Wood shredders

Increasing environmental requirements for production at logging and woodworking enterprises makes wood chipping equipment relevant and profitable. As a result of shredding wood waste, raw materials are obtained for the production of MDF, wood concrete boards, briquettes or pellets for heating private houses. Separately, the effectiveness of the use of shredders in logging plots should be highlighted, because heaps of branches, small size and other non-condition are disposed of on the spot.

offers a wide range of wood shredders, which are selected depending on:

- Requirements for the quality of chips or shredded wood;

- Composition of raw materials (waste) and their volumes;

- Directions for further processing.

In practice, a technique is used to line up machines with different types of grinding into a line, which allows obtaining a product with high consumer properties.

Types of shredders

At the first stage of processing waste woodworking production, chippers are used. By type, these machines differ in:

- Drum chippers suitable for processing waste wood and low-grade wood in the widest range of sizes.

- Disco chippers with 3 ... 4 movable knives fixed on a disc with grooves. The cutting process takes place during the movement of the disk and the passage of a movable knife, fixed on the disk relative to a fixed counter-knife. The size of the chip fraction is regulated by the extension of the knife blade relative to the plane of the disc, which is the base.

- Single-shaft and double-shaft wood shredders with circular knives have the highest performance. The shredder can process pallets, cable reels, etc., which may have nails, into chips. Chips are of poor quality and further processing requires magnetic separation to remove metal.

Deep processing of wood chips involves crushing to a size of 5 ... 12 mm. For this, a wood hammer crusher or a wood chip machine is used, which has a large number of knives or toothed discs. The feeding into the cutting zone is carried out from the hopper under its own weight or by means of a carriage with a drive.

A hammer crusher crushes wood chips using plates (hammers), which are fixed to the rotor and have a certain degree of freedom. Hammers fly over the sieve and crush the chips.

In some models of chippers, hammers crushing chips are installed on the rotor, in addition to chopping knives. A sieve is installed at the bottom of the machine, which calibrates the chips of the desired size. This arrangement reduces the size of the machine and allows you to get better quality raw materials.

Material production technology

Now you can consider the process of making chips. So, first you need to prepare the raw materials. The quality of this process depends on what kind of raw materials you need: peeled or barked, whole logs or waste. The wood chip crusher (chipper) now comes into play. The raw material is loaded through the hole into the hopper, where it is crushed.

Through special openings, the finished product enters the collection container or is sent along the conveyor to the drying chamber (if necessary). Next, the chips need to be sorted. Most often, vibrating screens are used for this, which have several platforms with cells of different diameters. Thus, you can quickly and easily separate large particles from small ones and improve the quality of your product.

Then the finished product can be packed and stored (or sent to the customer). It must be said that chips should be poured into special bins for short-term storage.

You also have the opportunity to simply fill up the product in special rooms, from where it will be shipped and delivered to customers. If you plan to expand your business, it is better to equip a special bunker gallery. It facilitates the process of loading the machines with chips. The fact is that a truck can drive right under the bunker.

In principle, these are all the features of the choice of equipment and the production of the presented material. Good luck!

