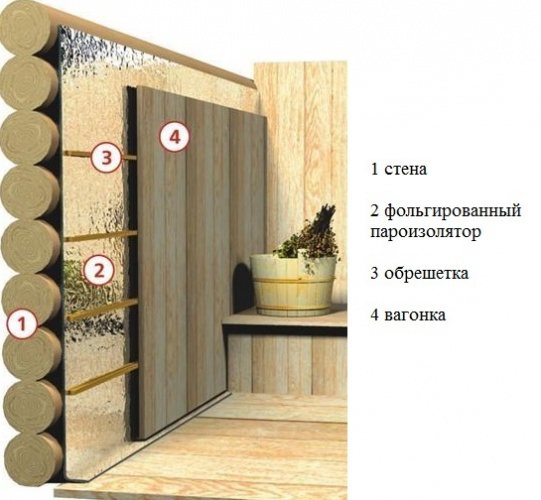

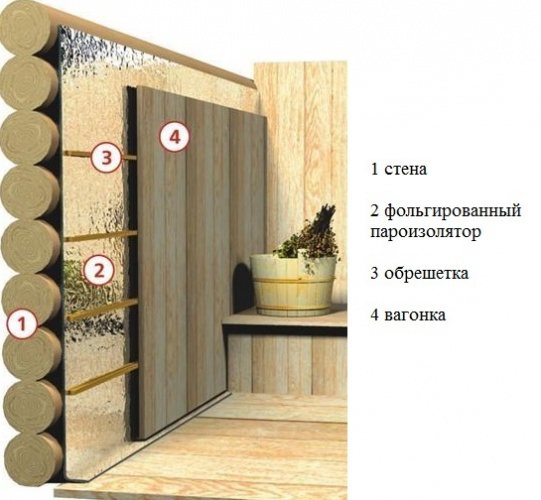

Most often, foil vapor barrier is used for a bath. In this room, more moisture is inside. Also, the interior is subject to sharp temperature fluctuations. That is why the vapor barrier is laid on the inside.

Usually the bathhouse is built of wood. And it tends to collapse under the influence of moisture. To prevent this from happening, it is important to use a vapor barrier material. It is this layer that will provide fast and high-quality heating of the room, with a minimum consumption of resources. For the most effective operation, it is important to follow the instructions exactly when installing the vapor barrier.

Stages of work:

- prepare a layer of insulation;

- for reliable vapor barrier, it is important to make the previous layer as even as possible;

- prepare wood planks: thin and short;

- divide the foil film into strips;

- fasten strips of material with wooden boards and nails, staples;

- the elements of the material must be superimposed on each other, with an overlap of twenty centimeters;

- you can connect the strips to each other with an adhesive or tape with foil-clad elements;

- glue the joints of the material with the wall, ceiling, floor, windows with tape.

Important tips:

- monitor the tightness of the vapor barrier layer;

- leave a gap for air between the vapor barrier layer and the decorative one, about two centimeters, the height of the boards for fastening will help in this;

- do not stretch the material, it deforms when heated, leave a sagging of two centimeters.

You can buy vapor barrier film at any hardware store. The price per square meter of such a film with aluminum foil starts from twenty-five rubles per square meter. It can withstand about one hundred and forty degrees Celsius with a "+" sign, is capable of reflecting about ninety percent of the heat. Environmentally friendly.

You can buy scotch tape with a metal element in the same store. The price for it fluctuates within one hundred rubles per fifty meters, fifty-five millimeters wide.

Successful renovation!

We will be grateful if you share the article on social networks with your friends.

Source: kvarremontnik.ru

What material is better to choose

The best steam and waterproofing of the bath will be a foil-based material. It retains steam very well and, at the same time, reduces losses by reflecting heat waves into the room. There are people who are sure that the foil for the bath does not affect anything, and this is an extra waste of money, however, as practice shows, almost everyone uses foil-coated materials when building baths.

Naturally, no one will use a simple thin foil, since it is very easily damaged. Building foil with a paper base is preferable.

There are several names of such material on the market:

- RufIsol S... Has a moisture-repellent kraft paper base. It can be used at temperatures from -60 to 120 o C.

- Alucraft... This type of material has an additional intermediate layer between the foil and the kraft paper in the form of a polyethylene film.

