A sauna stove is a specific heating device that requires a special approach when purchasing. And if there is a problem of choice, then it is not at all necessary to look for a suitable model among foreign brands. Perhaps, few people in the world understand better than Russians in bathing matters. A typical example: "Troika" is a trademark of a Russian manufacturer who knows the traditions of Russian baths and takes into account the climatic features of the country, which is important for the effective and long-term operation of the device. There are many models from which you can choose an option that is suitable in design, performance and cost.

Stove Troika for a bath

The Troika stove for a bath is made of 10 mm thick low-alloy steel. Such products have long been used in Russian steam rooms, and their owners give only positive reviews about the devices. The devices have a simple design, but they have high power and energy efficiency. Therefore, they quickly create the required temperature in the steam room, and at the same time they are able to heat a considerable amount of water.

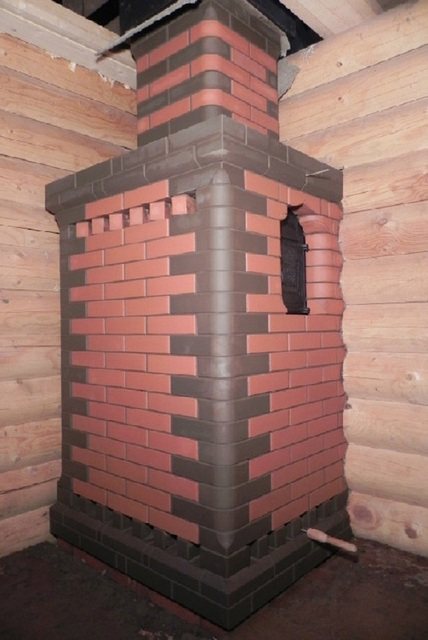

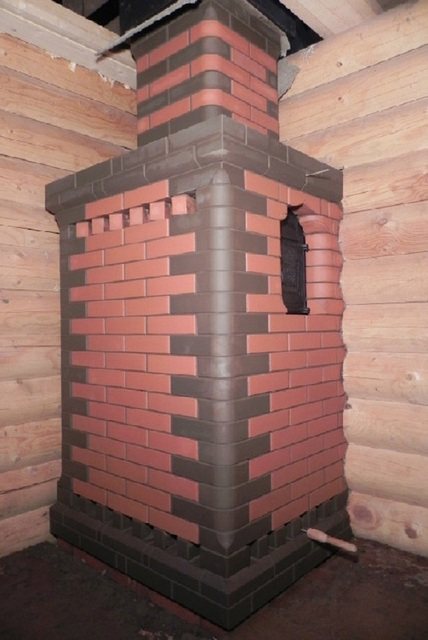

The manufacturer manufactures models intended for cladding them with brickwork, as well as for open use. Brick walls increase the heat capacity of the furnace, and as a result, increase the efficiency of their work.

You may be interested in detailed information on how the brick lining of the stove in the bath is performed.

Advantages and disadvantages of the Troika sauna stoves

Designers are constantly working on the modification of furnaces that are already in production, as well as developing new models with improved characteristics, based on the feedback and wishes of consumers. Therefore, the engineers managed to create heating devices that reproduce the microclimate of a classic Russian bath with "soulful" steam and a mild microclimate.

Furnaces with tunnel fireboxes will perfectly heat not only the steam room, but also the dressing room.

Installed at a permanent place of operation, the furnaces practically do not require preventive maintenance. It is enough to check and empty the ash drawer, and also to audit the chimney cleanliness once a season. As a rule, if high-quality hardwood firewood is used, then serious cleaning of the wound, more than five years later, will not be required. And the steel structure of the furnace itself is designed to operate for at least 15 years, but, as a rule, it will last much longer.

Perhaps you will be interested in information on how to make a chimney in a bath through the ceiling

The stoves are easy to install and operate. It is quite affordable to install the heater on your own, since it comes with detailed instructions supplied with photographic materials.

Models intended for subsequent cladding allow them to be used as a built-in firebox in brick ovens of various configurations.

The devices are quite economical in fuel consumption, but they keep heat well. So, if you heat the bath in the evening, then with good insulation it will be warm until morning.

A wide range of stoves from this manufacturer, as well as a range of prices for products that start from 30 thousand rubles, allow you to choose a suitable model even for a family with an average income. Not cheap, of course, but the purchase is made for a long-term use, and once in a lifetime it is quite possible to afford it.

The fire doors of Troika heaters can be glazed or made entirely of cast iron. The ovens provide for easy regulation of heated air convection.And to create high-quality steam, there is a special bowl with a channel for water to enter the lower zone of the heater. In this area, the heating temperature reaches 650 degrees. After passing through all the stone layers, light, crushed steam will enter the steam room.

