The issue of warming the foundation is quite popular today, since the cost of heating a house is very high. The most popular materials for warming the foundation are ordinary foam and expanded polystyrene (essentially the same foam, but made using modern technologies). The main difference between expanded polystyrene is greater strength and more convenient installation, therefore, we will consider its advantages, types and technology of insulation.

What you need to know about basement insulation

Quite often, the question is asked about the need to insulate the foundation. This is due to the fact that very few people know what it is for, especially if they will not be living in the house all year round. In addition to the fact that the insulated foundation allows you to save money on heating the premises in the winter, the insulation of the foundation makes it possible to:

- Make your stay in the house as comfortable as possible regardless of the season. This is achieved by the fact that the room will not be damp.

- Insulation of the foundation allows you to protect it from the harmful effects of weather conditions. For example, from swelling and freezing of the soil around it, which prevents the subsequent destruction of the foundation.

- If there is a basement in the house, the insulated foundation allows you to achieve comfortable conditions in it, which will make it possible to use the basement for various purposes, up to the arrangement of any rooms in it.

In addition to the fact that insulation allows you to achieve the listed goals, it is very important to know what properties the thermal insulation should have. Among them:

- The material must have low thermal conductivity.

- The material should not allow moisture to pass through itself, that is, it should be waterproof. If the insulation absorbs a large amount of water, then its properties will only deteriorate, and in winter, the accumulated moisture can deform it in the process of turning into ice.

- The material must be strong enough, otherwise it can deform under the influence of various forces from the soil.

All of these properties are possessed by expanded polystyrene, therefore, we will consider the insulation of the foundation with its help.

Insulation of a new foundation

Now we will consider a new technology for warming the foundation through the use of fixed formwork

Insulation of foundations with fixed formwork

Insulation of foundations with fixed formwork - photo

This method has many advantages and only two disadvantages.

- The first drawback is that the formwork can be used for the construction of the foundation only for low-rise wooden buildings. The load-bearing characteristics of the structure do not allow the method to be used for brick buildings.

- The second drawback is that the cost of foundation work can increase up to 30%.

Permanent formwork consists of hollow blocks made of expanded polystyrene.

Permanent formwork dimensions

Drawing of the end block of a permanent formwork

Fixed formwork - photo

Permanent formwork - corner block

Blocks are laid dry, fixation between themselves is carried out by special mechanisms in the thorn / groove. The design features of the permanent formwork make it possible to pour reinforced strip foundations. After the concrete has cooled, the trenches are filled up and you have a ready insulated foundation. Moreover, not on one side, but on both sides, the effectiveness of insulation, respectively, doubles. The thickness of the walls of the foam blocks varies widely, choose the optimal values taking into account the specific features of the foundation.If you follow the recommendations of the manufacturers of one-piece formwork correctly, the outer and inner surfaces will be of high quality. No seams will have to be foamed for one simple reason - there won't be any.

Video - Video guide for the installation of permanent formwork

Video - Installation of permanent polystyrene formwork

Advantages and disadvantages of expanded polystyrene

This type of material, oddly enough, has a number of advantages and disadvantages that you should definitely talk about. So among the advantages of the material are:

- High thermal insulation characteristics.

- The material is quite frost-resistant, which indicates its possible use in regions with a harsh climate.

- The material does not allow steam to pass through, which indicates low vapor permeability.

- Installation of expanded polystyrene is carried out without much effort, it is easy to fix and adjust to the required size.

- The surface of the foundation on which the material will be fixed does not require special preparation, therefore even slight irregularities are allowed.

- The cost of expanded polystyrene is not high, which allows it to be used by all segments of the population.

In addition to the listed advantages, it is also worth paying attention to its disadvantages, including:

- Insufficient resistance to fire, that is, it is quite easily flammable, therefore, on top of it, the basement should be finished only with non-combustible materials.

- The material is not resistant to damage from rodents, therefore, additional installation of a reinforcing mesh is recommended.

- Depending on the type, the material is capable of absorbing moisture, therefore it is recommended to use additional waterproofing.