Wood chipping equipment drive

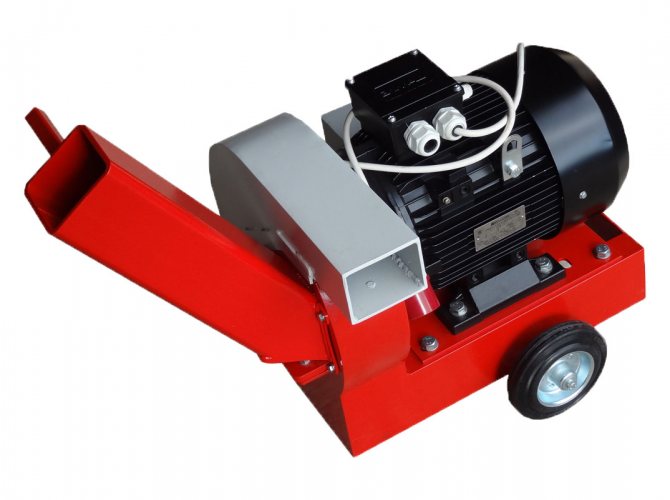

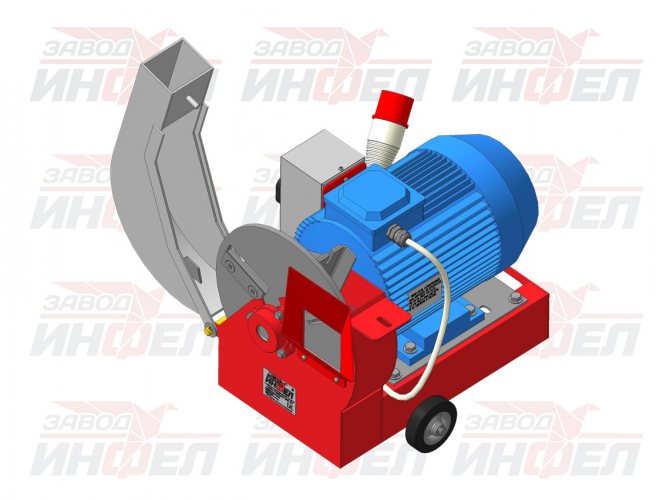

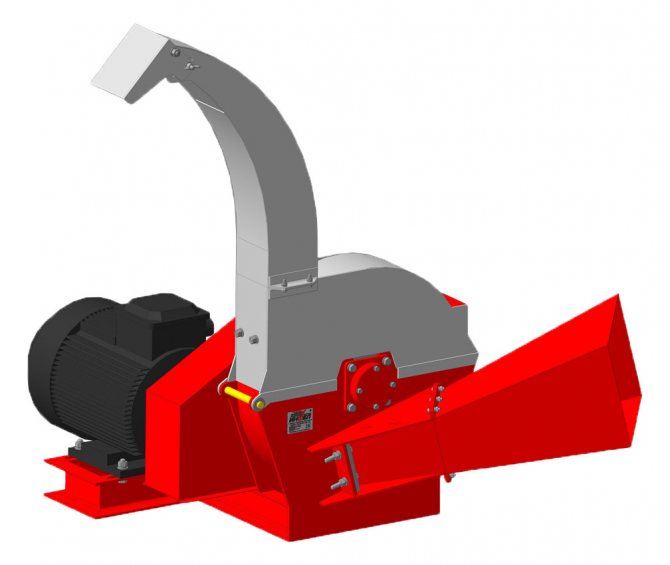

All types of equipment are equipped with an electric motor as standard. There are modifications with a drive from an internal combustion engine or with a power take-off shaft from a tractor. The optimum power is 5.5… 30 kW. Installations of lower power are used in summer cottages and private areas.

manufactures all types of wood waste disposal equipment. An extensive range of machine models allows you to select equipment for solving specific problems with optimal performance and quality of raw materials obtained for the purpose of further processing or sale to third parties.

Experience in the manufacture, implementation and operation of machines enables the company's specialists to give competent recommendations about the features of a particular model. For communication, call +7 or fill out the feedback form. Deliveries are carried out throughout the territory of the Russian Federation.

Wood shredders

All products in category Wood chippers

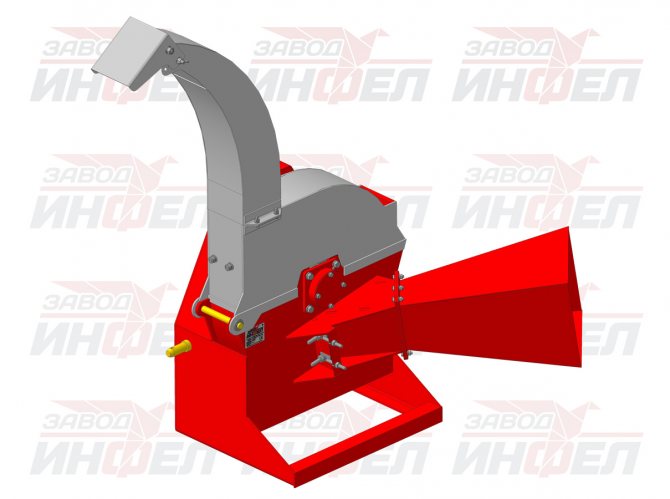

Designed for processing wood waste (tree tops, substandard pieces, large twigs, etc.) into technical chips. Has a built-in fan. The crusher is driven by an electric motor. Advantages: compact design (1680x690x900 mm) enables the use of this unit in limited production areas, high equipment performance (8-15 cubic meters per hour), 15 kW electric motor provides stable and uniform rotation of the rotor at a speed of 700 rpm, guaranteeing high quality and speed of material processing, operational safety.

