It is they that allow, in a very short period of time, to raise the temperature in the room by several degrees at once.

However, as a result of exploitation, as they say in full, sooner or later a moment comes when the duychik stops working. What to do in this case? Run to the store for a new Scarlet, Saturn or Comfort model and hope that they will be much more reliable?

Because they are not very expensive. However, it is not at all necessary to buy another fan heater if you can repair an existing one with your own hands.

In order to find the cause of the breakdown, you only need 2 things - a screwdriver and a multimeter.

The most important thing is to determine whether there is a contact in a particular circuit or not. Let's take a closer look at how the fan heaters are arranged, how to disassemble them, what most often fails, and trace the sequential chain of checking one element after another.

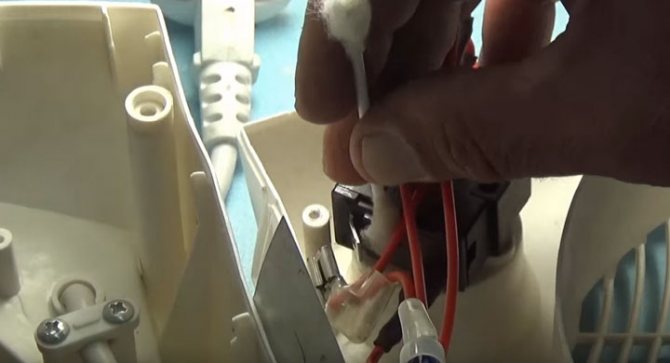

Power cord and poor contact

The first thing to do is to ring and check the integrity of the power cord and all visible contacts. Maybe you will not have to climb far into the insides of the device at all, but the trouble will be on the "surface".

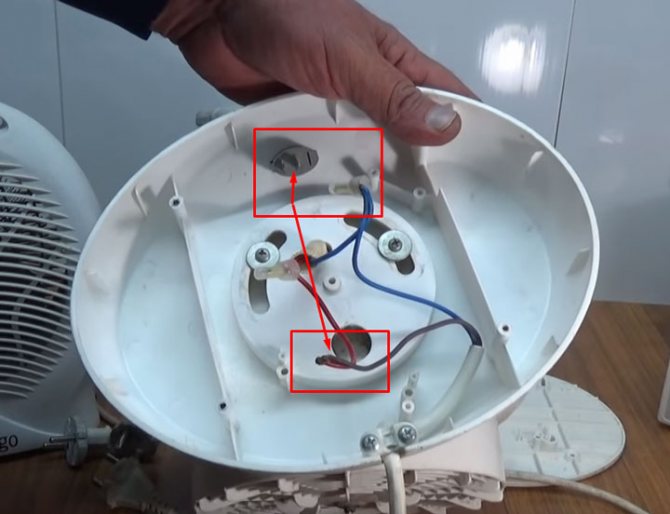

To do this, unscrew and remove the bottom or side cover, depending on your model.

Keep in mind that you should not unscrew the central screws initially, since a motor is attached to them.

Take them away and all the insides will fall apart. It will be better to have the engine itself sitting fixed to one of the covers.

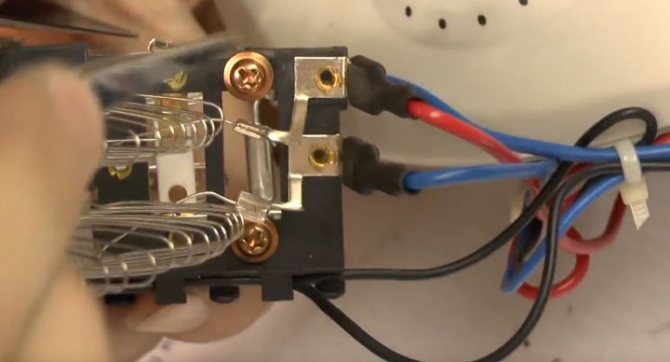

Next, find the contacts where the 220v power wires come. If you're lucky, sometimes without any devices you can immediately see burnt-out wiring.

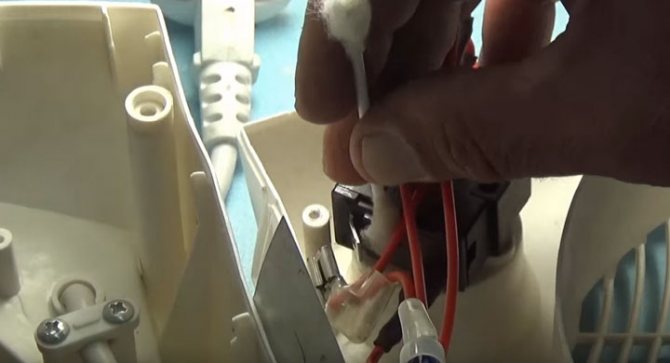

Put him back in place and all the repairs are over. If the problem is more serious, then just feel and pull all the terminal clamps.