- When filling the material with soil with solid particles, the material can be easily damaged, therefore it is recommended to install additional protection against mechanical damage.

Why else do you need to insulate the foundation?

Modern heaters do an excellent job with their main function - they keep the heat in the house.

In addition, carrying out such work during construction allows us to solve a number of other important tasks:

- Additional waterproofing. Concrete, at the base of the house, admits and absorbs moisture well, therefore it needs high-quality insulation. Another layer of protection makes the foundation stronger, which means that the whole structure is more durable and reliable.

- Thermal insulation material prevents severe freezing and subsequent expansion of the soil. This means that the foundation will not be subjected to additional loads. Thermal insulation is especially important when constructing buildings in areas with heaving soil.

- Correct insulation of the base of the house allows you to use basements as additional rooms: workshop, storage room and more. If desired, even a small home sauna can be arranged here.

- Now no one will argue that complex insulation of the whole house gives a significant saving in energy costs - heating costs are reduced. Thermal insulation of the foundation is the first step in this direction.

The method of carrying out the work also depends on the choice of materials for warming the foundation. What is more often used to build the base of a house: polyurethane foam, bulk mixtures or polystyrene? Let's consider what are their differences and advantages:

Polyurethane foam

It is a liquid product that is applied with a spray to the outside of the foundation.

Pros: Fast application and uniform coverage of the entire surface. It protects the building well from moisture and retains heat well.

Cons: high cost.

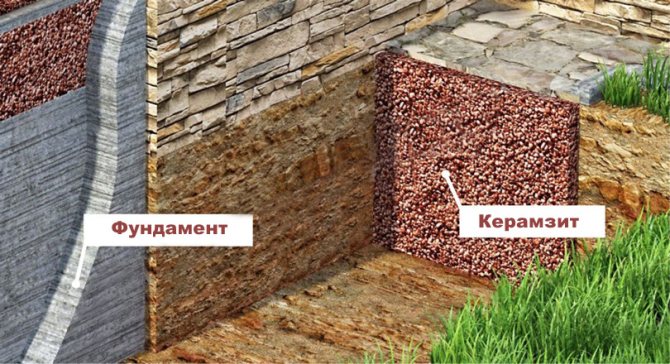

Loose mixtures

Expanded clay is an inexpensive natural insulation that is often used in modern construction.It provides excellent insulation of a monolithic foundation when erecting multi-storey buildings. It is also used in the construction of basements and basements.

Pros: ecological material, non-flammable, has sound insulation properties.

Cons: Requires additional waterproofing of the base.

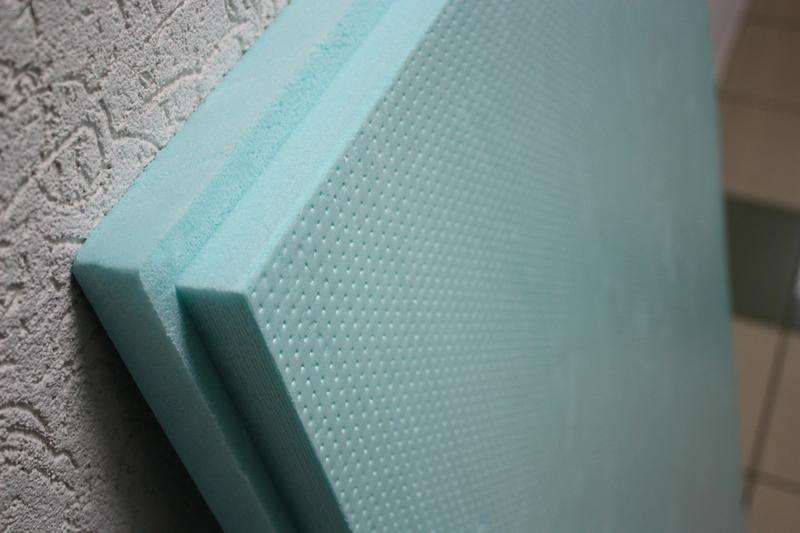

Expanded polystyrene boards

The finished slabs, using a special adhesive solution, are attached to the foundation and the lower part of the wall of the house.