In addition to wet steam, using Troika ovens in the steam room, you can create a Finnish sauna microclimate, for this you only need to correctly adjust the convection flows and exclude excessive moisture.

The advantages of furnaces can also be attributed to the possibility of filling it with a stone with a total weight of the bookmark from 100 to 250 kg. Due to such a large volume, devices are able to retain heat for a long time. Compared to the Troika ovens, analogues of other manufacturers have more modest volumes of stone filling capacity, which varies from 50 to 80 kg.

The heating temperature of the stones reaches 500 degrees. The Troika stoves use a specially developed and patented by the manufacturer process of heating stones in the stove from five sides at once. That is, all parts of the stove that separate the embedded stones from the fire have a maximum thermal load. At the same time, the manufacturer did not try to make this load more "sparing", since the task was to create devices that are capable of operating under extreme conditions without deformation and destruction. Therefore, even such a volume as 200 kg, heats up to high temperatures and obtains vaporization in just two hours.

The independent installation of the heating device can be complicated by its large weight, which can reach 330 kg - this factor can be attributed to the disadvantages of the product. However, all heating devices, including heating stoves, made of metal and having cast-iron elements in their design, have a rather large mass. Therefore, when installing the stove, in any case, one or more assistants will be required, depending on the weight of the selected model.

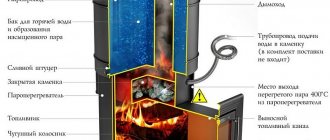

Some models are equipped with a heat exchanger, that is, the problem of a constant supply of hot water required for bath procedures is immediately solved.

For the manufacture of various designs of furnaces and their departments, low-alloy steel is used with a thickness of 10, 20, and for some parts - even 40 mm. Stainless steel with a thickness of 5, 8 and 10 mm will also be used. Such thicknesses provide a multiple margin of safety, which significantly increases the "longevity" of the device.

In all Troika furnaces, the principle of flame extraction is applied - this effect is achieved due to the correct ratio of the parameters of the holes for the passage of the flame, the diameter of the chimney and the shape of the combustion chamber.

If we talk about the aesthetic side, then almost all stoves have a presentable appearance. There is even a model with a Khokhloma painting applied to the facade. Some ovens are coated with heat-resistant enamel or lined with soapstone slabs.

Another important advantage of purchasing Troika ovens is the ability to ensure delivery and installation of the device by the company's specialists, who, if necessary, travel to any region of the country.

You may be interested in information on how a two-bell heating stove works

Positive and negative reviews

If you are interested in the Troika ovens, then you should read the reviews in more detail, from them you can understand that in winter these models melt for about 3 hours, in summer this time will be reduced. As buyers emphasize, a large amount of fuel for bathing procedures will not be required, while the heat during the operation of the device is retained in the room for about 10 hours. This equipment is inexpensive, but it does the job for two.

Users also note some disadvantages, among them a huge weight, which sometimes reaches 380 kg. This sometimes leads to difficulties during transportation and installation.Thus, in order to lift the unit, the strength of 4 people will be needed. Some owners of country houses and summer cottages also note that they do not really like the need to brick the front surface of the stove. But this is exactly what the manufacturer counted on when designing products. Finally, the walls are very thick, which entails a later release of heat. In this respect, these designs cannot be compared with the bare, thin-walled products that are common today.

What is the brick lining of the stove for?

Most of the models of bath stoves of the Troika trademark are intended for their subsequent facing with brickwork, as it is the best option for damp rooms.

In addition, brick is a natural material that does not emit toxic fumes when exposed to moisture and high temperatures. It is able to create a comfortable microclimate in the steam room, as it softens the harsh intense heat radiation coming from the heated metal walls of the stove, making it more comfortable for humans to perceive.

The stove for the Russian bath "Troika", faced with bricks.

So, the advantage of the brick lining of the furnace is that it allows you to:

- control convection air flows in the steam room, due to the presence of special doors and cavities in the masonry;

- to create a microclimate of a real Russian bath with long-term preservation of temperature and humidity, or an atmosphere of dry heat of the sauna;

- stop heating the air in the steam room, while continuing to heat the stove to keep the heat in the room for a longer time;

- quickly dry the steam room due to the high thermal inertia;

- extinguish the hard heat radiation coming from the hot metal walls;

- to make the operation of the stove safe for the steam room visitors;

- to equip a reliable and aesthetic structure that will decorate the bathhouse.

A few words must be said about the importance of control over convection air currents for a sauna room.

