Principle of operation

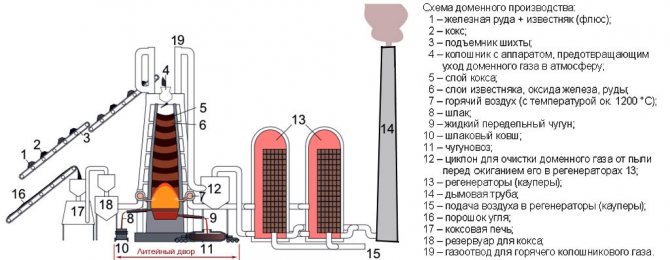

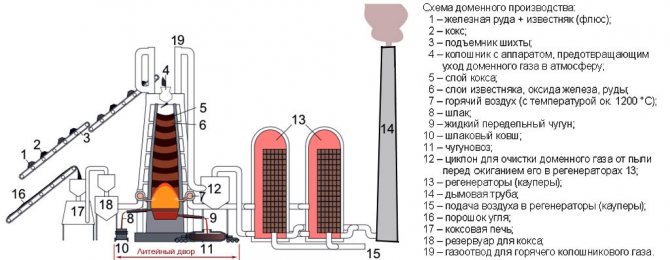

The principle of operation of a blast furnace is as follows: ore charge with coke and limestone flux is loaded into the receiving chamber. In the lower part, there is a periodic discharge of cast iron / ferroalloys and, separately, of the slag melt. Since the level of material in the blast furnace decreases during release, it is necessary to simultaneously load new batches of charge.

The operating process is constant, combustion is maintained with a controlled supply of oxygen, which ensures greater efficiency.

The design of the blast furnace ensures a continuous process of ore processing, the life of the blast furnace is 100 years, overhaul is carried out every 3-12 years.

Blast furnace photo

Photo1

Photo 2

Photo 3

Photo4

Photo 5

Who invented?

The modern blast furnace was invented by J. B. Nilson, who first began to heat the air supplied to the blast furnace in 1829, and in 1857 E. A. Cowper introduced special regenerative air heaters.

This made it possible to significantly reduce the consumption of coke by more than a third and increase the efficiency of the furnace. Prior to this, the first blast furnaces were actually dry-blown, that is, unenriched and unheated air was blown into them.

The use of cowpers, that is, regenerative air heaters, made it possible not only to increase the efficiency of the blast furnace, but also to reduce or completely eliminate the clogging, which was observed in case of technology violations. We can safely say that this invention allowed to bring the process to perfection. Modern blast furnaces work exactly according to this principle, although their control is now automated and provides greater safety.

What is a modern blast furnace like?

The lifespan of a blast furnace is relatively short for a facility of this size - about a decade. During this time, the structure is subjected to heavy loads, burdened by thermal heating, then capital repairs or demolition are required. Pig iron production cannot be called harmless; it is associated with emissions of phosphorus, sulfur and other not very useful substances into the atmosphere. Taken together, these circumstances induce many countries to curtail metallurgical production or modernize it (especially if the industry is basic and budget-forming). A modern blast furnace is a system that is quite simple in its principle, which, however, requires a complex control scheme with numerous control loops that ensure the most efficient use of raw materials and energy resources.

