Correct refueling of the air conditioner with your own hands will ensure its reliable operation and long life. In this regard, you need to have a complete understanding of when and how to service this device.

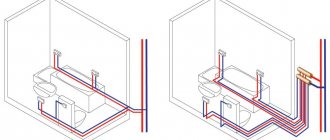

No matter how careful the installation and operation of the device is, some of the freon will still gradually flow out into the external environment, so sooner or later it will have to be replenished. The lack of freon will be indicated by the worst air cooling. The following instructions for refueling the air conditioner will help correct this situation.

Refrigerant types

There is no need to save on refueling, as low-quality refrigerant will lead to system breakdown

... The refueling procedure is best done twice a year. If done correctly, the system will run smoothly and efficiently. In addition, a properly filled home air conditioner can extend the life of this unit.

Any air conditioner, even the highest quality and most reliable air conditioner, comes a moment in operation when its power starts to drop. This becomes noticeable by the fact that the indoor climate begins to change over a longer period of time than before. With regular preventive cleaning of climatic equipment, the loss of the refrigeration process occurs only for one reason - freon leakage. There is a general misconception that gas injection is a rather laborious process that cannot be done on your own and, moreover, at home. However, it is not. you can independently fill the air conditioner at home, which will save a decent financial amount, which is necessary to pay for the work of service specialists.

The loss of power by the air conditioner occurs for several reasons:

- The evaporator and other internal parts of the indoor unit in the split system are dirty.

- More often this happens due to a decrease in the amount of freon that flows out through the connecting fittings, as a result of which the cooling capacity decreases.

Description of air conditioner malfunctions that can lead to loss of power.

Refueling frequency

To calculate how often the air conditioner needs to be refueled, it is necessary to determine what type of equipment is being used.

Thus, devices with split and multisplit systems are recommended to be refueled at least once a year. It is worth constantly monitoring the operation of the device and checking the level of the device at the slightest disturbance.

Air conditioners of mobile and window type practically do not require refueling. Unfortunately, their design does not allow for partial refueling. Only a full charge of the equipment is used.

If refueling is not carried out in a timely manner, the air conditioner compressor fails. Replacing the part only helps to fix the problem. This is a rather expensive and time-consuming process. It is better to constantly monitor the condition of the split system and undergo service annually. In any case, the appliance must be topped up with refrigerant at least once a year.

Which is preferable - to fill or top up the air conditioner?

Most often, a domestic split system does not require a full refueling, but a partial refueling is enough. There are several reasons for this. For example, an air conditioner was being repaired. After that, it must be refueled.

The split system has an air temperature of 19 degrees, and it heats the air up to 21 degrees. This means that the air conditioner needs to be refueled.

Any climatic equipment loses about 8% of the refrigerant per year, which makes it necessary to refuel any split system once every couple of years.

Before refueling, it is necessary to clarify the amount of freon in the system in order to fill as much as needed, since if the amount of freon is insufficient, the desired result will not be obtained, and if the amount is excessive, the compressor may fail.

There are the following options for refueling climatic equipment:

By pressure

... To determine the required amount of refrigerant, it is enough to carefully read the documents supplied with the equipment. When the collector is connected to the air conditioner, the freon pressure in the system is displayed. Having learned the value of the pressure required for the normal operation of the air conditioner, it is easy to calculate the amount of freon that is needed to refuel.

By mass

... The use of this option is advisable in order to completely fill the device, since before using it, all the freon is pumped out of the air conditioner, and then the volume of the system is again filled with freon. For this purpose, use special scales. Having learned the amount of gas in the cylinder, fill the required amount.

There is another way of filling climatic equipment with freon, only it is used most often after the repair of equipment, or in cases of air ingress into the system. This is a glass filling. Noticing air bubbles in the inspection window of the freon unit, the system is filled with freon before the bubbles are squeezed out of the pipeline. After that, the gas is vented to the equipment filling rate, when the required pressure appears in the system.