It is known that the Russian bath assumes not too high temperatures, amounting to 65 ÷ 75 degrees with a sufficiently high air humidity. Therefore, the most important factor for creating a microclimate for a Russian bath is the circulation of heated air in the steam room.

The brickwork covers the metal walls, while the convection openings are also closed, thus convection almost completely stops. At the same time, the movement of heated air is necessary to create a Finnish sauna microclimate, which, if desired, can be created by allowing hot air to enter the room.

Brick-faced stove - doors are provided in the walls of the masonry for access to the room for hot air.

If it is planned to create different microclimate options in the steam room, it means that special doors must be provided in the masonry to organize the flow of highly heated air into the room from the space formed between the metal and brick walls.

Video: Animated demonstration of the operating principle of the Troika sauna stoves

Reviews about ovens of the brand "Troika" for brickwork

The "Troika" stove for a bath, as mentioned above, can be designed to cover the front surface with a brick. Users choose such designs most often when comparing with other models of the manufacturer. They are presented for sale in 6 trim levels, one of them has a capacity of 20 kilowatts and weighs 210 kilograms. We are talking about model number 6M2. The permissible volume of a steam room for such equipment can vary from 8 to 16 cubic meters, while the dimensions of the device are 70x31x135 centimeters.Consumers like this model for the reason that its cost is low and amounts to 30.900 rubles.

The more serious model number 6 has a capacity of 35 kilowatts, its weight is 330 kilograms, and the allowable volume of the steam room can vary from 20 to 30 cubic meters. The cost of this model is average and amounts to 40,000 rubles. It is preferred by those users who do not want to purchase models at a higher price, while low-power options are not suitable for them.

The maximum power of this line is for model No. 5R. Its weight is 380 kilograms, the allowable volume of the steam room can vary from 30 to 40 cubic meters. According to users, the high cost is 68,500 rubles. fully justifies itself with quality characteristics and an attractive design.

Brief overview of Troika oven models

In order to better imagine what the Troika furnaces are, several models with different characteristics and designs will be demonstrated further. Manufacturer cost is shown for 2020.

Stove for Russian bath No. 06

Model No. 6 is considered one of the best Troika ovens. It is a steel body, which is lined with bricks.

The stove is intended for the steam room of a traditional Russian bath, and has a closed heater.

The product is equipped with a tunnel-type firebox, so the door should go into the steam room dressing room, which increases the safety of its operation.

The heater is able to create a microclimate in the room with soft steam, as close as possible to the atmosphere of a Russian bath with a traditional brick oven.

The heating time before carrying out water procedures is one and a half to two hours. In this model, there is no convection air flow in the heater, as it is of a closed type. Due to this, the stones maintain the heating temperature for a very long time, creating a light invisible steam.

This is how the stove for the bath "Troika" model No. 06 looks like before facing.

The chimney valve allows you to regulate the operation of the stove, setting the intensity of fuel combustion, and it can be controlled from the side of the dressing room. The combustion chamber has a great depth of 800 mm, so logs of 700 ÷ 750 mm long can be placed in it.

The stove in a real Russian bath always has a closed, unventilated stove with a large stone insert. Therefore, this model of the stove is equipped with a closed heater, designed for 200 or more kilograms of stone. Both the material of manufacture of the furnace and its design are selected so that it is able to withstand a mass of stones heated "red-hot" (and they are heated in the chamber to 500 degrees) without deforming.

In the manufacture of this model, steel 10 mm thick is used for the walls of the case, and 20 mm thick metal for the stove heated to extreme temperatures.

The stove, at the request of the consumer, can be equipped with a water tank with a volume of up to 100 liters, or a heat exchanger.

The heater can be fitted with an ordinary cast-iron door, or a fireplace-type door, that is, equipped with a heat-resistant glass.

The chimney diameter of 160 mm ensures normal draft irrespective of weather conditions and atmospheric pressure.

The oven comes with wheels for comfortable transportation of the device to the installation site.

The characteristics of the stove for bath No. 06 are presented in this table:

| Parameter name | Indicators and characteristics |

| Manufacturing material and its thickness, mm | Low alloy steel - 10 |

| Heat-receiving plate steel thickness, mm | 20 |

| Type of fuel | Firewood |

| The volume of the heated room, m³ | 20÷30 |

| Combustion chamber type | Closed, tunnel type |

| Heater type | Closed |

| The presence of cladding | Model for cladding |

| Water tank type | Remote |

| Steam cannon | there is |

| Cover material | Heat resistant enamel |

| Door material | Cast iron |

| Door opening type | Swing |

| Ash pan and grate | there is |

| Chimney diameter, mm | 160 |

| Furnace weight, kg | 330 |

| Stone bookmark weight, kg | 200 |

| Device power, kW | 35 |

| Linear parameters, mm (depth, width, height) | 800×420 ×1250 |

| Log length, mm | Up to 750 |

| Model cost, rub. | About 62 thousand |

| Warranty period, years | 3 |

Prices for a stove for a bath Troika 06

sauna stove Troika 06

Sauna stove No. 6 PM1

Unfortunately, it is not always possible to erect a brick cladding around a metal furnace. Therefore, the engineers of the manufacturing company have developed and launched into a series a new model of the furnace, capable of creating the desired microclimate without external brick cladding. This is how the model №06 PM1 was created, equipped with a convention control and making it possible to control the air flows in the steam room. The casing of the device is equipped in such a way that it allows to control the heating temperature of its outer walls.

Furnace No. 06РМ1 with convection control

Moving the valve makes it possible to control convection flows by directing and setting the speed of air movement. Thus, at will, creating intensive heating of the steam room or stones. This technology makes this oven model unique.

Furnace No. 06РМ1 is manufactured in two versions: from stainless steel with a thickness of 5 and 10 mm, or boiler steel, having a thickness of 10 and 20 mm, which, of course, affects the cost of the device. This enables buyers to choose an affordable model.

The body of the stove heats up quickly, accordingly heats the steam room and stones, creating a microclimate of a real Russian bath, commensurate with the capabilities of a brick oven. The absence of convection flows directly into the heaters of the stove makes it possible to warm up the stones up to 500 degrees, so the steam emanating from them turns out to be light and invisible.

If desired, you can choose an option with a heat exchanger and a water tank made of stainless steel with a volume of 72 ÷ 100 liters.

As in the previous model, the stove can be equipped with a solid cast-iron door or its panoramic glazed version.

The combustion chamber has a total depth of 700 mm, which allows the use of logs 600 ÷ 650 mm long.

The model is also equipped with wheels for easy transportation of the device to the installation site.

The characteristics of the stove for the bath No. 06RM1 with the control of the convention are presented in this table:

| Parameter name | Indicators and characteristics |

| Manufacturing material and its thickness, mm | Low alloy steel - 10 |

| Heat-receiving plate steel thickness, mm | 20 |

| Type of fuel | Firewood |

| The volume of the heated room, m³ | 12÷20 |

| Combustion chamber type | Closed, tunnel type |

| Furnace tunnel length | 160 mm |

| Heater type | Closed |

| The presence of cladding | Not required |

| Water tank type | Remote |

| Steam cannon | there is |

| Cover material | Heat resistant enamel |

| Door material | Cast iron |

| Door opening type | Swing |

| Ash pan and grate | there is |

| Chimney diameter, mm | 160 |

| Furnace weight, kg | 290 |

| Stone bookmark weight, kg | 140 |

| Device power, kW | 27 |

| Linear parameters, mm (depth, width, height) | 800 × 530 × 1300 (1450 mm with spigot) |

| Log length, mm | Up to 650 |

| Model cost, rub. | 55 to 65 thousand |

| Warranty period, years | 3 |

Sauna stove for Russian bath No. 06 with removable heater

This stove model has all the qualities described above inherent in Troika products. However, this option has some differences.

Stove for Russian bath No. 06 with removable heater

Model no. 06 with removable heater is intended for cladding with brickwork. It also ensures the creation in the steam room of the classic microclimate of a Russian bath with soft light steam. The stove is equipped with a tunnel-type firebox, which allows the laying of firewood from the dressing room. The heater is heated up for one and a half to two hours.

The firebox is 800 mm deep and allows the use of logs up to 750 mm long.

A distinctive feature of this model is the removable heater.

The characteristics of the stove for the Russian bath No. 06 with a removable stove are presented in the table:

| Parameter name | Indicators and characteristics |

| Manufacturing material and its thickness, mm | Low alloy steel - 10 |

| Heat-receiving plate steel thickness, mm | 20 |

| Type of fuel | Firewood |

| The volume of the heated room, m³ | 20÷30 |

| Combustion chamber type | Closed, tunnel type |

| Furnace tunnel length | 200 mm |

| Heater type | Closed |

| The presence of cladding | Brick cladding model |

| Water tank type | Remote |

| Steam cannon | there is |

| Cover material | Heat resistant enamel |

| Door material | Cast iron |

| Door opening type | Swing |

| Ash pan and grate | there is |

| Chimney diameter, mm | 160 |

| Furnace weight, kg | 330 |

| Stone bookmark weight, kg | 200 |

| Device power, kW | 35 |

| Linear parameters, mm (depth, width, height) | 800×420 ×1250 |

| Log length, mm | 750 |

| Model cost, rub. | About 78 thousand |

| Warranty period, years | 3 |

Sauna stove No. 02R "Khokhloma"

This model of the Troika stove is equipped with an unusual facade decor, made in the tradition of Khokhloma painting, which clearly emphasizes the purpose of the device for installation in a Russian bath.