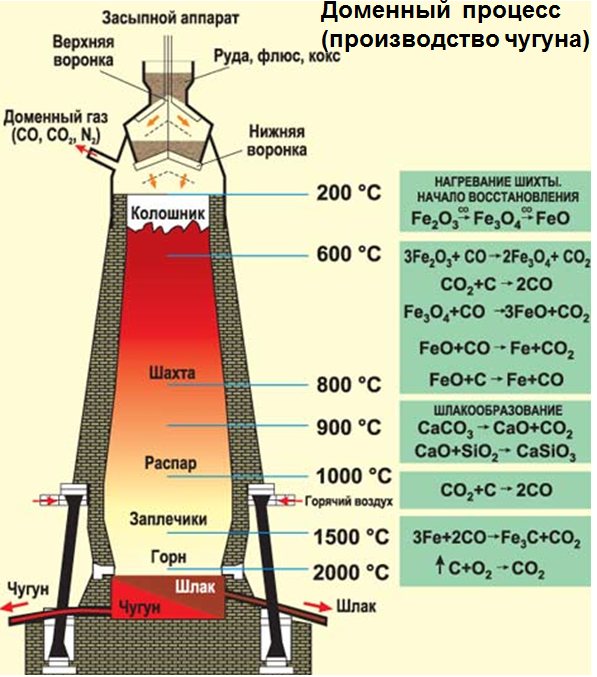

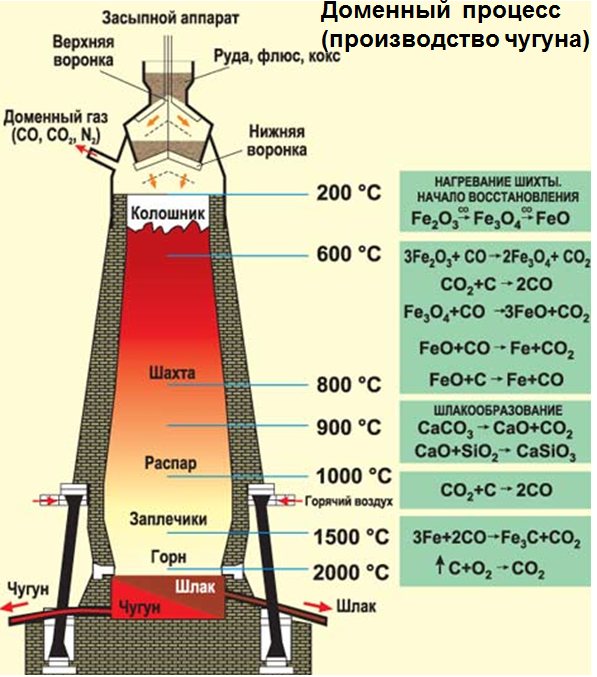

Domain process

Modern furnaces for melting cast iron provide about 80% of the total amount of cast iron, from the casting sites it is immediately fed to the electric smelting or open-hearth shops, where the ferrous metal is converted into steel with the required qualities.

Ingots are obtained from cast iron, which are then sent to manufacturers for casting in cupolas. To drain slag and cast iron, special holes are used, called tap holes. However, in modern furnaces, not separate, but one common taphole is used, divided by a special refractory plate into channels for feeding cast iron and slag.

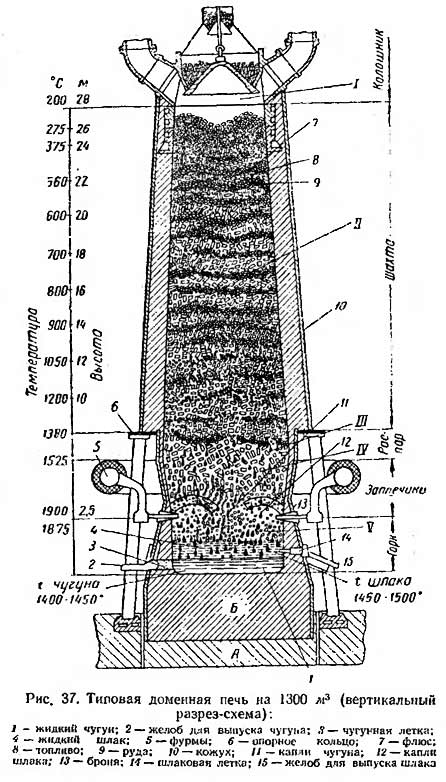

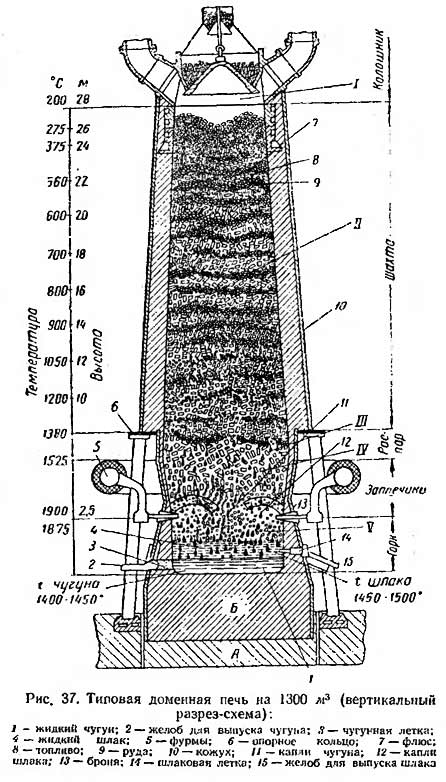

How does a blast furnace work?