Since the fan vibrates during operation, it is quite possible that some of them have simply moved away from their place. Bad contact on the terminal block can also be detected by the characteristic traces of burning.

Often such defects cause the fan heater to turn on and off spontaneously. Especially when you wiggle it and move it.

If you find this, clean and then wipe the pad with a cotton swab dipped in alcohol.

Next, use pliers to slightly squeeze the terminal and put it back on.

Only after all these manipulations, you can proceed to checking with measuring devices.

Switch the tester to the dialing mode, and with the probes, one by one, check the integrity of the power wires. To do this, touch the input contacts inside the fan and the metal pins on the plug.

If everything is OK, the tester will beep or show zero resistance.

If something works for you when you turn on the network, for example, a fan is spinning, but the air is cold, then the cord, of course, has nothing to do with it. In this case, its check can be omitted.

In the same way, a microswitch is called, which is sometimes built into the housing.

Switch its key and check that there is a chain.

These things very often fail at high currents. The repair in this case is quite simple. Two wires suitable for it are bite out and connected directly to each other.

The junction is insulated with a protective PPE cap or simple electrical tape.

The only negative - from now on, the fan heater will work immediately after you plugged the plug into the outlet.

When the switch has nothing to do with it, check the following circuit elements. By the way, don't forget about the mechanical part.

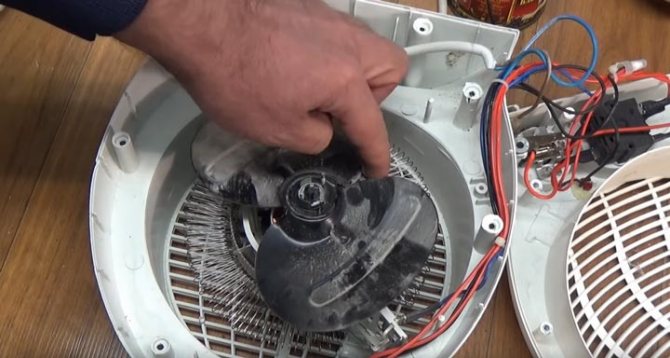

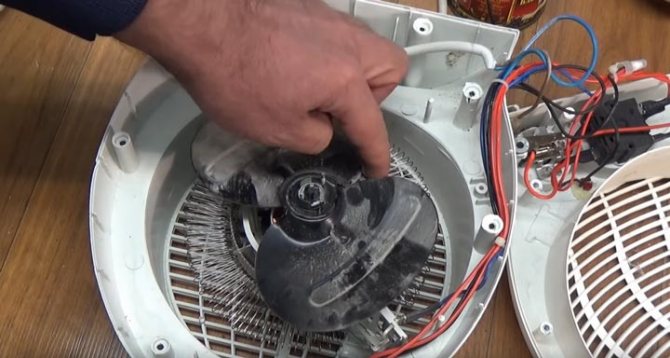

Immediately after opening the case, try to rotate the blades with your hand. They should rotate freely.

Here you need to make sure that nothing is sticking and there are no foreign objects stuck on the shaft.

https://youtu.be/D6UYxhdml9w

DIY water heater

Some craftsmen make low-power water heaters on their own. The main difficulty in assembly a self-made device becomes the manufacture of a coil (heat exchanger).

It uses a copper tube with a diameter not less than ½ inch... It is filled with sand and bent in the required configuration.

However, there is also easier way - a car radiator can become a heat exchanger. To it is added a 220 V duct fan, fixed on vibration damping springs.

All details are collected in the case, made of stainless steel, and flanged connections, the device is connected to the heating system.