- Izospan FB... It is a kraft paper with a layer of metallized lavsan. It is not considered a metal, which raises questions about its usefulness in the steam room. However, according to the manufacturer's statement, the material is capable of withstanding temperatures up to 140 ° C.

- Megaflex KF... An analogue of the previous version.

- Yutafol H170 AL... It has a membrane consisting of 4 layers, and such a vapor barrier is suitable for saunas and baths.

There is also a vapor barrier for a steam room in a bath with a fiberglass base. It has increased strength and is able to withstand up to 450 ° C (for a short time up to 600 ° C), which is even an excessive value. Such indicators allow it to be used when insulating chimneys.

Naturally, the cost of such material will be much higher. It has enhanced thermal insulation properties, so it will be possible to save on additional thermal insulation (reduce the layer).

According to the manufacturers' assurances, glass-fiber insulation is environmentally friendly, making it ideal for decorating baths. Although you will have to pay for it three times more than for the material on the basis of kraft paper.

Almost all material on the market is unbranded.

Famous brands include:

- Thermofol ALST - up to 400 о С;

- Folgoizol;

- Armofol - up to 150 ° C, there are variations on a self-adhesive base.

You can also use foil insulation. The installation method is the same as for simple insulation, thus saving on installation time.

There are such brands of foil-clad material:

- Isover Sauna;

- Ursa (Ursa);

- Sauna Butts.

Common types of vapor barrier

First of all, the choice of a suitable vapor barrier layer is determined by its location. For walls, a regular budget film is suitable, which properly copes with the tasks of retaining heat and possibly protecting the insulation from getting wet. The polyethylene is absolutely moisture resistant and reduces the time it takes to raise the temperature in the steam room.

This is the most affordable method, with certain disadvantages. Polyethylene film quickly loses its quality characteristics and gradually begins to deteriorate under the influence of high temperature, which is constantly held in the steam room.

We offer you to familiarize yourself with Ventilation in the bath (67 photos): diagram and device, how to make a steam room and dressing room with your own hands, ventilation of the "Basta" type

It is preferable to use such material on the walls, in the dressing room or where a place for rest is equipped. However, there is also a peculiarity here.Before purchasing the film, it is imperative to check it, fold it and carefully examine the emerging seam. If such a seam is present, then the film will deteriorate very quickly. It is desirable that the material remains as smooth as possible after folding.

Polypropylene film is considered a more modern and strong replacement for polyethylene. The material resists the effects of thermal energy much better, tears less and almost does not crack. The properties of the film do not deteriorate under the influence of high temperature or sunlight, therefore polypropylene is often used to equip the outer layer that protects the bath from the wind.

The cost of such material is much higher than polyethylene. Cellulose or viscose is used as a basis for film production. Recognizing such a material is not difficult at all, the rough surface of polypropylene looks like matte. In this situation, it is imperative to equip a ventilation gap, equipping a frame made of ordinary two-centimeter wooden slats under the front cover.

Kraft paper is a high strength paperboard that is often used in construction. The structure of the material allows steam to be trapped and protects the insulation. It is better to use such a vapor barrier for the rest room. If you make a vapor barrier in a steam room out of craft paper, the material will simply fall apart over time.

Roofing material or special glassine is often used as a vapor barrier. Often such material is chosen in the absence of the opportunity to use something better. In theory, products are capable of providing vapor barrier, since they are characterized by a long service life and moisture resistance. However, at elevated temperatures, glassine or roofing felt can release toxins and unpleasant odors.

Installation of vapor barrier on the ceiling

When installing a vapor barrier for a bath on the ceiling, watch out for the joints near it - the material should be laid overlapping on the wall to minimize heat loss. You can fix the material with the same double-sided tape, or by pressing it with strips. Thus, maximum reliability will be ensured.

Often, in addition to the main insulation, a layer of moisture-repellent material is also placed in the attic. There it is especially needed, since after rainfall, droplets of moisture can seep through the roof. In any case, it doesn't hurt to play it safe. Only in this case, vapor-permeable waterproofing will be required - it will allow the steam that has penetrated through the insulation to get into the attic and evaporate there.

It is also possible to vaporize the ceiling in the bath using generally available materials. This method involves the filing of ceiling beams with thick, more than 50-60 mm, boards, sometimes unedged. In the attic, a vapor barrier is laid on the boards.