How to find out the level of freon in the device

The main symptom - a decrease in the level of performance indicates an insufficient amount of freon. To find out the charge volume of the air conditioner, you need to find out how much refrigerant is in the device. Usually the amount of gas is indicated in the documents for the device. In the same place, manufacturers write the recommended amount of refrigerant for a single charge. Usually, 5-10 grams of the substance is used per square meter of the room.

Before the refueling procedure, you should find out what type of freon is in the device. The fact is that a refrigerant can consist of both one component and a multicomponent gas of complex composition. Freon, which has 1 type of gas in its composition, can be subjected to a partial refueling procedure. Freon with a complex composition cannot be filled. Remove all refrigerant from the device. Then just carry out the full refueling procedure.

Preparing the air conditioner for refueling or refueling

You need to know that self-preparation and refueling of climatic equipment is carried out with specialized tools, while freon is also needed. Therefore, think about where you will take all this.

Make sure that the vacuum pump has a pressure gauge and a check valve to prevent oil from entering the freon system.

In large cities, it is possible to rent these instruments. The rental fee will be less expensive than paying for the services of a professional called from the service center.

- Preparation for refueling the air conditioner is considered to be the study of the evaporator and condenser tubes, and the check of the freon line for integrity.

- After performing a visual inspection, pump nitrogen gas into the system through a pressure regulator equipped with a pressure gauge. After reaching the filling volume of a split-system of a particular model, nitrogen automatically stops flowing into the system. You will need to monitor the pressure gauge to find out if the pressure in the system is dropping.If there is no pressure drop, then the system is sealed, and the freon leakage occurred for a reason that is not related to damage to the circuit.

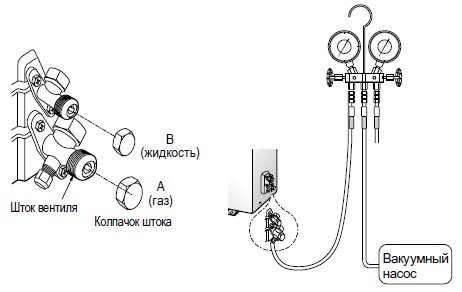

- After checking the system (as the professionals say - the system is pressurized), it is vacuumized, for which they use specialized devices: a manifold and a vacuum pump.

- Then the vacuum pump is connected to the device, for which a collector is used. Then open the manifold gas valve and turn on the vacuum pump.

- When the pressure gauge needle reaches the minimum value, turn off the pump and close the manifold gas valve.

This is the last stage of preparation for filling HVAC equipment.

After pressure testing and evacuation of the system, do not try to disconnect the collector from the air conditioner!

Determining the need to refuel the air conditioner

Regular maintenance of the split system involves refueling of freon at intervals of 1–2 years. This time period is determined by tests carried out by the manufacturers. In the documentation of any device, you can find a clause stating that it loses 6-8% of freon per year as a result of leaks.

However, there are situations when it is necessary to carry out unscheduled refueling of cooling systems:

- It is carried out in the event that the device starts to work with less power and does not suffer from contamination. In this case, the air is cooled worse than after installing a new air conditioner.

- And also the need to refuel the device can be determined by the characteristic "hum" of the compressor when the air conditioner is operating. This means that leaks have appeared in the structure, through which gas seeps out. This causes overvoltage in the compressor and inadequate air cooling.

It is worth noting that in the first case, the situation can be corrected by pumping freon into an incomplete compartment of the split system. If leaks appear in the structural elements, a complete replacement of freon in the air conditioner and repair of damaged parts will be required.

Other external signs of a refrigerant leak:

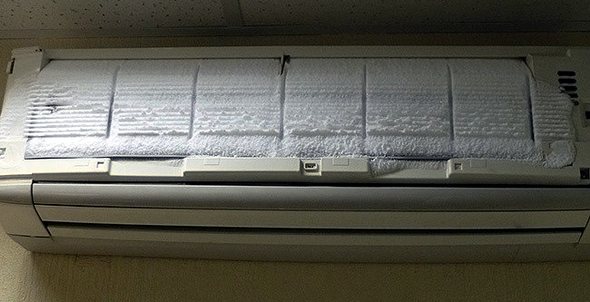

- Frost forms on the outside panel of the air conditioner.

