Design features of copper radiators

Copper radiators last longer as they are not subject to corrosion

The use of copper with a minimum amount of impurity allows you to reveal all the advantages of the material. Non-ferrous metal is not afraid of corrosion, it is strong and soft at the same time. The attractive appearance of copper batteries does not require painting. Heating devices are manufactured in various versions. Their design features affect the level of heat transfer.

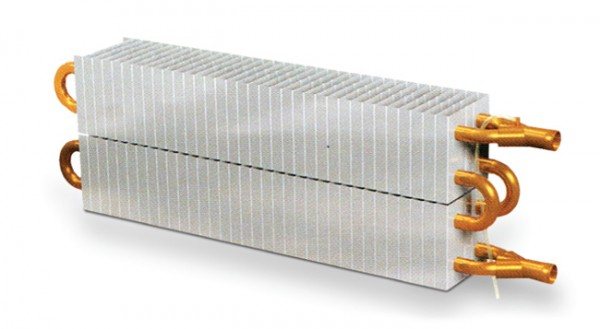

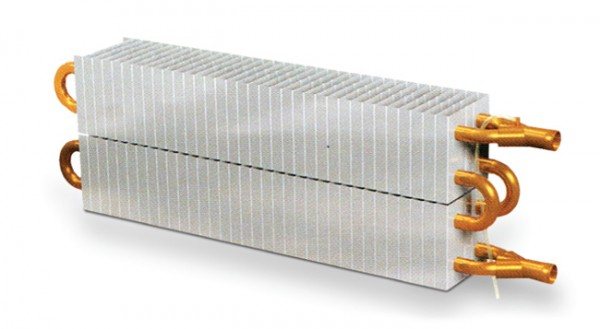

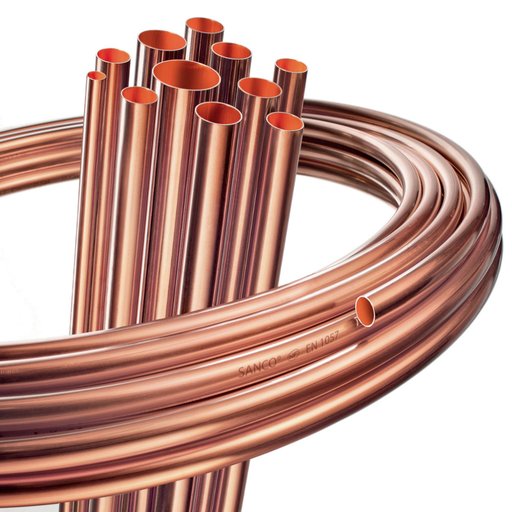

Radiators are made of copper pipes of various diameters. To increase the area of heat transfer, row plates of non-ferrous metal are welded to them. Tubular elements come in horizontal and vertical directions. The devices consist of several sections. The number of pipes and plates depends on the model. There are options on the market with a protective cover made of metal or wood. Decorative cladding is matched to the interior of the home owners.

Heat transfer principle

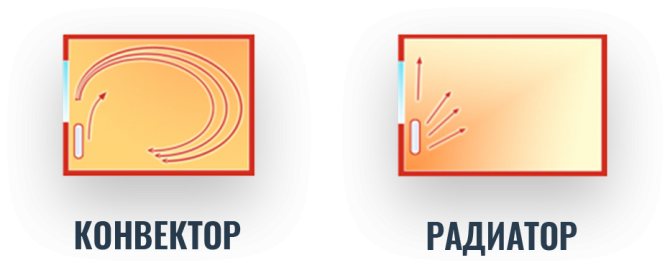

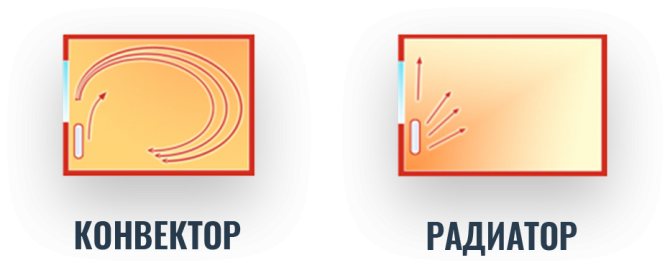

Heat transfer from the heating element to the inside of the room, which is heated, is carried out by means of heat radiation or convection. There is also a combined option - convection-radiating.

Heating devices that use radiation for heat transfer are sectional cast iron batteries or pipe radiators.