Switches and thermostat

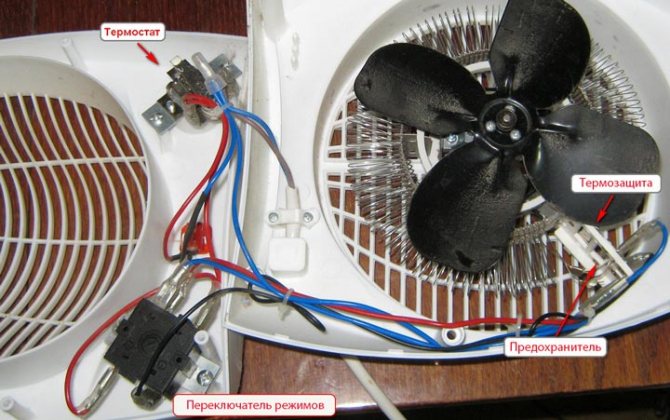

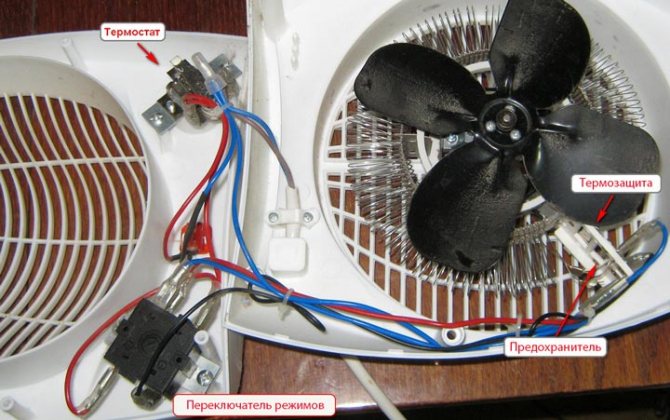

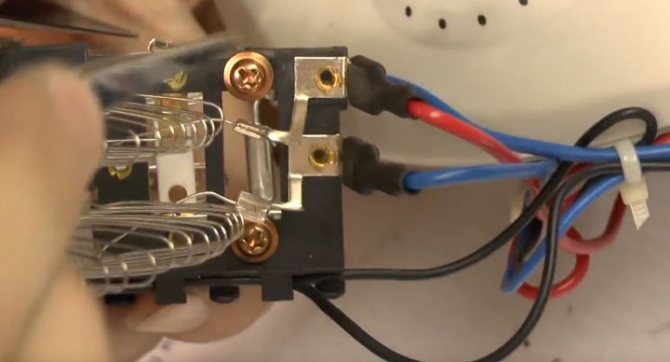

What other electrical components in the circuit can fail? Immediately after the power wires, there is a thermostat and a mode switch.

Outside the case, these are the "handles - wheels" familiar to everyone.

Some people mistake a thermostat for an element that regulates the speed of rotation of the blades. In fact, this is a bimetallic plate, and one of the power wires from the plug comes to it.

When twisting this handle, a barely audible clinking should be heard. This means the thermostat turns on and off. If there is no separate microswitch in the circuit, then it also performs its function.

But his main task lies elsewhere. When the ten and the heater body reach a certain temperature (which you yourself set by turning the knob), the bimetallic plate inside the thermostat bends and snaps off its contacts - the fan turns off completely.

The serviceability of this element is also checked with a multimeter. Bring two probes to the contacts and twist the handle. In the ringing mode, the sound will appear and disappear.

The mode switch is checked in the same way. By turning its knob, you turn on one ten, two, or simply put the duychik in fan mode without heating.

Only when you remove the terminals for dialing, it is better to take a picture in advance of their initial connection to a smartphone, so as not to confuse the contacts later.

The currents in these elements are not weak - about 10A. Therefore, the loss of the chain in them is not so rare. True, the very first check of the thermostat and 4-position switch can be done "by smell".

Burnout of contacts under such a load never goes unnoticed. Such things will definitely smoke and stink.

Classification

To find the right device, it is worth examining the presented assortment. Fan heaters are represented by a wide variety due to different criteria: power, heating element and mounting method.

Power

The power of the fan heater is 2 kW, but consumers prefer to buy 1-1.5 kW models in such cases:

- If the house has old wiring and there is a fire hazard.

- When you have to turn on several devices at the same time in the room.

- If you have to heat no more than 10 sq.m.

The minimum power indicator is selected taking into account 1 kW per 25 cubic meters. m. building. A regular outlet is designed for 16A, so you should not use a device with a power of more than 3.5 kW.

Heating electrical element

The most popular heating elements: heating element, spiral and ceramic grate.

The spiral is selected under the following conditions:

- When there is no financial opportunity to purchase a more expensive model.

- The heater will not be used around the clock.

- The noise of the fan does not play a role in the selection.

Ceramic lattice is 20 percent more expensive than spiral models. Advantage of the model:

- High fire safety.

- Are subject to round-the-clock operation.

- Long service life.

Heating elements are an average option, which is worth paying attention to at the optimal cost and the presence of additional functionality.

Mounting method - floor or wall

Wall models are fixed in one room, often found in stores to create a thermal curtain. Models of such a plan are compact and lightweight, and their power rating can be 2-2.5 kW. The wall-mounted fan heater looks like an air conditioner.

Floor heaters are safer and more mobile and can be easily moved from one place to another. In comparison with the above models, floor-standing fan heaters produce less noise and have higher performance. The movable swivel housing allows air to be directed to several points at once. In the summer they are often used as a simple fan. Externally, the model looks like a column, there are also round, rectangular shapes.

Additional features

Basic functions - changing the speed of rotation of the impeller and the power of the device. Manufacturers are trying to surprise consumers with new functionality:

- The ability to rotate the device, which allows you to direct the air in different directions.

- Roll-over protection sensor. This function is essential to protect children and animals.

- Splash-proof housing.

- Thermostat.

- The presence of a humidifier.

- Remote control by remote control.

- Ionizer.

