[contents]

There are several reasons why why does the water boil in the boiler heating. For example, boiling is often a consequence of the fact that the liquid heats up in the boiler faster than the heat energy is transferred to the heating main. This happens due to:

- incorrect installation of the system;

- the fact that there is no circulation (or its speed is low) - usually occurs in open-type systems with an expansion tank;

- too much power of the device compared to batteries;

- low amount of water in the line.

Low circulation rate

So, if the coolant circulates too slowly, then the coolant will not fully transfer the received heat and, as a result, the water in the boiler will boil. This only applies to systems in which there is natural circulation of liquid, and the angle of inclination or diameter of the pipes is not selected correctly.

Note! In systems with forced circulation, this happens only in those cases when the pump power is too low or it has completely failed.

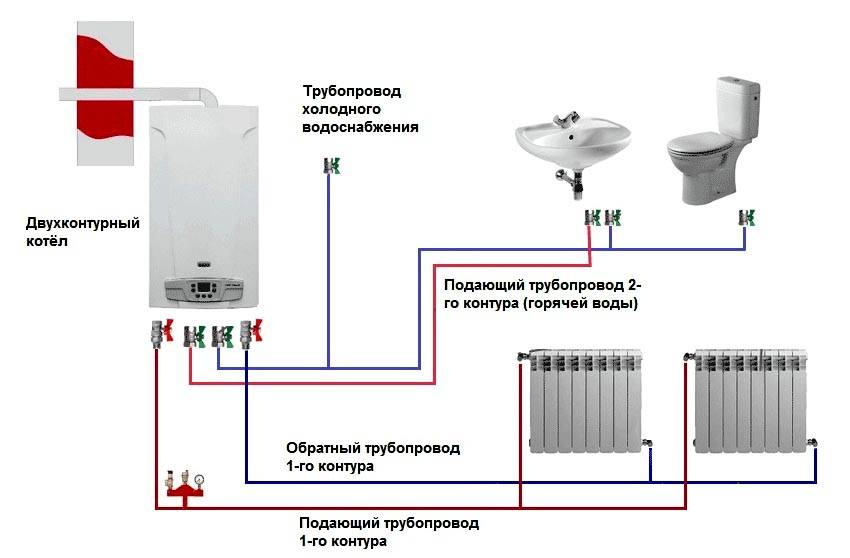

Description of an open heating system: what is it

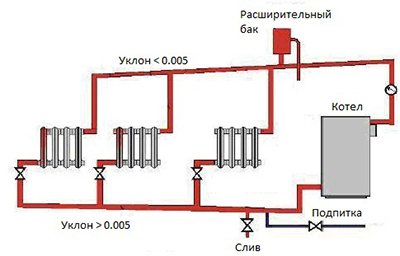

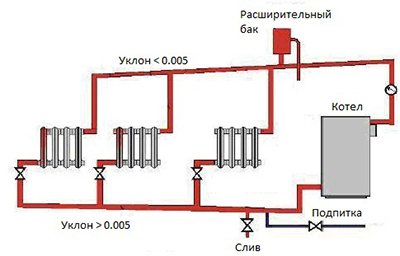

The OS heating circuit consists of a boiler located at the lowest point of the building - basement or pit.

Departs from the boiler vertical riser for coolant supply to the upper point of the building (attic or attic), where the expansion tank (RB) is located.

From the RB along the top of the building, there are horizontal pipes with a slight slope to the vertical risers, along which the coolant is delivered to the radiators.

The return line also leaves the heating devices at the bottom of the room with a slight slope towards the boiler.

Little coolant

If there is too little water in the system or air locks have formed, then this can also be the reason why the water boils in the heating boiler. If there is an expansion tank, then you just need to add water. In other cases, it is enough to bleed the air (if there is no automatic valve, of course).

To increase the intensity of circulation, the heating system should be re-equipped, and it is better, if possible, to install a circulation pump. In this case, even if the pipes are not tilted correctly, the water will circulate properly.

Most common situations

The most common source of the problem is an airlock in one of the nodes. It is necessary to carefully examine the entire system, focusing on the circulation of hot water. If a warm liquid comes from some pipeline instead of a hot one, then it is here that an accumulation of air has formed. It is necessary to bleed excess air from the system using drain valves. If this malfunction was not detected during the check, most likely, the reason for the boil lies directly in the functionality of the boiler.

Overheating of the boiler, which is the basis of the gravitational heating system, can be caused by insufficient circulation of the coolant in the circuit. In this situation, an expansion tank should be placed at such a point in the house that will be the most elevated, in this case an additional load will be applied to the boiler and the required heated resource will be directed to it.