Stove for Russian bath No. 02R "Khokhloma"

The relief is laser cut into a massive steel sheet, and then the indentations are filled with a bright red color, which makes the design stand out. The color chosen goes well with traditional brickwork. The upper edge of the front panel has a shape reminiscent of a Russian kokoshnik, which also supports the stylistic direction of the panel's design.

Perhaps you will be interested in information on how a brick oven is being built for a summer residence.

The stove is designed for facing with bricks, after which the facade will acquire a decent frame.

The characteristic features of the functioning of this furnace model are similar to those described above.

The main characteristics of the sauna stove No. 02P:

| Parameter name | Indicators and characteristics |

| Manufacturing material and its thickness, mm | Low alloy steel - 10 |

| Heat-receiving plate steel thickness, mm | 20 |

| Type of fuel | Firewood |

| The volume of the heated room, m³ | 12÷20 |

| Combustion chamber type | Closed, tunnel type |

| Furnace tunnel length | 200 mm |

| Heater type | Closed |

| The presence of cladding | Brick cladding model |

| Water tank type | Remote |

| Steam cannon | there is |

| Cover material | Heat resistant enamel |

| Door material | Cast iron |

| Door opening type | Swing |

| Ash pan and grate | there is |

| Chimney diameter, mm | 160 |

| Furnace weight, kg | 310 |

| Stone bookmark weight, kg | 150 |

| Device power, kW | 27 |

| Linear parameters, mm (depth, width, height) | 700×420 ×1450 |

| Log length, mm | Up to 650 |

| Model cost, rub. | About 82 thousand |

| Warranty period, years | 3 |

Video: Installation of the Troika Khokhloma sauna stove

Stove for Russian bath No. 01R "Bochka"

Sauna stove "Troika" No. 01R "Bochka" is one of the best options, of those that do not require brick lining. The stones placed in the grate fixed around the stove are able to well soften the harsh heat radiation that the metal walls give. The stove is able to create a comfortable microclimate of a Russian bath in the room, and then perfectly dry the steam room after carrying out water procedures.

The design has a high heat capacity, heats up quickly and well. And this is despite the fact that its mass together with stones is almost 400 kg. Therefore, when heated, the stones give off heat to the room for a long time.

Stove for Russian bath No. 01R "Bochka"

The device has an original appearance. A lattice is fixed around the furnace body, imitating a barrel in shape, tightened with forged hoops having the structure of the surface of aged iron. The vertical details of this lattice are coated with a wooden textured pattern. The vertical lamellas are connected to the hoops by means of hand-set rivets.

A massive cast iron plate is installed in the front part of the stove, which serves as a fireplace portal. The door is equipped with a fairly large panoramic glazing.

The stove is built into the wall separating the steam room and the dressing room, in which a relaxation room can be organized. From the side of the dressing room, the stove portal will look like a real fireplace, near which you can have a great time with a cup of tea, leaving the steam room. In the steam room there will be a stove body with a grate-stove, which will give a special flavor to the room.

The metal used to make the oven and grate, as well as the fasteners of the parts, are able to withstand high temperatures and loads without damage or deformation.

The device can be equipped with a water tank with a volume of up to 100 liters, or a heat exchanger for hot water

The main characteristics of the sauna stove No. 01R "Bochka":

| Parameter name | Indicators and characteristics |

| Manufacturing material and its thickness, mm | Low alloy steel - 10 |

| Heat-receiving plate steel thickness, mm | 20 |

| Type of fuel | Firewood |

| The volume of the heated room, m³ | 20÷30 |

| Combustion chamber type | Closed, tunnel type |

| Furnace tunnel length | 200 mm |

| Heater type | Grid |

| The presence of cladding | Not required |

| Water tank type | Remote |

| Steam cannon | there is |

| Cover material | Heat resistant enamel |

| Door material | Cast iron |

| Door opening type | Swing |

| Ash pan and grate | there is |

| Chimney diameter, mm | 160 |

| Furnace weight, kg | 220 |

| Stone bookmark weight, kg | 120 |

| Device power, kW | 20 |

| Linear parameters, mm (depth, width, height) | 620×750 ×1100 |

| Log length, mm | 750÷770 |

| Model cost, rub. | About 95 thousand |

| Warranty period, years | 3 |

Furnace No. 04 in soapstone cladding

Stove No. 04, designed for a Russian bath, belongs to the premium class appliances. It does not require brick cladding, since slabs made of soapstone are fixed on the outer surface of the metal walls.