Pros: resistant to mechanical damage, improve waterproofing.

Cons: there are joints between the plates.

Thermal panels

Recently appeared on the construction market. Suitable as basement insulation or basement walls.

Pros: provide good protection, aesthetic appearance does not require additional decorative work.

Cons: high cost.

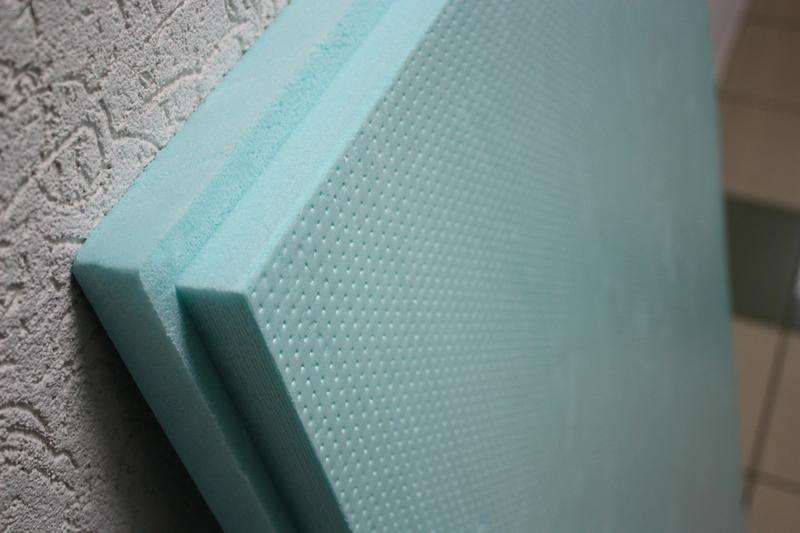

Types of expanded polystyrene

In modern market conditions, this material can be of different varieties. This is how two types of polystyrene foam are distinguished: it is foamed and extruded polystyrene foam. Let's consider each one separately.

Extruded polystyrene foam

This material is designated in the market by the letters XPS. It has better characteristics than foamed, and therefore is often used to insulate the foundation itself. So its advantages include:

- High thermal insulation capacity.

- High compressive strength of the material.

- The material has a homogeneous porous structure, its pores are closed, which provides good protection against moisture, that is, such material does not absorb moisture, and accordingly does not freeze in winter.

- The durability of such a material, according to the applications of its manufacturers, is about 50 years.

Expanded polystyrene foam

This type of material on the market is denoted by the letters EPS, and is popularly called ordinary foam. It is also often used to insulate various surfaces due to its low thermal conductivity, however, it has significant differences over extruded polystyrene foam:

- Polyfoam has the ability to absorb water, which reduces its heat retention rates. If you do not make additional waterproofing insulation, then in winter it can freeze, which will lead to its deformation and the formation of cold bridges.

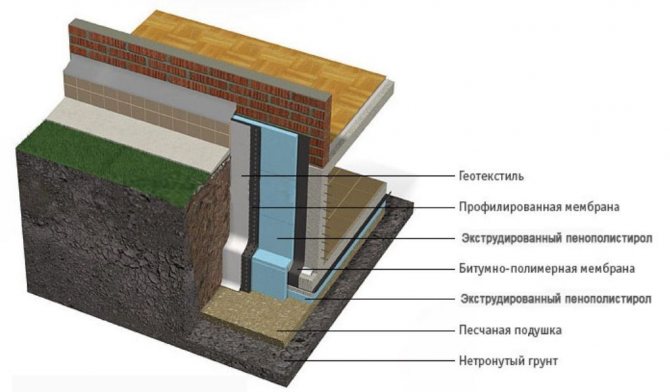

- The compressive strength of such a material is much lower than that of extruded material, therefore, it becomes necessary to provide additional protection, for example, arrangement around the foundation of additional brickwork or covering the insulation with profiled membranes.

