Why do you need thermal insulation of the base

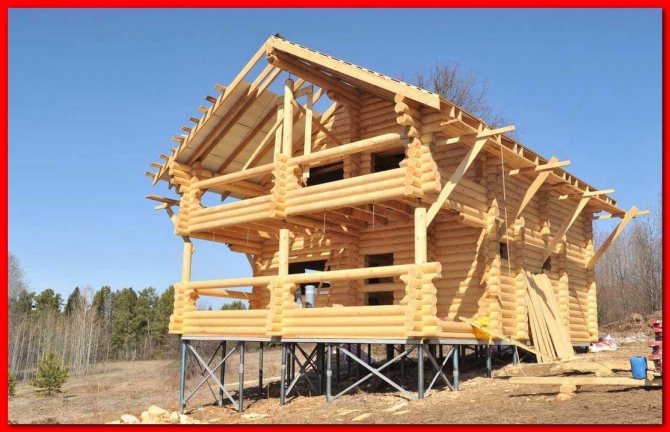

Insulation of the foundation of a wooden house can be internal and external. In any case, thermal insulation will help prevent many of the destructive factors.

External insulation (regardless of material) protects against freezing and the ingress of cold air into living rooms, saving about 1/3 of electricity. In addition, the externally insulated foundation is protected from the destructive effects of moisture from the soil, which prolongs the service life of communications and the very foundation of the building.

Arrangement of thermal protection from the inside contributes to the formation of an optimal microclimate in the basement and, accordingly, in the house, creates an obstacle to the penetration of groundwater and the accumulation of condensate, which excludes the appearance of mold.

How to insulate the foundation?

The easiest way is to insulate the columnar foundation by creating a pick... It is a variant of the basement of the building and protects the space between the building and the soil surface from various precipitation, freezing and wind.

Various materials can be used for picking up, influencing not only its design, but also the construction technology. Let's consider several specific options:

Wooden - from boards or from logs / beams. The sequence of work is as follows:

- dig a shallow trench (25-450 cm);

- cover it by a third with an even layer of sand or fine gravel;

- fix logs / beams with a pre-cut groove on the posts, insert boards (40-60 mm) into them so that the bottom board lies on a sandy pillow;

- cover the inner lower part with any heat-insulating material.

Insulation of the foundation.

To install the boards in a vertical position in a pick-up, it is planned to lay logs with a groove in a prepared trench and fix the next one to the bottom of the house. Now the boards are vertically inserted into the grooves.

Sometimes it is used to lay logs in a horizontal position between the posts, similar to the construction of a log house.

Brick or masonry. When creating such a filling, as in the first case, a sole is created for its walls (a trench with a pillow). Brickwork is 1.5 bricks, and the thickness of the stone wall should be no more than 300 mm. After that, the masonry is poured with concrete mortar (to ground level), reinforced with reinforcement.

Insulated drawers are used in houses installed on poles with a height of at least 0.75 m. After that, the columnar foundation is insulated:

- a steel frame is attached to the posts;

- any heat-insulating material is hung from the inside;

- from the outside, corrugated board is fixed on self-tapping screws;

- the gap between it and the soil is filled with gravel or expanded clay.

Important! It is not enough just to insulate the foundation - you need to make it ventilated. To do this, regardless of the type of filling made, small ventilation holes must be left in the walls on opposite sides, which are closed with special plugs in the cold season.

Varieties of foundations and methods of their thermal insulation

Depending on the method of support on the ground, the following types of foundations can be distinguished, used for wooden buildings:

- columnar;

- monolithic;

- tape;

- pile.