Talcochlorite is a rock of metamorphic origin and consists of 40-50% magnesite, 40-50% talc, and 5-8% chlorite. The proportions shown are inconsistent and may vary. After processing, this natural material has an attractive appearance, but the main thing is that it is excellent for lining furnaces, as it has excellent heat capacity. In addition, the stone is durable, neutral for allergy sufferers and does not require any special maintenance. Soapstone boulders are very widely used precisely for filling sauna stoves.

Furnace No. 04 in soapstone cladding

The manufacturer presents on the market several models with soapstone cladding, but differing in their design. Therefore, if you wish, you can choose the option that is more suitable in terms of characteristics and cost.

The characteristics of the furnace No. 04 of this model line are as follows:

| Parameter name | Indicators and characteristics |

| Manufacturing material and its thickness, mm | Low alloy steel - 8 |

| Heat-receiving plate steel thickness, mm | 20 |

| Type of fuel | Firewood |

| The volume of the heated room, m³ | 10÷20 |

| Combustion chamber type | Closed, tunnel type |

| Furnace tunnel length | 200 mm |

| Heater type | Closed |

| The presence of cladding | Talcochlorite boards, 40 mm thick |

| Water tank type | Remote |

| Steam cannon | there is |

| Cover material | Heat resistant enamel |

| Door material | Cast iron |

| Door opening type | Swing |

| Ash pan and grate | there is |

| Chimney diameter, mm | 160 |

| Furnace weight, kg | 360 |

| weight of a stone bookmark, kg | 120 |

| Device power, kW | 20 |

| Linear parameters, mm (depth, width, height) | 800×700 ×1250 |

| Log length, mm | 750÷770 |

| Model cost, rub. | About 130 thousand |

| Warranty period, years | 3 |

Prices for a stove for a bath Troika 04

sauna stove Troika 04

Sauna stove No. 05r-GT60 for gas operation

Stoves that use natural gas as fuel are great for baths installed directly in the house. The devices are unpretentious in maintenance and have several degrees of protection:

- with pressure drops in the gas line;

- in the absence of draft in the chimney;

- in case of voltage surges in the electrical network.

The furnace is equipped with an automatic system that allows you to maintain the required temperature for the required length of time. To do this, it is enough to set the required parameter once by setting it on the control panel, and when the oven is turned on, the temperature will be very stable both in the steam room and in the heater.

You may be interested in information about what long-burning wood-burning stoves are for heating a house.

In addition to individual operation, gas models of stoves are perfect for installation in commercial baths.

Stove for Russian bath No. 05r-GT60 with gas burner

Such a stove can be set in "standby mode", in which it will be heated up to 50 ÷ 60 degrees, that is, keep the steam room warm. Well, it is possible to achieve the required temperature directly for taking bath procedures in a very short time.

Simple control of the burner allows even a person far from electronics to cope with this task. Turning on and off the gas supply is carried out with one button, while the temperature can be adjusted by turning a special knob.

The stove has a significant power, which allows heating large baths in a short time.

The presented furnace 05R-GT60 is equipped with two heaters, which have different heating technology. Thanks to this, it is possible to operate the device around the clock, while obtaining a stable steam quality. For this, the required burner temperature is set in the automatic system, and the heaters can be used alternately.

Model 05R-GT60 is designed for facing with brick, which will increase the efficiency of the furnace and soften the heat emanating from the metal, and create a comfortable atmosphere of a Russian bath in the steam room.

As in other Troika models, the 05R-GT60 package includes wheels for easy transportation of the product to the installation site.

The characteristics of the furnace No. 05r-GT60 on gas are as follows:

| Parameter name | Indicators and characteristics |

| Manufacturing material and its thickness, mm | Low alloy steel - 10 |

| Heat-receiving plate steel thickness, mm | 20 |

| Type of fuel | Gas |

| The volume of the heated room, m³ | 30÷50 |

| Combustion chamber type | Closed, tunnel type |

| Furnace tunnel length | 200 mm |

| Heater type | Closed |

| The presence of cladding | Brick-faced oven |

| Water tank type | Remote |

| Steam cannon | there is |

| Cover material | Heat resistant enamel |

| Chimney diameter, mm | 160 |

| Furnace mass, kg | 390 |

| Stone bookmark weight, kg | 280 |

| Device power, kW | 56 |

| Linear parameters, mm (depth, width, height) | 800×420 ×1800 |

| Model cost, rub. | About 120 thousand |

| Warranty period, years | 3 |

* * * * * * *

In addition to the above lines of stoves for Russian baths, it also produces other models - heating devices for saunas and "ofuro". The brand's assortment includes coal-fired stoves, models designed for outdoor barbecues, special devices for burning paper documents, as well as heating boilers of the Suvorov line.

