After the end of the heating season, the issue of changing radiators comes to the fore. If your apartment has leaky cast-iron batteries, then it's time to send them to a well-deserved rest, installing modern models instead. Private developers, equipping a heating system, often cannot decide which radiators are better - aluminum, bimetallic, cast iron, because each of these models has its own advantages and disadvantages. The consumer may be at a loss when hears the recommendations of the sellers in the stores of the relevant goods. If you are also solving this issue, then it is worth comparing aluminum and bimetallic radiators.

Comparison of aluminum and bimetallic batteries

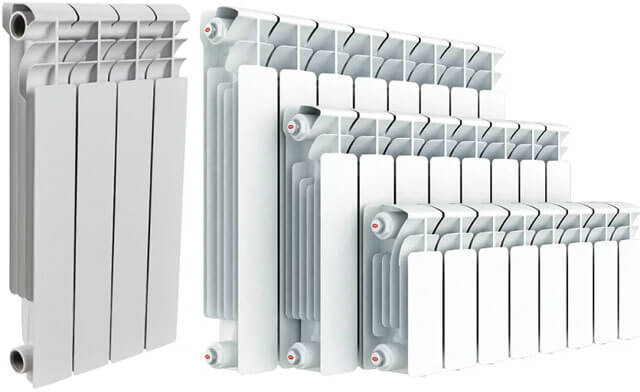

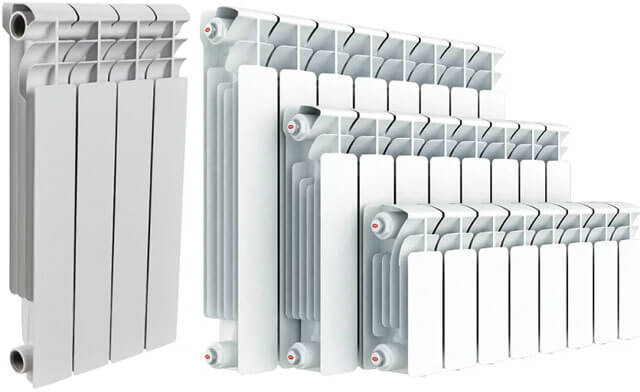

Aluminum radiators look good and neat, they have several sections that are connected by nipples. There are gaskets between the sections, they provide the desired tightness. The ribs are located on the inside, they increase the heat transfer area to 0.5 m2. Such batteries are manufactured according to one of the technologies existing today. For example, the extrusion method makes it possible to obtain cheaper and lighter products, but their quality cannot be called high. Today, this technique has already been abandoned in Europe.

If you are thinking about the question of how bimetallic heating radiators differ from aluminum ones, then you should pay attention to the fact that the latter can also be made by casting. The products are more expensive, but they will last longer. Bimetallic batteries are made using two different metals. The body has fins, which are based on an aluminum alloy. Inside the body there is a core made of pipes, hot water flows through them. Such pipes are made of copper or steel, but the first option is less and less common today. Many consumers are also thinking about how to find out if the radiator is aluminum or bimetallic in front of them. The diameter of the latter is smaller compared to aluminum models. Therefore, there is a higher likelihood of clogging. When consumers consider the advantages of bimetallic radiators over aluminum, they first of all note a more attractive appearance. After all, all the components of such products are hidden inside, so the design is able to satisfy the most sophisticated requests.

Which radiators are best suited for which systems

Which heating radiators are better, aluminum or bimetallic, depends on the characteristics of the room, the coolant and the climatic conditions of the area. In case of doubt and uncertainty, it is best to turn to professionals who will help you determine the type of product.

How to choose the option you need if you can't contact a specialist at the moment? In this case it is necessary to build on the pressure in the coolant network... As mentioned above, the difference between these types of heating batteries lies in the ability to maintain their qualities at different levels of network pressure.

For private boiler rooms, where the pressure does not exceed 2-6 atmospheres, inexpensive aluminum batteries are perfect, and it is better to use prefabricated products that can be independently serviced, and for arranging apartments in multi-storey buildings, you definitely need to use bimetallic batteries.

It is also important to consider the chemical composition of the coolant.Exceeding the standard water alkalinization rate will adversely affect aluminum and lead to its rapid destruction. There is no such danger for bimetallic products.