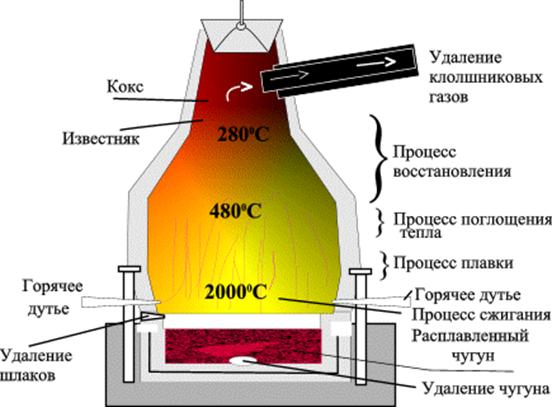

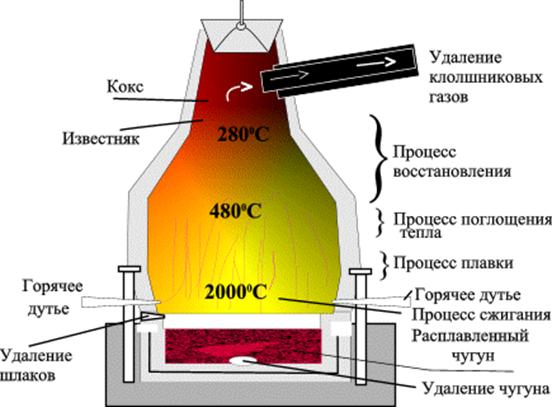

The blast furnace process completely depends on the excess of carbon in the furnace cavity; it consists in thermochemical reactions that take place inside when all components are loaded and heated.

The temperature in the blast furnace can be 200-250 ° C directly under the top and up to 1850-2000 ° C in the active zone - steam.

When hot air is supplied to the furnace and coke is ignited in the blast furnace, the temperature rises, the process of decomposition of the flux begins, as a result of which the content of carbon dioxide increases.

With a decrease in the column of material in the charge, the reduction of iron monoxide occurs, in the lower part of the column, pure iron is reduced from FeO, flowing into the hearth.

As the iron flows down, it actively contacts with carbon dioxide, saturating the metal and giving it the required properties. The total carbon content in iron can range from 1.7%.

The meaning of the word domna

Examples of the use of the word blast-furnace in literature.

In case of repeated violations of these Recommendations, the administrator of the higher-level zone has the right to revoke the previously delegated domain and transfer it to another organization or reserve the right to administer it.

We have to organize a tight barrage over the remains of the last blast furnace, where they hover, mmm.

If there are several applications for the same domain, the decision to delegate it is made in the order in which applications are received in the registration queue.

It was all like that, Blast furnaces melted metal, And the guys changed their pipes for the Beatles bell-bottoms, And while I was in a cafe Carrying her large portfolio, the house manager was planting his liter.

Domna Panferovna was out in Yerusalim, she was immersed in the living Erdani, in the holy river.

They say that the feminine name Domna, used as a joke, stuck to the iron-smelting furnace.

In all countries, among all peoples, universities were emptied, the intelligentsia was dying out - the brain of the peoples, museums, paintings and book depositories were gathering dust, falling apart, winding down, - the peoples were ruled by a soldier, wise as a barracks watch, and a gate, energetic as a cinema, who believed that everything industry and the economic life of peoples - there is only: the stock exchange and fraud in high and low currencies: it is not for this reason that in England, France, Italy - blast furnaces, factories and factories did not smoke - and coal mines, eternally black and dusty, were flooded with water. after others, hundreds, thousands, collapsed, went bankrupt - firms, trading offices, banks, enterprises - and workers, tens, hundreds of thousands, millions, were unemployed - the lumpen proletariat went from one professional office to another factory office in big cities, in strike-breucherstvo, - spending the night no one knows where, because for many years nothing had been built in Europe, and in England alone it was necessary to build a million houses - not because will then feel

If I could not bring you this more or less comforting news tonight, Monsieur Jordan, I think I would have climbed onto the blast furnace and thrown myself into the top of the furnace.

Domna Vlasyevna fell silent: she was quiet and submissive, but to the end she was already sitting in a great tightness.

Nikon was burdened by this chicken work: he would rebuild the blast furnace, put the rolling machine, and then what?

I said that Petsha and I had fathers working in the puddling shop, while Kolushka’s had that one at the blast furnace all his life.

And the Concordia Command reports that the double detonation of that blast furnace appears to have cracked the mainland platform.

Coke and ore were now fed into the blast furnace continuously, and not periodically, as in the production of crucible iron.

There was a time - Chelyshev was also considered a maniac, indomitable aspiring to build the bequeathed Kurako, unseen in Russia, an obedient whopper - a blast furnace.

Either she does not exist at all, or she obediently acts in the blast furnace, growing minerals on the surface of the burned-out hazel and, therefore, is completely subject to man.