Experts recognize the installation of a circulation pump and equipping the heating system with a mixing circuit as the most practical method of solving the problem. Both types of devices allow reducing the load on the functionality of the heater; cooled water will be added to the network. The boiler will receive a return flow, it will provide its natural cooling.

High boiler output

If the power of the device is higher than the heat transfer of the line, this can also lead to boiling of water. Especially if the air supply control system is broken or missing at all. There are several options for solving the problem:

- put an automatic adjustment system;

- put a similar, but semi-automatic;

- change the boiler (if it is made by hand);

- increase the number of batteries;

- increase their power.

Note! In addition, you can embed an indirect heating boiler into the main line - this device will "absorb" some of the energy from the water heating system and will serve as a kind of heat accumulator.

Installation of an open heating system: photo

Before installation, it is necessary to carry out calculation of radiators, hydraulic calculation of the circulating head, develop a wiring diagram, draw up a list of materials and components.

Photo 1. Floor-standing steel-colored gas heating boiler installed in a room with all equipment.

The OS consists of the following elements:

- Heating boiler - gas or solid fuel.

- Pipes.

- Expansion tank.

- Radiators.

- Fittings (taps, boiler piping, valves).

- Circulation pump (optional).

Photo 2. A circulation pump embedded in the pipes increases the efficiency of the entire heating system.

Installation features:

- Pipe slope horizontal supply and return loungers - not less than 3-5 mm per running meter.

- Use pipes with a diameter of at least 30 mm.

- Expansion tank volume 15% of the total volume coolant.

Photo 3. Expansion tank, made of metal, mounted under the ceiling of the attic of a private house.

Scheme

On a diagram made on a convenient scale on a sheet of graph paper, must be indicated:

- Dimensions of the premises where the OS pipes pass.

- Layout of pipes.

- Placement of radiators, boiler (ensuring the required height difference between the boiler and radiators), expansion tank, pipe fittings.

- Sizes of pipe blanks.

- Elements for fastening pipes to building elements.

Installation steps:

- Prepare a set of necessary tools (depending on the selected pipe material).

- Install the boiler and boiler equipment according to the boiler operation manual.

- Make an expansion tank, install it in the attic.

- Install the vertical riser.

- Install radiators in rooms.

- Finalize the pipesconnecting all elements of the system.

- Insulate the expansion tank.

- Fill in the system.

- Check the system for leaks.

- Carry out a test run.

Expansion tank for OS

Any open tank can serve as an expansion tank (RB). homemade metal container or a flask with the required volume not less than 15% from the total volume of the coolant in the system.

RB performs the following functions:

- Serves as a buffer tank to accommodate excess coolant, which arise due to the expansion of the liquid when heated in the boiler.

- Provides atmospheric pressure in the system.

- It is the element through which air bubbles leave the system. The rise of air bubbles is ensured by the slope of the pipes.

Installation recommendations:

- Installation of a vertical riser from a boiler withIt should be made from a steel pipe with a diameter of 40-50 mm.

- The size of the remaining pipes - the larger the better (less hydraulic resistance).

- Best to use cast iron radiators.

- Try minimize the number of turns of pipes and valves.

- Apply only full bore ball valves.

Features of installation in a private house

Before work, you should make sure that the structure of the house meets gravity system requirements:

- Small area (no more than 150 m²).

- The presence of an attic.

- Possibility of low boiler installation in relation to the last radiator.

What to do if water boils quickly in the tank?

If it is found that the water boils quickly, you need to complete the entire a set of actions for emergency shutdown of the boiler (listed in the operating instructions) to avoid damage to the equipment.

Then you need to figure out the reasons.

If the water boils when the boiler is first started, then it is necessary to check the hydraulic calculation and the correctness of the selection and installation of all elements.

If the water boils after some time after normal operation, then you need to check the following parameters:

- coolant level in the system (the need for recharge);

- boiler operability;

- normal operation of the check valve (if there is a pump with a bypass);

- normal operation of the expansion tank.

The water in the heating boiler boils - what to do?

Let's analyze the situation when the water in the heating boiler boils, and it turns off in emergency mode due to overheating of the coolant. Consider several types of boilers and the common causes of such a problem in them.

Boilers with automatic ignition.

The water circulation in the heating circuit is interrupted.