Using foam as insulation strip foundation

The use of foam is considered a universal way to insulate the foundation from the outside. This is facilitated by a number of advantages of this material:

- it can be used in any type of basement, including with or without heating;

- it is fixed with special glue, which is considered the fastest installation method;

- foam has low thermal conductivity;

- 20 cm of material is enough to provide sufficient thermal insulation for the strip foundation.

- the size of the slab made of this material can be easily adjusted, because it can be easily cut with a clerical knife.

Styrofoam slabs

To attach the foam to concrete, a simple technology is used: several symmetrical droplets of glue must be applied to the underside of the sheet, and then the prepared surface must be applied to the concrete. In order for the fixation to be reliable, the joints are also treated with glue.

The thermal insulation layer must be closed with another layer of waterproofing. But if the shallow strip foundation (or MZLF) is insulated, the foam layer above the ground level can be covered with a layer of plaster.

Prerequisite: before plastering, it is necessary to reinforce the foam layer to prevent its destruction.

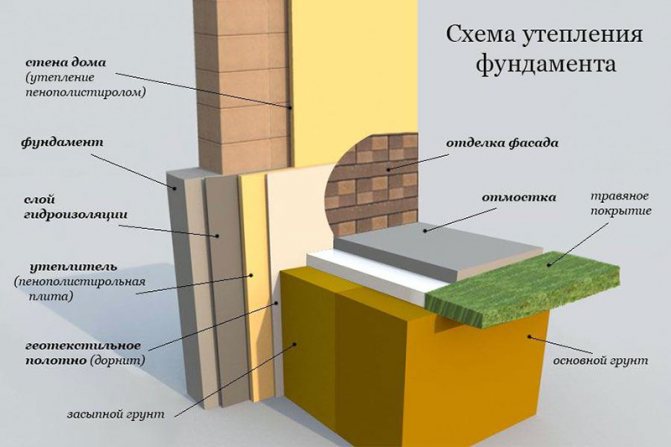

Foundation insulation technology

The technology of insulating the walls of the foundation with expanded polystyrene is not too complicated, but it can still be divided into several stages.

- preparatory work

The first step is to prepare the foundation for subsequent insulation. For this you need:

- Dig up the foundation around the entire perimeter, that is, make a trench around it about 1 m wide and a depth that corresponds to the depth of the foundation.

- Further, the surface of the foundation is cleaned of all dirt and earth, substandard concrete, and, if necessary, level the surface with cement mortar so that there are no large protrusions and pits in it. If there was a need to make cosmetic repairs to the foundation, it must be allowed time to dry, after which you can proceed to the next stage.

- The thickness of the insulation should be about 10 cm, however, for a more accurate determination, it is necessary to carry out appropriate calculations, depending on weather conditions. As a rule, to achieve the required thickness of the insulation, polystyrene foam is laid in several layers.

- If the site has an elevated level of groundwater, or there is a well, it is necessary to make drainage. To do this, a layer of sand is placed on the bottom of the trench, on top of which a layer of geotextile is laid. Next, a layer of gravel is laid and a perforated pipe filled with gravel, which is additionally wrapped with geotextiles. A layer of sand is poured over the gravel and pipes. The pipe must be taken to a drainage well or to the nearest collector.

- Further, the surface of the foundation must be waterproofed using various materials. Self-adhesive insulation is most often used, which is well ironed with a roller.

Having done all the necessary manipulations, you can proceed to fixing the expanded polystyrene sheets.

- fastening of sheets

Fastening of expanded polystyrene sheets should be carried out according to the following rules:

- Sheets of material are fixed to the surface of the foundation using special adhesives, and it is highly discouraged to use organic solvents, dowels or hot fixing. This can damage both the thermal insulation and the waterproofing.

- It is necessary to apply the adhesive composition to the sheets of material pointwise, that is, in the corners and in several places in the center of the sheet. After applying the glue, the sheet must be well pressed against the foundation surface and held in this position for a while. As a rule, the instructions for the adhesive composition indicate the retention time of the board.