Each additional function adds a certain amount to the cost of the heater.

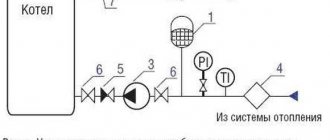

Fan heater thermal protection

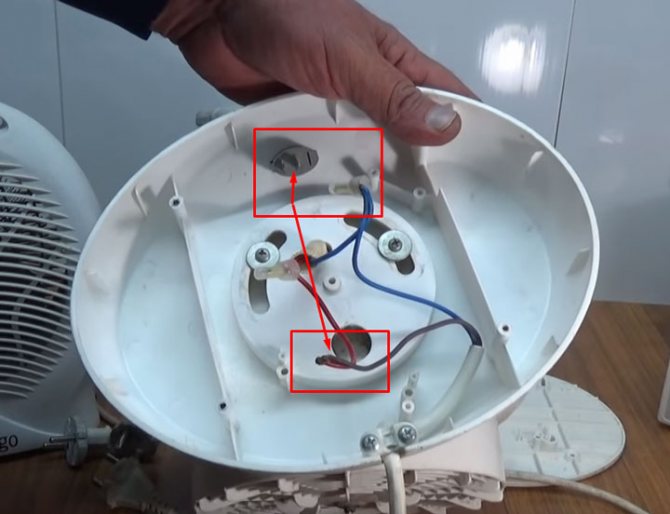

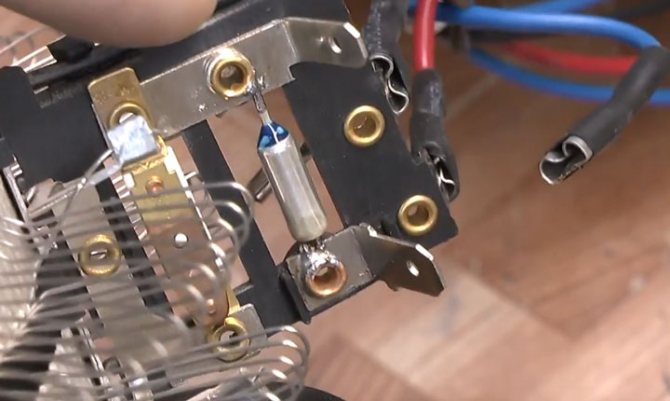

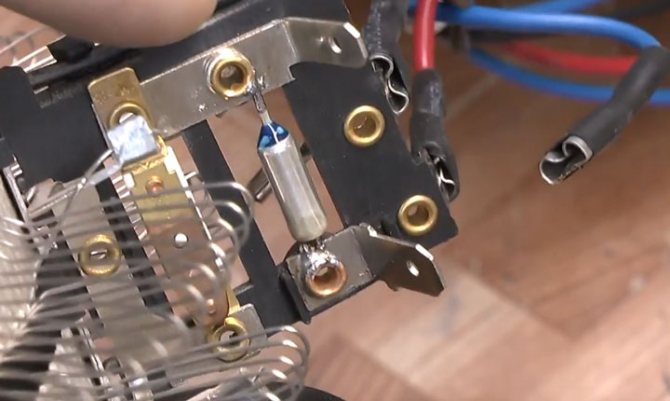

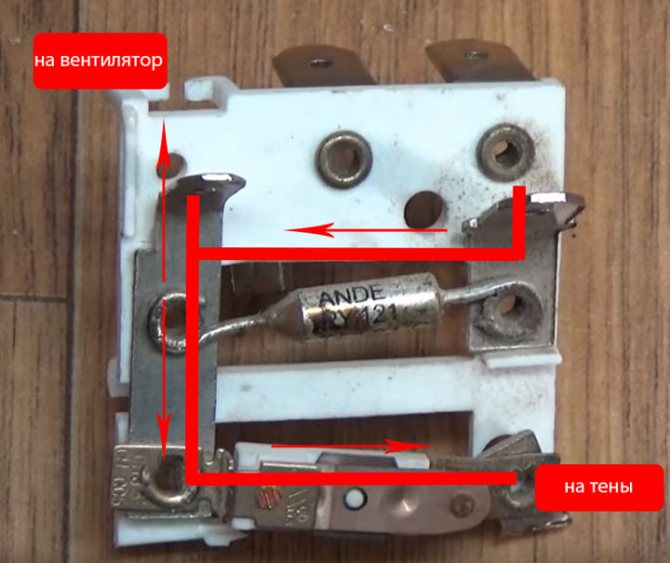

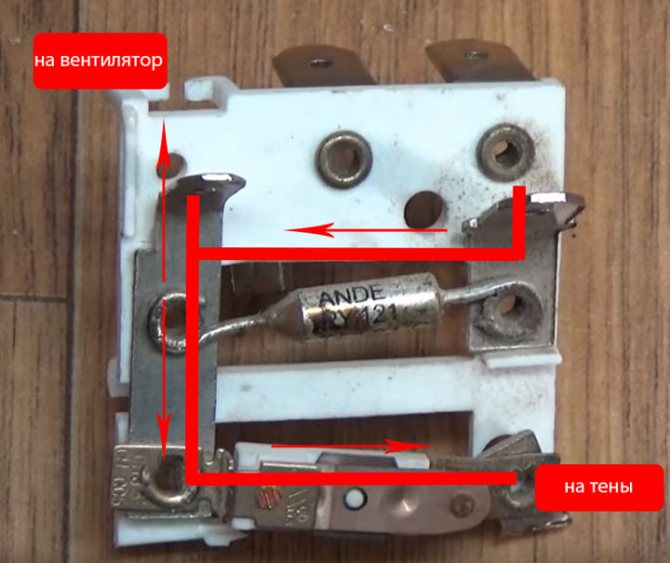

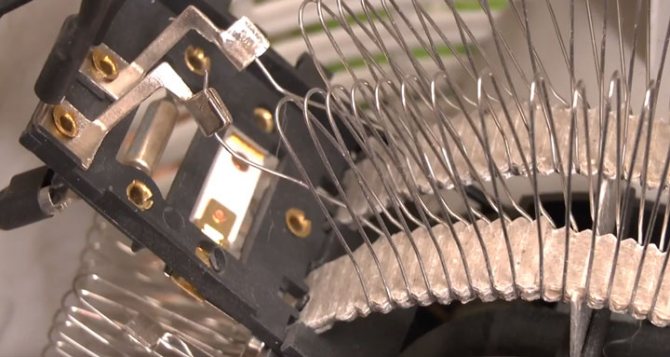

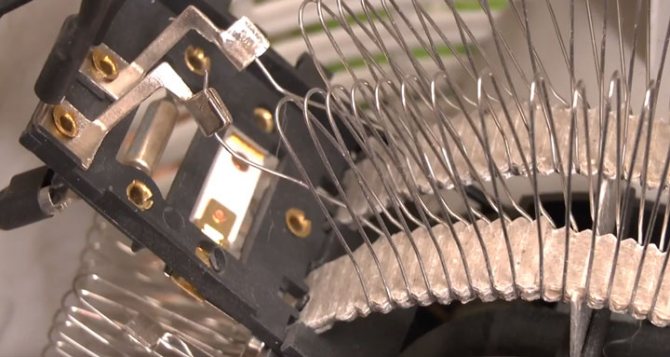

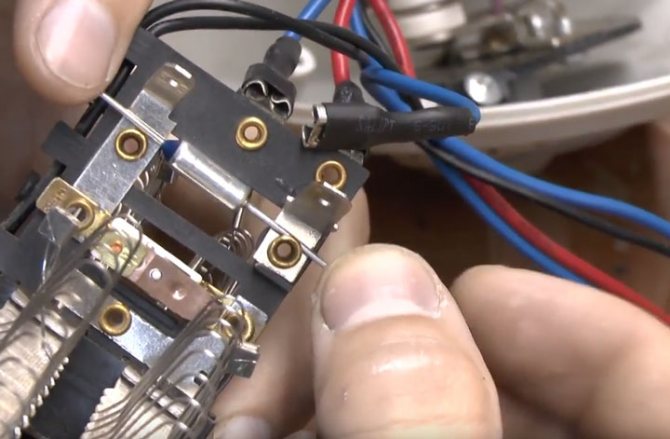

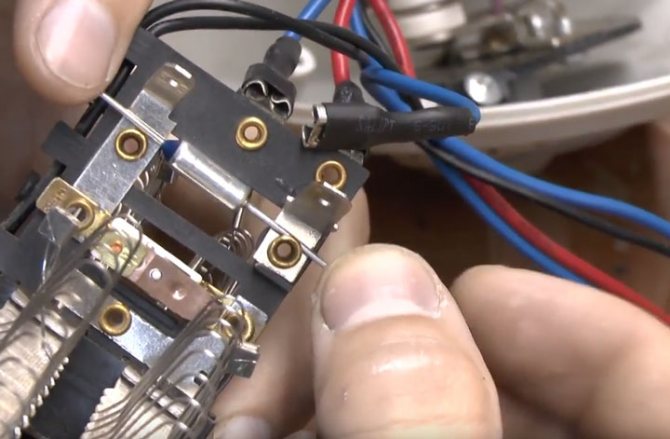

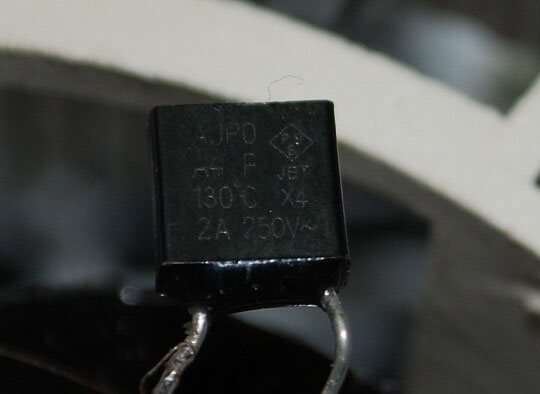

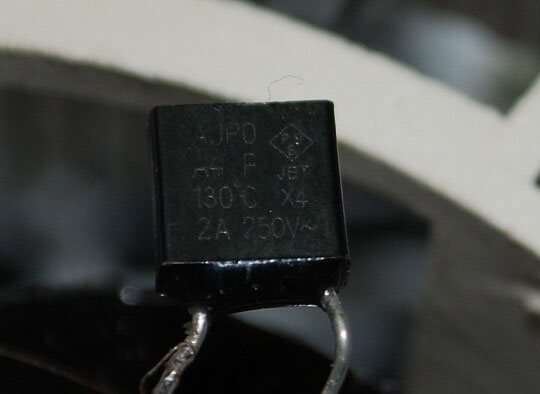

If everything is in order here, let's move on. Two protection systems are located right next to the ten. They consist of a bimetallic plate and a 121 degree thermal fuse.

Both of these elements, in good condition, should give a circuit and make a sound when ringing, i.e. show a short circuit across itself.

Keep in mind that you cannot connect anything directly here! It is this system that provides fire protection.

Remove it, and no UZIS and other devices will save you from sparking.

Power is supplied here to the top right pin. Further, through the fuse, the voltage goes to the left connector.

A cooler and sometimes a neon indicator are connected from this connector on top. And from below, through the thermoplate, power goes to two ten.