Which batteries are better when it comes to heat dissipation?

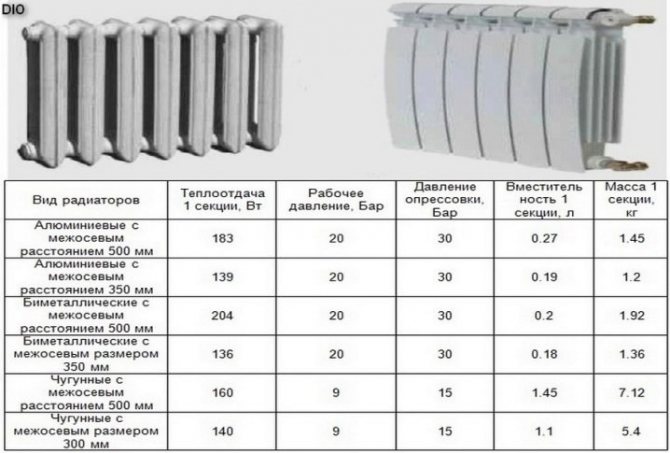

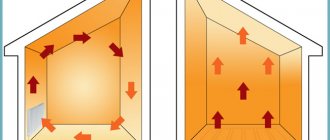

If you are deciding how aluminum radiators differ from bimetallic ones, then it is worth comparing them also in terms of the intensity of heat transfer. Aluminum radiators are taking the lead in this matter. One section is capable of delivering approximately 200 watts of thermal energy or more. Half of the heat is given off as radiation. The other half is convection. The ribs of the battery allow for increased heat dissipation. Aluminum has no equal in this matter. Among other things, it has minimal thermal inertia. If you turn on such batteries, then after 10 minutes it will be warm in the premises of a house or apartment.

If we are talking about a private building, then with the help of aluminum radiators it is possible to save a lot. Today, aluminum and bimetallic heating radiators are becoming popular, the characteristics of which are presented in the article. The latter differ in heat dissipation, which depends on the manufacturer and model. This parameter will be lower compared to an aluminum radiator. This is due to the fact that the steel core reduces heat transfer, which is 1/5 less compared to an aluminum battery of the same dimensions.

Manufacturing and design of aluminum radiators

There are two types of aluminum radiators - extrusion and cast. The former are cheaper than the latter, but inferior to them in quality.

Extrusion Aluminum Radiators

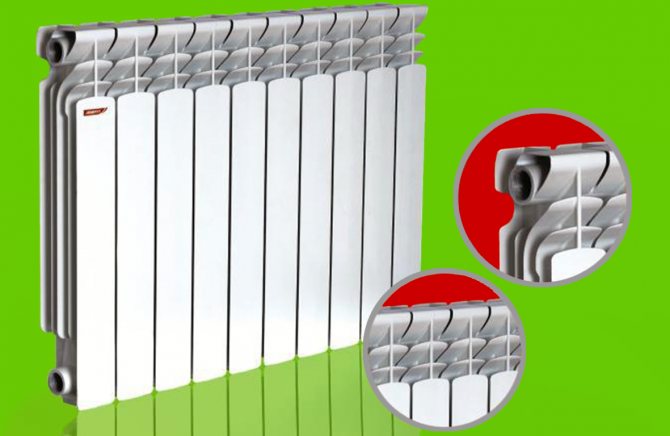

The battery section consists of three parts, which are glued together with a special compound. The upper and lower parts are made by casting. The middle part, which contains the vertical channels, is by means of extrusion.

Cast aluminum radiators

The sections of such batteries are made by means of casting; they do not have such seams and joints as extrusion ones. Thanks to the one-piece construction, they better withstand pressure.