Source: library of Maxim Moshkov

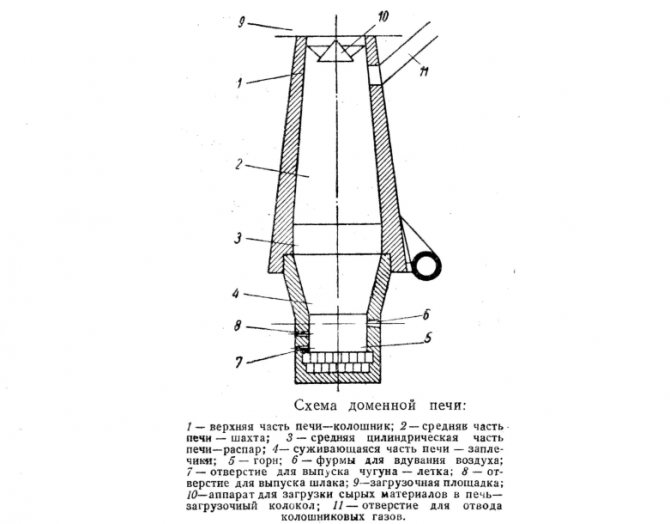

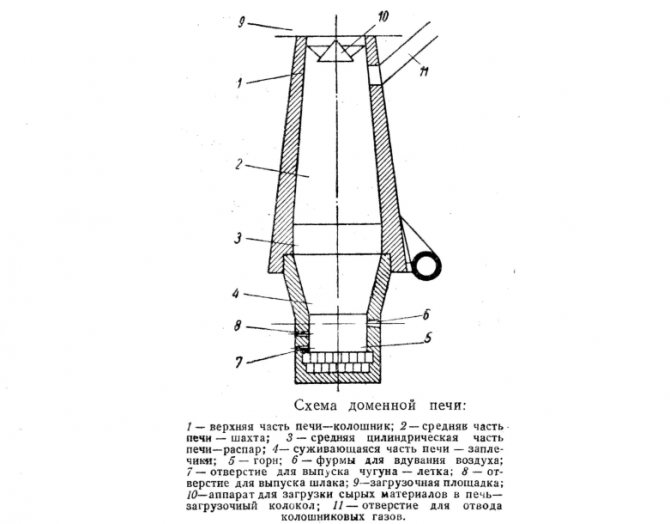

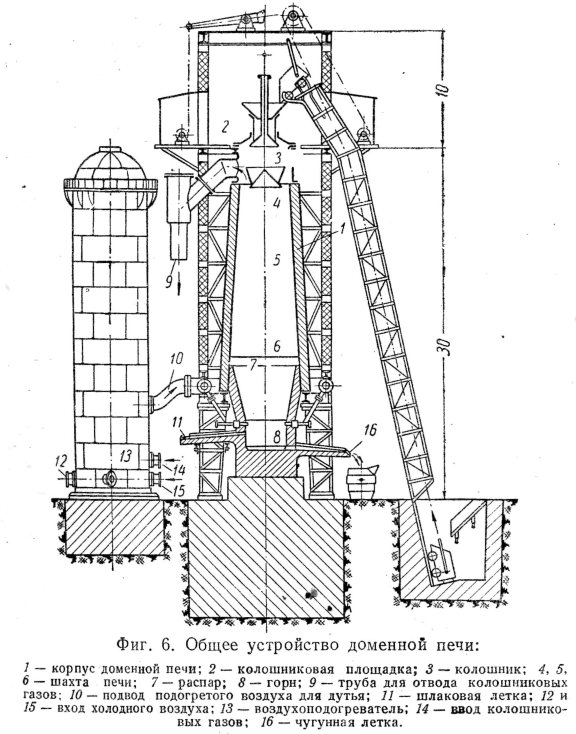

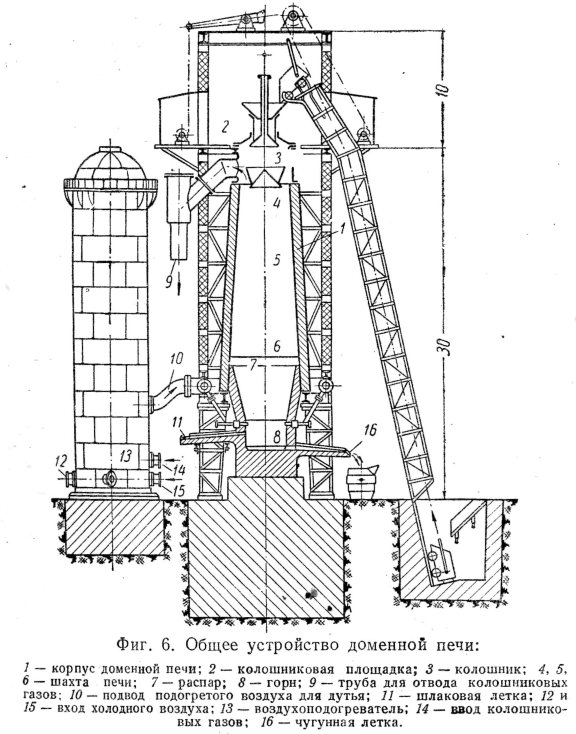

Blast furnace diagrams

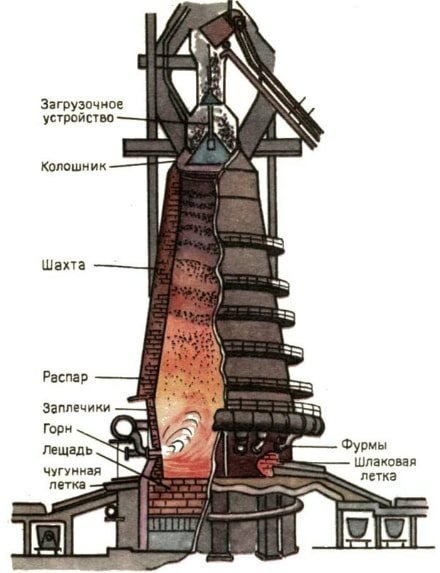

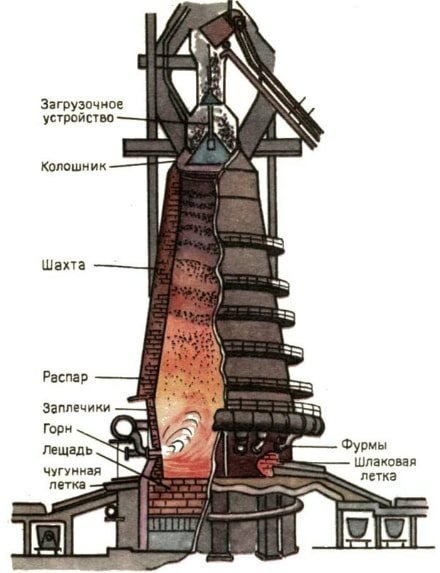

Blast furnace diagrams in section (different options):

Scheme 1

Scheme 2

Scheme 3

Scheme 4

Scheme 5

Blast furnace device

The blast furnace design is very complex; it is a large complex, which includes the following elements:

- hot blast zone;

- melting zone (this includes the forge and shoulders);

- steam, that is, the zone where FeO is reduced;

- a mine where Fe2O3 is reduced;

- top with material preheating;

- loading of charge and coke;

- blast furnace gas;

- the area where the column of material is located;

- slag and liquid iron outlets;

- collection for waste gases.

The height of the blast furnace can reach 40 m, weight - up to 35,000 tons, the capacity of the working area depends on the parameters of the complex.

The exact values depend on the workload of the enterprise and its purpose, requirements for the volume of metal obtained and other parameters.

A more detailed version of the device:

Blast furnace repair discharges

To maintain the working condition of the blast furnace, major repairs are carried out regularly (every 3-15 years). It is divided into three types:

- The first category includes work on the release of melting products, inspection of equipment used in the technological process.

- The second category is a complete replacement of equipment items subject to medium repair work.

- The third category requires a complete replacement of the device, after which a new filling of raw materials with straightening of the top is performed.

Systems and equipment