Convection heating devices transfer almost all the heat from the coolant through convection natural processes, i.e. due to air circulation inside the heated room throughout the volume from bottom to top.

In this case, the circulating air itself becomes a heat carrier when it passes through the heating elements of the heater. As a rule, the working surface of such elements has a ribbed surface.

Related article: Installation object and requirements for it

These are the following types of devices:

- plate heating convectors;

- convectors with MA heat exchanger;

- copper-aluminum heating radiators.

During the operation of these devices, the circulation of air inside the room leads to the fact that the entire volume is heated evenly and there are no zones with different temperatures inside. In addition, the movement of layers inside the space evens out the humidity and normalizes this indicator.

Copper-aluminum convector

Convection-emitting devices transfer heat in related proportions between convection and radiation.

Such devices include:

- panel steel radiators;

- aluminum sectional heating batteries.

Advantages and disadvantages

Copper pipes and radiators withstand pressures up to 16 atmospheres

Despite the high cost, copper batteries are installed in private houses and apartments. The popularity of the devices is justified by the advantages of the material:

- high level of heat transfer;

- long-term operation;

- pressure resistance up to 16 atmospheres;

- no deposits form on the inside of the pipes;

- coolant temperature up to 150 ° C;

- resistance to impurities in the coolant.

The soft metal does not leak when the pressure rises briefly. Copper batteries are lightweight and versatile.

Disadvantages:

- The devices are sensitive to abrasive particles. Their presence in the fluid flow accelerates the wear of the products.

- Ferrous metal fittings must not be used during installation. This leads to oxidation of copper.

- The high cost of copper radiators is a major drawback for most buyers.

Non-ferrous metal is not afraid of corrosion that occurs in contact with water and air.But copper products are susceptible to oxidation due to a chemical reaction on contact with aluminum or steel.

The main advantages of copper batteries

The products described in this article are considered the most optimal option for any heating system, regardless of whether it is individual or centralized. And if we compare them with other types of radiators, then there are a lot of advantages and unique properties, which can only indicate one thing: copper radiators are one of the most profitable monetary investments. And among the many advantages, the following are worth highlighting.

- High degree of heat transfer. As already noted, in the production process, pure copper is used, due to which the heat from the working fluid is transferred to the house fully and without any losses. It turns out that this is an ideal choice for many systems, in particular, for a centralized highway in apartment buildings, where the temperature of the liquid, as you know, rarely exceeds 60 degrees.

- Long service life. Copper is resistant to all kinds of deformations, the action of corrosion inhibitors and other harmful phenomena; copper batteries are able to last 15-20 years, and sometimes even all 50, while any troubles are not delivered to the user at all.

- Low weight. The copper, from which these radiators are made, weighs a little, and therefore even the largest products with a large number of sections are lightweight. Consequently, there is no excessive load on the walls, and, accordingly, there is no need to use special reinforcing fasteners.

- Low temperature resistance. At a subzero temperature of the working fluid, copper products may be slightly deformed, but in no case should they burst. For this reason, the risk of defrosting is practically reduced to zero.

- Profitability. In the images in this article, you yourself can see that all copper heating radiators are characterized by a small cross section. In this regard, a little working fluid is required, and the user will be able to save on fuel without any damage to the efficiency of the heating system.

- The maximum permissible temperature of the working fluid in the system is 250 degrees. This is one of the reasons why copper batteries are the best solution for grids. By the way, according to the instructions from the manufacturers, some models are quite capable of functioning at higher temperatures, gaining maximum efficiency.

- High pressure capability. As noted at the beginning of the article, copper batteries work fine with a pressure of 16 atmospheres. As for the pressure test, for these products it can reach 25 atmospheres. It is precisely because of the increased resistance to pressure that radiators can be installed in both individual and centralized networks, and the quality of the working fluid does not play a special role in this.

Note! Experts recommend installing copper radiators in those heating networks where the working fluid contains a large amount of chlorine salts. After all, if, for example, traditional steel devices are used for such a liquid, then in any case problems will arise - up to clogging of the pipeline.

In a word, buying a copper radiator is definitely a profitable investment that will pay off soon.