If the budget is running out at all, then cardboard impregnated with linseed oil, waxed paper, glassine, or other material of similar properties can be used as its capacity. The edges and joints are carefully processed, after which a mixture of pasty clay is spread on top. Sometimes straw or sawdust is added there to give the finished material an increased viscosity, and the formation of a minimum number of cracks in the future.

After the clay layer is completely dry, the newly formed cracks are smeared over, and again they wait for the material to dry. Further, they are already moving on to laying the heat-insulating layer, and the ceiling in the steam room itself is sewn up with wooden clapboard.

Varieties of foil vapor barrier in the form of a film

Foil vapor barrier for walls can be represented by a film. It is able to protect the insulation from moisture that penetrates from the premises.If you use such a vapor barrier in a bath, then the inner lining can be reliably protected from rotting and mold, which appear due to condensation after turning off the steam room.

Such a foil-clad reflective vapor barrier will reflect heat, and the condensate simply will not settle. The film can be made on the basis of kraft paper, this option is inexpensive, easy to handle, hygroscopic and quite easy to tear.

The vapor barrier can also be carried out on a polymer basis, in this case it is durable and strong, but it will cost more. If there is aluminum sputtering on the surface, then the thickness will start from 0.3 microns, however, with a decrease in the thickness of the spraying, the heat reflectivity will deteriorate.

Foil vapor barrier for frame walls can have an aluminum foil base. In this case, the thickness of this layer will start from 10 microns, which will guarantee the maximum level of reflection. Such materials are susceptible to corrosion and therefore require additional protection. Experts advise to insulate the walls of rooms with high humidity using foil films on a polymer basis with aluminum spraying, since they do not corrode and are capable of undergoing high temperatures. They are durable, which greatly simplifies installation.

Kraft films can only be used in dry rooms, they cannot be used in bathrooms or kitchens. For underfloor heating, it is recommended to purchase a film with aluminum foil, which distributes heat, smoothing cold bridges if the pipes are not laid tightly enough.

Installation of a vapor barrier layer in a washing room

In order for the bath to work without problems for as long as possible, it will be necessary to provide a vapor barrier in the washing compartment. It also has excessive humidity, and the temperature readings are much lower, which is far from normal conditions.

Therefore, it is important to provide not only high-quality vapor barrier for the steam room, but also for the washing room. Although in this case, you can do without foil-based material. Diffusion membranes are ideal. They will not allow steam to penetrate into the insulation, and if the membrane from the inside is equipped with a hygroscopic layer, then the moisture in the insulation will be retained.

This suggests that if droplets are formed on the rough surface of the membrane, they are retained until they evaporate under the influence of air currents. For this to work, you need to leave a ventilation gap between the finish and the vapor barrier.

Make sure that the vapor barrier is fixed to the surfaces with the correct side - with the foil facing out. Otherwise, the material will collapse very quickly, and it will be necessary to completely replace it, otherwise it will be impossible to use the bath.

Advantages of foil vapor barriers

A metallized layer on a vapor barrier base significantly improves the properties of the barrier, and gives it tangible advantages over conventional films.

The produced assortments of reflective vapor barrier can be selected for any room based on the price-quality factor. It will equally have vapor barrier protective properties. And long-term operation in conditions of even excessive humidity (typical for a bath) will not lead to the formation of mold and mildew.

But, to get a fully functioning vapor barrier in a room is possible only taking into account its specifics, and most importantly, compliance with the installation rules.

Source: stylekrov.ru

Feasibility of installing a vapor barrier layer in other rooms

It is up to you to decide whether or not to install the vapor barrier in other rooms. In the same dressing room, after the bath procedures, the humidity level will definitely rise.If your bath is made of wood, and you do not plan to insulate it either from the outside or from the inside, then you do not need to lay such a layer of vapor barrier - drying will be carried out naturally, since the tree breathes and vapors will escape through it. But in this case, it does not hurt to install a normal ventilation system, otherwise problems may also arise over time.

But if your bath was built of foam blocks or bricks, then the vapor barrier must be installed inside the entire bath without fail. In addition, when designing a ventilation system, it should be borne in mind that it will be necessary to dry not only the layers of insulation and steam and gyro insulation, but also the walls, due to the fact that they are made of hygroscopic material.

Consequently, the vapor barrier layer is complemented by a layer of moisture-repellent material. There are two methods of insulating a brick bath, and both of them involve laying a foil material that will act as a vapor barrier and, at the same time, retain heat.