- After turning on the device, it “adjusts” for a long time before starting to cool.

- Traces of oil are visible on the tubes of the device.

Detailed instructions for refueling the air conditioner

For self-refueling of climatic equipment, it is necessary to use some devices:

- Digital scales;

- Digital thermometer;

- Gauge manifold;

- Hex key set.

The use of a two- or four-position manifold is allowed. A two-position manifold is used when evacuating and refueling climatic equipment, however, the hose of the additional equipment is reconnected, as a result of which an air lock is created, which must be released by opening the liquid valve located on the manifold.

If you are using a four-position manifold, you do not need to do this. This device has a completely sealed system with no contact with air.

- Before starting work, it is necessary to open the locks that are located in the service fittings of the air conditioner - this will allow the remaining freon in it to be released from the device.

- When the gas is completely out of the equipment, the locks are closed.

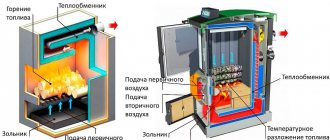

Now you are offered information on how the HVAC equipment is filled with freon using the overheating indicator method. Overheating is an indicator of the difference between the temperature of the superheated steam and the boiling point of freon. The temperature of the superheated steam is taken with an electronic thermometer (while the device must be turned on). The boiling point of the gas is indicated by a low pressure gauge located on the manifold.

How to fill an air conditioner or a split system?

The normal indicator of the difference in these temperatures should be between 5 and 8 ° C. If the difference exceeds 8 ° C, it is necessary to fill the split system with freon, the amount of which is insufficient.

- To fill the system, a cylinder filled with freon is installed on the scales.

- Then the scales are set to "zero", after which the valve on the cylinder is opened, and, at the same time, for just one second, the liquid valve on the manifold is opened slightly, releasing excess air that is in the hoses.

- Then the gas valve located on the manifold opens. During the period when refueling is carried out, the pressure in the system rises, and the temperature on the thermometer drops.

- These actions are carried out until the difference between the indicators of the manometer and thermometer, which are located on the gas pipe of the split system, reaches 5 - 8 C °.

- The final step is to close the gas valve on the manifold, and then close the valve on the freon bottle. By looking at the scale, you can find out how much gas was needed to fill the system.

The equipment operation is checked by connecting the device to the line. In case of insufficient filling with freon, the taps are frozen over (this is the main indicator). If this does not happen, then you have refueled the climatic equipment correctly.

The most common problem faced by owners of domestic climate systems is refrigerant leaks. Questions immediately arise: how to recognize a leak in time, how to fill a household air conditioner, who to contact?

Refrigerant volume

The amount of gas in the air conditioner directly depends on the total size of the route for this gas. In the case of buying a new split system, the instructions usually contain the amount of freon from the manufacturer. But, in any case, refueling the air conditioner at home must be done, taking into account the length of the highway.

As a result, there are no identical values for all air conditioners that can be taken as a base with full or partial filling. In addition, all split systems are functioning, and at the same time, the gas evaporates in a closed loop. It is impossible to find out the amount of refrigerant in the system, but it is possible to determine the pressure in the circuit, and then conclude that it is necessary to refill the split system.

Freon leak - how serious is it?

A timely detected coolant leak, shutdown of the air conditioner will help to avoid serious damage, financial costs for repairs. But the consequences of untimely diagnostics of a malfunction can be serious, up to the replacement of the entire system. What happens if the freon leak lasts for a long time unnoticed:

- Overheating of the compressor of the external block of the split system. It is cooled by freon. Due to insufficient amount of coolant, it will constantly heat up, which will lead to breakdown and failure. It is likely that an expensive compressor will need to be replaced.

- Overheating of the compressor will lead to the breakdown of units, units that are directly connected to it.

- Together with freon, oil circulates through the cooling system to lubricate the compressor. When a leak is formed, it exits through the hole, thereby damaging the capacitor. Compressor parts are not properly lubricated.