The processed raw material is small-fraction wood waste (wood chips, sawdust, shavings, etc.). Consists of crushing chamber, clutch guard, clutch and electric motor. The crushing chamber consists of a body, a cover and a rotor. The body is mounted on the frame and bolted to it. Inside the housing, on the side walls, there are radial slots for installing a sieve, which consists of two parts. The cover is installed on the top flange of the housing. On its side walls there are also radial grooves for installing a sieve and a cast iron deck. The working body of the crusher is a rotor, which consists of a shaft, discs, spacer washers, hammers. The product is fed through the inlet in the lid and, thanks to the impact of rotating hammers and the impact of particles on the deck, is crushed. The fineness depends on the size of the sieves.

Mobile wood waste shredder with Diesel engine power 22 h.p. hydr. feed, diam. up to 200 mm, up to 10 m³ / hour

Shredding into shavings. Grinding into sawdust. Shredding into chips.

Shredding into shavings. Grinding into sawdust. Shredding into chips.

Designed for processing wood waste (tree tops, substandard pieces, large twigs, etc.) into technical chips. They have a built-in fan. The IDM-10 crusher is driven by an electric motor, and the IDM-10T is aggregated with the MTZ-80, MTZ-82, T-150 tractors and their modifications, mounted on a 3-point hydraulic hitch and driven from a power take-off shaft through a cardan transmission ...

The DOS-1 crusher is designed for processing wood waste into technological chips (tops of trees, substandard pieces, large branches, etc.). The chips are ejected by a rotating rotor through the chip chute. Ejection height - 3.5 m. DOS-1 crushers can be used for processing woodworking waste, during industrial or sanitary felling. When cutting down in cities, processing of branches (up to 100 mm in diameter) can reduce the cost of transporting cut trees. In addition, the chips obtained during the processing can be used in the production of wood-based panels, fuel briquettes, used for compost and other purposes. The mobile unit (DOP-1) can work on site in parallel with cutting.

Mobile wood waste shredder with Diesel engine power 40 h.p. hydr. feed, diam. up to 200 mm, up to 18 m³ / hour

Wood waste shredder with diesel internal combustion engine 60 HP - hydr. innings/

Productivity (0.5-1 mm) up to 900 kg / h; (2-3 mm) - up to 2000 kg / h. Power 22 * 2 = 44 kW. The size of the receiving window is 990 * 605 mm.

The productivity of the machine is up to 36 m3 / hour. Workpiece dimensions up to 1 m. Power 23.5 - 24.2 kW

Wood waste shredder with diesel internal combustion engine 60 HP - hydr. innings/

The size of the loading window is 250 * 250 mm. Power 30 kW. Productivity up to 3000 kg / hour (8 cubic meters / hour)

The productivity of the machine is up to 2 m3 / hour. Workpiece dimensions up to 0.6 m. Power 3.2 kW

The dimensions of the loading window are 300 * 120 mm. Total power consumption 35.2 kW. Productivity 2-4 tons / hour, chips. Drum diameter 400 mm. Number of movable knives 6 pcs. The maximum diameter of the raw material is 100 mm.

On the website Stankoff.RU you can buy equipment for processing wood waste from leading manufacturers. In stock and on order more than 46 models of crushing equipment at the best prices. Only great deals with detailed descriptions and photos. Check prices with managers.

Equipment for the wood chips production shop

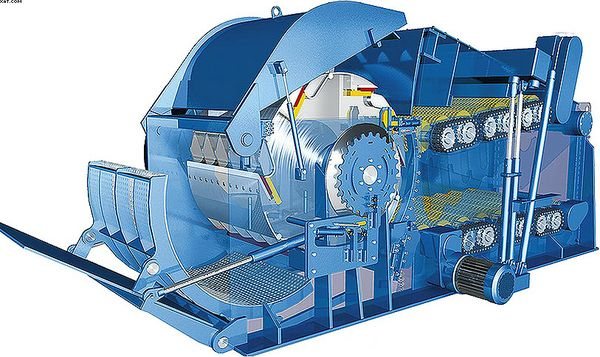

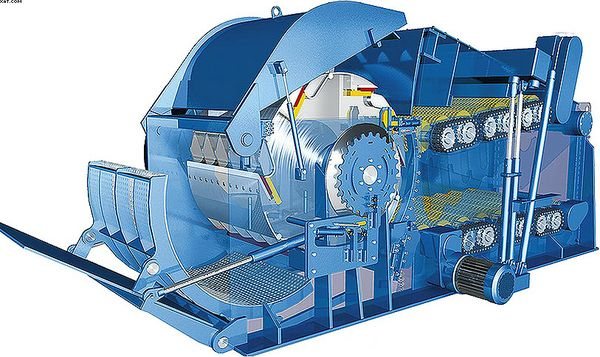

Wood chipper Vecoplan VTH 2000 M NFT

Having decided on the direction of business, you can proceed to the next stage of organizing the workshop - the purchase of equipment. The main apparatus here is a chipper for the production of wood chips. It is she who turns the raw materials into the final product, which means that the quality of the manufactured products will depend on her.