Why do you need foil vapor barrier ↑

As mentioned above, a vapor barrier layer with a metal aluminum coating is used in special cases and only in some types of buildings, why is it necessary?

1

Firstly, the most important function of a foil vapor barrier is the ability to keep structures from getting into them with excess moisture. But, unlike other films and membranes, analogs with an existing metallized coating still perform the work of a heat reflector. That is, foil layers of vapor barrier are primarily needed where it is worth increasing energy savings.

2Secondly, in such rooms as baths and saunas, the use of conventional films and membranes is impractical, since high temperatures will quickly render the protective layer unusable. And in conditions of high humidity, a protective layer is simply necessary.

Thirdly, the use of foil vapor barriers will be in demand in timber frame construction and the construction of houses from logs / beams. This will increase the energy efficiency of the building with excellent protection of the supporting structures from vaporous moisture.

Also, a good solution would be to use a vapor barrier with a layer of foil in the premises of summer cottages, outbuildings, balconies and attics, which are poorly or not heated at all. This will both protect the structures from condensation and reduce the overall heat loss of the room.

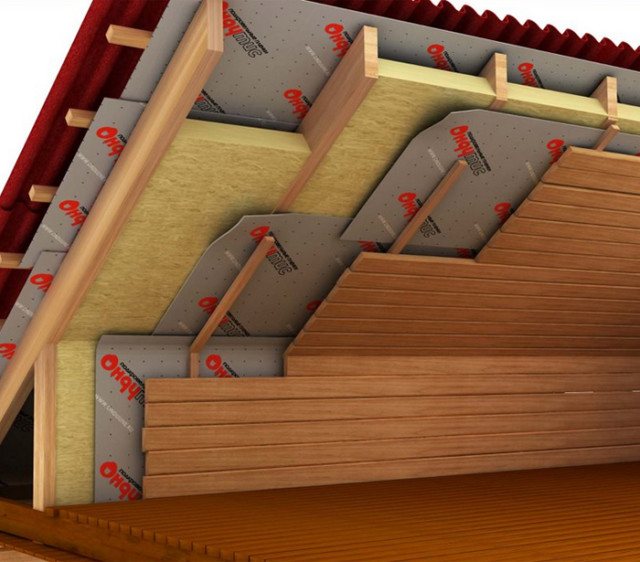

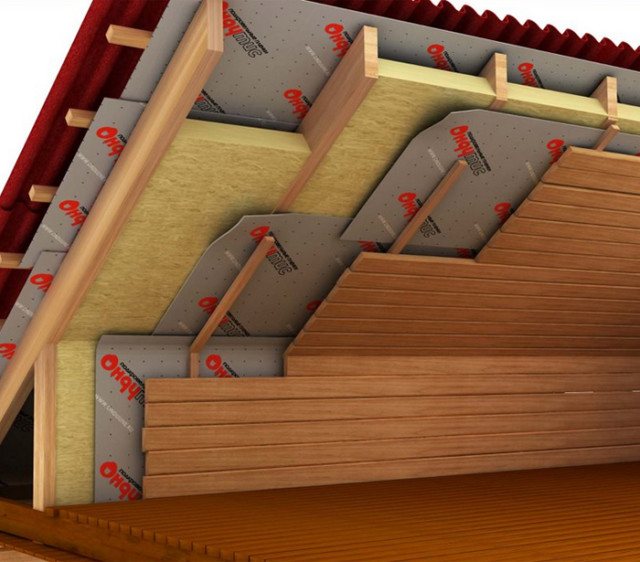

Laying a vapor barrier on the roof of a bath

To ensure normal vapor barrier in the bath, you need to install it not only on the walls and ceiling, but also on the roof. To do this, a vapor barrier membrane is laid out on a wooden frame in the attic, and a heater and waterproofing on top. And already on it, the installation of the counter-lattice is carried out with the subsequent fastening of the roofing material.

In the article above, we examined in detail how to make a vapor barrier in a bath. It is necessary to clearly understand how vapor barrier differs from waterproofing, to understand their characteristics, so that after the completion of all work, unforeseen nuances do not arise. If everything is done correctly, the finished bath will last a very long time.