- Moisture is likely to penetrate through the leak hole into the system.

The result is a repair with a possible replacement of the compressor or the entire system as a whole. To avoid large unforeseen costs, it is necessary to use the equipment correctly, carefully monitor its condition, and carry out scheduled technical work.

Refueling

The standard loss of freon of any air conditioner is 10-15%. This means that any device, even with optimal use and careful maintenance, requires replenishment of Freon.In cases where the refueling of household air conditioners is carried out out of time or in violation of the required standards, breakdown and even inevitable damage to the equipment occurs. Therefore, the problem of refueling should be treated as carefully as possible.

Reasons for reducing the level of freon:

- Leakage

- Volume reduction after renovation work

- Mechanical damage to the device

- Incorrect operation.

The refrigerant is located in the pipes connecting the outdoor and indoor units of the split system. Tubes are attached to the blocks using rolling joints fastened with nuts. Insufficiently tight connection between them provides gas leakage.

Internal parts of the air conditioner, such as the compressor and fan, also cause leaks. The fact is that the vibration that they create contributes to the occurrence of cracks in the pipes with the refrigerant and their further grinding.

In cases where repairs were made on the internal parts, refueling of air conditioners is also required. For example, after the restoration and soldering of compressor parts, a leak occurs at the work sites.

Before the procedure, it is necessary to clarify what type of freon is used. The markings can be found on the product documents and on the indoor and outdoor units. It is necessary to monitor the amount of refrigerant charged. The disadvantage will lead to increased operating conditions and equipment wear. If there is an excessive amount of Freon in the device, it will also lead to ineffective and unstable operation.

Causes of coolant leakage

The main, most common causes of freon leaks are poor-quality installation, improper operation.

- Freon is an inert, odorless, colorless gas. It is safe for humans and the environment. It can evaporate from the air conditioner system through connections, installation joints of the route. If the assembly, installation of the system is done correctly, freon will not evaporate, or evaporate in small quantities. Then it is enough to refuel every 1.5-2 years for the equipment to work properly.

Poor installation will have a negative effect on the equipment, you won't have to wait long. The weak points of the installation will immediately show themselves.

- Untimely maintenance, improper operation is also the cause of refrigerant leakage.

- Mechanical damage to the track. Pipeline wear is an unlikely cause. But it also has a place to be. With constant vibration of the outdoor unit, the pipes with the coolant are frayed, forming leak holes. It is also possible that foreign objects fall onto the track, which can damage it.

- Re-assembly / disassembly of equipment.

Signs of a freon leak

With careful attention to the air conditioner, timely maintenance, it is easy to determine that the operation of the equipment has deteriorated, external changes have occurred. Signs of a Freon leak:

- The operation of the air conditioner has worsened, it has stopped cooling / heating the air as quickly as before, it does it weakly, ineffectively.

- The compressor safety sensor is constantly activated, reacting to excessive heat. It stops the equipment.

- Darkening of the compressor insulation.

Refrigerant leaks at the pipes

- The presence of oil on the elements of the split system, the smell of burning after switching on, the oxidation of the oil (checked by a test for the level of acidity).

- Burnt insulation near the capillary tube in the supply line.

- Icing of the pipes of the outdoor unit.

Icing of the external branch pipe of the air conditioner

As soon as signs of freon leakage appear, it is necessary to turn off the air conditioner, do not use it until troubleshooting. The best thing is to call specialists who will test the system, find the cause of the breakdown, and eliminate it. After all, the cause of a malfunction may not only be a coolant leak.

If there is complete confidence that the cause of the malfunction is precisely the leak, it is possible to eliminate it yourself by refilling the system with refrigerant.

Precautions when working with freon

If you are going to fill the air conditioner with your own hands - remember:

- Chlorine brands are harmful to the body. Avoid contact with mucous membranes (eyes, mouth), and do not inhale them.

- With a high concentration of freon, you can get poisoned. Therefore, do not work indoors - be sure to open the window and the door, if available - turn on the hood (in the kitchen and in the bathroom).