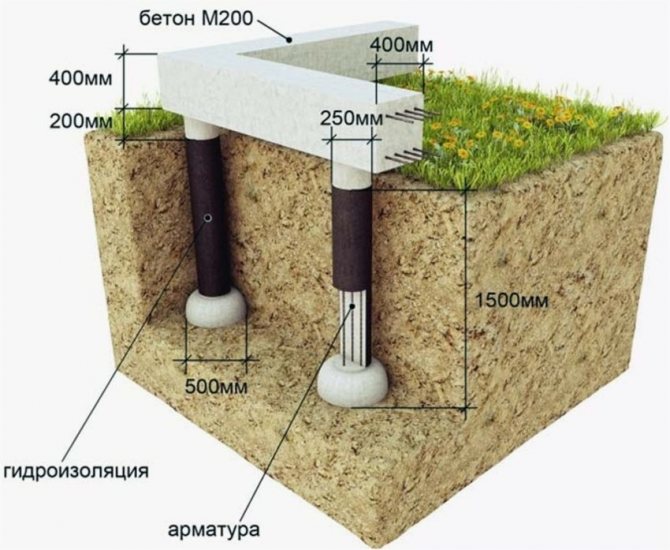

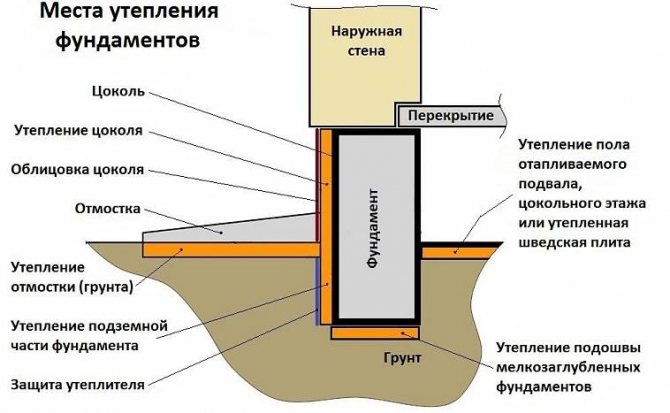

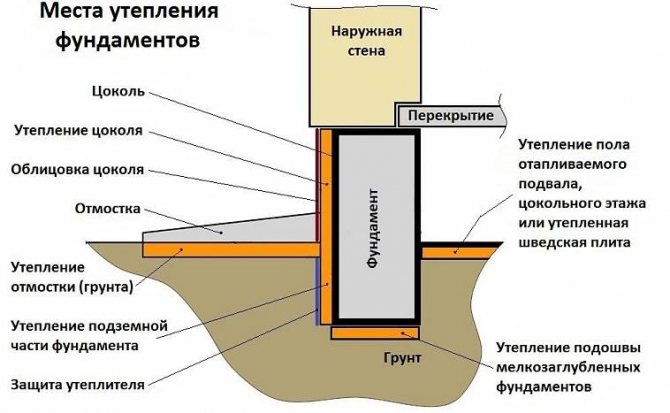

For the construction of wooden and frame houses, in most cases, shallow foundations are used. They are made of concrete or brick in the form of a strip or slab structure.It is better to insulate such a foundation from the outside. The thermal insulation layer is located at a distance of about 1.5 m, behind which a frost-free soil layer is created.