Varieties of foil vapor barrier

Foil vapor barrier is offered for sale today in a wide range. In order for the material to fulfill its functions, it is important to make the right choice. It is necessary to pay attention to the fact that the polymers included in the composition of the substrate can have different structures. They are composed of polypropylene foam and polyethylene foam. For more impressive temperatures, the first option should be used, while the second is relevant for a less aggressive environment.

Foil vapor barrier for a bath is presented in the Penotherm version. In this case, we are talking about a material that includes expanded polypropylene foam. The material can be used in the temperature range from -40 to +150 ° С.The vapor barrier is characterized by a low-hazard class of toxicity and moderate flammability. When used, there is almost no thermal shrinkage.

If you want to equip a system of underfloor heating, then you should prefer NPPLE. This variety can also be used for a steam room. Foil vapor barrier "Izospan FB" is designed to form a vapor barrier in saunas and baths. The material can be used at fairly high temperatures. That is why the Izospan vapor barrier plus foil insulation is excellent for particularly difficult conditions.

How to properly insulate the ceiling in a bath?

Your own country house cannot do without a bath. It must be mandatory. Having decided on its construction, it is necessary to clarify all the nuances of ceiling insulation. Correctly executed thermal insulation will reliably retain heat, which will make it possible to save money on energy resources: coal, wood, gas, electricity.

The bulk of the owners of country houses prefer to build on their personal plot, the so-called Russian baths.

Such objects are erected from the following materials:

- solid and rounded logs;

- profiled timber and rectangular section;

- ordinary planed boards.

For the bath, coniferous wood is more often chosen. This is due to their pleasant smell and medicinal properties. The complete facility consists of three rooms: a dressing room, a steam room and a washroom.

The choice of thermal insulation

- Expanded polystyrene. In addition to the proper thermal insulation properties of this material, it has a high level of sound insulation. Plates are laid on the waterproofing end-to-end. To seal the joints, the gaps are filled with construction foam, and then glued with tape.

- Polyurethane foam. This material differs from expanded polystyrene in that it does not support combustion. The other characteristics are the same. Produced in panels and small blocks. Thanks to this, they can be laid in any hard-to-reach places.

- Foam concrete. When insulating the ceiling with this material, flat panels with a thickness of 30 mm are used. Foam concrete is all covered with pores. Thanks to this and the thin layer, the material has a low weight, but high thermal insulation qualities.

- Expanded clay. It is the best bulk thermal insulation material. It's so light it doesn't even sink in water. It is poured onto the outside of the wooden ceiling of the bathhouse and covered with foil.

Mineral wool

Mineral wool is classified into the following groups:

- Stone. Produced from molten rocks.

- Glass. It is based on fiberglass made using innovative technologies.

- Slag. Produced from blast furnace slag. Has astringent properties.

Foamed glass

This thermal insulation material is unique. It is made from glass and carbon. The main characteristics are the following:

- It does not absorb moisture as it is water-repellent.

- Does not burn.

- Differs in increased wear resistance and durability.

- Consistently high thermal insulation qualities are maintained throughout the entire period of operation.

- Foamed glass is resistant to mechanical stress and deformation. As a heater for ceilings, it is used on any objects. It is laid on any surface (wood, concrete, metal).

All of these materials are environmentally friendly and harmless to human health. They do not emit toxic and other harmful substances. They are ideal heat insulators for baths and other facilities.

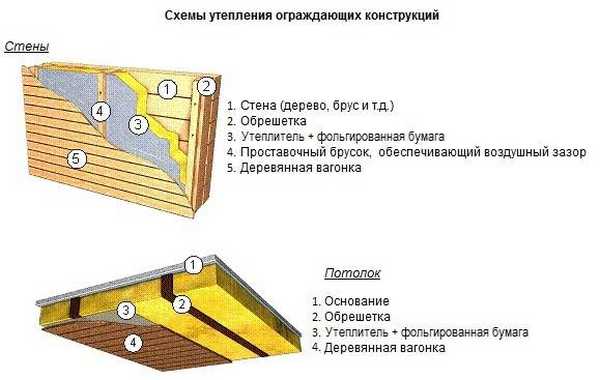

Reliable protection against heat leakage from the bath is created as follows:

- From below, the ceiling is covered with a vapor barrier material. For this, aluminum foil is used.

- On top of the vapor barrier, or rather, on the outside of the ceiling (in the attic), a thin layer of clay is laid, and a heater is placed on it.