Therefore, when deciding which stove to choose for a bathhouse or at home, it is quite possible to opt for this particular product, which has won the trust of consumers due to the high quality and reliability of the products offered. We also recommend reading about the rating of sauna stoves, perhaps you will like something from this rating.

Open-type stoves

Models with an open stove are something in between devices for a Russian bath and a sauna. The mass of such models (unlike sauna stoves), as well as their strength, is large, but the heater is no longer ventilated. Due to the lack of convection, air does not pass through the stones, which means that they get warmer.

Important information! Models with an open heater take longer to warm up the steam room, but they have a higher heat capacity.And if we compare them with stoves for a Russian bath, then they are significantly inferior both in terms of the volume of loaded stones and in temperature.

Conclusion: "Troika" with an open stove is the best option for those who want to buy a high-quality model capable of providing good steam, but extremely easy to install. The line is represented by five models, for convenience, their main characteristics are given in the form of a table.

Table 2. Comparative characteristics of models with an open heater

| Name | power, kWt | Weight, kg | Loading stones weight, kg | Allowable steam room volume, m³ | Dimensions (WxDxH), cm | Cost, rub. |

| Model No. 1 (complete with a water tank) | 20 | 130 | 120 | 10-18 | 62x60x110 | 20 380 |

| Model No. 7 (equipped with a stone net) | 18 | 75 | 160 | 10-18 | 45x70x110 | 16 200 |

| Model No. 2 (complete with a tank) | 20 | 130 | 100 | 10-18 | 90x40x90 | 20 970 |

| Model No. 5 (complete with a tank) | 20 | 150 | 120 | 10-18 | 90x60x110 | 21 100 |

| Model No. 8 (no heat exchanger and no tank) | 20 | 150 | 120 | 16-24 | 90x40x110 | 18 100 |

APPENDIX: How to choose a sauna stove by power

It would seem that everything is simple. Manufacturers of sauna stoves always indicate how much steam room a particular model is intended for. Well, the volume itself is also calculated without any special problems - by multiplying the length, width and height of the room.

And it is recommended to select the oven so that the calculated volume falls approximately in the middle of the range indicated by the manufacturer.

But there are some nuances that are still recommended to be taken into account. The volume of a fully heated room indicated by the manufacturer can still be called "reference". In other words, this is an “ideal” steam room, in which there is practically no heat loss. In fact, it happens a little differently, that is, not all baths correspond to such an "ideal".

It's okay - you can calculate such a "virtual volume" in which all the nuances of the steam room design will be taken into account. A special online calculator will help with this.

Below will be given a few explanations on how to work with the application.

Calculator for determining the required power of the sauna stove

Go to calculations

Explanations for making calculations

The calculation is not difficult:

- To begin with, enter the dimensions of the steam room in the appropriate fields.

- The next step is to evaluate the walls. Very often, during the construction of a bath, the walls are fully insulated, including thermal insulation with a reflective foil layer. And only after that they are sheathed with a natural board (clapboard). This state of affairs can be taken as a standard. But when building a bathhouse in a log house from a log or a bar, they sometimes skimp on insulation, leaving the wooden walls as they are, without any further finishing at all. And in order to warm up such an array of wood, additional power is required.

- Further, the installation principle of the oven is taken into account. If it is completely located in the steam room, all the heat remains here. When the firebox is brought out into the dressing room, the generated heat is partially consumed outside. That is, it makes sense to make a small correction.

- There can be doors by heat leakage from the steam room. It is one thing when the door leaf is very accurately fitted to the opening and has internal thermal insulation, and it is another thing if the door is a simple board-type shield, or, as it became fashionable not so long ago, it is completely glass. The program will make adjustments to this circumstance as well.

- There may be a window in the steam room. If it is, and this is indicated in the calculator, then two additional data entry fields will appear, in which you should indicate the type of window and its area (if there are several windows, the total area).

- Finally, in the “perfect steam room”, all surfaces are finished with wood. In fact, there is something else - areas, moreover, quite significant in area, lined with ceramic tiles or stone. And in view of the very high heat capacity of these materials, a corresponding amendment can be provided. An additional data entry field will appear, in which you should indicate the total area of such tiled areas.

You may be interested in information on how to properly knead the mortar for lining the oven with tiles.

The result will show the very "virtual volume" of the steam room, which is recommended to be guided by when choosing the optimal model of the sauna stove. Read the warm film floor under linoleum in our article.