You can buy a high-tech line that allows you to make different types of wood chips. But the cost is quite high - up to 3,000,000 rubles. But for entrepreneurs who are on a budget, it is better to assemble a line of separate devices - dryers, crushers, dyeing tanks and filling machines.

When equipping a workshop, it is worth choosing a wood shredder especially carefully. And the choice will depend on the planned production volumes and the available investments. There are several types of crushers on the equipment market:

- single-disk,

- drum,

- hammer.

Each of the designated types of machines is good in its own way. Therefore, when buying, it is better to pay attention not to the grinding method, but to other parameters. So, a good chipper, what is it?

- The thickness of the body in the part of the apparatus where the cutting elements are located must be at least 20 mm. Only in this case the chip crusher will serve for a long period without breakdowns and downtime.

- Knives made of wear-resistant steel will grind the raw material better and faster.

- It is good if the hydraulic feed consists of not one, but two pinch rollers.

- Limit switches, which the machine will be equipped with, will protect workers from accidents.

- Having the machine rotate 360˚ will make it easy to store the chips when they are thrown out of the crusher.

- The machine will work longer if the number of knives is more than 2.

The following brands of budget crushers have proven themselves excellently - LASKI, BOXER. The price of cars does not exceed 200,000 rubles.

If we talk about the total cost of equipping the workshop, then the price of equipment for the production of chips of average capacity will not exceed 800,000 rubles. The line will include the entire set of machines and apparatus necessary for the production of a quality product. Of course, if we talk about more powerful machines, then their cost will be much higher - up to 2,000,000 rubles. But it is hardly advisable to equip the workshop with high-performance equipment until the distribution channels are well established.

And in order to further reduce the cost of equipping the workshop, you can think about purchasing supported equipment. The cost of used machines will be much lower, but here you need to pay even more attention to the choice of the technological line.

We recommend these articles:

We organize the production of SIP panels with our own hands.

Prospects for opening your own pallet business in Russia.

How to choose the right machine for the production of chipboard?

Purpose and advantages of wood chipping equipment

The problem with the disposal of substandard material exists at all logging and wood processing enterprises. Equipment for wood chipping allows solving the issue of freeing the territory from industrial waste and increasing profitability by earning additional profit from the sale of recycled products.

When working with any type of wood, waste is generated in the form of branches, slats, slabs and scraps of various shapes obtained during the manufacture of lumber. Garbage disposal is a costly and time-consuming procedure, alternative to which is a practical way of using crushing equipment. Machines grind substandard into chips or sawdust of the desired fraction, providing raw materials for sale or their own production:

- chipboard, plywood, fiberboard, wood concrete;

- fuel briquettes and pellets;

- pulp, paper and cardboard products.

Small-fraction chips and sawdust in agriculture are used as bedding for livestock, for plant protection and soil fertilization. Shredded wood has good filtration capacity and provides high-quality biochemical water purification from insoluble compounds. Larger waste is required for the operation of boilers, pyrolysis furnaces and gas generators.

Production equipment

Before starting a business, you need to decide on the equipment. There is not much of it:

- Chopping machine;

- Apparatus for removing bark from a tree;

- Drying chamber;

- Wood cutting machine;

- Sorting machine.

The main machine at the enterprise is a woodchip chipper. She is the heart of the workshop. They are of three types:

- Disk. The simplest machines, the lowest in price and the weakest in terms of productivity. Ideal for starting a business with minimal investment. The principle of their operation is quite simple: from 2 to 4 knives work in the knife disc, which turn the initial product into chips. There are options with manual and hydraulic feed: the second is more expensive, but also much more convenient.

- Drum. In comparison with the former, they can produce more product in the same time. Requires high power for normal operation. The wood is fed into a studded drum (manually or automatically), where it is subsequently processed.

- Rotary. Heavy chippers, the most powerful class of machine tools. They can process pieces of wood up to 1 meter in diameter. Suitable for large enterprises with large production volumes.

Do-it-yourself equipment for the production of wood chips is purchased both at specialized sites and from hands.It should be borne in mind that despite the cheapness of used machines, problems with them are much more common and, in addition, they may require initial repairs.