- Mineral wool, expanded clay or other thermal insulation specified in the list can be used as thermal insulation material.

- A cement-sand screed is sometimes placed on top of the insulation, but this can not be done. This is an unnecessary expense of money.

What material for a bath, ceiling and thermal insulation is better, no one knows for sure. Each owner of the personal plot chooses the materials and type of construction based on their own preferences.

In total, there are three types of ceilings created in a Russian bath:

- Wall-mounted. They are made on objects no more than 2.5 meters wide.

- Hemmed. In this case, the width of the bath does not matter.

- Panel. In the construction of the ceiling, fiberboard or PVC panels are used here.

Today, many insulate the ceilings in their own baths on their own. This allows you to save a significant part of your money and keep yourself busy with interesting work.

General information about the material

Izospan is a polymer film that is a diffuser membrane. The characteristics differ depending on the species. The main function is to prevent the penetration of moisture from the outside or from the inside to the building materials. The membrane is in demand in rooms with high humidity or when insulating with vapor-permeable insulators. Izospan prevents:

- the appearance of rot and fungus on the ceiling beams;

- soaking of the insulation, which reduces its effectiveness;

- blocks the formation of condensation.

The material is distinguished by mechanical resistance and elasticity, which prolongs the service life and eliminates damage due to shrinkage or deformation. During operation, the film does not emit harmful substances, therefore, it complies with environmental standards. The polymer does not crack at subzero temperatures.

Varieties

The manufacturer divides Izospan into 4 categories:

The first option is used for external work. It is laid on the surface of walls and roofs. Izospan blocks the penetration of moisture inside, but lets it out. The effect is possible due to the structure of the canvas, the outer part of which is smooth. The second type is laid indoors. The vapor permeability coefficient is lower than that of membrane A. This is necessary to retain moisture inside and block it from settling on wooden and concrete floors.

Izospan B is used for ceilings and interfloor floors. The third version of waterproofing is laid on the floor. Its plus is an insulation layer that blocks freezing and reduces heat transfer. Izospan C is used in tandem with a heater for liquid or electric heating. Category D - adhesive tapes required for joining the seams of the mounted canvas.

Is it necessary to insulate and vapor barrier a bath?

Each owner of a steam room or anyone who is just going to acquire one has a natural question about whether heat and vapor insulation of this room is needed. Arguments against it can be the fact that not so much time is spent in the bath, as well as the fact that it is cheaper to carry out additional heating than to waterproof the bath and insulate it.

To specialists, such arguments will seem ridiculous. Any builder will say that the vapor barrier of the walls and ceiling in the steam room will save you time and resources spent on heating the room. In addition, these additional works will significantly increase the operating time of the bath, regardless of what materials it is built of.

It should be noted that the vapor barrier of the ceiling and walls cannot be carried out separately. In addition, vapor barrier implies that insulation will also be performed and vice versa - individually, these processes will not be effective.

Wall vapor barrier

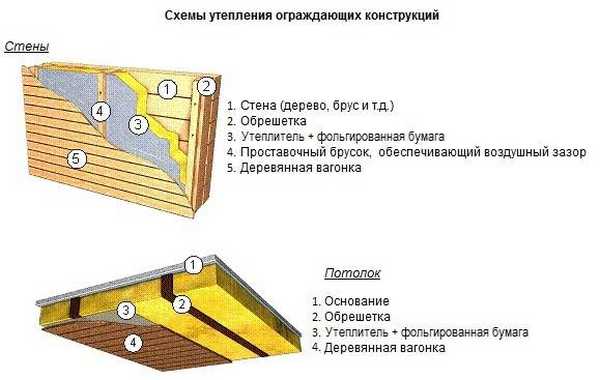

The scheme of vapor barrier of the steam room walls is practically no different from the "pie" on the ceiling.The whole difference is in the thickness of the thermal insulation layer (for the ceiling it is twice as large). It is also recommended to lay a foil film or membrane on the walls in the steam room (do not forget to ensure its "entry" to the ceiling and floor).

The vapor barrier must be glued at the joints with tape

It is also necessary to glue the places where the vapor barrier material joins with window or door openings, other structural elements - the less vapors penetrate under the film, the better the protection and longer service life of the bath will be without repairing and replacing insulation elements.