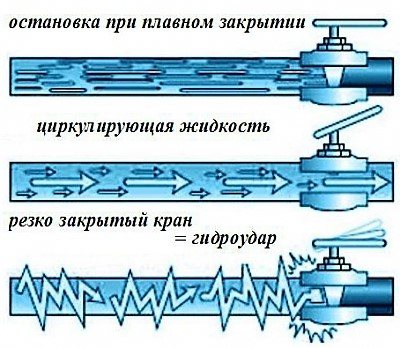

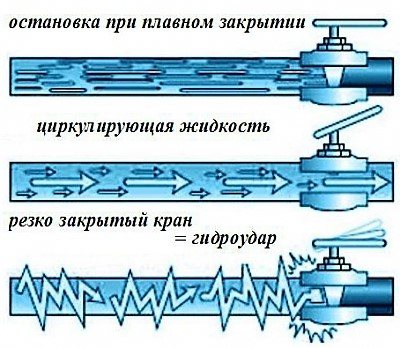

Differences between aluminum and bimetallic batteries in terms of the ability to undergo water hammer

In this matter, aluminum is on the second together. Its working pressure is not so high, it varies from 6 to 16 atmospheres, and in some models this parameter reaches 20 atmospheres. If you install such radiators as a component of central heating, then the products may simply not withstand the effects of high pressure. A water hammer can cause the battery to burst, and a hot flood will turn out in the apartment. Therefore, you should not risk installing an aluminum radiator in an apartment of a multi-storey building.

If you are wondering how bimetallic radiators differ from aluminum ones, then it is worth comparing these products in terms of their ability to withstand high loads. Bimetallic batteries have a strong steel core, which is prepared for high pressure head. Such products are able to withstand pressure from 20 to 40 atmospheres. Therefore, it can be argued that bimetallic radiators are more reliable in case of unstable pressure, when there is a possibility of water hammer.

What is the difference between aluminum batteries and bimetallic

Aluminum radiators are made of one metal and do not have a core, bimetallic ones, on the contrary, have internal steel tubes for coolant circulation and external aluminum fins for good heat transfer.

However, outwardly, both types of products are similar and have an attractive aesthetic appearance that can match any interior.

Heat transfer indicators

Since the outer part responsible for heat dissipation for both types of batteries is made of aluminum, they have good heat dissipation rates.

But for products consisting of only one metal, it is about 15 ... 20% higher.

Corrosion resistant

Anti-corrosion resistance is higher for bimetallic batteries, since the coolant circulates through steel pipes, which are more resistant to corrosion, as well as to an aggressive environment.

However, steel is also susceptible to rust when air enters the system, which is possible with seasonal coolant drains.

Resistant to pressure and water hammer

Thanks to the internal steel pipes, which can withstand the high working pressure of the fluid and its drops, the bimetallic battery is more resistant to water hammer.

Ease of installation

Both types of the described elements of the heat supply system are easy to install, however, aluminum batteries are lighter, which makes their installation somewhat easier.

Life time

The possibility of long-term operation depends on many factors:

- working pressure in the system;

- the chemical composition of the coolant;

- presence / absence of water hammer;

- circulating fluid temperature;

- seasonal coolant drains.

If the radiator is selected and installed correctly, the service life declared by the manufacturer is:

- for aluminum products - 20 ... 25 years;

- for bimetallic - 25 ... 30 years.

Interaction with coolants

Aluminum batteries are highly dependent on the quality of the coolant. When the pH level rises above a certain value, they are susceptible to corrosion and further leakage.

In bimetallic products, a steel pipe is in contact with the coolant, which is more resistant to an unfavorable environment and pH fluctuations.

Which radiator to choose from the point of view of the coolant

Quite often, owners of real estate and apartments wonder how aluminum radiators differ from bimetallic ones. This issue should also be considered from the point of view of the coolant. Aluminum is capable of entering into chemical reactions, so water is just a treasure for it. It contains so many chemical impurities that the walls of the batteries can corrode during operation. Therefore, if the ph-level of the water flowing in the system exceeds 8 units, then you should expect trouble. However, using central heating, it is simply impossible to keep track of these parameters.

Even during a chemical reaction, aluminum is able to release hydrogen, which creates a fire hazard. Therefore, it is necessary to bleed air from such radiators from time to time. Steel pipes located in the core of a bimetallic product are less demanding on water quality. This is because steel is not as reactive as aluminum alloys. Corrosion will get to such material, but it will not happen so soon. Among other things, manufacturers cover the surface with a protective layer, sometimes stainless steel is used in the manufacturing process, but it makes radiators expensive.