Features of operation

You should start with the transportation and installation of the stoves, because everything here is not as good as we would like. The weight of the Troikas is quite large (from 120 kg to 390 kg), so it is difficult to install them. Otherwise, the installation procedure is the same as for other metal furnaces.

The installation process is regulated by SNiP 41-01-2003.

SNiP 41-01-2003. Download file

SNiP 41-01-2003 (Heating, ventilation and air conditioning)

Also, the basic installation requirements can be found in the document below.

Installation requirements. Download file

Installation Requirements

Considering the brick lining, the Troika oven needs a separate foundation. However, there is also a positive point: there will be no need to worry that thieves will steal a heavy 300-kilogram stove.

Prices for Troika ovens

oven Troika

Video - Stove "Troika", model no. 05

Correcting design flaws

The size of the firebox is 370x410x500 (width / height / depth). The area of the canal is no less than a large side of a brick. The chamotte reaches right to the very grates of the chamber in stones. It will not hurt to raise more grates of stones - you will get closer to the zone of the highest flame temperature. You can put a wall in the stone chamber, you can add another partition between the new and old chamber walls. You will get two channels, half a brick each. As a result, the partition will strengthen the new wall and prevent it from collapsing under the pressure of stones. you can just throw bricks without mortar and try.

The new partition will be T-shaped. When viewed from above from the side of the blower door, it is an inverted T that has been rotated 90 degrees counterclockwise. The middle stick will rest against the middle of the wall above the existing pass. The fire passes through the stones through the newly built wall, and through the two resulting channels it descends to the existing chimney.

Another simple solution: reduce the volume of stones, but increase their heating area. You will need welding, a cutting machine and a little more iron. You need to take out the sheet, cut a hole in the middle and weld a basin on top. It should turn out to be something like an inverted metal basin. At the bottom, you can still weld on strips for greater heat susceptibility. As a result, it turns out that the hottest gases will always be in this cap, and not just lick the metal and be eliminated further. The heating area will also increase and the temperature of the stones will become much higher. The volume of stones will actually decrease, but it will look like there are many of them.

Advantages of household solid fuel boilers

Solid fuel boilers for heating houses and other premises remain a popular source of heat energy generation, since they are one of the most economical heat sources. Modern household solid fuel boilers have become much more perfect than their predecessors of the last century. They are designed to obtain thermal energy from the combustion of organic solid fuel. Solid fuel boilers can be partially or completely autonomous sources of thermal energy and their operation may not depend on external energy suppliers.

Our boilers operate on one fuel load for a rather long time in a wide range of generated capacities (power adjustment up to 35 times) and operate in automatic mode maintaining the specified power. Automatically stop generating thermal energy in emergency situations.They minimize heat loss with flue gases, by narrowing the range of its variation, and also minimized the growth of deposits in the furnace and on the heat exchange surfaces, thanks to the lining of the corresponding surfaces, which increases the frequency of boiler maintenance and its service life, and increases efficiency. Equipping boilers with a DHW circuit, the possibility of electronic control of the thermal power of a solid fuel boiler brings its functionality closer to gas boilers. Therefore, when choosing a boiler for a private house, it is necessary to assess not only the operating costs, but also the primary costs of equipping the heating system. Although the operating costs of a gas boiler are slightly less than a wood-fired boiler, if we take into account the primary costs of equipping the heating system with a gas and solid fuel boiler, then a solid fuel boiler will be more profitable even with a long service life of the heating system. Moreover, the rate of growth in gas prices significantly exceeds the growth in prices for firewood in many regions of the country. And the safety requirements for gas boiler equipment are higher than with a solid fuel boiler. Therefore, a solid fuel boiler for heating a private house is a relatively inexpensive, safe and effective way to heat any living space, independent of external energy suppliers.

Place an order on the website or call us to get a free expert consultation on any questions.

Boilers "Suvorov-M".

The Suvorov-M series boilers use the same innovative solutions as the Suvorov Eco boilers:

- high-precision input air control system;

- flue gas temperature control system;

- nitrogen selection system.

But in addition to them, a more perfect supply of secondary air has been made, which allows more complete combustion of the pyrolysis gases, liquid and solid fractions formed during the decomposition of wood. To increase the furnace core and increase the temperature in it, which is necessary for a more complete combustion of the indicated fractions, the walls of the furnace are lined with fire-resistant silica plates. In boilers of this series, a change in the ratio of primary and secondary air is implemented depending on the generated power, which provides an additional reduction in heat losses and, as a result, an increase in efficiency.

In general, due to some complication of the design in the Suvorov-M boilers, it was possible to achieve higher technical and operational characteristics, which are at the level of known analogues or surpass them.