Bath vapor barrier: the sequence of laying materials for the ceiling and walls

Materials for hydrizolation

It is possible to prevent heat loss through the ceiling and walls of the steam room with the help of modern building materials, or with those materials that our ancestors used for the same purposes. The latter option is becoming more and more popular due to the desire of the population to use materials and technologies that are environmentally friendly and harmless to human health.

Our ancestors carried out the vapor barrier of the ceiling and walls using the following materials:

- red moss;

- cuckoo flax;

- flax fiber;

- tow.

Red moss and cuckoo flax were used to caulk the gaps between the individual ceiling elements. They have good thermal insulation properties and prevent mold and bacteria that cause decay. Linen and tow was used to upholster the ceiling.

Do-it-yourself bath ceiling waterproofing

It is quite easy to finish the walls and ceiling with vapor barrier, even without any experience in construction or repair. Therefore, everyone can carry out this operation.

This will require simple tools:

Sheet materials, such as film, paper, cardboard, are attached to the ceiling with a stapler or pressed with bars.

The lining or other finishing wood is fixed with dowels, having previously drilled holes in the walls and ceiling.

The clay is applied with a spatula directly onto wood or insulation. They are pre-primed to prevent mold and to improve adhesion to clay.

Advantages of foil vapor barrier

Foil is a material that creates a maximum barrier, preventing precipitation from entering the insulation material by 100%. It is she who is most often used to decorate the bath.

Many people use ordinary foil, but it is quite fragile, it can break through from the slightest pressure.

Manufacturers have taken care of eliminating this shortcoming. They created a two-layer material. It consists of a flexible and durable material and aluminum foil spraying. Such a tandem brings maximum benefit, reducing negative indicators to a minimum.

This type of vapor barrier material can retain over seventy percent of the thermal mass. It is easy to attach to the wall, any other surface. It is fixed on a wooden base with a stapler. For concrete and other surfaces, mounting tape is used. This film can be easily divided into the required elements. She tolerates very high temperatures well - more than plus one hundred degrees, low - below forty. Therefore, it is often used for a bath.

Vapor barrier for a bath on the ceiling

The construction of a bath in the houses and dachas of a modern person is not uncommon. If you took up the construction of such a building, it is likely that you will be faced with several tasks that will need to be solved. One of the pressing issues that are most often of interest to those who want to get a bath is a vapor barrier for a bath on the ceiling.

Such a room can be attributed to the number of buildings with special arrangement and rules of use.Among the essential properties of a bath is the ability not to let through, to retain heat in the room. This is an important condition for a bath, since it is the vapor barrier that will create the desired microclimate in the room. And also the ability to not let heat through will affect the durability of the structure. Provided that the vapor barrier is not done correctly, steam will leave the room, and moist heated air can deform the ceiling. Incorrectly made thermal insulation will lead to the fact that you will spend more time and fuel heating the bath, and as a result, the operation of the premises will become impossible. Therefore, insulation of the ceiling and vapor barrier of a bath are important aspects in the design and construction of such a room.

How to properly put a vapor barrier on the ceiling of a bath?

Next, we will consider the step-by-step process of laying the vapor barrier and get acquainted with the advice of experts on how to correctly put the vapor barrier on the ceiling of the bath. Previously, experts advise paying attention to the type of roof, namely the presence or absence of an attic. In the event that such a room has an attic or an attic, the ceiling will be much less permeable to wet steam, but this does not mean that you can not do vapor barrier at all. As a rule, the same materials are used to insulate the ceiling with the attic, but it is recommended to cover the boards from the side of the roof with clay.

Finding out which vapor barrier is the most effective for the ceiling of a bath is not so easy. We offer the most reliable methods.

Option 1

- The wooden ceiling is sheathed with wooden boards, the thickness of which is at least 5 cm. A vapor barrier made of foil or thick cardboard impregnated with linseed oil is laid on top of the boards.

- Then the ceiling is covered with clay, after which they begin to dry out thermal insulation.

- Next, we proceed to the installation of insulation. As a material for insulation, you can use mineral wool, expanded polypropylene, expanded clay, etc.

- Fasten the plank flooring on top of the insulation.

Option 2

- Grooved boards are hemmed to a square beam.

- The boards must be pre-treated with linseed oil in order to make the material water-resistant.

- On top of the ceiling beams, boards must be laid, between which the gaps must be processed.

- On top of the board, you need to glue it over with roofing material, foil or polyethylene.