- It is recommended to start gluing the sheets, starting from any lower corner of the foundation, gradually passing along the base, and then moving to the next row in a checkerboard pattern.

- All gaps that arise between the plates of the material must be carefully foamed or filled with glue.

- When the first row of insulation is laid, it can be covered with half of the soil, which will simplify further work.

- The corners of the foundation must be insulated with an additional layer of slabs, since they are the weakest point.

- It is necessary to insulate the basement of the foundation in the same way as the rest of the, the only thing is that you can use special disc dowels to fix it. As a rule, 3-5 umbrellas will be enough to secure one plate.

- plastering and backfilling of the foundation

At the end of the work, the insulation must be completely plastered with glue for finishing work. In addition, to give greater strength, they additionally use a reinforcing mesh for external work, which is embedded in the applied plaster.

The part of the foundation, which is below the ground level, is poured back. It is also recommended to perform a blind area.This will give more protection to the foundation from the effects of climatic conditions.

In conclusion, I would like to say that by observing fairly simple rules for warming the foundation, you can achieve high-quality thermal insulation of the foundation, which, in turn, will reduce the cost of heating the premises in the winter. In addition, expanded polystyrene is a durable, durable and affordable material that will significantly increase the service life of both the foundation and the house as a whole. Therefore, the question of how and why to insulate the foundation with expanded polystyrene is fully disclosed.

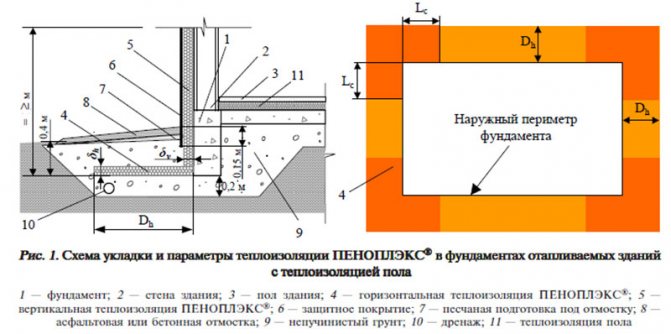

Insulation of the foundation of the house with polystyrene foam, extruded polystyrene foam outside

The effectiveness of insulation with foam or expanded polystyrene mainly depends on the thickness of their layer.

To determine the desired thickness thermal insulation for the foundation, you can use the following formulas:

and

According to the first of them, the thickness of the insulation is calculated for the part of the foundation above the ground level, according to the second - for the underground part.

The accepted designations are deciphered as follows:

- δt is the thickness of the thermal insulation layer in meters;

- R0 priv. - the reduced level of resistance to heat transfer of the foundation material, is taken according to the degree days of the heating period (GSOP) and is expressed in m2 ° C / W;

- δ - foundation thickness, m;

- λ is the coefficient of thermal conductivity of the foundation material, expressed in W / (m ° C);

- λ ut - coefficient of thermal conductivity of polystyrene foam (expanded polystyrene), W / (m ° C).

but worth understandingthat the normative indicators are based only on the average values of temperatures and the duration of the cold period. Therefore, it will be quite permissible to use the norms of the thickness of foam insulation, traditional in construction:

- 50 mm for the south of the country;

- 50-100mm for mid-latitudes;

- 100-150 mm for northern regions.

Insulation of the foundation on screw piles. You will read about this in our next article. And here is an article about the insulation of the strip foundation.

Installation of the blind area

Insulation of the foundation cannot be considered complete without the final insulation of the basement and the arrangement of the blind area. The latter is a narrow path along the perimeter of the building, concreted or covered with asphalt. Its width varies depending on the roof overhang, the minimum is 600 mm. The sloping surface protects the foundation from rain and melt water flows. In addition, the blind area insulates the soil along the house, which is especially important for regions with cold climates.

Insulation of the blind area

In frosty winters and clay soil prone to uneven freezing, for additional insulation, it is advisable to complete the construction of the blind area with plates of extruded polystyrene foam. The strength and elasticity of this material is consistent with the functions assigned to the blind area.