What is better aluminum or bimetallic radiators

Each of the products has advantages and disadvantages. Therefore, the choice depends on:

- type of heating system (individual / centralized);

- presence / absence of coolant drain;

- the price the consumer is willing to pay.

for installation in an apartment

Apartments in high-rise buildings, as a rule, are heated centrally, so their owners cannot control the composition and acidity of the coolant.

In this case, preference should be given to bimetallic products that are more resistant to fluctuations in the acidity of the fluid involved in the heating process, and also well tolerate its high operating pressure and water hammer.

The choice of radiators by the temperature of the coolant

Installation of aluminum, bimetallic heating radiators is carried out quite often today. However, before purchasing such products, you should inquire which ones are capable of working when exposed to water of impressive temperature.Aluminum is able to withstand 110 ° C, which is average. For bimetallic radiators, this characteristic reaches 130 ° C, so these products benefit.

When do you need to choose heating radiators

Replacement of radiators is faced by:

- during cosmetic repair;

- at the time of buying new apartment;

- when heating is connected to private house or cottage.

You need to understand: the way to heat an apartment building and a cottage differ in some ways.

Reliability and durability

If you are thinking about the question of how aluminum radiators differ from bimetallic ones, then you should first of all understand that aluminum products will be destroyed by water hammer, corrosion and frequent, as well as impressive, temperature changes. Therefore, in terms of reliability, the leaders are again products made of two metals, they combine the best qualities of each material. Such products are ready to serve for more than 20 years, naturally, in this case we are talking about a high-quality product of brands that have established themselves in the market. Aluminum radiators have half the service life. Once installed, they are ready to serve for 10 years.

Pros and cons of aluminum heating radiators

Positive aspects:

- Fast heating - the room warms up quickly, with the correct calculation of the number of sections, 15 minutes is enough to warm up the room;

- Light weight - this is convenient not only during transportation, almost any surface is suitable for installation, even MDF or chipboard;

- Good heat dissipation - the coolant effectively heats the room, transferring most of its heat;

- Low cost - this option is one of the cheapest, not at the expense of quality and energy efficiency.

Negative sides:

- The presence of rubber gaskets - aluminum is sensitive to deformation, therefore, rubber seals are provided at the joints of the sections, which can leak over time and require replacement;

- Risk of corrosion - the interior of channels and collectors is sensitive to water quality and is destroyed over time by acids dissolved in it;

- Mayevsky valve - periodically it is necessary to drain the accumulated hydrogen in the system;

- Sensitivity to water hammer - the strength of aluminum is lower than that of copper and steel, therefore, with a sharp increase in pressure, breakthroughs of the system are not excluded;

- Risk of damage - during transport and installation, there is a risk of deformation of the sections, which can subsequently lead to leaks.

Comparison for ease of installation

Bimetal and aluminum lend themselves quite easily to comfortable installation, they weigh less when compared with cast iron. There is no need to use powerful brackets for fastening, even a drywall wall will be able to support a small weight. If the supplied pipes are made of plastic, only fittings and a set of keys are needed for installation work. But as practice shows, bimetallic batteries are still easier to install, since steel cannot deform, unlike aluminum, which is soft metals.

Characteristics of radiators. How to compare and choose the best

To choose the right radiator for an apartment, office or private house, you need to compare the advantages and disadvantages for a number of characteristics.

Important! Some Chinese-made radiators, despite the declared characteristics, show discrepancies in the results under laboratory conditions - up to 35%. Be careful when choosing a manufacturer

Heat transfer level

For comfortable heating 1 sq. m. apartments with a ceiling height of 2.7 m require a heat transfer of 100 watts. Each section of the aluminum heatsink can provide up to 212 watts, while the bimetal heatsink can provide a maximum of 185 watts.

Water hammer and high pressure

Water hammer is a pressure surge in a pipe that appears:

- at the moment of an interruption of the circulation pump at the station;

- due to the presence of air zones in the pipeline;

- with a sharp closure of the tap, shut-off valves.

The water hammer lasts a split second - but this time is enough to damage the radiator. Aluminum is not the most reliable metal for houses with central heating and can withstand up to 16 atm., While bimetallic models with a steel core calmly take on 20 atm., And some - all 40 atm.

Maximum coolant temperature

For aluminum radiators, this is 110 degrees. Interestingly, aluminum reacts to temperature changes quickly, and holds a large volume - up to 0.46 liters. This is a plus. Bimetallic ones contain only 0.18 liters of water, but the temperature is also kept higher - up to 130 degrees.