- If liquid freon gets on the skin, you can get frostbite. Therefore, you only need to work with rubber gloves and closed clothing (not a T-shirt or a T-shirt with shorts).

If during operation the refrigerant gets on the skin or mucous membranes, it must be immediately washed off with water, and the place must be lubricated with petroleum jelly.

If you experience symptoms of suffocation, or any other abnormal signs, you must immediately stop working, leave the room and ventilate it.

What is a cabinet air conditioner: overview, scope, functions

Why can the air conditioner gurgle, how is it dangerous and what to do?

Similar posts

How to fill a household air conditioner? Scheme of actions

Scheme of actions when filling the air conditioner with coolant:

- Blow out the internal block of the system, the freon pipeline to dry them from moisture (may cause a malfunction of the compressor).

- Remove the caps from the valve, service port.

- Connect a vacuum pump to the charge sensor.

- Connect a three-way valve to the charge sensor.

- Use a pump to evacuate the climate system. The evacuation time is 30 minutes, but it can be varied by the capacity of the vacuum apparatus.

- The refueling gauge's monometer should show a pressure level of 760 mm Hg. Art.

- If the pressure has not reached the desired value, then there is a leak. It is necessary to find the place of the depressurization of the pipeline using the freon leak indicator.

- Repair the leak.

- Close the priming sensor valve. Switch off the evacuator.

- Open the suction 3-way valve, 2-way liquid valve on the outdoor unit with a wrench (turn counterclockwise).

- Make a test run of the climate system.

- Take readings of the pressure level inside the system, current indicators. In this case, the air conditioner operates at maximum cooling / heating mode.

- If necessary, add refrigerant to the equipment.

- With a reduced pressure, a short path of the coolant (1-1.5 m), an excess amount of gas - remove excess freon from the system.

The need to carry out work

When buying new equipment, it does not need to be injected with freon, since this is done by the manufacturer. During repair, refrigerant is pumped to the outdoor unit. The main thing is to do it carefully and not allow it to leak. Another thing is cleaning, which is carried out in a planned manner.

Filling of air conditioners with freon is carried out in the following cases:

- if in the process of installation or transfer to a new place, its leakage was allowed;

- after disconnecting the highways for subsequent repair;

- after a freon leak as a result of leakage.

Window apparatuses rarely need such a procedure, which is not the case with automotive appliances. Constant vibration leads to loss of refrigerant.

According to the recommendations of companies, the air conditioner should be refilled with freon once 1 year. Practice shows that there is no need for such a frequency. It is enough to carry out the procedure at intervals of 4-5 years. This is due to the high quality of butt joints. If a leak occurs, the apparatus is disassembled and the fault locations are searched.

There are signs indicating a deficiency in the freon system:

- due to a decrease in the efficiency of the equipment, the indoor unit begins to drive warm air;

- the compressor goes into non-stop operation at maximum load;

- the display shows an error;

- the service port of the outdoor unit with the liquid supplied to it is covered with ice;

- freezes the evaporator of the indoor unit.

We recommend that you familiarize yourself with: Siphon for air conditioner

Types of freons for filling household air conditioners

Air conditioning systems are charged with various coolants. For household, the most common are R22 and R410a.

The R22 substance cools the climate systems previously produced. Now it is banned in Europe due to the destructive effect on the ozone layer of the planet. However, in the CIS countries it is used for refueling.

The R410a refrigerant replaced its predecessor and is used in modern air conditioners. Differs in high cost, complex composition. The cost of installing equipment fueled with R410a has increased.

What signs indicate that it's time to fill or top up the air conditioner with freon?

It is impossible to say exactly with what frequency a partial refueling or a full refueling of the air conditioner with freon should be performed. It is necessary to regulate and check the refrigerant pressure in the system constantly, at each scheduled and unscheduled maintenance of air conditioners. If the climatic equipment is installed correctly, during its operation, all the necessary requirements given by the manufacturer are observed, then it does not need a full refueling with freon even 10 years after use. It will be enough to partially recharge the air conditioner with refrigerant once every 4 - 5 years for its stable and efficient operation.