A blast furnace is not only an installation for the production of pig iron, but also numerous auxiliary units. This is a charge and coke feeding system, slag, molten iron and gases removal, an automatic control system, cowpers and much more.

The operating principles of the furnace have remained the same as they were centuries ago, but modern computer systems and industrial automation have made the blast furnace more efficient and safer.

Cowpers

The modern blast furnace design involves the use of a cowper to heat the supplied air. This is a cyclic unit made of heat-resistant material, which provides heating of the nozzle up to 1200 ° C.

When cooling down, the cowper turns on the packing to 800-900 ° C, which allows to ensure the continuity of the process, reduce coke consumption and increase the overall efficiency of the structure.

Previously, such a device was not used, but starting from the 19th century. it is necessarily a part of the blast furnace.

The number of cowper batteries depends on the size of the complex, but usually there are at least three of them, which is done with the expectation of a possible accident and preservation of performance.

Top-top apparatus

Top-bottom apparatus - this part is the most critical and important one, which includes three gas valves operating according to a coordinated scheme.

The cycle of this node is as follows:

- in the initial position, the cone is raised, it blocks the exit, the lower cone is lowered;

- the skip loads the charge into the top;

- a rotating funnel turns and passes the raw material through the windows onto a small cone;

- the funnel returns to its original position, closing the windows;

- the small cone is lowered, the loading goes into the intercone space, after which the cone rises;

- the large cone assumes its original position, releasing the charge into the cavity of the blast furnace for processing.