Replacing heating batteries in an apartment

Earlier we talked about how to independently change the battery in an apartment, in addition to this article, we advise you to read this information for all the details, see here

Principle of operation

The temperature in copper radiators rises quickly and warms up the room

Radiators are the part of the heating system that is responsible for transferring heat. The liquid circulating in the circuit is heated in the boiler.It is piped to the batteries. The high temperature of the water will heat up the metal. Copper has a high thermal conductivity, the indicator exceeds the characteristics of steel several times. The work of radiators is based on physical processes:

- Thermal conductivity is the transfer of energy from heated bodies to colder ones. Pure copper, which is used in the manufacture of batteries, has a value of 401 W / (m * K). This is one of the highest values among metals.

- Thermal radiation - hot metal spreads infrared waves.

- Convection is the transfer of heat by a stream of air. Cold air masses pass through the radiator and their temperature rises. The heated stream rises to the ceiling. Heavy cold air takes its place, making the process continuous.

The copper radiator is highly efficient. Its characteristics ensure a rapid rise in room temperature.

Pros of copper-aluminum batteries

Aluminum and copper are distinguished from other metals by their increased heat transfer. Compared to other metals that are also used for the manufacture of radiators, the heat transfer rate is several times higher. Which undoubtedly affects the benefit of copper-aluminum radiators. The advantages of this system include:

- High thermal conductivity

- Long service life

- Heating temperature control

- Overheating of the coolant does not happen

- Reinforced installation

- Good tolerance of negative environmental factors, water hammer

- Affordable price

- Possibility of installation in an apartment building

Which battery to choose

The cost of radiators is not the last criterion when buying a device. Aluminum batteries are sensitive to the composition of the coolant, have a low operating pressure, and are sensitive to water hammer. They are not recommended for installation in apartments with central heating. Aluminum appliances will be the best budget solution for a private house. Copper batteries do not have the above disadvantages. They are effective, resistant to aggressive influences.

When choosing between copper and aluminum radiators for cooling, take into account related factors. The non-ferrous metal structure has a small diameter and corrodes faster. Aluminum tubes with a cross section 2 times larger are less likely to clog and last longer.

Aluminum or copper-aluminum batteries?

Of course, these types of radiators have undoubted advantages over other types of heating systems. In Russia, the winters are cold, and every owner wants to insulate his house as much as possible, while saving on heating.

Aluminum selection criteria

Aluminum radiators are the ideal solution for heating a small room. Statistics show that the demand for batteries made from this metal is the highest. Low cost, lightness of construction, ease of installation are the main factors when choosing radiators made of aluminum.

Aluminum batteries are suitable for any indoor installation. They are not afraid of temperature drops and high degrees of the coolant. Aluminum has high thermal conductivity and convection.

The shape of the device is designed for the purpose of uniform heating of the air. The internal volume of this system is insignificant, so a low-power pump is suitable. Despite this, it has a significant return of thermal energy.

In the markets you can find a huge variety of colors for aluminum radiators. What is also a plus of this choice.

The buyer can only be confused by the fact that aluminum structures are sensitive to the pH environment. At a high rate, the system will not last long. Does not tolerate the presence of impurities in liquids. To avoid corrosion, the composition of the coolant should be monitored. If this is not possible, then it is better to abandon aluminum radiators.

Methods for mounting copper radiators

To make efficient heating and not spoil the interior, choose one of two methods of installing batteries.

Wall mount

Copper radiator on legs with bottom connection

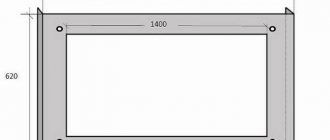

Brackets are used for wall mounting the batteries. They are fixed to the supporting structure and serve as the basis for the installation of heating devices. The best option for placing radiators is under the window. According to building codes, the length of the device should be 50-75% of the size of the window structure. The rules require batteries to be installed at a distance of 60-100 mm from the floor and 30-50 mm from the wall.

On legs

Floor placement has its advantages: the load on the wall is eliminated, and installation is simplified. Such models are popular in interiors with panoramic windows. They are installed in cottages, country houses, offices. The disadvantage of the batteries on the legs is the limited connection, only floor piping is suitable.

Comparative characteristics of radiators made of different materials.

The main parameters by which heating devices are chosen are:

- lifetime,

- strength,

- thermal conductivity,

- price,

- the weight,

- appearance.