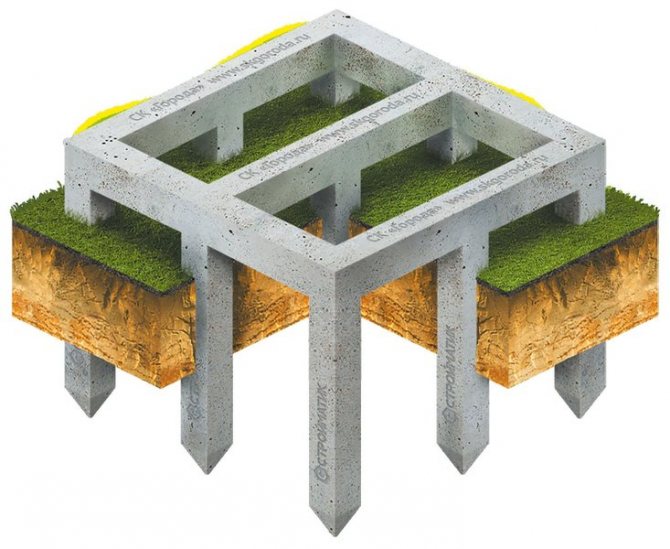

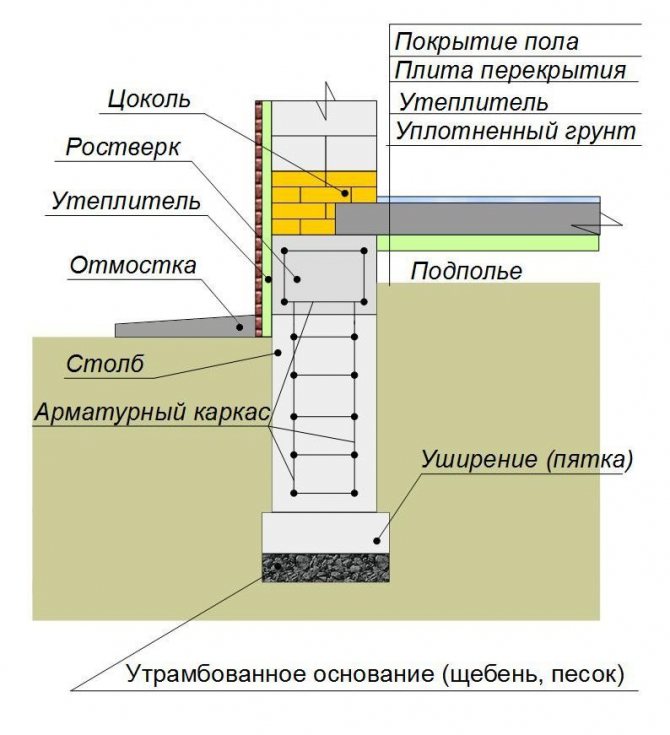

Columnar base

This type of foundation is equipped with pillars that are dug in below the freezing line by about 2 m.

The pillars are located at all corners and intersections of the building structure, as well as in places with maximum load.

In this case, the basement is made of a large thickness and the floors are thoroughly insulated, there is no basement.

Pile structures

When making a screw base, instead of monolithic pillars, piles are used, which are screwed into the ground.

It is insulated in the same way as a columnar foundation.

Monolithic foundation

Monolithic is made in the form of a slab under the base of the house, the basement is not provided in this case.

To equip its buried version, they dig a pit; for a small one, the top layer of soil is simply removed. Such a foundation can be insulated with any modern materials only from the outside.

Tape

A tape-type foundation is created under the walls along the perimeter of the building, provides for a basement, it can be made of concrete blocks.

It can be insulated from the outside and from the inside without any problems.

The need for insulation

A strong foundation is the key to the reliability of the entire building. The lack of insulation will lead to the destruction of the structure of the structure. Damage to one support will lead to uneven load distribution and destruction of the grillage. This defect will adversely affect the floor and walls of the building. In frequent cases, the formation of cracks and distortions is noted. The slightest destruction in the foundation foundations for two-story houses is especially dangerous, because the higher the walls, the more pronounced the problems associated with the violation in the foundation will be. This situation is manifested if a failure occurred with one post.

When choosing insulation for the foundation, you should pay attention to the important characteristics that the material should have. Namely:

- have a low coefficient of thermal conductivity;

- have a density corresponding to the standards, because this feature affects the load indicators on the foundation;

- fire resistance;

- the insulation should not absorb moisture, otherwise dampness and mold will appear.

Why is it necessary to insulate a columnar foundation? Thermal insulation prevents heat loss from structural floors in basements. The impact of severe frost on an open foundation leads to critical consequences that affect the stability of the entire building. Reinforced concrete structures and metal screw piles contribute to the loss of heat from the soil, which in turn leads to heaving of the soil.

To exclude such situations, additional measures are taken to insulate the base:

- by isolating the space under the building from various drafts and frosty air;

- to install heat-insulating coatings on the surface of the columnar supports;

- insulate the soil that is adjacent to the buried pile or columnar zone.

If you have a question, how to insulate the floor of a bathhouse on a columnar foundation? The insulation cake is built using such a technology so that steam is removed from the insulation through the waterproofing membrane. If foam is used, then the membrane is not needed.

The choice of insulation

The most popular insulation materials for insulating the base from the outside are:

- expanded clay;

- polystyrene, polystyrene, penoplex;

- polyurethane foam.

Cotton wool

Internal insulation of the foundation of a house, as a rule, is carried out with the use of cotton materials (mineral, glass, basalt).

They will require double-sided waterproofing (to avoid getting wet, the formation of lumps, the penetration of cold through the voids).