That is, when this main fuse burns out, both the fan and the heating stop working. When the bimetallic plate is triggered, only the heating is turned off, the fan continues to rotate as before, cooling the spiral.

On the back of this double protection, on the opposite contacts of the heating element, the wiring from the mode switch is suitable.

Turning it on, we connect either one ten in the chain, or we use two spirals at once. It turns out that a phase is supplied to the fuse, and zero is applied to the contacts on the reverse side through the switch. Or vice versa, depending on how you plugged the plug into the outlet.

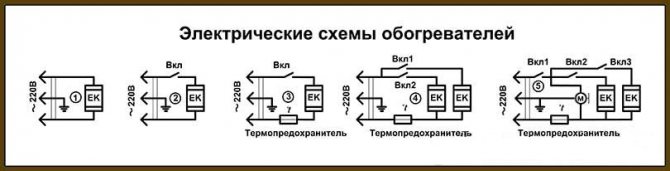

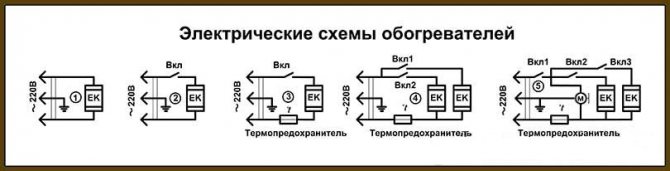

Typical wiring diagrams for heaters heaters are as follows:

Very often in this chain, it is the thermal fuse that is the main reason for the inoperability of the entire device.

At the same time, its replacement is not as simple as it seems at first glance. It is not for nothing that the plant uses rivets here, not soldering.

Principle of operation

The appliance generates heat, which is distributed around the room by means of a fan.The heater consists of three key elements - a housing, a heating element, and a fan. Choose a model from a metal shell that will protect against possible fire.

The fan power is very diverse. The higher the indicator, the faster the heat will spread throughout the room. The fan speed is changed by the regulator knob. There are two types of fans:

- Axial, noisy, not whimsical to maintain, have 3-8 blades.

- Tangential - work quietly and are considered to be more productive.

How to replace a thermal fuse

Soldering is not recommended here, since during the soldering process the temperature rises above the calculated 121 degrees. But if you have no choice, you will have to use a good heat sink.

Bite out an unsuitable fuse and flux the brass holes in the rivets.

The thermal fuse itself, namely the wiring suitable for it, is tightly squeezed with tweezers or curved long-nose pliers. Thus, when soldering, the heat will, as it were, be removed through them, without reaching the body itself.

Of course, you will not achieve 100% heat dissipation, but still most of it will go through the wide jaws of the instrument.

If you don't want to solder at all, you can use screws. The main thing is to have bends of sufficient length.

Bend them with a ring, and put small screws in the places of the rivets. Use these screws to secure the fuse to your seat.

You can select and order the required thermal fuse for any temperature and current from here.

If you have not found exactly the same in degrees, choose models with temperatures from 110 to 140C, no more.