The market today offers radiators made of cast iron, steel, aluminum, copper, aluminum-steel and copper-aluminum. With proper installation of systems and proper maintenance, almost all radiators can serve for at least 25 years, but copper radiators have no competitors, whose service life can reach hundreds of years. In terms of mechanical strength, copper is inferior to cast iron and steel, but in its ability to withstand sharp fluctuations in the pressure of the coolant, it is in the lead. Only serial cast-iron radiators are inferior in design, as well as in weight. In terms of thermal conductivity, if we compare cast iron, steel and copper, the latter is almost 6 times more efficient than its competitors. Aluminum, whose thermal conductivity is 230 W / m * K, is not far behind it. The cost characteristics of radiators depend not only on the metal from which they are made, but also on the number of sections, on the brand. The most affordable are cast iron and steel, then aluminum radiators, a little more expensive - bimetallic, and the most expensive - batteries made entirely of copper, however, there is something to pay for. Before talking about copper-aluminum radiators, consider the pros and cons of heating devices made entirely of either one or another metal.

The copper heating radiator is not yet in wide demand for several reasons. Firstly, the price of a pure copper battery is quite high - up to 25 thousand rubles (this amount can be used to equip an entire apartment with cast-iron or aluminum radiators). Secondly, traditionally heating systems in multi-storey buildings are made of steel pipes, which causes some discomfort when installing copper appliances. For all other parameters: durability, heat transfer and ease of use, environmental friendliness, copper radiators are unmatched.

Aluminum batteries have gained particular popularity due to their attractiveness, low weight (compactness) and very affordable prices. In addition, many European manufacturers have begun to actively promote their products on the Russian market. "High heat output + attractive design + affordable price" - this is the formula for the success of aluminum heaters. However, sellers are in no hurry to inform buyers about some of the inherent disadvantages of these radiators that complicate its efficient operation in a district heating environment. In particular, this is the low resistance of the metal to ruptures during sudden pressure drops in the network (especially during test runs in preparation for winter). The second problem is related to the quality of the coolant, which contributes to the rapid corrosion of the metal. Very often, the service life of aluminum batteries is twice as low as stated by the manufacturer.The price of a heating panel depends on the number of sections in it, the cost of one section starts from 160 and can go up to 900 rubles.

You can, of course, buy an aluminum or copper radiator, but it is better to opt for a bimetallic one.

Equipment for the installation of copper radiators

Shut-off valves can also be selected from a similar metal

One of the factors for the safe operation of the heating system is the installation of shut-off valves.

Mayevsky crane

For normal operation of the water heating system, the batteries must be equipped with a Mayevsky crane. This device serves to evacuate the air accumulated in the pipes. It is installed at the top of the battery. The shut-off valve is opened after starting the system to release trapped air and prevent the formation of plugs. After turning the valve one turn, a hiss characteristic of air outlet appears. The tap is kept open until a trickle of water appears.

Shut-off valves

Taps and valves are needed to adjust the amount of coolant in the batteries, as well as forced draining. Shut-off valves allow you to shut off the water flow in the event of a radiator breakdown. It is made of brass, the connection with the branch pipe is threaded. Thermostatic expansion valves, depending on the model, require manual override or are automatic.

Bypass

A bypass pipe is installed between the inlet and outlet lines. Its diameter is less than the cross-section of the pipes to be connected. The jumper allows the coolant to move around the battery. The element is typical for a one-pipe heating system. A tap can be installed on the bypass, then the movement of water is controlled.

When installing copper radiators, ferrous metal fittings must not be used. To avoid chemical reaction, all fittings must be made of brass.

Inertia of the heating system

The inertia indicator of the heating system determines how quickly heating devices transfer heat from the coolant to the interior of the room that is being heated, as well as how long the system continues to heat the room after the end of the boiler operation.

Modern design criteria for heating systems, in which thermostatic equipment is used, imply a quick response of the heater when the temperature inside the room changes. It must quickly reach operating power and shut down without unnecessary heat loss.

The system, in which the regulation is fast, makes it possible to reduce heating costs by up to 20%, which is confirmed by the conducted observations.

The thermal inertia of heating devices (and the heating system as a whole) determines such a factor as the ability to quickly cool or heat up.

Factors Determining Thermal Inertia

- coefficient of thermal conductivity of the material from which the heater is made;

- the total volume of the coolant in the heating device.

Thermal conductivity is measured in W / m ° C. Below are the indicators of thermal conductivity for some materials from which heating devices are made:

- cast iron - 45;

- steel - 55;

- zinc - 100;

- aluminum - 230;

- copper - 420.

- cast iron radiator - 10 l;

- steel panel radiator - 3.5 l;

- aluminum radiator - 2.4 liters;

- bimetallic radiator - 1.5 l;

- copper-aluminum - 0.7 l.