Skip

Skips are special charge lifters. With the help of such hoists, overshoes from the skip pit grab the raw material supplied upward along the inclined overpass.

Then the galoshes are overturned, feeding the charge into the loading area, and are returned downward for a new portion. Today this process is carried out automatically, special computerized units are used for control.

Tuyeres and tap holes

The nozzle of the furnace lance is directed into its cavity, through which the course of the melting process can be observed. For this, peepers with heat-resistant glasses are mounted through special air ducts. At the cut, the pressure can reach values of 2.1-2.625 MPa.

The holes are used to drain cast iron and slag; immediately after release, they are tightly sealed with special clay. Previously, cannons were used, which were lined up with a plastic clay core, today remote-controlled cannons are used, which can come close to the structure. This decision made it possible to reduce the trauma and accident rate of the process, to make it more reliable.

Notes

- Early elections of the Head of the rural settlement "Domninskoe"

- ↑ 12

Population of the Russian Federation by municipalities as of January 1, 2020 (Russian) (July 31, 2017). Date of treatment July 31, 2020. Archived July 31, 2020. - System "Tax reference" (unspecified)

(unavailable link). Date of treatment June 5, 2011.Archived March 4, 2020. - REGISTER of administrative territorial and settlements of the Trans-Baikal Territory as of 01.01. 2013 Archived copy of January 25, 2020 at the Wayback Machine on the website of the Ministry of Territorial Development of the Trans-Baikal Territory

- Domna village

in the Encyclopedia of Transbaikalia - 2002 All-Russian Population Census. Tom. 1, table 4. The population of Russia, federal districts, constituent entities of the Russian Federation, districts, urban settlements, rural settlements - regional centers and rural settlements with a population of 3 thousand or more (unspecified)

... Archived February 3, 2012. - All-Russian population census 2010. The population of the Trans-Baikal Territory by urban districts, municipal districts, urban and rural settlements, urban settlements, rural settlements (unspecified)

... Retrieved September 11, 2014. Archived September 11, 2014. - The population of the Russian Federation by municipalities. Table 35. Estimation of the resident population as of January 1, 2012 (unspecified)

... Retrieved May 31, 2014. Archived May 31, 2014. - The population of the Russian Federation by municipalities as of January 1, 2013. - M .: Federal State Statistics Service Rosstat, 2013 .-- 528 p. (Table 33. Population of urban districts, municipal districts, urban and rural settlements, urban settlements, rural settlements) (unspecified)

... Retrieved November 16, 2013. Archived November 16, 2013. - Table 33. The population of the Russian Federation by municipalities as of January 1, 2014 (unspecified)

... Date of treatment August 2, 2014. Archived August 2, 2014. - Population of the Russian Federation by municipalities as of January 1, 2020 (unspecified)

... Date of treatment August 6, 2020. Archived August 6, 2015. - Population of the Russian Federation by municipalities as of January 1, 2020

- Schedule of trains at Domna station

- MOU average general education art. Blast furnace

- Stepanov Mikhail Alekseevich. Directory> People> Experts (unspecified)

... "Center for Military-Political Research MGIMO". Date of treatment October 5, 2020. Archived October 5, 2020.

How to make a blast furnace with your own hands?

Nuances

The production of pig iron is a highly profitable business, but it is impossible to organize the production of ferrous metal without serious financial investments. A blast furnace with your own hands in "handicraft conditions" is simply unrealizable, which is associated with many features:

- extremely high cost of a blast furnace (only large plants can afford such costs);

- the complexity of the design, despite the fact that the drawing of the blast furnace can be found in the public domain (above the diagram), it will not work to assemble a full-fledged unit for the production of cast iron;

- individuals and individual entrepreneurs cannot engage in activities for the manufacture of cast iron, for this simply no one will issue a license;

- the deposits of raw materials for ferrous metallurgy are practically depleted, there are no pellets or sinter on free sale.

But at home, you can assemble an imitation of a furnace (mini-blast furnace), with which you can melt metal.

But these works require maximum attention and are highly discouraged in the absence of experience. Why might such a construction be required? Most often, this is heating for a greenhouse or summer cottage with the most efficiently used fuel.

Tools and materials

To make a structure at home, you need to prepare:

- metal barrel (can be replaced with a pipe with a large diameter);

- two pieces of circular pipe with a smaller diameter;

- section of the channel;

- Sheet steel;

- level, hacksaw for metal, tape measure, hammer;

- inverter, set of electrodes;

- bricks, clay mortar (necessary for the foundation of the structure).

All work must be carried out only on the street, since the process is quite dirty and requires free space.

Step-by-step instruction

- On the prepared workpiece in the form of a barrel, the top is cut off (it should be left, as it will be needed further).