Efficiency and performance

For each heater, the manufacturer indicates the comfortable and maximum area of the room for which this or that device is intended. Thanks to these parameters, it is easiest to understand what kind of device you need. In most cases, the dependence here will turn out to be strictly linear: if the power of the heater is twice as high, then it will give about twice as much heat per unit of time.

The type of heater in this case does not matter: if two heaters have spent the same amount of energy, then they heated the room in the same way (but not necessarily at the same time!).

Thermal relay

Another fuse, or rather a thermal safety relay that protects the engine itself, is hidden quite far away. It is designed to protect the windings from overheating.

Conventional floor fans are provided with the same protection. Details about the specifics of their verification and replacement can be found in the article at the link below.

Usually it is self-healing, that is, after some time after the windings have cooled down, the duychik can be restarted without any problems. It looks like this.

You turn on the cold fan heater to the network, it works for a while, after which the blades stop rotating spontaneously. The heating elements are still heating at first, and then they are also cut down.

After cooling, as if nothing had happened, the whole cycle is repeated over again. If your device has similar symptoms, and the thermostat has nothing to do with it, then look in the direction of this particular winding protection.

By the way, when the thermal fuse burns out at 121 degrees, take a closer look at the bimetallic plate after it. Most likely, there is also something wrong with her.

In theory, it should work earlier. Otherwise, the fuse will blow again shortly. Therefore, if there is any suspicion, it is better to replace both parts at once.

After repair, be sure to collect all the wires with zip ties in one bundle and hide away from the blades. Otherwise, they can easily be cut with a screw.

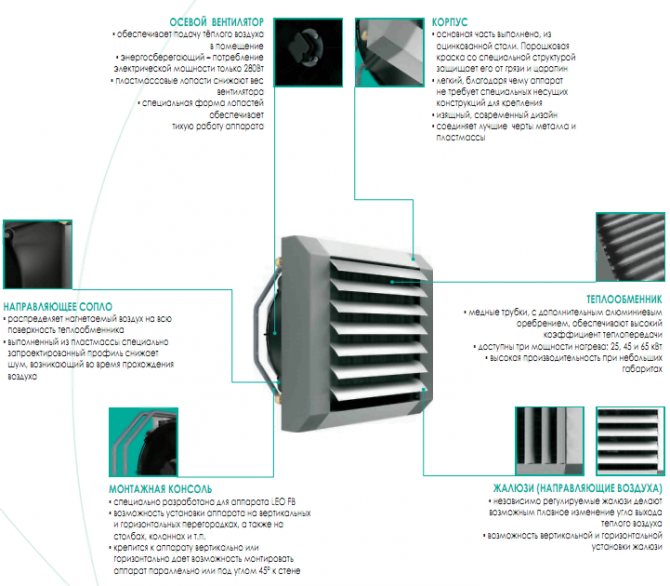

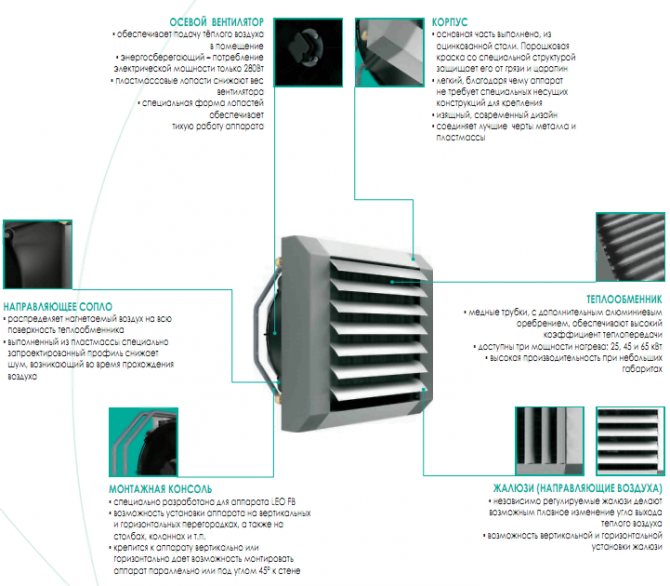

The main features of the KEV-40T3,5W3 fan heater "Teplomash"

If you need a more powerful device, you can purchase Teplomash water heaters. The above model, for example, costs 18,500 rubles. This fan heater is intended for heating administrative, industrial, office and warehouse premises. The installation is universal, that is, the device can be mounted both horizontally and vertically, which expands the area of use. Water heaters "Teplomash" are mounted with a bracket, which provides the ability to adjust the angles of rotation and tilt of the unit. Adjustable louvers can be used to direct the air flow to the desired area. Water heaters of this type are industrial devices, they are powered from a 220 volt network. Air consumption per hour can vary from 800 to 1600 cubic meters.