The volume of the coolant in various heating devices

As you can see from the MA list, radiators have low thermal inertia. In other words, they heat up quickly and cool down just as quickly.

Radiator inside

Important! Significant cost savings during the operation of heating systems with a decrease in thermal inertia indicators are observed when using thermostatic valves.Therefore, MA radiators (which belong to non-inertial ones) must be equipped with appropriate equipment.

The lack of inertia, together with the high thermal conductivity of the materials from which the copper-aluminum radiators are made, allow the temperature in the heating system equipped with them to be adjusted quickly and efficiently (for example, when opening a window or when exposed to direct sunlight).

Related article: Heating as part of the interior

How such radiators are arranged and used can be seen in the video:

Variety of copper radiators

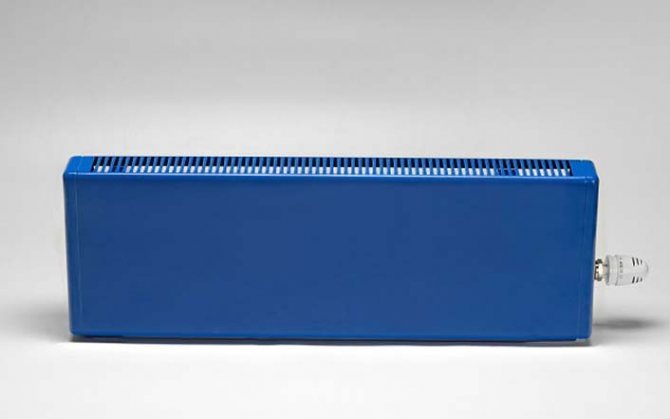

Copper plate radiator in a metal casing

When choosing a suitable option for radiators, it is worth evaluating their appearance and technical characteristics. The main one is the heat transfer of the device, it shows what area the device can heat. The batteries can be installed in rooms with high humidity. Various models of heated towel rails are available for bathrooms. In stores, there are copper radiators of domestic and imported production. Products from China are not recommended, they are cheaper due to the use of thin sheets of copper. Radiators are of limited service life. An alternative to buying an expensive radiator will be a bimetallic model. The heat carrier in them is made of copper, and the outer panels are made of aluminum.

Among the variety of heating devices, copper radiators stand out with a minimum of disadvantages. They are versatile in use and have high heat dissipation. The significant cost is the only minus of the devices.

Is a revolutionary product in the field of heating systems. The use of advanced SCAD (Super Care Advanced Deformation) technology in the production of a heating element made of pure copper and a decorative casing made of oak wood has created a previously unattainable super-powerful, ultra-compact and elegant heater.

Heating devices of the CLASSICstyle series are designed for liquid heating systems for residential and public premises. The device is used both in autonomous heating systems with closed circulation of the coolant and in central heating systems. Wall-mounted heating devices are designed for lateral connection to the heating system and are equipped with a universal set of fasteners (right or left connection), and are also available in two versions: for flow connection and for circulation.

Efficiency

It is no secret that of the materials used, copper, silver and gold are the top three in terms of thermal conductivity.

The thermal conductivity of copper exceeds the thermal conductivity of steel and cast iron by 4-6 times, and of aluminum by 1.5-2 times.

The homogeneity of the materials used is also important to achieve the maximum heat transfer effect. When heat waves pass, at the interface of inhomogeneous materials (for example, the place of an alloy of copper and aluminum in bimetallic radiators), resistance arises, which reduces the efficiency of heat transfer, and therefore heat transfer.

The heating element of the CLASSICstyle heater is made entirely of copper (total copper and silver content at least 99.97%). Due to the homogeneity of the material used (both pipe and copper plates), losses of the transferred thermal energy are excluded. The high thermal inertia of the device leads to rapid warming up of the heated room.

Durability

Convectors CLASSICstyle are unique devices of their kind - only timeless materials are used in their manufacture: copper and solid wood of a valuable species - oak. 96% of the copper ever mined by mankind is still in circulation, and oak furniture has long been inherited.

Aesthetics and design

The laconic severity of the design of the CLASSICstyle heater means sophistication and individuality.The classic shape and lively texture of the wooden casing will emphasize the style and aesthetics of any room, give a feeling of comfort, tranquility and luxury. It is the tree in the interior that most often causes warm feelings in a person. A beautiful and majestic tree, its unique shape and rich texture contributes to the creation of a healthy microclimate in the house.