If the air conditioner is installed poorly, then it may need a full refueling with freon after the first start. It often happens that freon immediately evaporates into the atmosphere. If such a problem occurs, the air conditioner will immediately stop cooling or heating the air and will not start. Partial filling of climatic equipment with freon may be required even if the pipeline is leaking.

Signs indicating the need for full or partial refueling of air conditioners:

- low efficiency indicators,

- difficult start of climatic technology;

- frost on the freon pipe;

- icing of the indoor unit and freon line;

- ineffective cooling or heating of air;

- extraneous noise, crackling in the indoor unit;

- the appearance of a peculiar smell;

- high temperature of the air leaving the outdoor unit.

If at least one of the listed signs is found, there is an urgent need to refuel the air conditioner.

Types of freon for filling air conditioners

What type of freon is used for filling air conditioners?

- R22 (classic freon, which is ideal for refueling air conditioners of all models and manufacturers, the cost of R22 refrigerant is low, it is absolutely safe for human health and the environment, refueling and refueling of air conditioners with R22 freon will be the cheapest),

- R-410A (this refrigerant is half of R125 freon, it does not have a destructive effect on the ozone layer, allows the use of more pressure and significantly increases the performance of climatic equipment, although refueling the air conditioner with this type of freon will cost more, but the user of the equipment can significantly save on electricity),

- R-407C (this type of freon consists of three refrigerants, it is used to refuel industrial-type air conditioners, this type of freon is not isotropic, therefore, when leaking, its light components evaporate first, this leads to the fact that it is impossible to partially charge the air conditioner with this type of refrigerant, at a price it is available, but due to its peculiarity it is rarely used for refueling air conditioners).

The price for refueling air conditioners ranges from 2 to 10 thousand rubles. To find out exactly how much it will cost to charge a specific model of HVAC equipment with refrigerant, contact the consultants of the companies that provide this service.

Refueling of household air conditioners. Precautions

Despite the safety of R410a freon for the environment, you should observe safety measures when working with it:

- Do not breathe in R410a refrigerant, it destroys lung tissue, causing shortness of breath, asthma.

- The split system, filled at the production site with R410a, must be refilled with these substances.

- A special compressor oil is used with R410a. It differs from the predecessor mineral oil R. It is necessary to very carefully fill the equipment with a mixture of R410a and oil, as the latter absorbs moisture from the environment. Therefore, the equipment should not be left for a long time in high humidity conditions.

- It is necessary to use tools made to work specifically with R410a freon (pressure sensors, filling hose, leak indicator, rolling mechanisms, evacuator, etc.).

- Higher pressure R410a assumes a certain diameter of copper pipes (not less than 0.7 mm).

- It is forbidden to leave air, moisture in the pipeline system.

- When carrying out installation, service work - ventilate the room.

Subject to certain conditions, it is possible to refuel the climatic equipment yourself. Nevertheless, it is best to use the services of specialists who will not only refuel the air conditioner, but can, if necessary, identify other malfunctions of the device.

Features of inverter air conditioners

Multi-zone air conditioning system

Constructive device of a household air conditioner

Air conditioners are now installed almost everywhere. Many people own home appliances, but when they do not cool the room, it becomes necessary to repair it. In order to save money, you can do this yourself - charge the refrigerant following the instructions in the article.

What is the conditioner used for?

When freon is mentioned, a parallel is immediately drawn with the refrigerant of the refrigerator, but for household air cooling, a certain type of it is used, which is different from that used in freezers. So, the most commonly used freon brands:

- R-22

- it proved to be the most reliable carrier, it has a high cooling efficiency, in contrast to similar refrigerants of the R-8 brand and others. When using them, the production of cold by the device can significantly decrease, and the consumption of electricity can increase. - R-134 a

- a newer type of freon is safer for nature, since it does not affect its ozone layer. It is now used extremely rarely due to its high cost.