Styrofoam

Styrofoam can also be used. It is affordable, cheap, easy to install. But this is a fragile material, so you need to work with it carefully.

Despite its fire safety, when insulating outside, experts prefer foam, since contact with electrical wiring is excluded, and the performance characteristics of the insulation make it possible to create an effective thermal insulation system.

PPU

Polyurethane foam is considered a universal insulation. It is usually used as a heat insulator under floors and in basements.

It is applied by spraying on the surface. It forms a heat-insulating layer after drying.

It does not need additional insulation, is very lightweight, and lasts a long time.

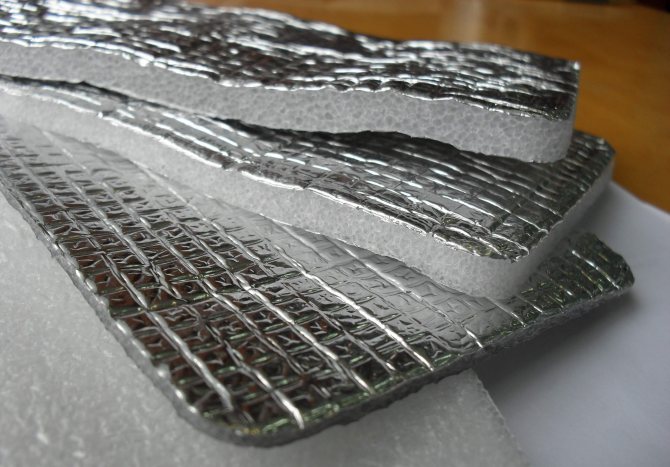

Penofol

Penofol, foamed polyethylene covered with aluminum foil, is also used to insulate the foundation. It is thin, retains heat well, protects against moisture.

It is used as an additional material with other types of insulation.

EPS

More often, for any method of insulating the supporting base, extruded polystyrene foam is used.

It is a versatile material that has excellent moisture-repellent properties, is relatively cheap, and has a long service life.

Expanded clay

Expanded clay is a good choice for insulating a shallow foundation. Due to the porous structure of the granules, it keeps heat well. It is an environmentally friendly and inexpensive material. Often thermal insulation with expanded clay is carried out outside.

For this, the foundation is dug around the entire perimeter, cleared of the ground. After that, all cracks are eliminated in the base and waterproofing is installed. Protection against moisture can be done using a coating method, for example, with bitumen mastic or by pasting with waterproofing materials (as an option, roofing material). Insulation is poured into the trench and a concrete screed is poured.

How to insulate the foundation?

Mineral wool characteristics.

As a heater, it is possible to use one of the many materials, the main difference between which is in their cost:

- Polyfoam (expanded polystyrene) is very popular, easy to use, cost-effective (reduces heat loss by a quarter).

- Penoplex with high strength, durability and low thermal conductivity. In demand in the construction market.

- Polyurethane foam is the most effective foundation insulation, it perfectly reduces the level of heat loss. The only drawback is that you cannot do without special equipment during its installation.

- Mineral wool is a fairly popular material. Available in rolls or slabs. Convenient to use, has a fairly low level of thermal conductivity.

- Expanded clay - the most budgetary option for thermal insulation. Used as additional insulation. Before using it, it is required to create a formwork from the inside of the foundation.

To make the foundation warm, it should be remembered that the procedure must be carried out at least to the depth of soil freezing. This is individual for each region. Moreover, it is necessary to insulate together with the pick-up:

- Along the perimeter of the trench with the help of special glue, fix the foam boards (the best option for thermal insulation of the columnar foundation). In this case, the sheets should be as tightly fitted as possible to each other, without any gaps. In this way, you can reliably insulate the foundation from the inside.

- Carry out waterproofing work, which will reliably protect the underground space from moisture: fix the foam boards to the foundation from the outside. And then the base of the house will become not only warm, but also moisture resistant.

- Fill up the trench with earth or expanded clay, make a blind area.

Everything, excellent thermal insulation of the columnar foundation is ready, you can proceed to the next stage of construction work!