Environmental friendliness

Without a doubt, natural materials are the most environmentally friendly.

Copper has been proven to inhibit bacterial growth. In other words, although copper does not kill bacteria, the growth of bacterial colonies on copper stops immediately, and in the absence of colonial growth, they quickly disappear. Therefore, in many medical institutions, especially in the USA and Japan, functional furnishings (doorknobs, taps, etc.) are made of copper.

In addition, in order to ensure absolute safety for health, in the manufacture of CLASSICstyle, no paints and varnishes are used on the heating element. Thus, when exposed to high temperatures, the CLASSICstyle does not emit harmful substances into the environment and does not "dry" the air, maintaining a healthy microclimate.

Reliability

The use of timeless materials and the unique design of CLASSICstyle heating devices make them one of the most reliable and resistant to external influences. Press fittings recognized by experts from all over the world, the absence of unnecessary connecting nodes, the use of a seamless copper pipe without welding seams - this is a guarantee of calmness, warmth and comfort.

It is known that in Russian central heating systems, rust, scale and various deposits are present in the coolant, and, as a result, due to their mechanical effect, the inner surface of the radiators is damaged, which eventually leads to the failure of the radiator. During the operation of CLASSICstyle, after about 100 hours, a resistant water-insoluble protective layer - tenorite - forms on the inner surface of the copper pipe. It protects the surface in contact with the coolant from further chemical and mechanical wear without loss of heat transfer. And this is forever! Due to their low chemical activity, the copper elements of the CLASSICstyle heater do not change their thermal characteristics during the entire service life (copper does not interact with nitrogen, hydrogen and carbon even at high temperatures). And this, unlike most radiators, eliminates the problem of additional maintenance and preventive costs.

The versatility of connecting copper convectors to the heating system (left or right connection), the presence of a standard 3/4 inch thread, a complete set of installation equipment ensures simplicity and high speed of installation.

Technical characteristics of CLASSICstyle copper convectors:

Heating system

| autonomous, central | |

| Operating temperature | not more than 150 ° С |

| Operating pressure | no more than 1.6 MPa (16 atm) |

| Test pressure | 50 mPa (50 atm) |

| Heating connection | output ¾ NO |

| Heating element service life | not less than 49 years, subject to the rules of operation |

Completeness of delivery:

Heating element 1 piece: copper pipe М1 - d28, ribbed copper plates М1 - d28, press fitting - 28 · 3/4;

Decorative cover 1 pc. (solid natural oak);

Mounting plate 1 pc .;

Bracket 2pcs .;

Dowel 4 pcs .;

Dowel 8pcs.

Choosing CLASSICstyle convectors, you choose: a reliable, environmentally friendly, durable, most efficient heating appliance with a sophisticated design. All-copper convectors of the new generation CLASSICstyle are the solution to heating problems for the next 49 years!

One size for all convector models with / without jacket: 830 * 420 * 110mm / 830 * 240 * 70mm

Aluminum electric radiators>

With the constant rise in the cost of heating services, many consumers are looking for alternative ways to heat their homes. The electric aluminum radiator is very popular today and this is due to its technical characteristics.

Over the past decade, many manufacturers have begun to pay close attention to improving the efficiency of electric heating household appliances. Many countries are already moving away from using gas, coal and coke to heat homes and industrial plants. The most popular and safest forms of energy today are wind power and sunlight. In Europe, for example, electric batteries have been used in everyday life for a long time. They have become popular in the CIS countries as well.

Typically, electric aluminum heating radiators consist of two elements:

- The heater is ten - a tube that heats up when the device is connected to the mains.

- Heat dissipating element - this is an external battery box with holes through which heat is transferred from the device to the air in the room.

In order for an apartment with this type of heating to be really warm, you should calculate in advance how much power the radiator should be and how many sections it should consist of.

According to the principle of operation, aluminum electric batteries are divided into liquid and non-liquid models. The advantage of the former is that they can be used both for connection to a general heating system and as separate heaters powered by a heating element. These devices are equipped with a temperature sensor, and many of them are controlled by a remote control.

Liquid-free types of electric batteries are very light, they heat up quickly, but it is not possible to connect them to central heating.

They can be carried from room to room or hung on walls, and are best used in intermittent residential areas such as summer cottages or retail outlets.

Another advantage of electric batteries is the ability to set the heating mode, which saves energy costs when there is no one in the room. There are models in which you can customize the program for several days at once, taking into account the time of day.