One of the important steps before laying a vapor barrier on the ceiling in a bath is antiseptic prophylaxis. Processing wood materials will allow you to protect yourself from further problems. Choosing insulation, you can use special expensive materials, as well as natural improvised means - dry earth, clay.

Installation technology

An integrated approach to insulation, waterproofing and vapor barrier will provide effective protection against moisture and prevent heat loss.

The installation technology provides for the use of modern vapor barrier materials: film, foil and membrane.

Steam insulation of a bath and a sauna is carried out in several stages:

- Preparatory stage.

- Installation of waterproofing.

- Insulation laying.

- Installation of a vapor barrier.

- Decorative cladding of surfaces.

Ceiling

With excessive exposure to high temperatures and humidity, the ceiling surface first of all needs careful insulation and processing with protective vapor barrier materials.

The vapor barrier of the ceiling of the bath is performed in the following order:

- The log ceiling is preliminarily sheathed with boards 6 cm thick. A foil material of 100 microns or thick cardboard treated with linseed oil is fixed on top of the lathing.

- Next, a softened clay layer is laid out and a vapor barrier is laid.

- Insulating material is evenly applied to the vapor barrier layer. The ceiling of the bath can be insulated with mineral or basalt wool up to 5 cm thick.It is recommended to choose ecological wool or expanded clay filler as a seamless insulation.

- A waterproof membrane or wooden flooring is fixed to the insulation. This will prevent possible moisture penetration into the insulation layer.

Walls

What kind of vapor barrier to choose for installation on the walls in wet areas of the bath? As a rule, glassine, films on an aluminum and polyethylene base are used for this. These are the most affordable and inexpensive materials.

The vapor barrier of the walls of the bath is performed in the following order:

- A wooden lathing is installed on the supporting wall structures, the thickness of which is 2.5 cm greater than that of the heat-insulating layer.

- Insulation is mounted between the elements of the crate. For this, you can use mineral wool or glass wool.

- A vapor barrier is laid on the insulating layer. How should the material be laid to prevent heat loss and steam penetration? Installation is carried out from the far corner, the edges of the film are fixed with an overlap of 12 cm. For fixation, a stapler and metal staples are used, the joints are sealed with tape.

- It is important not to forget which side to lay the vapor barrier on. The foil heat-reflecting base of the film is directed towards the interior of the room, and the foamed base is directed towards the insulation.

- A wooden crate is mounted on the vapor barrier to create a technological gap for natural ventilation.

- A wooden lining is fixed on the crate.

How to make a floor vapor barrier? The installation technology depends on the design features of the bath. As a rule, the steam room is equipped with a wooden flooring equipped with a drain hole, which can lead to significant heat loss.

The correct solution to the problem is a multi-layer floor with waterproofing, insulation and vapor barrier.

Work on the vapor barrier of wooden flooring is carried out as follows:

- A thin layer of liquid waterproofing is applied to wooden boards.

- Basalt wool is mounted on top.

- A vapor barrier material that is resistant to decay is laid on the insulating layer.

- Next, a concrete screed of the base of the required thickness is carried out and a decorative floor covering is laid - porcelain stoneware or tiles.

- A wooden flooring is laid on the lined base for the convenience of using the steam room.

Roof

In some cases, it is not enough to perform only the vapor barrier of the wall and ceiling surfaces, in order to provide protection against high humidity, it is necessary to take care of the vapor barrier of the roof.

For this, a special insulating membrane is mounted in the attic in the wooden floor of the bathhouse, on top - an insulating layer, on it - waterproofing. A counter-lattice is installed on the waterproofing layer, to which the selected roofing material is fixed.

Other premises

Whether it is worth performing vapor barrier in other bath rooms, the owner of the building decides on his own. If the wooden bath is not insulated from the inside and outside, then the vapor barrier can be excluded - the drying of the interior will be carried out thanks to the natural ventilation of the wood.

Brick, block and concrete buildings require vapor barrier installation. In this case, not only the material for insulation is subject to drying, but also the entire structure of the bath - walls, floors and ceilings.

Therefore, when installing the vapor barrier layer, additional waterproofing of the surfaces is provided.

Do-it-yourself installation of vapor barrier materials is technically simple, but requires a responsible approach and attention. Only in this case reliable and effective protection of the steam room from the destructive effects of moisture and hot steam is ensured.