When is it better to insulate the basement of a wooden house

The optimal period for arranging the foundation insulation is considered to be the beginning of construction work, when the walls are not erected and the subfloors are not ready. But if at the construction stage heat protection was not provided, then it can be made during the operation of the building.

If there is an opportunity to choose the option of insulation, then it is better to focus on the external one. According to experts, internal insulation shifts the dew point, and the foundation is easily affected by external humidity and cold, which quickly destroy it.

The insulation layer in the basement creates increased dampness, which can be eliminated with additional ventilation, and this is an additional cost.

Another disadvantage of arranging the system from the inside is a noticeable reduction in the area of the room.

Stages of warming the foundation with your own hands

To carry out high-quality insulation of the base of a wooden structure, you need to perform the following actions:

- Select the soil around the foundation if the work is carried out after the construction of the house.

- Clean surfaces from dirt, mold and grease.

- Remove unstable fragments, repair cracks and potholes.

- After the material has dried, treat it with a deep-penetrating primer or anti-corrosion agent.

- Waterproof the base.

- Fix the insulation in accordance with the method recommended by the manufacturer.

- If required, apply another layer of waterproofing or exterior finish.

Backfilling and tamping of the soil can be carried out only after the adhesives have completely solidified.

Features of the implementation of thermal insulation

Before arranging the insulation system, the foundation of the building in use must be completely dug out. The surface is cleaned of soil and other contaminants, damages and cracks are removed.

Waterproofing layer

It is important to protect the base from groundwater. For this, waterproofing is performed.

Bitumen mastic, special deep penetration solutions, roofing material, liquid rubber are used as waterproofing materials.

Insulation installation

For external heat protection, foam plastic or extruded polystyrene foam plates are most often used. The insulation is installed using a special glue without organic solvents. Additionally, you can fix them using dowels with a wide head. After the glue has completely dried (after about two days), backfill the underground part of the foundation.

The material is attached to the base in the same way. But in the upper part it is necessary to use a non-combustible insulation, for example, mineral wool. So the plates of expanded polystyrene or polystyrene, which do not have high fire resistance, are separated from the wooden structures of the building.

Reinforcement and cladding

A reinforcing mesh is installed on the surface of the insulation, which is recessed into the glue solution.

Then you can make the finishing. For this, artificial stone or brick, tiles, decorative plaster are suitable.

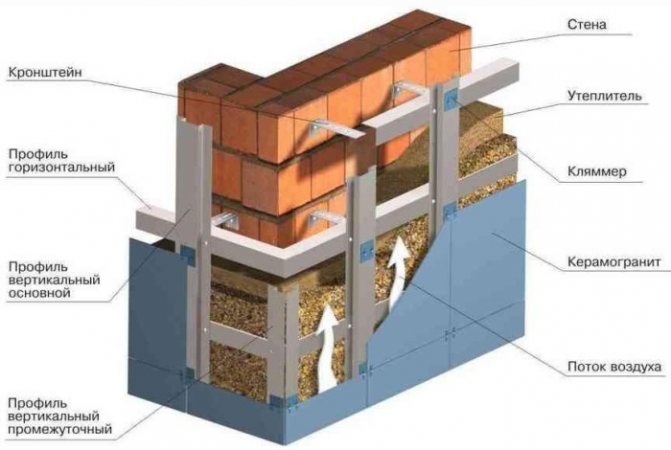

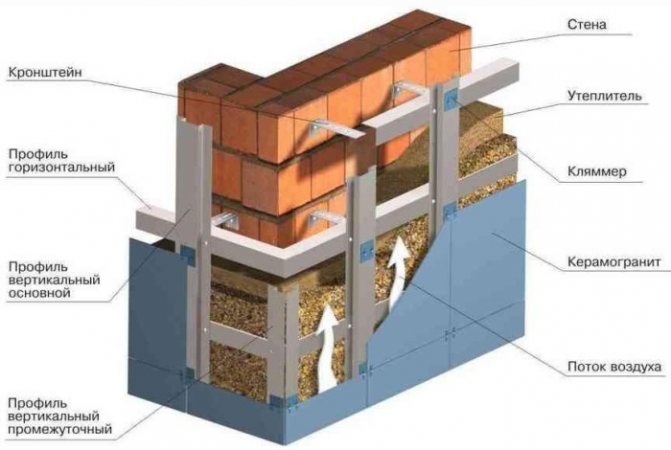

Ventilated facades

In the event that fibrous materials are used as insulation, after its installation it is necessary to lay a vapor barrier layer. After that, a crate is installed, on top of which the facing material is attached.