- A circle with a diameter smaller than the diameter of the barrel is cut out of steel, a hole is made in it for a pipe.

- The pipe is carefully welded to the circle; at the bottom, sections of the channel are attached by welding, which will press down the fuel during the operation of the furnace.

- The furnace cover is made from the previously cut bottom of the barrel, in which a hole is made for a mortgage hatch with a door. It is also necessary to make a door through which ash residues will be removed.

- The stove must be installed on the foundation, since during operation it heats up very much. To do this, first a concrete slab is installed, then several rows of brick are laid out, forming a depression in the center.

- To remove combustion products, a chimney is mounted, the diameter of the straight part will be larger than the diameter of the furnace body (required for better gas removal).

- The reflector is not an obligatory element of the design, but its use can improve the efficiency of the furnace.

Design features

The features of such a self-made oven are:

- the level of efficiency is good;

- there is the possibility of working in an offline mode up to 20 hours;

- it is not active combustion that occurs in the furnace, but smoldering with constant heat release.

The main difference between a "household" blast furnace will be the restriction of air access to the combustion chamber, that is, smoldering of wood or coal will occur at a low oxygen level. An industrial blast furnace works on a similar principle, but household blast furnaces are used only for heating, metal cannot be melted in it, although the temperature inside the chamber will be sufficient.

Multiple domain names for a site: how to do it right

Home Articles Domain Name Registration

The site can have several domain names (aliases), in principle, their number is limited only by common sense. But often the creation of synonyms for an existing domain name is caused by practical necessity, for example, the most common case is that the old domain name was obtained from the provider and is a third-level domain name (for example, site.ural.ru), it is known to many customers and partners of the organization and it can be liquidated it is impossible, but it does not belong to an organization, it is difficult to write, it is not prestigious, and investing money in its promotion is unreasonable. It is recommended to register a second-level domain name (for example, site.ru) and make it synonymous with the existing one. It's important to do it right, so that search engines index such a site as one site and not as three sites:

- site.ural.ru

- site.ru

- www.site.ru

Your actions:

- Register the domain name site.ru for your organization, acting under the agreement of your organization with RU-CENTER (www.nic.ru) or under your agreement with a partner RU-CENTER.

- Your site exists on some hosting, you need to "bind" a new domain name to this hosting.

- Contact the hosting administration to provide DNS servers (at least two) to support the domain. Also ask to register address records (A) with the IP address leading to site.ural.ru.

- In the section for RU-CENTER clients https://www.nic.ru/login/, write in the domain name parameters the DNS servers of the DNS1 and DNS2 domain provided by the hosting administration.

- After completing the domain name registration process, contact the hosting administration with a request to register the received domain name as a synonym for the existing site site.ural.ru.

- no matter what domain name the user would type in the address bar, it will instantly change to the main one www.site.ru.

- search engines will index exactly the domain you want - www.site.ru.

Now we have three domain names leading to one site. The main domain name will be www.site.ru. In order for it to be in the index of search engines, write it in the file.htaccess

which is in the root directory, the following:

- RewriteEngine on

- RewriteBase /

- RewriteCond% {HTTP_HOST} ^ site.ru $

- RewriteRule ^ (. *) $ Https://www.site.ru/$1 [NC, R = 301, L]

- RewriteCond% {HTTP_HOST} site.ural.ru $

- RewriteRule ^ (. *) $ Https://www.site.ru/$1 [NC, R = 301, L]

First part:

- RewriteCond% {HTTP_HOST} ^ site.ru $

- RewriteRule ^ (. *) $ Https://www.site.ru/$1 [NC, R = 301, L]

serves to redirect the site from site.ru to https://www.site.ru. Using this code, you can do the opposite. Second part:

- RewriteCond% {HTTP_HOST} site.ural.ru $

- RewriteRule ^ (. *) $ Https://www.site.ru/$1 [NC, R = 301, L]

serves to redirect site mirrors to the main one, i.e. if you have sites www.site.ru and site.ural.ru, then by specifying such a code, you create a situation when a user, typing site.ural.ru in the address bar, gets to site.ru Note !!! The method is applicable for hostings using an apache server with support for the Rewrite (mod_rewrite) module. Create a file “robots.txt

"At the root of the site, where specify:

- User-Agent: *

- Host: www.site.ru

After you have done all of the above:

- no matter what domain name the user would type in the address bar, it will instantly change to the main one www.site.ru.