Step-by-step instructions for refueling the air conditioner

Before refueling, you need to check the integrity of the cooling line, view all its pipes. If everything is in order, you can start preparatory work for refueling:

- System pressure testing

... If outwardly no deviations are detected, then gaseous nitrogen must be injected into the system. This is doable with

reducer and pressure gauge

... When the volume of the air conditioner is completely filled, nitrogen will stop flowing into the system. With complete sealing, the pressure in the unit will be constant, but if it drops, then the freon leakage occurs due to damage to the pipes, which should be soldered. Otherwise, if everything in the system is hermetically sealed, then you can proceed to evacuation; - Vacuum pump connection

... When choosing this device, you need to check that it has a pressure gauge and a check valve. The first will be responsible for the pressure, and the second will prevent oil from entering the freon. The pump is connected to the air conditioner through a manifold. Before starting it on the manifold, you need to unscrew the gas valve.When the minimum value is set on the pressure gauge, it will be necessary to activate the pump and close the valve on the manifold.

Split system refueling progress:

- Equipment preparation

... To carry out refueling you need digital devices -

scales and thermometer, set of keys and gauge manifold

... It is better to use a four-position manifold to avoid reconnection and air formation in the tube; - Prepare a bottle with freon

... It must be weighed, and then open the valve on it and then close it to release air from the hose; - Prepare air conditioner

... On it you need to set the temperature to 18 degrees and turn on the device to cool the room; - Manometer connection

... On the device, you need to find the largest tube coming from the external unit, unscrew the cap from it and connect the pressure gauge to the vacated place, and its other end is already connected to the bottle with freon; - Refueling process

... The pressure should rise, and when it reaches 5-8 bar, you need to close the valve on the cylinder and the pressure gauge. Replace the cap.

To find out how much gas was required to refuel the climatic technology, you need to put the cylinder back on the scales and compare the mass with the previous reading.

Advice:

All the necessary tools for refueling can be rented in any service that serves air conditioners. Paying these costs will be cheaper than calling a specialist to your home.

Preparing to refuel the air conditioner

Do-it-yourself refueling of the split system begins with the preparation of the necessary tools:

- a cylinder with freon (about the choice of the required material - see below);

- dry nitrogen cylinder;

- communication tubes with threaded connection elements;

- pressure gauge;

- electric scales;

- vacuum pump for technology.

And also manual refrigerant charging requires the following preparatory measures:

- Dry the parts of the air conditioner. To do this, you can make a purge with freon or nitrogen itself. The first method is used if the freon compartment is located at the front of the device.

- Check all elements of the system for leaks by creating a high pressure. This method can determine the presence of a freon leak.

- Remove air from the device using a vacuum.

How often should the air conditioner be refilled?

Its leakage from the cooling system can occur for several reasons, but most of the refrigerant is lost during transportation through copper pipes located between the units of the device. Because of this, it is necessary to periodically refuel the carrier - even older models of air conditioners require this to be done every 2 or 3 years.

If the tubes are damaged, freon leaves the equipment very quickly. Their damage occurs during transportation of equipment, improper installation or strong pressing of the pipes to each other. Although the air conditioner does not vibrate during operation, the rear wall of the air conditioner may affect the contact of these pipes. If the loss of freon is caused by damage to the tubes, then refueling it without repair will not help.

You can see and feel the loss of freon by several obvious signs:

- Frost will begin to appear on the outside of the unit.

- When the air conditioner is turned on, the room where it is installed cools very slowly.

- The operation of the device is accompanied by the smell of gas (see also - how to get rid of an unpleasant smell).

In any of these cases, you need to immediately repair the air conditioner or fill it with freon. If this is not done, the device may overheat, and this will lead to its breakdown.

Refueling rates for air conditioners

Automatic refueling of air conditioners is possible, unfortunately, only for automobile climate control equipment, but not for home. Refueling of household and industrial systems is carried out under the control of pressure gauges, scales or visually.

There are no standards for refueling air conditioners.

It is necessary to add refrigerant as much as it has evaporated or leaked out. If the equipment is refueled from scratch, the instructions provide recommendations for operating pressure. They are guided by them when it is necessary to fill the air conditioner.