Reliability and durability

Aluminum is susceptible to corrosion because it itself is not protected from contact with water. Good aluminum models use high quality alloys that guarantee durability. But this durability is still inferior to bimetal, because steel does not corrode at all.

Easy to install

It is recommended to wash bimetallic radiators more often, because the diameter of the steel pipe inside is small, blockages may occur.

In general, they are easier to install because there is less risk of deformation. Both bimetallic and aluminum models can be easily secured with a set of keys and fittings, without powerful brackets.

Price comparison

If you are faced with the question of how aluminum radiators differ from bimetallic ones, then it is worth considering these products also in terms of price. The second option is 1/5, and sometimes 1/3 more expensive compared to aluminum products. This difference is quite significant, so today bimetal is not so common among private consumers, because it is not available to everyone. Bimetallic devices have a higher hydraulic resistance, so more energy is required to pump water, which increases the cost of operation.

Positive properties of aluminum batteries

Aluminum radiators are lightweight and durable, easy to transport and install. In addition, they also have a number of important advantages:

- small size (compared to cast iron, shorter in width);

- very high level of heat transfer;

- working pressure corresponding to the needs of modern heating systems;

- you can choose a product with a certain number of sections according to the heated area;

- good heat dissipation, which means efficiency;

- the ability to adjust the temperature regime using built-in thermostats;

- excellent aesthetic appearance.

The advantages of aluminum radiators over bimetallic ones are in a lower price, which is very important for the consumer.

Choosing a radiator for a specific heating system

Having considered the main characteristics of radiators, we can conclude which model is suitable for a particular system. If you use central heating, then the pressure in it can change dramatically, sometimes the mark reaches exorbitant values, and water hammer occurs. The temperature will not be stable, it can change during the heating season and even during the day. The composition of the coolant does not differ in purity, it contains chemical impurities, abrasive particles, and there is no need to talk about an acceptable ph level either. Based on all this, it can be argued that it is best to refuse aluminum batteries in such systems.

Features of aluminum heating radiators

The sections of heating batteries made from it can withstand a pressure of 16 atmospheres. This is quite sufficient for operation in systems where there is no risk of water hammer. The working pressure of central heating systems is about 6-10 atmospheres, depending on the number of storeys of the building.

Aluminum perfectly conducts heat, which allows you to effectively heat the room.

Aluminum batteries give off heat by 50-60% due to radiation and 40-50% due to convection. An air cutter increases convection by 20-25%, which increases heat transfer.

Most aluminum radiators can withstand temperatures up to 110 degrees, which is quite enough for the regular operation of heating systems in which water circulates.

If the heating system uses a heat carrier with a high boiling point, for example, propylene glycol, then the situation becomes more complicated. In the event of an accident or malfunction, its temperature may rise higher, causing the battery to break.

Aluminum is sensitive to the acidity level of water, if it is above 8 pH, then the metal begins to collapse. This metal is a catalyst and hydrogen is released when interacting with an acid. This leads to the formation of air pockets in the heating system. Therefore, all aluminum heating devices are equipped with a Mayevsky tap.

The real service life of aluminum radiators varies from 10 to 15 years, it depends on the operating conditions and the quality of the product.

The installation of aluminum radiators is no different from any other battery section. But this metal is quite soft, so during installation it can be deformed, which will lead to leaks. Deficiencies may not appear immediately, but during operation, after one, two, or even five years.

Comparison of aluminum and bimetal

In order to understand what is better aluminum or bimetal, one should compare these two metals. The average buyer will not be able to correctly identify the metal from which this radiator is made. After all, both types of radiators look the same both in shape and in terms of painting. They are often painted with either colored or white enamel. The surface itself can consist of separate sections or be monolithic.

A bimetallic battery has an average heat output, while an aluminum battery has a high one. In bimetallic devices, the maximum working pressure is 20 atmospheres, while in aluminum only 16. The disadvantage of both devices will be that they are quite unstable to corrosion.

The batteries have a maximum warranty period of 25 years. The price of bimetallic devices is much higher than aluminum ones.

Important! Repair and maintenance of aluminum and bimetallic radiators can be done independently.