- search engines will index exactly the domain you want - www.site.ru.

| Tweet |

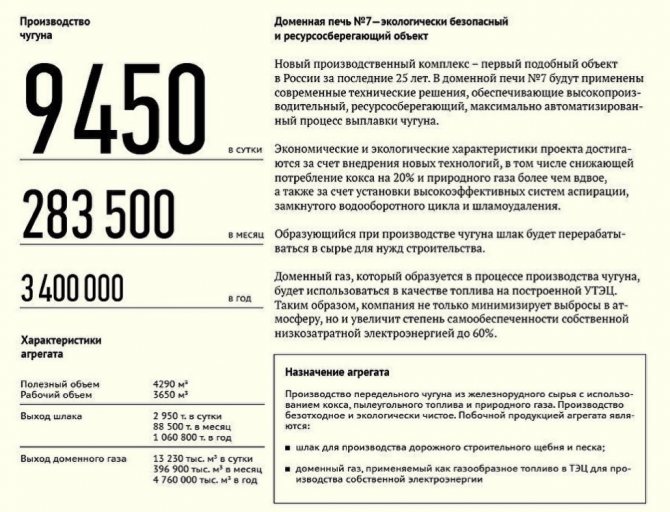

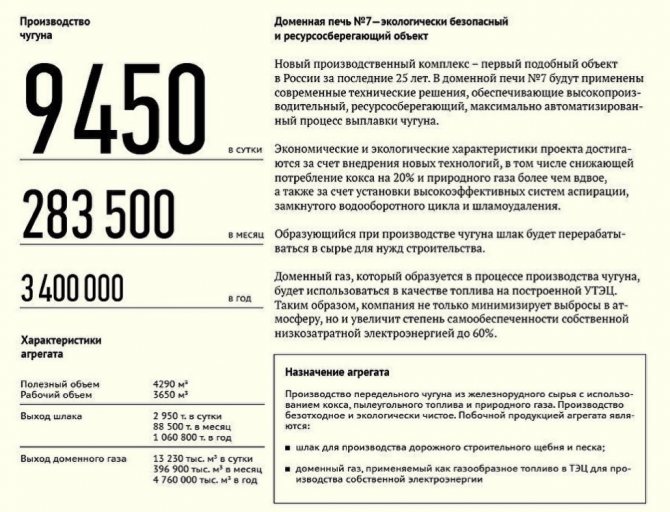

Cost based on the example of efficiency no. 7

The manufacture of blast furnaces is a resource-intensive and expensive process that cannot be put on stream. Since blast furnaces are used exclusively in industry, their design and assembly are carried out for a specific metallurgical complex, which includes many objects and nodes of the internal infrastructure. This situation is observed not only in the Russian Federation, but also in other countries of the world that have their own metallurgical facilities.

The cost of manufacturing and assembling a blast furnace is quite high, which is associated with the complexity of the work. An example is the large blast-furnace complex No. 7 called "Rossiyanka", installed in 2011. Its cost amounted to 43 billion rubles, the best engineers from RV and foreign countries were involved in the production.

The complex includes the following units:

- receiving device for ore;

- supply stations of the bunker overpass and the central unit;

- bunker overpass;

- compressor station (installed at the casting yard);

- installation for injection of pulverized coal;

- recycling CHP;

- control center and administrative building;

- foundry yard;

- blast furnace;

- air heating blocks;

- pumping station.

Complex productivity:

The new complex ensures the production of more than 9450 tons of pig iron per day, the useful volume of the furnace is 490 cubic meters, and the working volume is 3650 cubic meters. The design of the blast furnace ensures waste-free and environmentally friendly production of pig iron; blast furnace gas for thermal power plants and slag used in road construction are obtained as by-products.

Cast iron tap [| ]

Play media file

Blast furnace iron tapping

It is a rectangular channel 250-300 mm wide and 450-500 mm high. The channel is made in the refractory masonry of the hearth at a height of 600-1700 mm from the surface of the flask. Channels for slag holes are laid out at a height of 2000-3600 mm. The channel of the cast-iron taphole is closed with a refractory mass. The cast-iron tap is opened by drilling a hole with a diameter of 50-60 mm with a drilling machine. After the release of pig iron and slag (in modern large blast furnaces, the release of pig iron and slag is carried out through cast iron nozzles), the holes are clogged with an electric gun. The toe of the cannon is inserted into the taphole and a tap refractory mass is fed into it from the cannon under pressure. The blast furnace slag tap is protected by water cooled elements, collectively referred to as slag stoppers, and a pneumatically operated, remotely controlled lever structure. Large-volume blast furnaces (3200–5500 m3) are equipped with four cast-iron tapes, working alternately, and one slag tap. The release of pig iron and slag from the blast furnace includes the following operations:

- opening of the cast iron tap (if necessary, and slag);

- service directly related to the outflow of pig iron and slag;

- closing the cast iron tap (if the slag was released through the slag, then the slag);

- repair of a taphole and gutters.