The isothermal jet has an effective length of 12 meters. Before purchasing such a device, it is worth considering that it provides for the need for free space, the length, width and height of the fan heater are 480 x 318 x 408 millimeters. You may need outside help to carry out the installation work, since the mass of the device is significant and is equivalent to 18.5 kilograms.

Lining up communications

It is necessary to take into account that the heating main must provide the required cross-section (the diameter must meet the technical requirements). And yet, the necessary flow of the coolant must be provided through the fan heater. If the diameter of the pipes and the temperature of the coolant are sufficient, but the speed of movement (flow) is very low, this will negatively affect the thermal power of the device!

Also, consider how to connect the power supply, control circuits. Calculate the required distances for purchasing the required length of the electrical wire.

And one moment. Make sure that the wall (or ceiling) on which the fan heater will be mounted is strong enough to withstand the load.

Features of the assembly of some types of fan heaters

There are several types of fan heaters, each of them, quite naturally, has its own characteristic pros and cons. Before you start assembling the fan with your own hands, you should familiarize yourself with some of the features of the device.

Fan heater

Assembling the simplest heat fan with your own hands will not be difficult for a home craftsman. Some of the necessary parts can be found in stocks of old equipment stored in a pantry or garage. The air heater with your own hands can be assembled on the basis of the old computer system unit. For this you will need:

- PCB sheet measuring 20 × 30 cm.

- A couple of meters of nichrome wire with a diameter of 0.2-0.3 mm.

- System unit (parts, except for the cooler, are removed from the unit).

- 12V power supply.

- Thermal fuse for the heater, designed to switch off at temperatures above 70 ° C.

- Cable, regulators, switches, fasteners, electrical tape or heat shrink tubing.

The design of the air heater is very simple and it will not be difficult to assemble it yourself.

By the way, a person who is versed in electrical engineering can make a temperature controller with his own hands using inexpensive radio components. For assembly, a TL431 stabilotron from a charger, an electronic meter board, a car relay and other common parts are suitable.

- From fiberglass, parts are cut out for the manufacture of a frame with slots for installing a ten (nichrome spiral).

- The nichrome thread is twisted into a spiral (for this purpose, a drill or screwdriver is used, operating at slow speeds, with a fixed rod with a diameter of 2-3 mm).

- The spiral is installed in the frame and fixed, power is connected at the points of attachment of the ends of the spiral, a thermal fuse is mounted in the break of the power wire.

- A frame with a spiral is installed in the system unit.

- The 12V power supply is connected to the cooler.

- The case is closed, installed on a dielectric material support and the operation of the heater is checked.

An economical option is a water heater fan. The heating element in this case is a heat exchanger made from a copper pipe or a used car radiator. The heat carrier is supplied to the heat exchanger from the pipes of central heating or individual heating, and electricity is consumed only to ensure the operation of the fan. It is recommended to install such a fan heater in the heating system on the return pipe. When installed on the supply, a working fan greatly cools the pipe and the coolant enters the heating radiators below the required temperature.

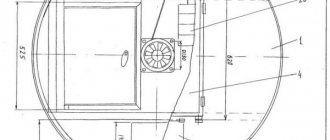

Heat gun

Making a heat gun with your own hands is quite simple. A heater of this type is used for quick heating and drying of walls, floors, damp cellars and during some types of construction work. To make a mini gun, you can use some parts of unusable household appliances, and buy the missing ones.

You will need the following list of materials:

- Motor and impeller (suitable for a failed vacuum cleaner or kitchen hood).

- A spiral from an unnecessary electric stove is used as a heating element.

- A pipe with a diameter of 150 mm with a wall thickness of 3-5 mm can be made independently from sheet metal.

- Thermal relay, opening the circuit in case of overheating, switch,

- Asbestos sheet.

- Metal grill.

- Cable and fasteners (rivets or bolts with nuts).

The assembly is carried out in several stages:

- The motor and fan are attached at the end of the pipe.

- Strips are cut out of asbestos and a grid is assembled, on which a heating coil is attached (for this purpose, ceramic insulators can be used).

- The resulting heating element is attached to the pipe end opposite to the fan.

- The motor and spiral are connected to a switch. The diagram provides for a separate connection.

- Metal protective grilles are installed at both ends of the pipe.

- A mobile or stationary stand is made of materials at hand that are resistant to temperature influences.

WATCH THE VIDEO

If desired, a layer of thermal insulation is attached to the pipe. On the one hand, this increases the level of safety during work, on the other hand, it reduces the heat transfer of the device.

Electric fireplace

A homemade fan heater is used as a heat source for an electric fireplace. A portal for a fireplace with your own hands is easy to make from drywall. To do this, a frame is mounted from a metal profile of the required configuration and sheathed with sheets of drywall, after which the outer surface is decorated with facing materials. Inside the portal, a structure is installed that simulates the burning of wood or coal (finished products are equipped with lighting). It is important to provide a hole in the structure in advance for cable routing.