Thus, a ventilation gap is formed between the insulation and the finish, so that moisture does not accumulate in the insulation and it does not lose its properties.

Various insulation options

Before starting installation work on the outside, it is recommended to clean the surface and clarify whether it will be necessary to lay a waterproofing layer.The construction of the taps will close the distance between the base pillars, and limit the penetration of various sediments into the interior. Columnar supports are in unequal conditions. The outer line of the pillars is subject to a more intense frost impact than the inner support elements. For this reason, these parts are insulated more efficiently. How to insulate a columnar foundation at home with your own hands - the first step is to study the methods and choose the most suitable one.

Installation of thermal insulation outside

This technique has many advantages:

- the outer heat-insulating layer will preserve the strength characteristics of concrete;

- regardless of the type of foundation and insulation building material, the cold will not penetrate into the building;

- an externally insulated foundation will be reliably protected from a humid environment, and changes in atmospheric temperature will be "extinguished".

Insulation is mounted inside

This option is used less often, since the thermal insulation laid inside has more negative qualities than advantages. If a basement is provided in the house, then the thermal insulation inside will prevent the formation of condensation and organize a comfortable microclimate. The disadvantages include more serious factors - the foundation part from the outside is defenseless against the effects of frost. The change in atmospheric temperatures and heaving of the soil entails deformation and the formation of cracks in the base.

To carry out work on insulation with penoplex, you will need to perform the following actions:

- The surface layer of the base is covered with a special adhesive mastic. The entire surface should be treated - from the sole to the top of the frame structure.

- The products are pressed to the zero level against the vertical surface.

- The zero-level zone and the grillage are additionally secured with umbrella dowels.

- To attach heat-resistant dowels, holes are drilled in the foundation element.

- The panels are not difficult to fit into the groove. After completing the work, it is recommended to check all seams and insulate with polyurethane foam.

To insulate the base with foam, you will need:

- The working surface is thoroughly cleaned from dirt.

- If there are irregularities and gaps, they should be repaired.

- Work starts from the bottom up.

- An adhesive mixture is applied to the foam plate.

- The sheets are glued to the surface and fixed with plastic dowels.

- The next layer is reinforcing mesh.

- A layer of putty is applied.

- Finish the work with a finishing putty.

Polyurethane foam for foundation insulation

The popular and fast method is carried out with a blowing machine.

- The foundation is cleaned of dust and earth particles, construction debris.

- Insulation applied to the base. The foamed mortar will fill in any unevenness without leaving gaps, air pockets or voids.

- Grasping of the composition is fast. Polyurethane foam is characterized by increased adhesion to the surface.

- The result is a monolithic synthetic board with high strength.

For reliable waterproofing, it is recommended in addition to lay a waterproofing on top of the insulation with water-repellent properties - liquid rubber, polyurea.

Installation of extruded polystyrene foam

- A waterproofing layer is laid.

- Expanded polystyrene plates are fixed from below, then they move up.

- If bitumen-roll material is used as waterproofing, it is recommended to heat the bitumen to 60 degrees, after which plates can be applied. For better adhesion of the elements, a clamp should be made.

- In the case of using other types of waterproofing products, the thermal insulation is attached with a special mastic. It is distributed on the plate in strips.

- The product is applied to the waterproofing material and pressed.

It is not recommended to leave the columnar foundation completely open.As a last resort, cold pickup should be performed. This type of fence will fill in the gaps between the corner supports. Do-it-yourself insulation of a columnar foundation is carried out using various improvised building materials. To do this, take a brick, stone, cinder block, board, beams, sheet products. It is not recommended to use blocks with a porous structure for the construction of the intake, due to the absorption of moisture by the material.

If you have a question how to insulate the foundation of a wooden house and wooden supports were used in the construction of the foundation. Then, even with the use of hydro and thermal insulation, when the temperature drops, delamination of the wood material will occur, which will lead to the formation of cracks.