Due to the slow movement of the coolant in the heating system, the water in the heat exchanger overheats, and the boiler stops in emergency mode. The speed of fluid movement in the system can be affected by reduced performance or breakdown of the pump, contamination of the filter installed on the "return" of the heating circuit, improper operation of the three-way valve.

The performance of the circulation pump is reduced due to contamination of the turbine blades or internal cavity.

Photo 1 - gas boiler circulation pump module with automatic ignition.

To revise it, you need:

- Smoothly stop by moving the knob of the water temperature regulator to the extreme zero position and, after waiting for the process to complete, disconnect the boiler.

- Dismantle the front part of the housing.

- Determine where to install the pump.

- Close the shut-off valve (No. 2, No. 3, No. 4, photo 2) of the supply, return, and cold water supply.

- Drain the boiler through the drain cock and leave it open.

- Loosen the pump fasteners until air enters the circuit to drain the residual fluid from the system.

- Dismantle the mount, power plug and remove the module (engine with turbine).

- Clean the blades, inner cavity and rubber seal of the mechanism from dirt.

- Assemble the pump.

- Open the cold water inlet tap.

- Open the make-up valve slightly to check the tightness of the hydraulic part of the boiler.

- Open the flow and return valves.

- Fill the system with water to a pressure of 1 bar.

- Turn on the boiler in recirculation mode to remove air.

Photo 2 is an example of the piping of the heating system.

In boilers with electronic control, in the event of a pump breakdown, the corresponding fault code will be displayed on the dashboard, which is deciphered using the boiler passport or electronic catalogs posted on the manufacturer's website.

Checking and cleaning the filter:

- Stop the boiler smoothly.

- Using the taps (No. 1, No. 2) installed in front of the filter and behind it, shut off the water supply.

- Using the filter drain valve, drain the water from the isolated area.

- Unscrew the flask and clean the strainer.

- Collect all filter components.

- Open previously closed valves.

- When the system pressure drops, recharge the circuit.

- Switch the boiler on to the venting position.

Checking the three-way valve.

In double-circuit wall-mounted gas boilers, switching from heating mode to the position of hot water supply is carried out using a three-way valve. It consists of a servo (gear motor), stem, rubber seals, valve and body with inlet and outlet ports. A malfunction of this device can lead to the cessation of the circulation of the coolant and, as a consequence, the overheating of the heat exchanger is formed.

To check the condition of the three-way valve, it is necessary to smoothly stop the boiler and disconnect the system from power. Check the serviceability of the engine, and for this, connect the ohmmeter probes to the power terminals. If it shows 80 - 300 Ohm, then the engine is in good order, and if other readings (0 or 1), then it is faulty.

The three-way valve may not switch due to a jammed actuator gearbox or deformation of the valve itself. If a valve malfunction is detected, it is changed to a serviceable one, or it is subject to revision.

Boilers with semi-automatic ignition.

Heating equipment equipped with Eurosit 630 automation, or similar, is semi-automatic, because the main burners are ignited by the wick flame, which burns throughout the entire operation of the boiler.

Reasons and methods for eliminating water boiling in boilers with semi-automatic ignition.

Malfunction of the coolant temperature sensors.

The temperature of the water in the heating circuit is monitored by sensors (thermistors), which are located in the flow and return lines of the boiler. A serviceable sensor, when the temperature of the coolant changes, changes its resistance. For example, at 25 ° C it will be approximately equal to 10 kΩ, and at 45 ° C it will be 4.913 kΩ. By the type of design, the sensor can be overhead (takes parameters through the copper wall of the pipe) or submersible (contacts the coolant without an intermediary). If the probes are not inspected in time, then a non-metallic coating will form on the contact surface, impairing heat transfer and causing them to be damaged.

To investigate the state of the thermistor, a tester is connected to the sensor contacts in the ohmmeter position. If it commits:

- resistance in the range of 1 - 30 kOhm, which means the sensor is serviceable;

- 1 or 0, the probe must be replaced.

Temperature sensor replacement procedure:

- Depending on the type of probe, it can be unscrewed or removed from the pipe.

- Before installing a new sensor, for overhead thermistors, on a prepared base, from which dirt, oxides, fat are removed, thermal paste, for example, MX 4, is applied. For immersion probes, the seat is cleaned, and a fumlent is wound on the mounting thread.

Thermal grease for clamp-on temperature sensors.

If the probe breaks down in automatic boilers, a malfunction code will be displayed on its dashboard. Also, the coolant can overheat due to a pump malfunction and filter contamination. Methods for identifying and correcting such problems are described above.

buildip.ru